Continuous bulk preparation method of acrylonitrile-ethylene propylene diene monomer (EPDM)-styrene (AES) resin

A technology of EPDM rubber and styrene resin is applied in the field of continuous bulk preparation of acrylonitrile-EPDM rubber-styrene resin, and can solve the problems of large amount of solvent, difficult removal and high post-processing cost, Achieve the effect of reducing equipment investment and production costs, simplifying post-processing procedures, and reducing material back-mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

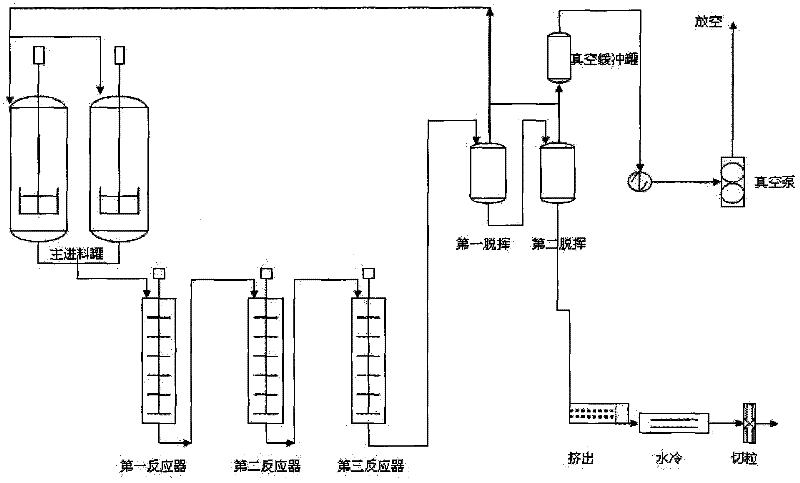

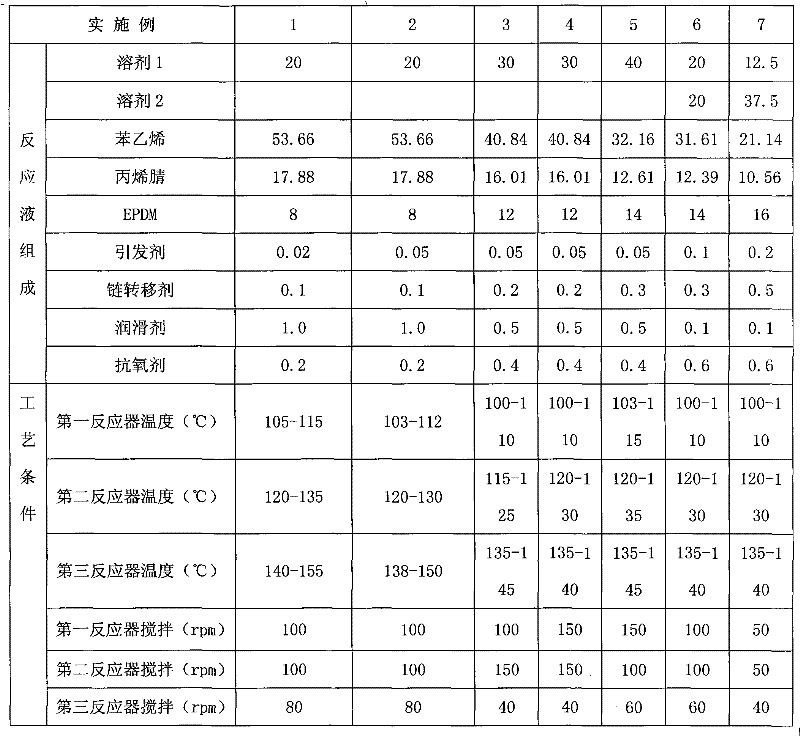

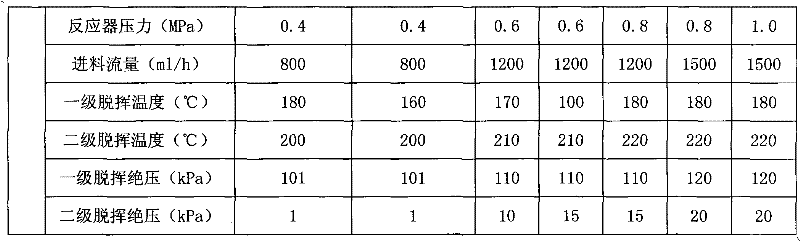

[0040] In the nitrogen-purged sol tank, add toluene and EPDM according to the parts by weight in Table 1, stir at 60°C for 8 hours until EPDM is completely dissolved, add styrene, acrylonitrile, tert-butyl perbenzoate, weight ratio 1:1 compound antioxidant of antioxidant 1076 and antioxidant 168, α-methylstyrene linear dimer, calcium stearate, continue to stir for 4 hours, after the sol is completed, the reaction solution enters three series In the tower reactor, the reaction flow diagram is as follows figure 1 shown. Continuous polymerization was carried out according to the conditions in Table 1, and the resulting polymerization product was subjected to steps such as devolatilization, extrusion, water cooling, and granulation to obtain yellowish resin product particles.

[0041] Table 1

[0042]

[0043]

[0044] Measure the tensile strength of the obtained resin product according to GB / T 1040.2-2006, measure the flexural strength according to GB / T 9341-2008, measure...

Embodiment 2

[0048] Add various raw materials according to the steps in Example 1, wherein the solvent is ethylbenzene, the initiator is tert-butyl peroxy-2-ethylhexyl carbonate, and the rest of the raw materials are the same as in Example 1. The obtained resin product was measured according to the same method in Example 1, and the results are shown in Table 2.

Embodiment 3

[0050] Add various raw materials according to the steps in Example 1, wherein the solvent is n-hexane, the initiator is 1,1-bis(tert-butylperoxy)cyclohexane, and the rest of the raw materials are the same as in Example 1. The obtained resin product was measured according to the same method in Example 1, and the results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com