Air discharge heating apparatus, system and method for diesel engine under full operating condition

A technology of a heating device and a heating method, which is applied to the electric control of the exhaust device and the exhaust gas treatment device, and the exhaust gas treatment, etc., can solve the problems of the catalyst falling off easily, the power consumption of the heating device being large, the structure of the regeneration system being complicated, etc. The effect of reducing regeneration energy consumption, extending regeneration mileage, and reducing accumulation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

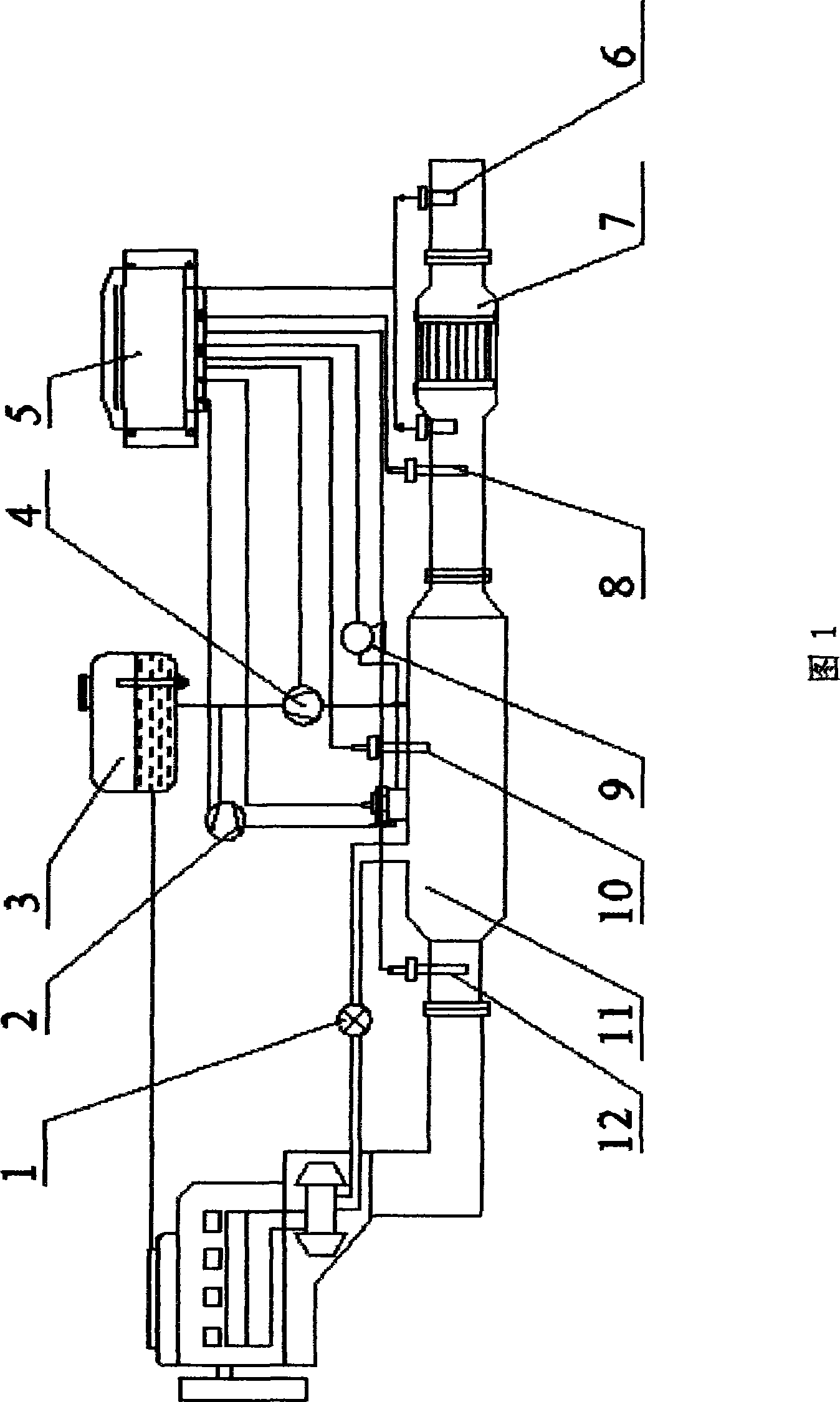

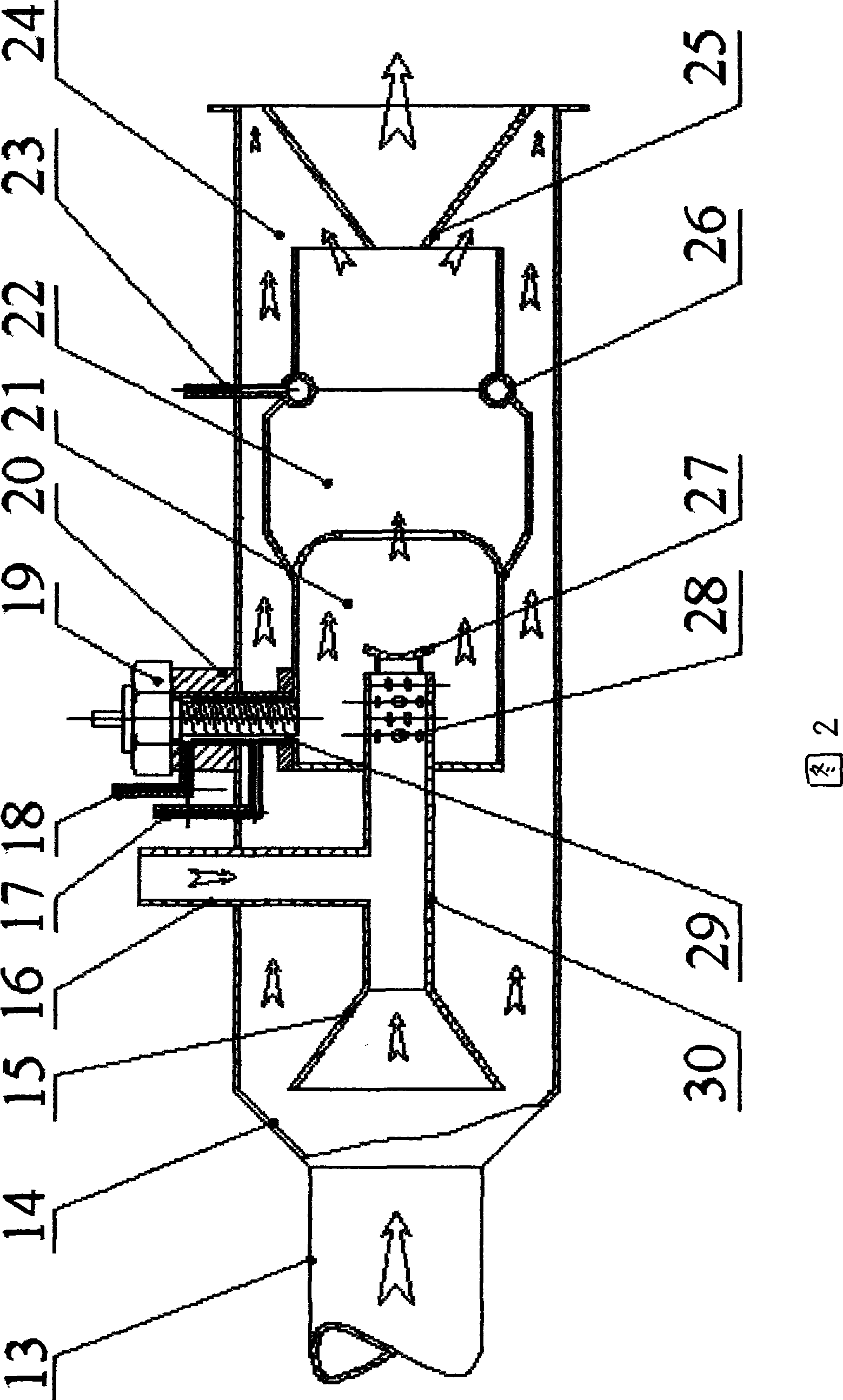

[0057] Fuel System

[0058] Part of the fuel is taken from the engine oil return line, and the fuel enters the burner through the fuel meter under the action of the pressure