Automatic pallet machine

A palletizer, fully automatic technology, applied in the stacking of objects, destacking, transportation and packaging of objects, etc., can solve the problems of high operation and maintenance costs, large area of the depalletizer, and complex mechanical structure. , to achieve the effect of good improvement difficulty, reduction of manpower and simple mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

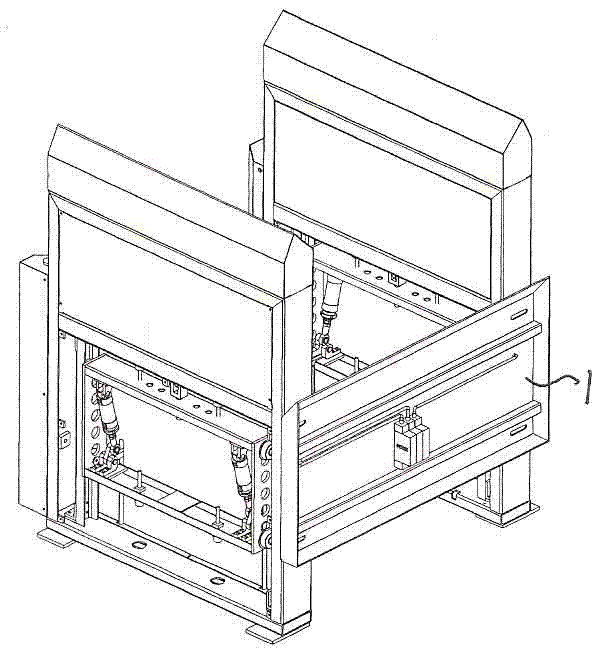

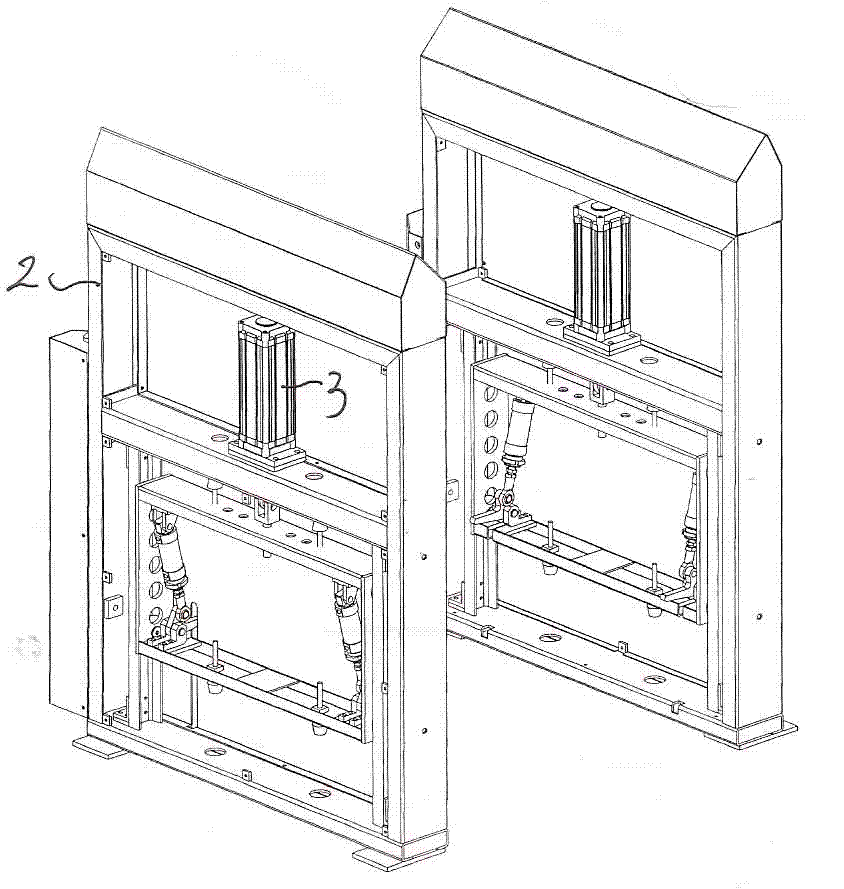

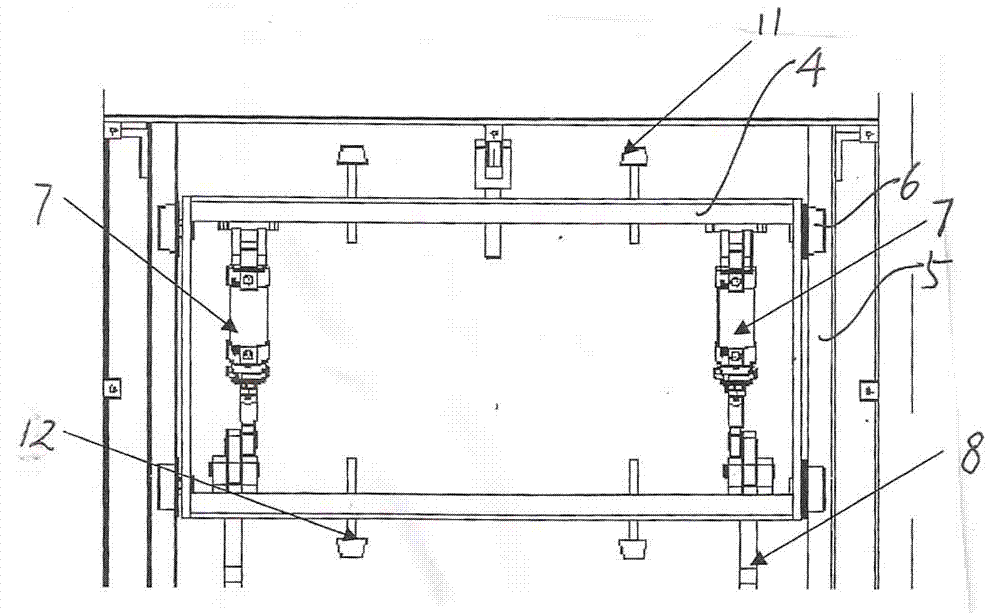

[0024] A fully automatic pallet machine, comprising left and right lifting mechanisms, a front guide device is arranged in front of the left and right lifting mechanisms, and a rear support that connects the left and right lifting devices and restricts the pallets in place is arranged behind the left and right lifting devices Plate 1; the left and right lifting devices have the same structure, including a main body frame 2, a lifting cylinder 3 is mounted on the main body frame, and the lifting cylinder 3 is connected with the inserting mechanism, and the lifting cylinder drives the inserting mechanism to move up and down; the inserting mechanism includes Frame 4, the guide wheel device 6 that moves up and down along the roller guide rail 5 is mounted on the frame, the disc cylinder 7 is mounted on the frame, the piston rod of the disc cylinder is connected with the tongue 8 that inserts the pallet 14, and the piston rod drives the tongue to extend out, pull back.

[0025] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com