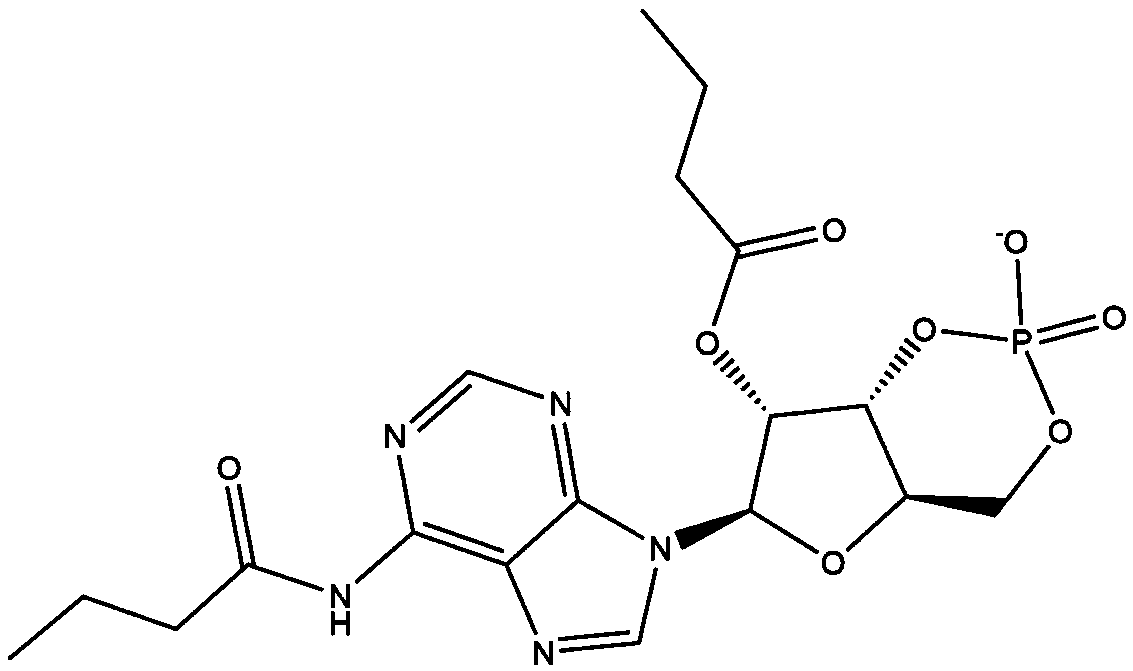

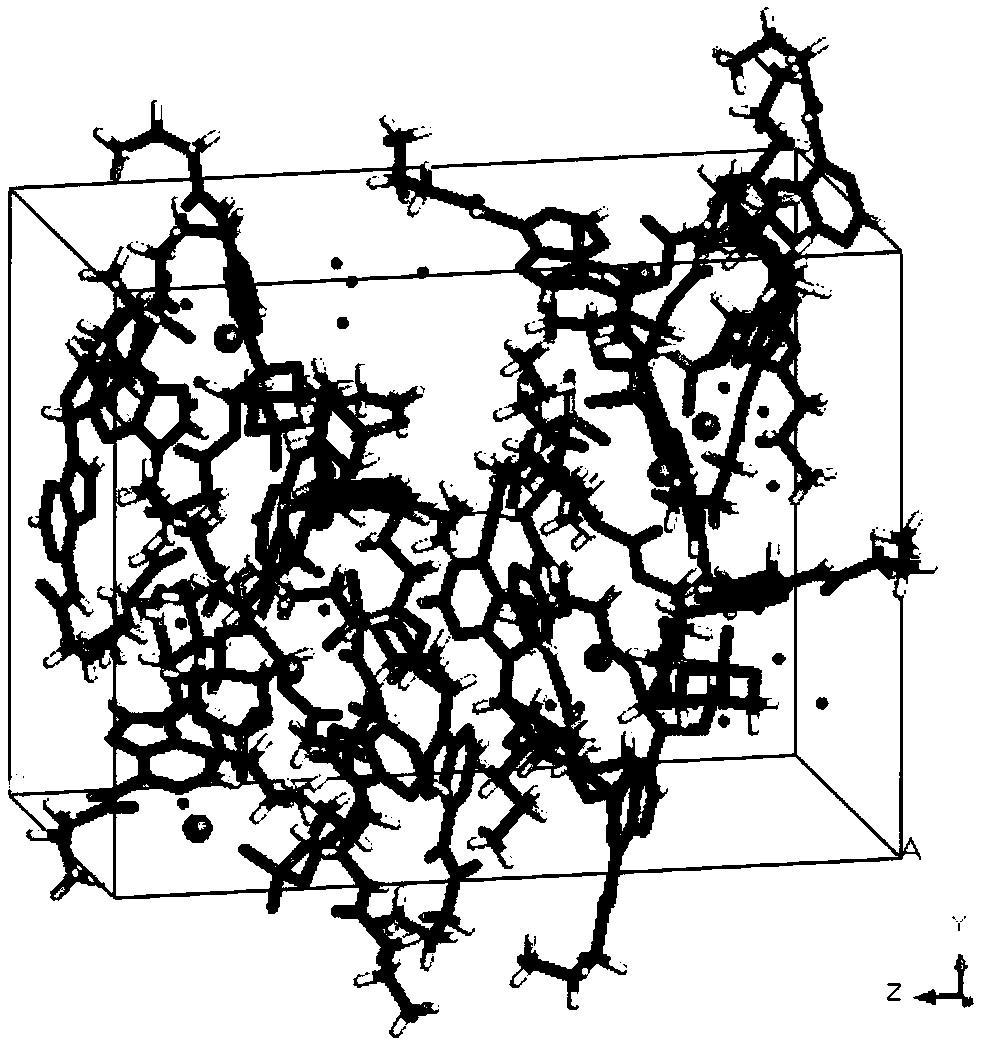

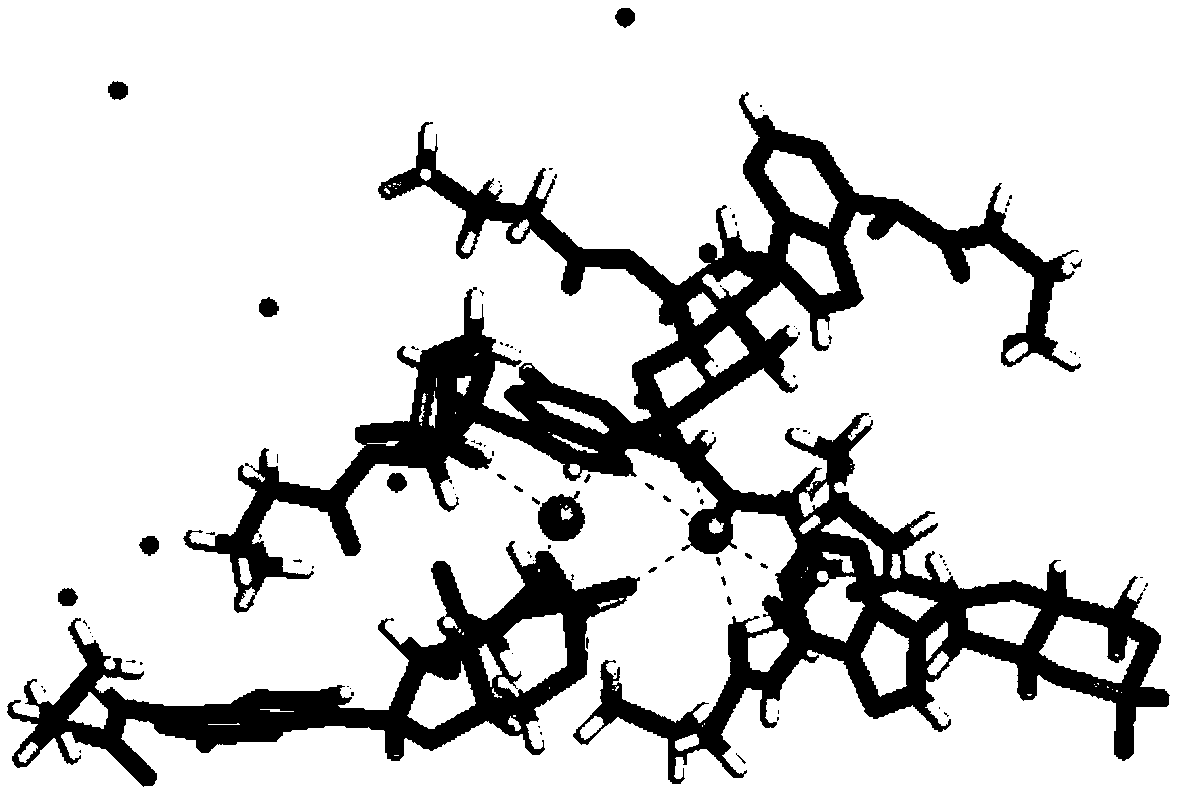

Crystal of dibutyryl adenosine cyclophosphate calcium salt

A dibutyryl cyclic adenosine phosphate calcium salt and crystal technology, which is applied in the field of crystalline powder of dibutyryl cyclic adenosine phosphate calcium salt, can solve problems such as unsuitable for large-scale production, hygroscopicity, instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Take 150g of crude dibutyrylcyclic adenosine monophosphate calcium salt, add it to 1000mL of absolute ethanol, and fully dissolve it at 50°C. The process is carried out in a 1.5L crystallizer with a jacket, and the stirring speed is controlled at 200r / min. A three-curved impeller impeller is used with a diameter of 80 mm. The top of the crystallizer is equipped with a condensation reflux device, and the temperature of the jacket of the crystallization system is controlled by cooling circulating water. After dissolving for 10 minutes, slowly lower the temperature at a rate of 2°C / h, and at the same time pump in isopropanol at a flow rate of 2.0mL / min. The volume of added