Miniature box-type leacher for special oil

An extractor and box-type technology, which is applied in the field of special oil miniature box-type extractors, can solve the problems of small production volume special oil development and processing, etc., and achieve the effect of improving the extraction production effect, good granularity, and stable meal output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

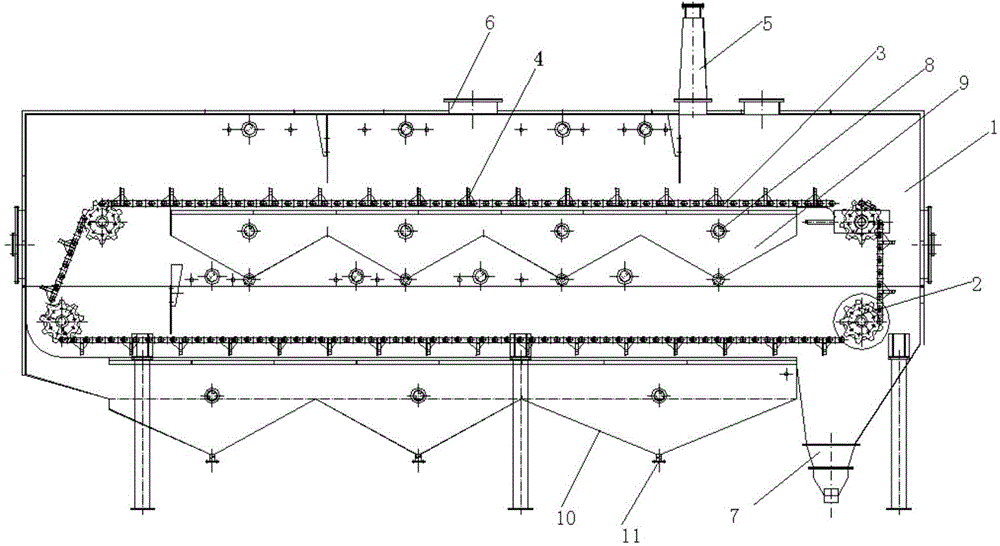

[0014] Referring to the accompanying drawings, a special oil miniature box-type drag chain scraper flipping type extractor includes a box-type extractor housing 1, and a plurality of driving sprockets 2 are arranged in the box-type extractor housing 1, and a plurality of driving The sprocket 2 is fitted with a box chain 3, and the outer side of the box chain 3 is fixed with a push plate 4 at intervals. The upper and lower ends of the box-type extractor shell 1 are respectively equipped with a storage box 5, a manhole 6, and a discharge port 7. A feeding auger is provided under the storage box 5, and a plurality of pushing box grids 9 as leaching units are arranged in the box-type extractor shell 1, and the circulating mixed oil forms a immersion pool above the pushing box grids 9, and the box-type The bottom surface of the extractor housing 1 is provided with a plurality of oil buckets 10, the oil inlet of the oil buckets 10 is equipped with a circulating pump 11, and the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com