Preparation method of amorphous granular resistant starch

A technology of resistant starch and amorphous particles, applied in the field of carbohydrates, can solve the problems of complex production process and low purity of resistant starch, and achieve the effects of low energy consumption, high dry heat reaction efficiency, and good heat resistance stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

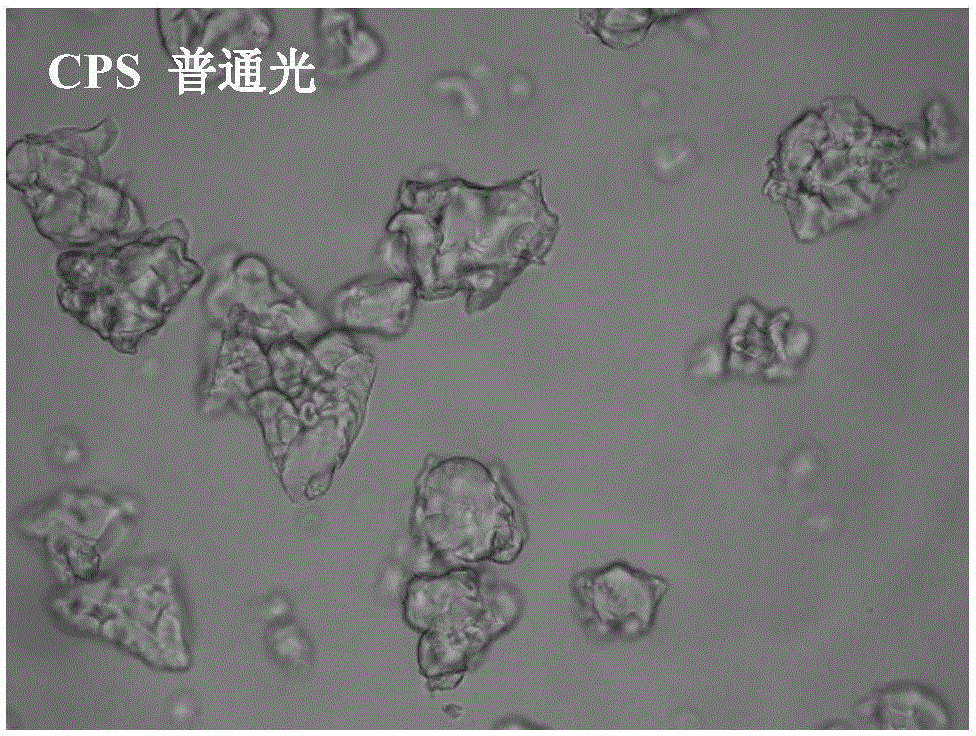

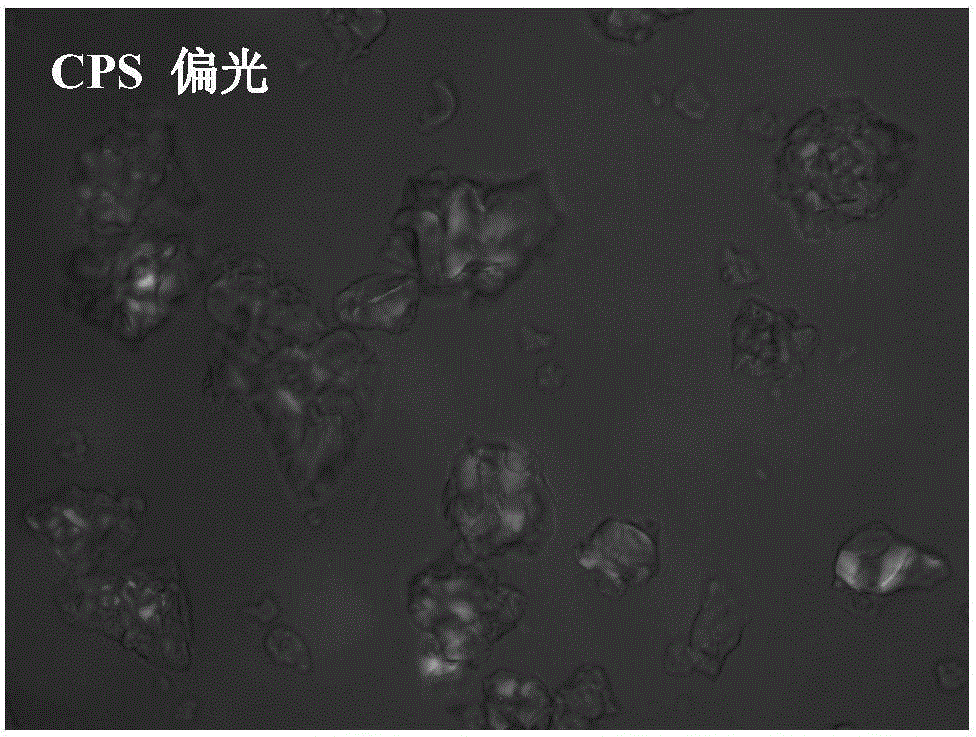

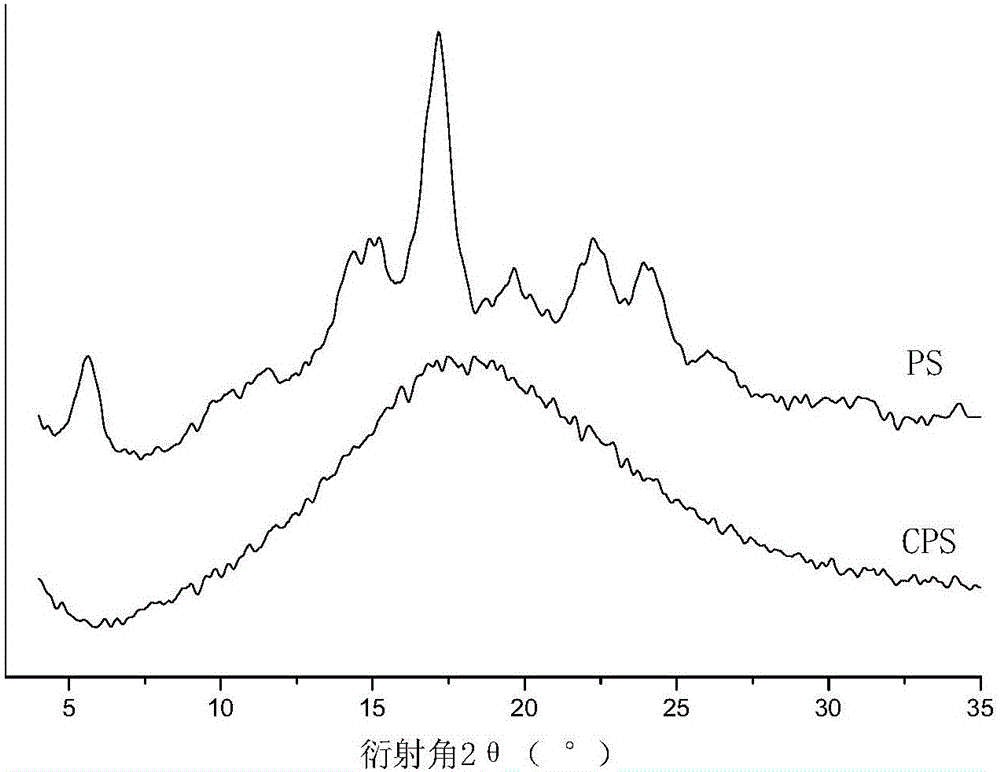

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing amorphous granular resistant starch, comprising the steps of:

[0036] (1) adding water to potatoes (dry basis) to prepare 10% (w / w) starch emulsion;

[0037] (2) configuration mass concentration is the NaOH solution of 20%;

[0038] (3) Slowly add the NaOH solution prepared in step (2) that accounts for 50% of the dry weight of the starch into the starch emulsion dropwise while stirring, and stir at 30° C. under normal pressure until a transparent concentrated starch solution is obtained.

[0039] (4) Neutralize the concentrated starch solution to pH 6.5 with dilute hydrochloric acid ethanol solution with a mass concentration of 5%, then wash with ethanol solution, and dry to obtain alkali-pretreated starch;

[0040] (5) Dissolve citric acid accounting for 40% of the alkali-pretreated starch dry weight in 20mL ethanol solution to obtain a citric acid-alcoholic solution, and disperse the alkali-pretreated starch obtained in step (4) in the citric...

Embodiment 2

[0063] A method for preparing amorphous granular resistant starch, comprising the steps of:

[0064] (1) glutinous rice starch (dry basis) is mixed with 15% (w / w) starch emulsion;

[0065] (2) the configuration concentration is a NaOH solution of 30% (w / w);

