Extraction device and method

An extraction device and extraction tank technology, which is applied in solvent extraction, separation methods, chemical instruments and methods, etc., can solve the problems of small footprint and achieve the effects of small footprint, reduced footprint, and reduced back-mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Example 1: Extraction unit comprising a mixing and clarification extraction tank

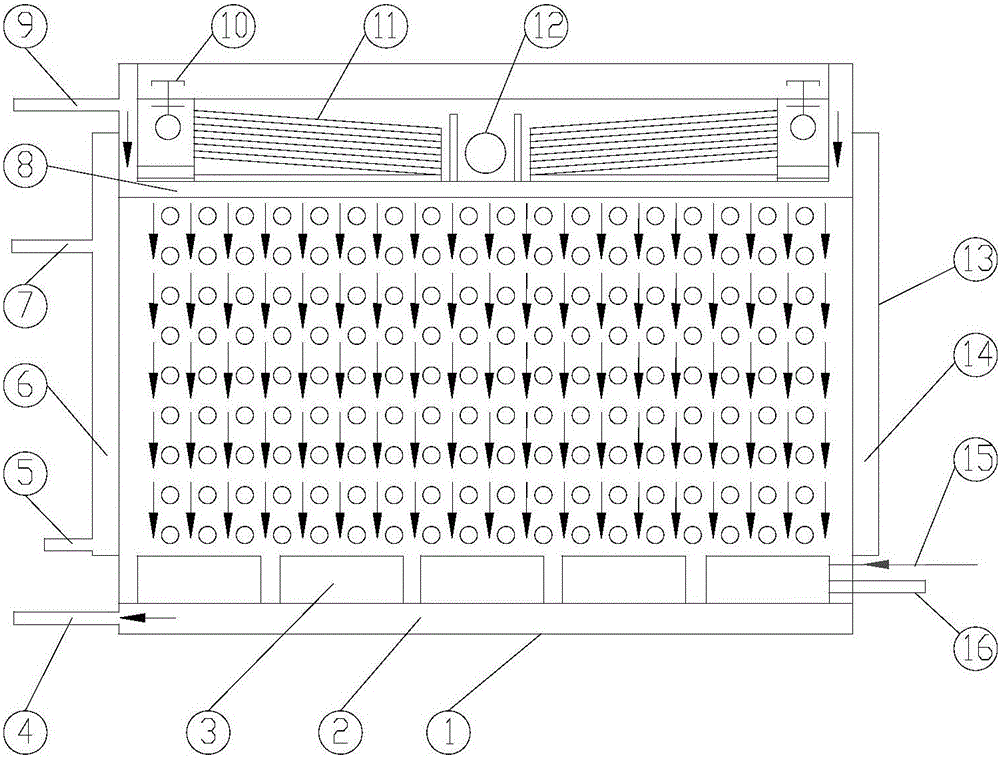

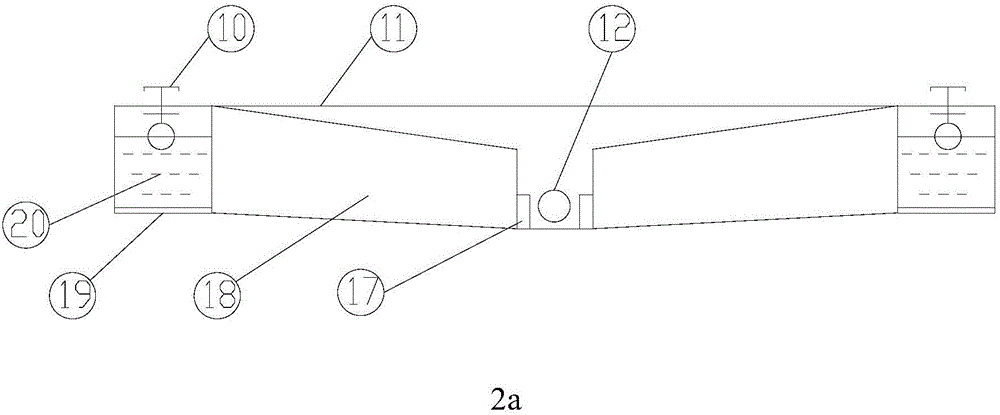

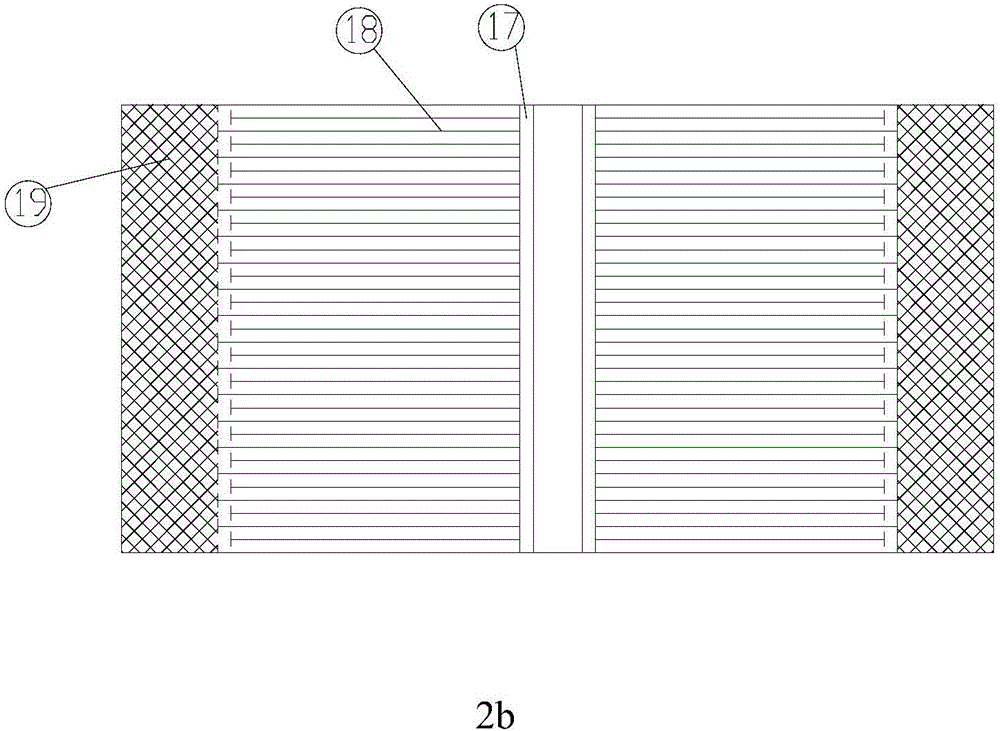

[0090] An extraction device comprising a mixing and clarification extraction tank, such as figure 1 shown. The mixing and clarifying extraction tank 1 includes a mixing chamber 2 , a clarifying chamber 13 , an organic liquid film generator 3 , a three-phase separation device 11 and a liquid distributor 8 .

[0091] The mixing chamber 2 is a container with an internal cavity, and 1-N organic liquid film generators 3 (N is a positive integer, and N≥1) are fixedly installed in the bottom of the mixing chamber 2, and the organic liquid film generators 3 pass through the gas phase Connect the air inlet 15 and the light phase input port 16 with the light phase distribution pipeline; the lower part or bottom of the mixing chamber 2 is provided with one or several heavy phase discharge ports 4, and the heavy phase discharge port 4 is preferably arranged on the adjacent organic Between the liqui...

Embodiment 2

[0098] Example 2: Three-stage mixing and clarification large phase extraction device

