Finely-pulverized coal separator for warehouse type pulverizing system of 100-1,500MW coal-fired power plant boiler

The technology of a fine powder separator and a pulverizing system is applied to a device whose axial direction of the cyclone can be reversed, a cyclone device, etc., which can solve the problems of less coal powder collection output, affecting boiler combustion, and low separation performance, etc. Achieve the effect of improving energy conversion efficiency, improving combustion effect, and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

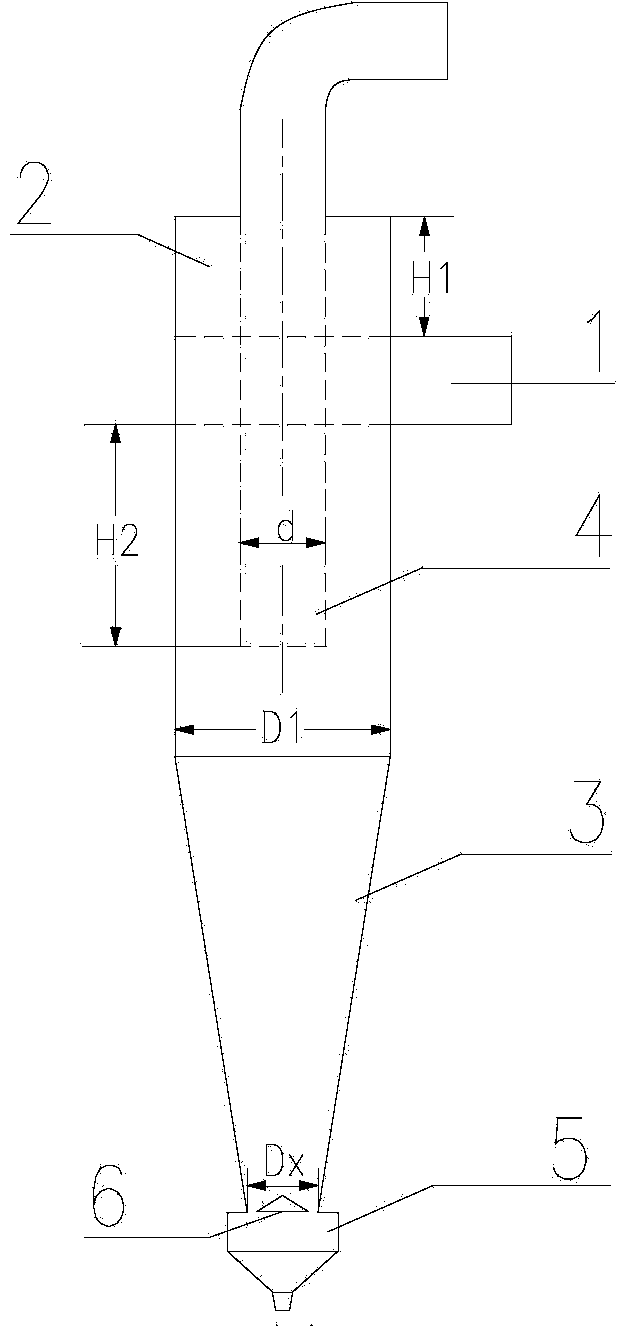

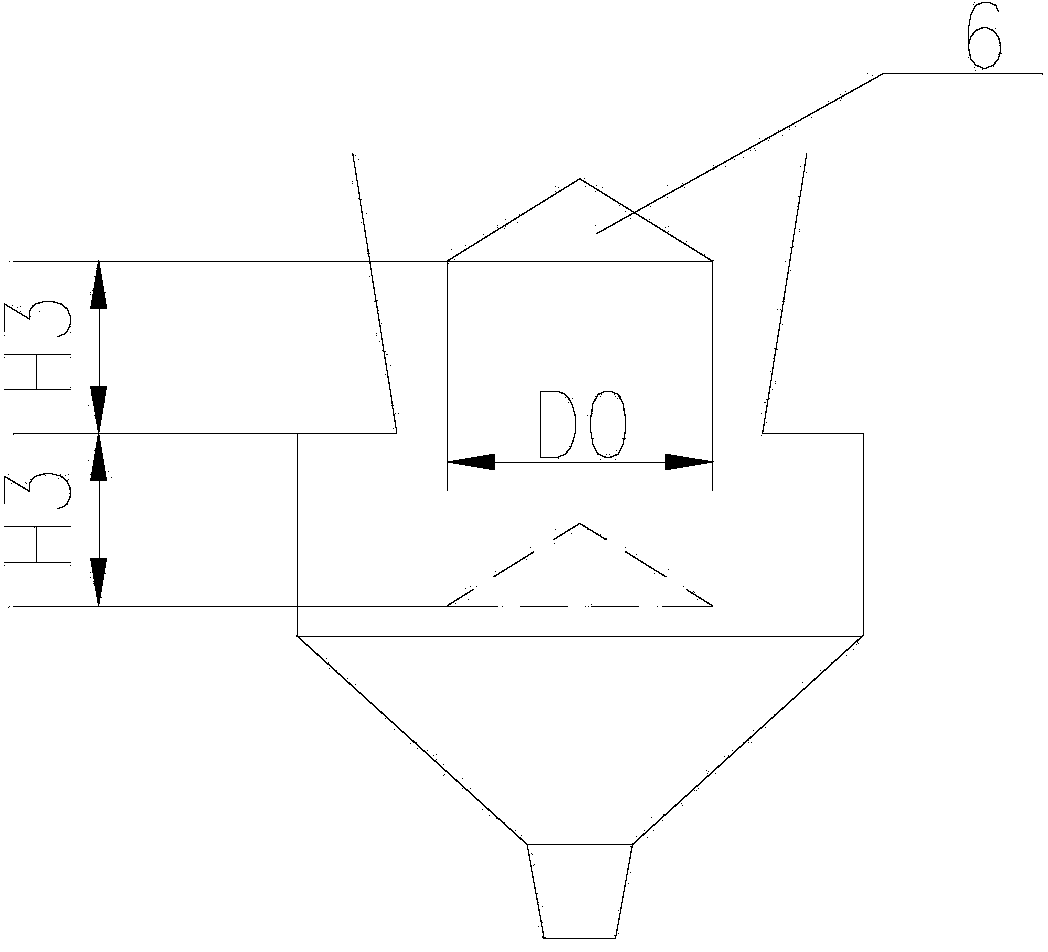

[0029] Embodiment 1 of the present invention: as figure 1 As shown, a fine powder separator used in a 100MW ~ 1500MW coal-fired power plant boiler storage pulverization system, including separator tangential inlet 1, separator cylindrical shell 2, separator lower cone 3, exhaust Pipe 4, separator lower hopper 5, separator tangential inlet 1 is set on the upper part of separator cylindrical shell 2, separator lower cone 3 is set on the bottom of separator cylindrical shell 2, exhaust pipe 4 is set On the top of the separator cylindrical shell 2, the separator lower hopper 5 is located at the bottom of the separator lower cone 3; the inlet of the separator lower hopper 5 is provided with a separator anti-mixing cone device 6; the separator lower The diameter of the outlet at the bottom of the cone 3 is not less than the inner diameter of the exhaust pipe 4 . The diameter of the outlet at the bottom of the separator lower cone 3 is 1 time of the inner diameter of the exhaust pi...

Embodiment 2