[0066] (3) Slowly add an alkali solution accounting for 25% (w / w) of the starch dry basis into the starch milk dropwise while stirring, and stir at a normal pressure of 35° C. until a transparent concentrated starch solution is obtained.

[0067] (4) Neutralize the concentrated starch solution with 5% (w / w) dilute hydrochloric acid ethanol solution to pH 6.5, then wash with ethanol solution, and dry to obtain alkali-pretreated starch;

[0068] (5) dissolving citric acid accounting for 30% of the alkali pretreated starch dry weight in a small amount of ethanol solution to obtain a citric acid alcohol solution, dispersing the alkali pretreated starch obtained in step (4) in the citric acid alcohol solution, and placing it ...

Embodiment 3

[0074] A method for preparing amorphous granular resistant starch, comprising the steps of:

[0075] (1) Tapioca starch (dry basis) is mixed with 30% (w / w) starch emulsion;

[0076] (2) the configuration concentration is a NaOH solution of 40% (w / w);

[0077] (3) Slowly add an alkali solution accounting for 20% (w / w) of the starch dry basis into the starch milk dropwise while stirring, and stir at 25° C. under normal pressure until a transparent concentrated starch solution is obtained.

[0078] (4) Neutralize the concentrated starch solution with 5% (w / w) dilute hydrochloric acid ethanol solution to pH 6.5, then wash with ethanol solution, and dry to obtain alkali-pretreated starch;

[0079] (5) dissolving citric acid accounting for 35% of the alkali-pretreated starch on a dry basis in a small amount of ethanol solution to obtain a citric acid-alcoholic solution, dispersing the alkali-pretreated starch obtained in step (4) in the citric acid-alcoholic solution, and placing i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com