Patents

Literature

66results about How to "No embrittlement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Adhesive for road antiskid layer and preparation method of adhesive

ActiveCN102731967AEnhanced chemical corrosivenessEnhanced environmental corrosion resistanceChemistryPliability

The invention discloses an adhesive for a road antiskid layer. The adhesive is formed by mixing 7-10 parts of modified epoxy resin, 3-5 parts of a modified epoxy curing agent and 10-14 parts of talcum powder in parts by weight, wherein the modified epoxy resin is prepared by dissolving a toughening agent, a coupling agent and an anti-aging agent into 80-120 parts of Bisphenol-A epoxy resin and 40-100 parts of soft epoxy resin; the modified epoxy curing agent is prepared by adding a dispersing agent and a defoaming agent into an epoxy curing agent which is 4-8% of the total volume of the Bisphenol-A epoxy resin and the parts of soft epoxy resin. In the prepared method disclosed by the invention, the preparation technology and operation are very simple and convenient and each step is finished at normal temperatures and pressures, so as to bring convenience to industrial production; the prepared adhesive has excellent mechanical property, deformation property, durability and anti-pollution property and can be well bonded with the original road; the adhesive can be well bonded with stones so that the stones are not easy to come off; and the adhesive has low temperature flexibility and does not crack after extrusion.

Owner:重庆市智翔铺道技术工程有限公司

Process for carrying out vacuum cleaning, oil removal and wax removal by modified hydrocarbon cleaner

The invention relates to the technical field of electroplating pretreatment, in particular to a process for carrying out vacuum cleaning, oil removal and wax removal by a modified hydrocarbon cleaner. The process comprises degassing ultrasonic cleaning, vacuum cleaning, vacuum steam flushing, vacuum drying and the like. A plurality of flows are carried out in the vacuum environment with a certain vacuum degree and are matched with a degassing ultrasonic cleaning and vacuum cleaning technology and the modified hydrocarbon cleaner. For the cleaning process, in the whole process, harmful substances of halogen and the like, such as trichloroethylene, methylene chloride, tetrachloroethylene and the like, cannot be used and additional drying equipment is not required. Particularly, the process has excellent cleaning effect on irregular articles with blind holes, joints, gaps, cracks and the like. Meanwhile, the defects of oil removal and wax removal of the conventional process are overcome.

Owner:广东新球清洗科技股份有限公司

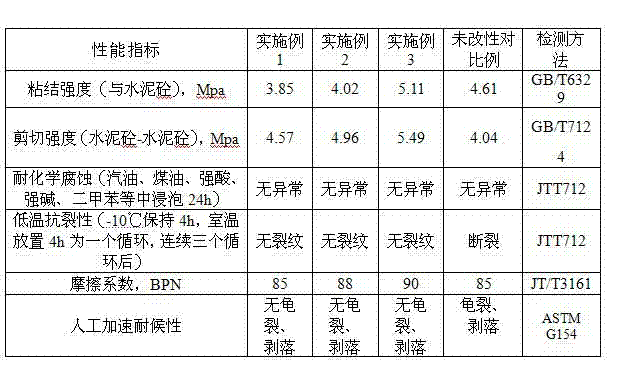

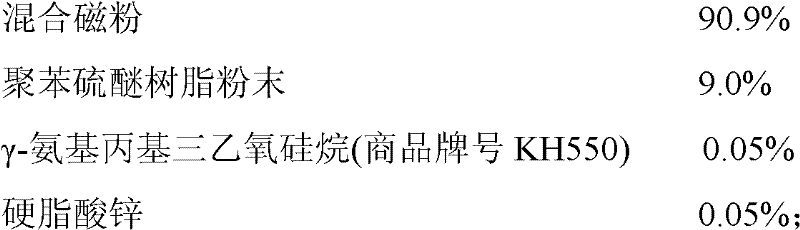

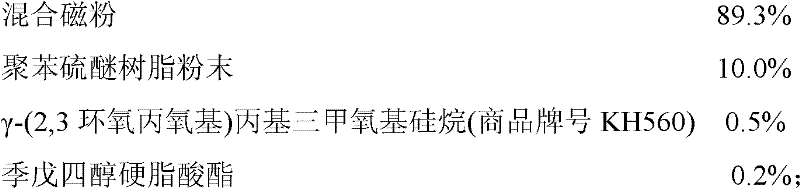

Injection molding permanent magnet composite material containing polyphenylene sulfide and preparation method thereof

ActiveCN102504534AExcellent overall performanceExcellent magnetic propertiesMagnetic powderNeodymium iron boron

An injection molding permanent magnet composite material containing polyphenylene sulfide includes the following components by mass: 78% to 91% of mixed magnetic powder, 8% to 21% of polyphenylene sulfide resin and 0.05% to 1% of coupling agents. The mixed magnetic powder includes the following components by mass: 50% to 96% of neodymium iron boron permanent magnetic powder, 1% to 49% of samariumiron nitrogen permanent magnetic powder and 1% to 45% of ferrite permanent magnetic powder. A preparation method of the injection molding permanent magnet composite material includes the following processing steps: (1) preparing multi-element composite magnetic powder, (2) mixing and pelleting and (3) injection molding.