isopropanol is 800-1200mL. Then put it into the tank, carry out solid-liquid separation by suction filtration, wash the filter cake with 400mL of anhydrous acetone, then place it in a blast drying oven at 35°C, and dry it for 4h with an airflow with a relative equilibrium humidity RH of 65%, and then obta...

Embodiment 2

[0065] Take 300g of crude dibutyrylcyclic adenosine monophosphate calcium salt, add it to 1000mL of water, and fully dissolve it at 10°C. The process is carried out in a 2L crystallizer with a jacket, and the stirring speed is controlled at 200r / min, using a two-leaf anchor Stirring paddle, paddle diameter is 90mm, crystallization system jacket adopts cooling circulating water to control temperature. After fully dissolving for 30 minutes, slowly raise the temperature at a rate of 2°C / h until the temperature rises to 60°C, maintain for 2 hours, then put it into the tank, and separate the solid and liquid by suction filtration, using 300mL methanol aqueous solution with a methanol volume fraction of 95%. Wash the filter cake, then place it in a blast drying oven at 40°C, and dry it with an airflow with a relative equilibrium humidity RH of 45% for 4 hours, and then obtain the pure product of dibutyrylcyclic adenosine phosphate calcium salt, and determine the moisture content by K...

Embodiment 3

[0067] Take 100g of the crude product of dibutyrylcyclic adenosine monophosphate calcium salt, add it into 1000mL n-propanol ethanol solution (the mass ratio of n-propanol and ethanol is 1:1), fully dissolve at 50°C, the process is in a jacketed 1.5 It is carried out in a crystallizer of L, the stirring speed control is set at 250r / min, and the temperature of the jacket of the crystallization system is controlled by cooling circulating water. After fully dissolving for 15 minutes, first cool down to 35°C at a rate of 2°C / h, then cool down to 10°C at a rate of 1°C / h, keep for 2 hours, and then put it into the tank, and separate the solid and liquid by suction filtration. Wash the filter cake with 250mL of absolute ethanol, then place it in a blast drying oven at 50°C, and dry it with an airflow with a relative equilibrium humidity RH of 55% for 4 hours, and then obtain the pure product of dibutyrylcyclic adenosine monophosphate calcium salt, Karl Fei The moisture content determ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com