regulating valve. Part of it enters the burner evaporation chamber for primary combustion, and the other part enters the exhaust interlayer for tertiary combustion.

[0059] intake system

[0060] The burner intake system mainly includes three parts: one is that the air pump provides a small amount of fresh air for ignition; the other is that the turbocharger provides fresh air for combustion under certain working conditions; Exhaust is used for combustion.

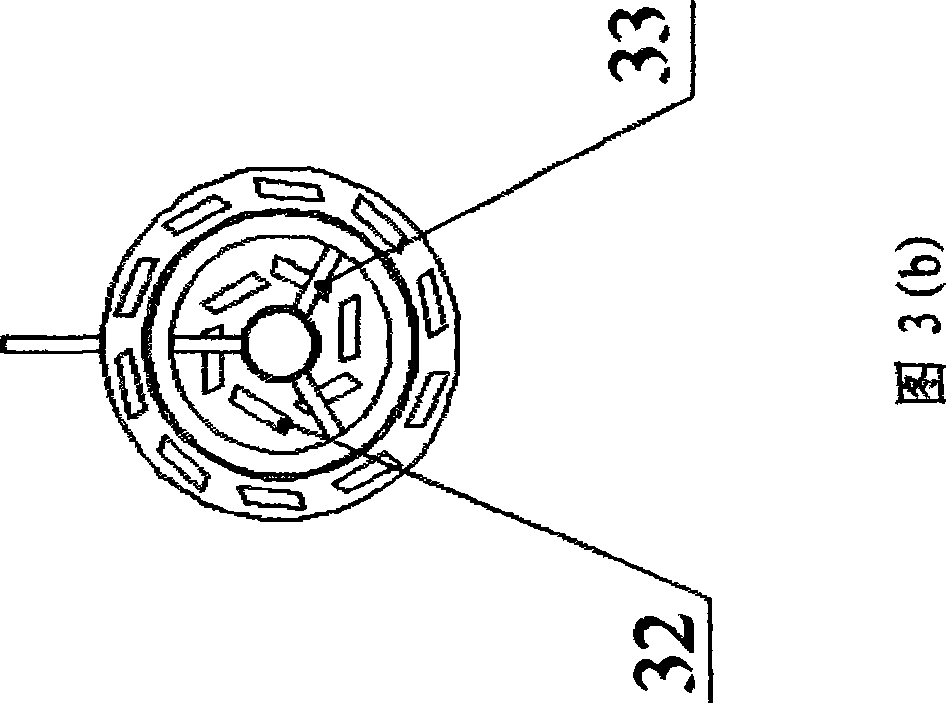

[0061] ignition device

[0062] After the glow plug is energized to preheat the fuel adsorption network, the fuel enters the evaporation chamber and evaporates on the surface of the adsorption network and is ignited by the glow plug. The micro air pump can effectively improve the ignition reliability and avoid the carbon deposition problem of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com