Casting-fly-ash ceramsite and preparation method thereof

A grey pottery and granulation technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as lack of treatment methods, damage to the ecological environment, occupation of land resources, etc., to reduce costs and avoid pollution , reduce the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the foundry dedusting ceramsite includes:

[0031] S1, the step of preparing materials, prepare materials according to the following parts by weight: 95-105 parts of casting dust, 10-50 parts of Portland cement, 1-5 parts of redispersible rubber powder, 1-5 parts of polyvinyl alcohol, water reducing 1-5 parts of agent solution and 0-5 parts of bentonite.

[0032] Specifically, one of naphthalene-based superplasticizers, aliphatic superplasticizers, amino superplasticizers, and polycarboxylic acid superplasticizers is first selected to form a superplasticizer solution, and the solid content of the superplasticizer solution The amount is 35-45%, and then according to 95-105 parts of casting dust, 10-50 parts of Portland cement, 1-5 parts of redispersible rubber powder, 1-5 parts of polyvinyl alcohol, and 1-5 parts of water reducer solution. 5 parts and 0 to 5 parts by weight of bentonite are weighed.

[0033] S2. Mixing step: mixing foundry dus...

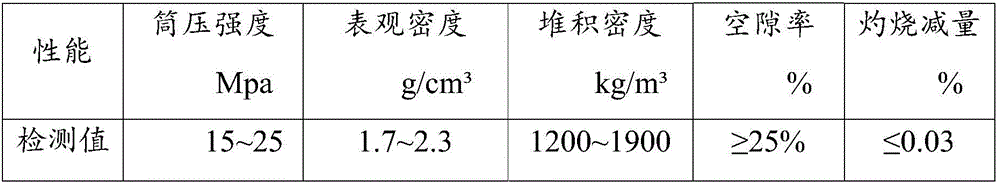

Embodiment 1

[0045] In this embodiment, a kind of cast dust removal ash ceramsite is made by mixing various raw materials through granulation and curing. 4 parts of redispersible rubber powder, 3 parts of polyvinyl alcohol, 5 parts of superplasticizer solution and 3 parts of bentonite.

[0046] Wherein, the water reducer is a naphthalene-based high-efficiency water reducer, and the solid content of the water reducer solution is 40%.

[0047] The preparation method of the foundry dust removal ash ceramsite, first, according to 100 parts of foundry dust removal ash, 30 parts of Portland cement, 4 parts of redispersible rubber powder, 3 parts of polyvinyl alcohol, 5 parts of water reducing agent solution and 3 parts of bentonite The parts by weight are weighed and prepared. Secondly, put the foundry dust, portland cement, redispersible rubber powder, polyvinyl alcohol, water reducer solution and bentonite into the mixer and stir for 15 minutes to make them evenly mixed. Afterwards, the mixt...

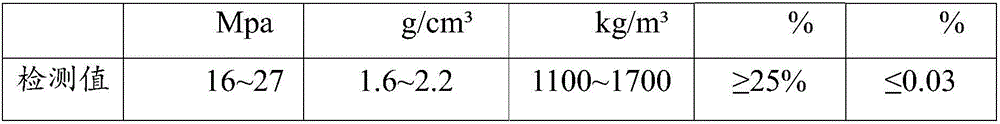

Embodiment 2

[0053] In this embodiment, a kind of cast dust removal ash ceramsite is made by mixing various raw materials through granulation and curing. 5 parts of redispersible rubber powder, 5 parts of polyvinyl alcohol, 5 parts of water reducer solution and 5 parts of bentonite.

[0054] Wherein, the water reducer is an aliphatic high-efficiency water reducer, and the solid content of the water reducer solution is 38%.

[0055] The preparation method of the foundry dust removal ash ceramsite, first, according to 100 parts of foundry dust removal ash, 30 parts of Portland cement, 4 parts of redispersible rubber powder, 3 parts of polyvinyl alcohol, 5 parts of water reducing agent solution and 3 parts of bentonite 105 parts of dedusting ash, 50 parts of Portland cement, 5 parts of redispersible rubber powder, 5 parts of polyvinyl alcohol, 5 parts of superplasticizer solution and 5 parts of bentonite are weighed and prepared in parts by weight. Secondly, put the foundry dust, Portland ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com