Cyclone separator with grooved wall surface

A technology of cyclone separator and wall surface, which is applied in the direction of cyclone device and the device whose axial direction of the cyclone can be reversed. Particles bounce back to the mainstream area again, and there is no way to raise the flow direction, etc., to achieve the effects of reduced short-circuit flow, reduced wear, and improved separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Cyclone Separator for Fluid Catalytic Cracking Regenerator

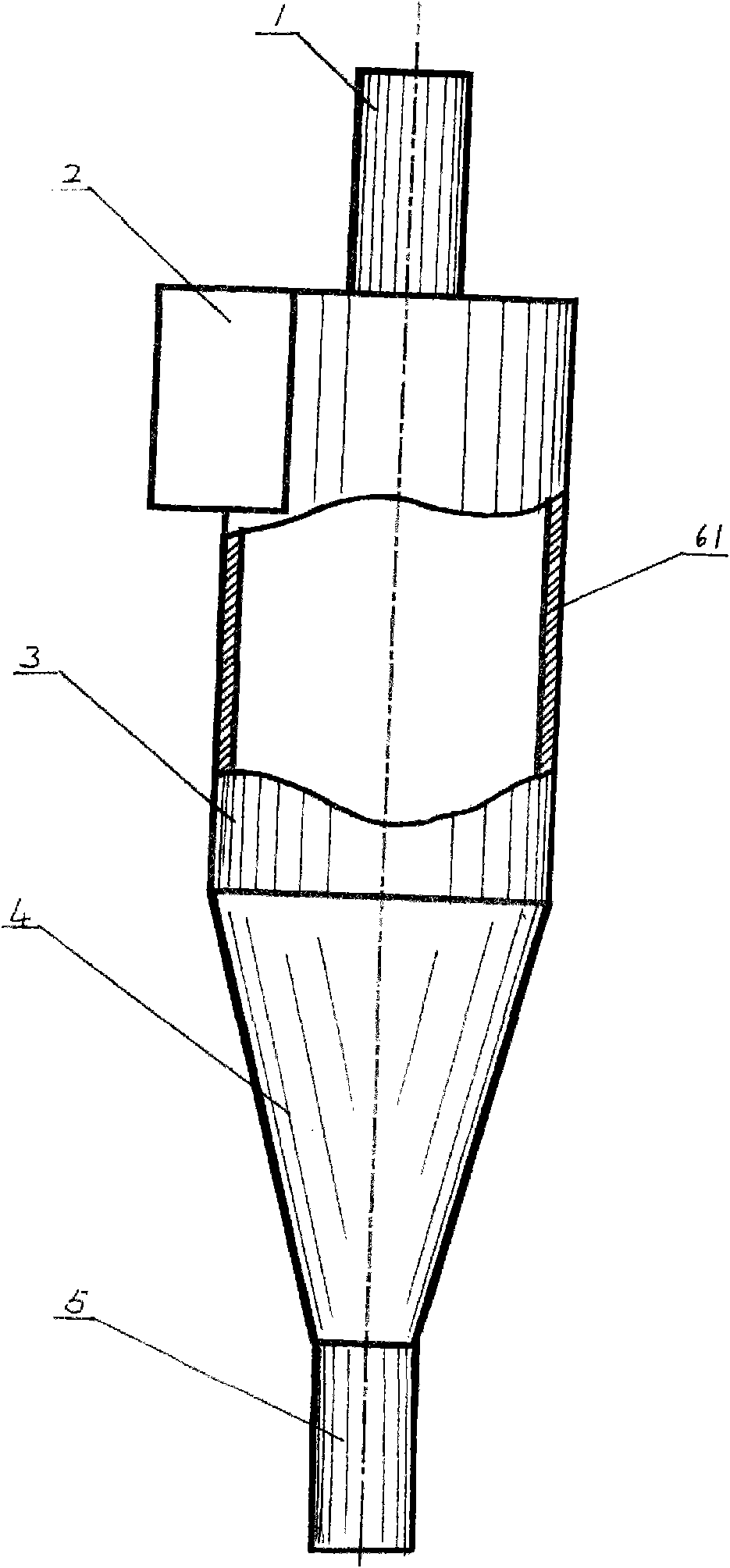

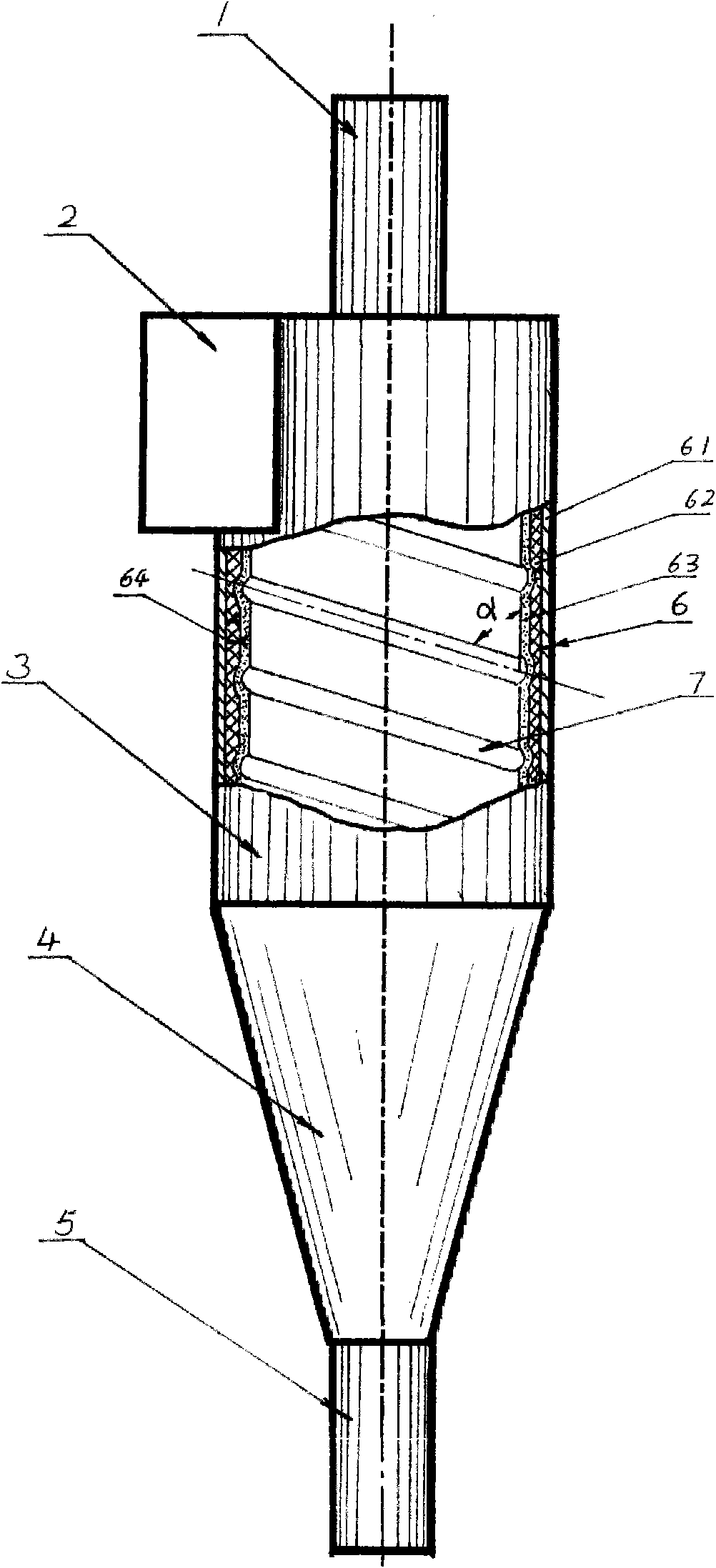

[0035] Depend on figure 2Shown, the cyclone separator with grooved wall surface of the present invention is mainly made up of air riser 1, material system inlet 2, cylinder body 3, cone 4 and tailpipe 5, wherein: air riser 1, material system inlet 2, cylinder The body 3, the cone body 4 and the tailpipe 5 form the whole cyclone separator in order from top to bottom, and a channel 7 is arranged on the wall surface of the inner wall 6 according to the flow direction of the medium with a relatively high density of the material system. Starting at the entrance 2, the channel 7 forms an included angle α of 0-90°C with the direction of fluid flow, and the ratio of the area of the channel 7 to the wall surface swept by the fluid is 0-0.9.

