Fireproof interface agent for polystyrene foam heat insulation material and preparation method thereof

A technology of polystyrene foam and thermal insulation material, which is applied in fire-resistant coatings, conjugated diene coatings, coatings, etc., and can solve the problems of flammability of polystyrene boards and the inability of common interface agents to meet fire protection requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

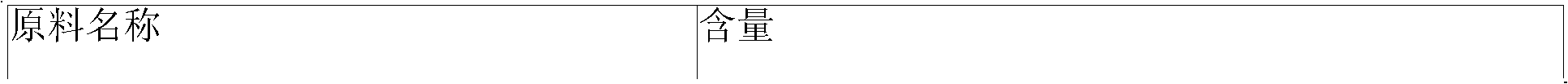

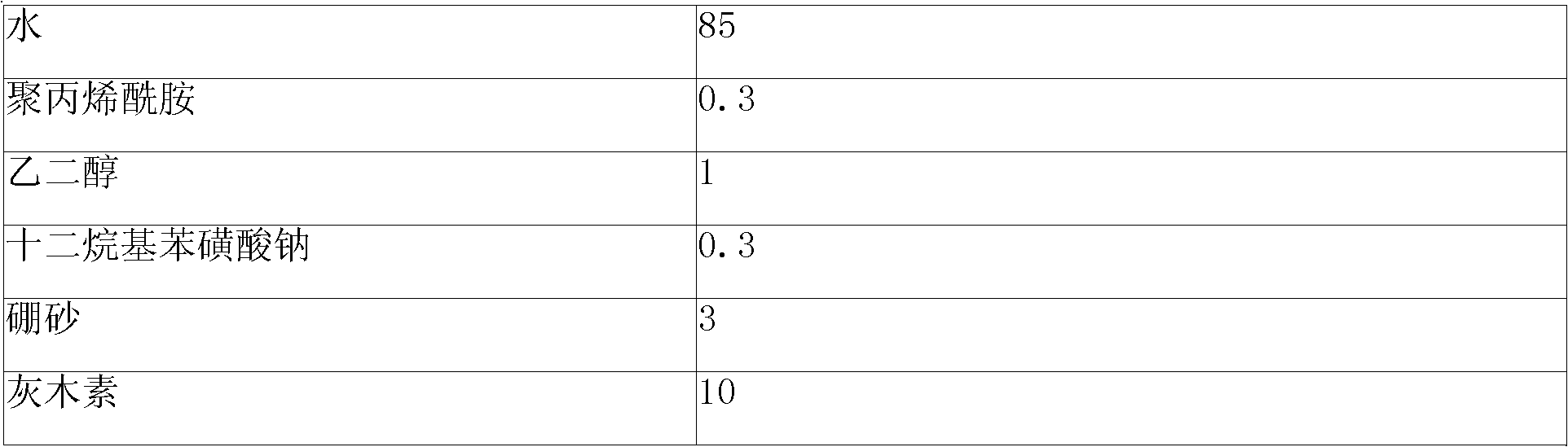

[0094] The preparation of component A of the fireproof interface agent for polystyrene foam insulation materials is divided into the preparation of the molded polystyrene board fireproof interface agent and the preparation of the extruded polystyrene board fireproof interface agent. See Table 1 and Table 2:

[0095] Please refer to the three formulas listed in Table 1 for the preparation of component A of the fireproof interface agent for molded polystyrene boards of the present invention. First, weigh each component according to formula 1 in Table 1, then mix styrene-butadiene emulsion, water glass and preservatives and stir at low speed for more than 5 minutes, then add NaOH, high second, ammonium polyphosphate, pentaerythritol, urea in sequence, After stirring for more than 20 minutes, after stirring evenly and without granular matter, the product of component A 1 of the present invention is obtained, which is discharged and packaged.

Embodiment 2

[0097] Prepare molded polystyrene board fireproof interface agent A component 2 according to formula 2 of table 1. The preparation method is the same as in Example 1.

Embodiment 3

[0099] Prepare molded polystyrene board fireproof interface agent A component 3 according to formula 3 in Table 1. The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com