[0035] Embodiment 2 of the present invention: as figure 1 As shown, a fine powder separator used in a 100MW ~ 1500MW coal-fired power plant boiler storage pulverization system, including separator tangential inlet 1, separator cylindrical shell 2, separator lower cone 3, exhaust Pipe 4, separator lower hopper 5, separator tangential inlet 1 is set on the upper part of separator cylindrical shell 2, separator lower cone 3 is set on the bottom of separator cylindrical shell 2, exhaust pipe 4 is set On the top of the separator cylindrical shell 2, the separator lower hopper 5 is located at the bottom of the separator lower cone 3; the inlet of the separator lower hopper 5 is provided with a separator anti-mixing cone device 6; the separator lower The diameter of the outlet at the bottom of the cone 3 is not less than the inner diameter of the exhaust pipe 4 . The diameter of the outlet at the bottom of the separator lower cone 3 is twice the inner diameter of the exhaust pipe 4...

Embodiment 3

[0040] Embodiment 3 of the present invention: as figure 1 As shown, a fine powder separator used in a 100MW ~ 1500MW coal-fired power plant boiler storage pulverization system, including separator tangential inlet 1, separator cylindrical shell 2, separator lower cone 3, exhaust Pipe 4, separator lower hopper 5, separator tangential inlet 1 is set on the upper part of separator cylindrical shell 2, separator lower cone 3 is set on the bottom of separator cylindrical shell 2, exhaust pipe 4 is set On the top of the separator cylindrical shell 2, the separator lower hopper 5 is located at the bottom of the separator lower cone 3; the inlet of the separator lower hopper 5 is provided with a separator anti-mixing cone device 6; the separator lower The diameter of the outlet at the bottom of the cone 3 is not less than the inner diameter of the exhaust pipe 4 . The diameter of the outlet at the bottom of the separator lower cone 3 is 4.4 times the inner diameter of the exhaust pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com