Moisture-proof coating citicoline sodium capsule and preparation method thereof

A technology of citicoline sodium and capsules, which is applied in the field of moisture-proof coated citicoline sodium capsules and its preparation, and can solve the problems of unclear specific components of pharmaceutical excipients, affecting filling, and easy moisture absorption of citicoline sodium, etc. problems, to achieve the effect of controllable range of key process parameters, good moisture-proof function, stable and controllable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

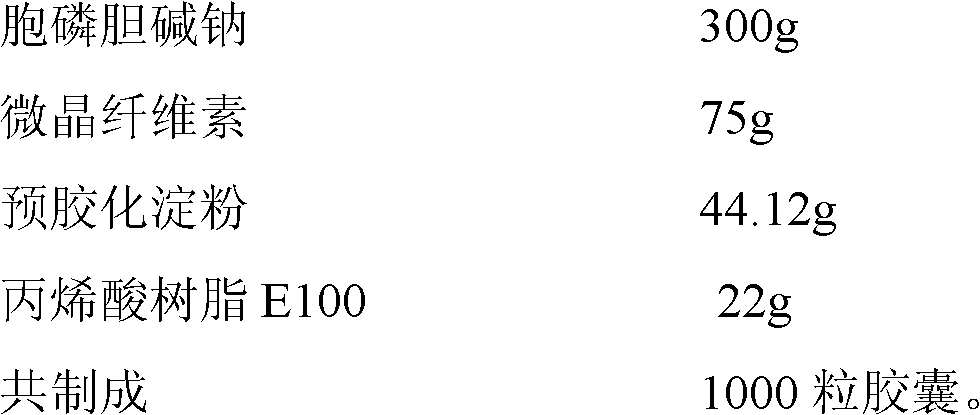

[0031] Embodiment 1: Recipe composition:

[0032]

[0033] Preparation Process:

[0034] The citicoline sodium of the recipe quantity is pulverized and passed through a 100-mesh sieve, and the pregelatinized starch and microcrystalline cellulose of the recipe quantity are respectively passed through a 40-mesh sieve, for subsequent use; the citicoline sodium, pregelatinized Starch and microcrystalline cellulose, use water as a wetting agent to make soft materials, set the extrusion rate of the extrusion spheronizer to 20-30HZ, the spheronization speed of 300rpm, and the spheronization time of 30s. Dry at 50°C to obtain citicoline sodium immediate-release granules.

[0035] Take the moisture-proof coating material acrylic resin E100 in the recipe quantity, and prepare a coating liquid with a solid content of 5wt%. Get the above-mentioned citicoline sodium immediate-release granules and place them in a fluidized bed for coating: the inlet air temperature is 40-60 °C, and the...

Embodiment 2

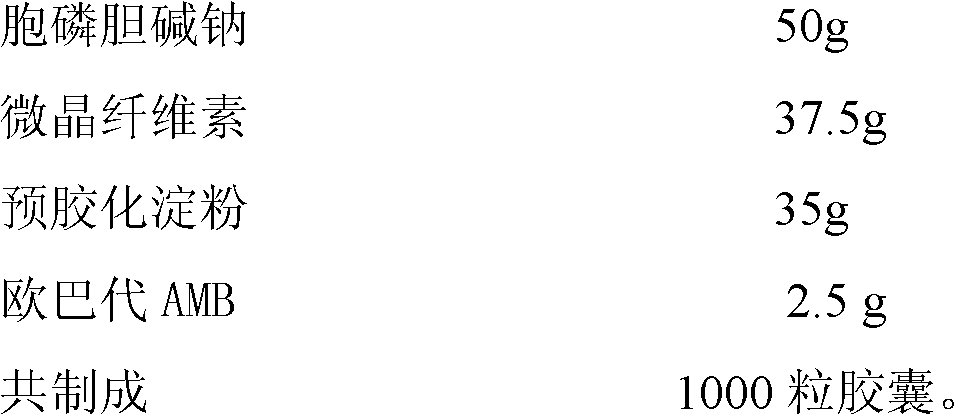

[0036] Embodiment 2: Recipe composition:

[0037]

[0038] Preparation Process

[0039] The citicoline sodium of the recipe quantity is pulverized and passed through a 100-mesh sieve, and the pregelatinized starch and microcrystalline cellulose of the recipe quantity are respectively passed through a 40-mesh sieve, for subsequent use; the citicoline sodium, pregelatinized Starch and microcrystalline cellulose, use water as a wetting agent to make soft materials, set the extrusion rate of the extrusion spheronizer to 20-30HZ, the spheronization speed of 500rpm, and the spheronization time of 1min. Use the extrusion spheronization method to prepare pellets, then at 30 Dry at -50°C to obtain citicoline sodium immediate-release pellets.

[0040] The moisture-proof coating material Opada AMB in the prescription amount was taken and prepared into a coating liquid with a solid content of 10 wt %. Get the above-mentioned citicoline sodium immediate-release pellets and place them ...

Embodiment 3

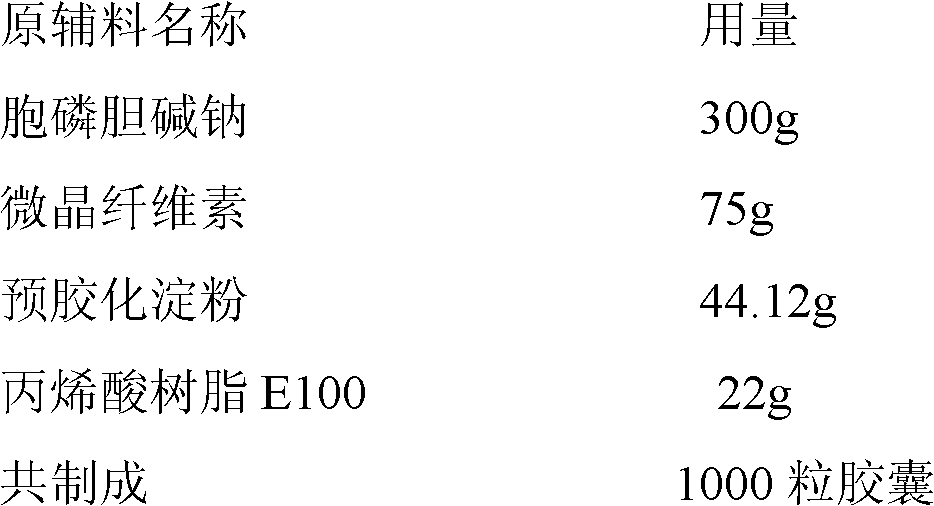

[0041] Embodiment 3: Recipe composition:

[0042]

[0043] Preparation Process:

[0044] The citicoline sodium is pulverized and passed through a 100-mesh sieve, and the pregelatinized starch and microcrystalline cellulose are respectively passed through a 40-mesh sieve for subsequent use; the sifted citicoline sodium, pregelatinized starch and microcrystalline cellulose are , and dry pressing the granules to obtain immediate-release citicoline sodium granules.

[0045] The moisture-proof coating powder of the recipe quantity was taken and prepared into a coating liquid with a solid content of 3wt%. Get the above-mentioned citicoline sodium immediate-release granules and place them in a fluidized bed for coating: the inlet air temperature is 50-70 °C, and the inlet air volume is 600-800 m 3 / h, the atomization pressure is 1.0-1.5bar, the material temperature is 30-40°C, the spray rate is 60-200g / min, keep the fluidized state after coating, and continue to dry for 5-15min ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com