[0099] A three-stage mixing and clarification large phase extraction device, such as Figure 4 shown. The three-stage mixing and clarifying large-phase extraction device includes: a three-stage mixing and clarifying extraction system, a heavy phase conveying system, a light phase conveying system, a gaseous phase conveying system, an interstage heavy phase regulating pipeline 25, an interstage light phase regulating pipeline 26 and interstage light phase overflow pipeline 27.

[0100] The three mixing, clarifying and extracting tanks 1 are vertically stacked with the ground as the horizontal plane, and supported by supports to form a three-stage mixing, clarifying and extracting system. The bottom mixed and clarified extraction tank 1 is the first-stage extraction tank, the upper layer of mixed and clarified extraction tank 1 is the second-stage extraction tank, and the upper layer of mixe...

Embodiment 3

[0117] Example 3: Utilize the three-stage mixing and clarification provided in Example 2 to extract Y, Sm, Eu and other elements in the tailing liquid of rare earth leaching

[0118] Taking a rare earth leaching tailing liquid as the heavy phase, the input flow rate is 10t / h, the light phase is saponified P507-kerosene solution, the input flow rate is 0.5t / h, the gas flow rate is 150L / h, and the heavy phase and light phase loads are 20 . The height of the single-stage mixing and clarifying extraction tank 1 is 3 meters, the total tower height after including the heavy phase storage tank 34 and the light phase storage tank 44 is about 12 meters, and the cross-sectional area of the mixing chamber 2 is 1 m 2 , the total volume of the mixing chamber 2 of the single-stage mixing and clarifying extraction tank 1 is about 3m 3 , clarification chamber 13 sectional area 0.18m 2 , the total volume is about 0.45m 3 .

[0119] Taking the measurement results of element Y concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com