[0036] Grooves are made on the wall of the cyclone separator along the particle flow direction, and the inner wall 6 and the channel 7 are channels formed by pressi...

Embodiment 2

[0043] Example 2: Cyclone Separator after Combustion in Circulating Fluidized Bed

[0044] In the pulverized coal circulating fluidized bed combustion boiler system, the cyclone separator is the most important unit equipment. Relying on the efficient operation of the cyclone separator, the reduction of boiler unburned loss and the improvement of boiler efficiency can be realized. When used in the coal combustion process, the flue gas and unburned coal powder at high temperature enter the cyclone separator, and the lining 63 of the cyclone separator will prevent the wall surface of the metal outer wall 61 from directly contacting the high temperature medium. damage its strength. The mixture enters from the entrance 2 of the system and flows downward in rotation. The pulverized coal and ash will be separated and thrown to the wall and enter the channel 7 formed by the lining 63, and flow spirally downward along the channel 7. When the flow approaches the tail pipe At 5 o'clock...

Embodiment 3

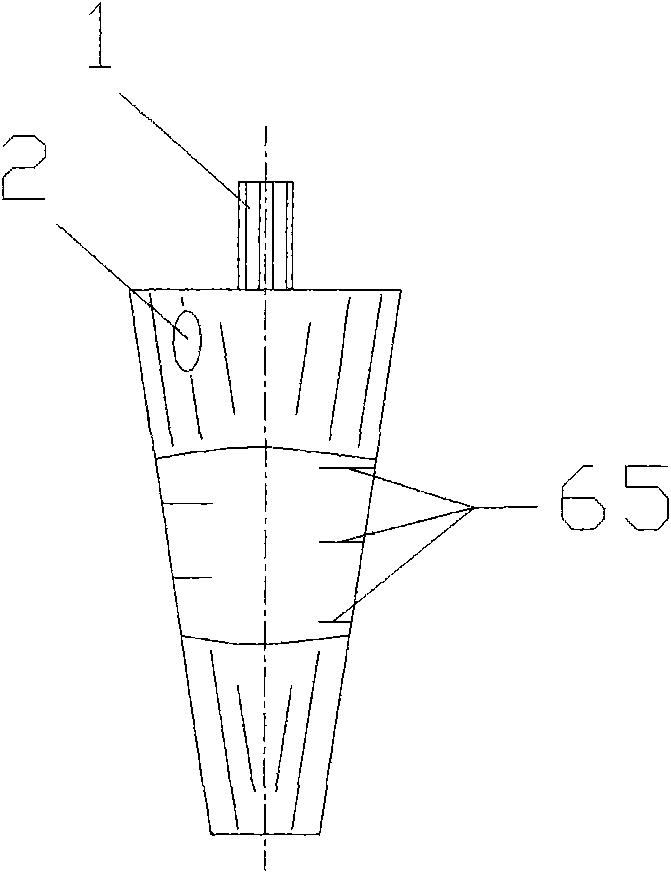

[0046] Embodiment 3: cyclone separator

[0047] One of the important equipment for processing oilfield production fluid is cyclone separator, especially for offshore oil platforms with small space, efficient and compact cyclone separator is an important equipment to improve the working efficiency of offshore oil platforms, as described here The structure and working principle of the cyclone separator is similar to that of the cyclone separator. The structure for separating gas-solid heterogeneous systems is generally called a cyclone separator; for the separation of liquid-solid or gas-liquid heterogeneous The structure of the phase system is generally called a cyclone separator or a cyclone.

[0048] On the wall surface of the cyclone, intermittent channels are opened along the flow direction of the particles, and the inner wall 6 and the channel 7 are formed by milling along the spiral direction on the wall. The diameter of the cyclone separator is 100mm, the cross section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com