Owner:SICHUAN UNIV

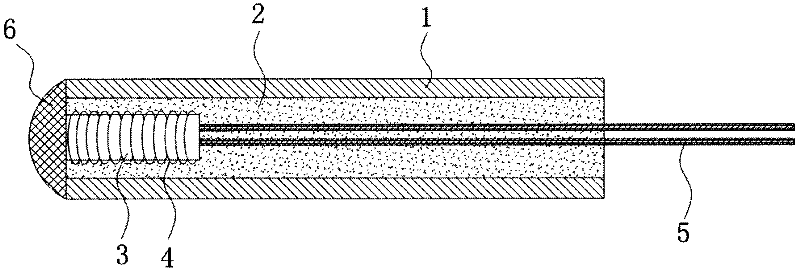

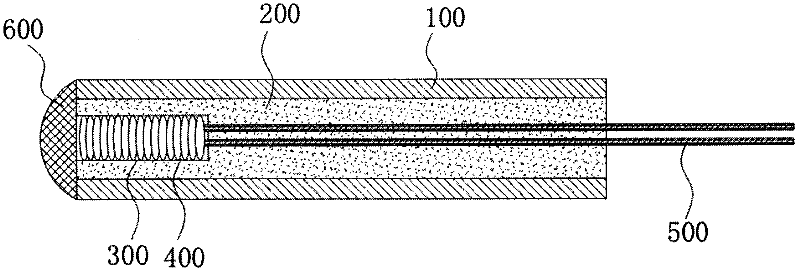

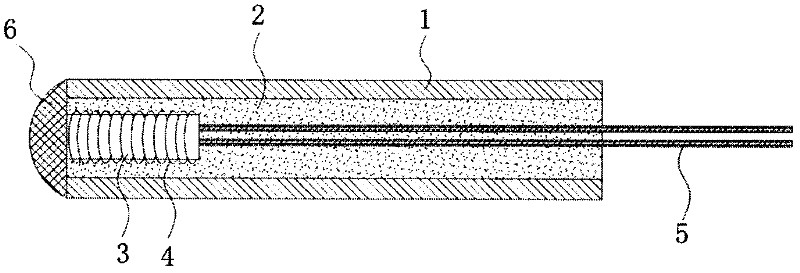

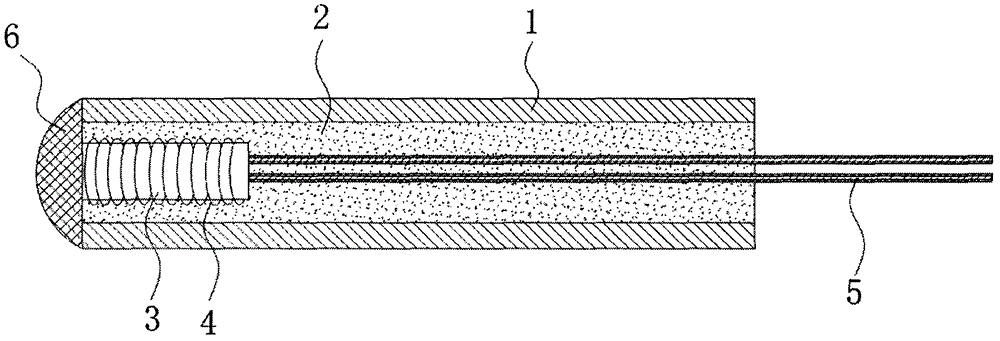

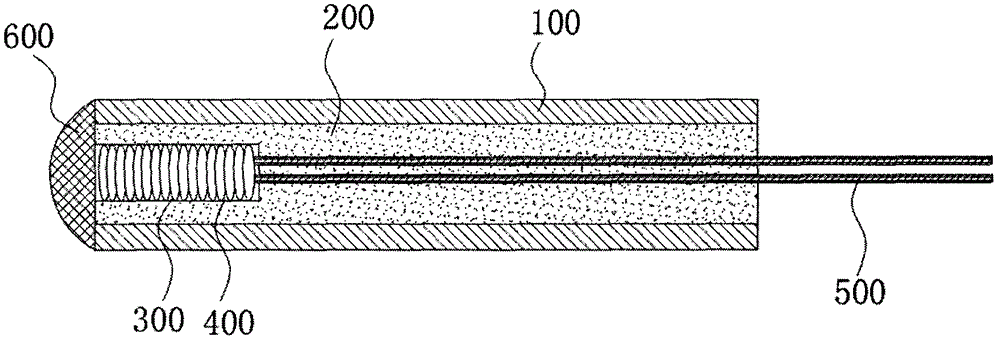

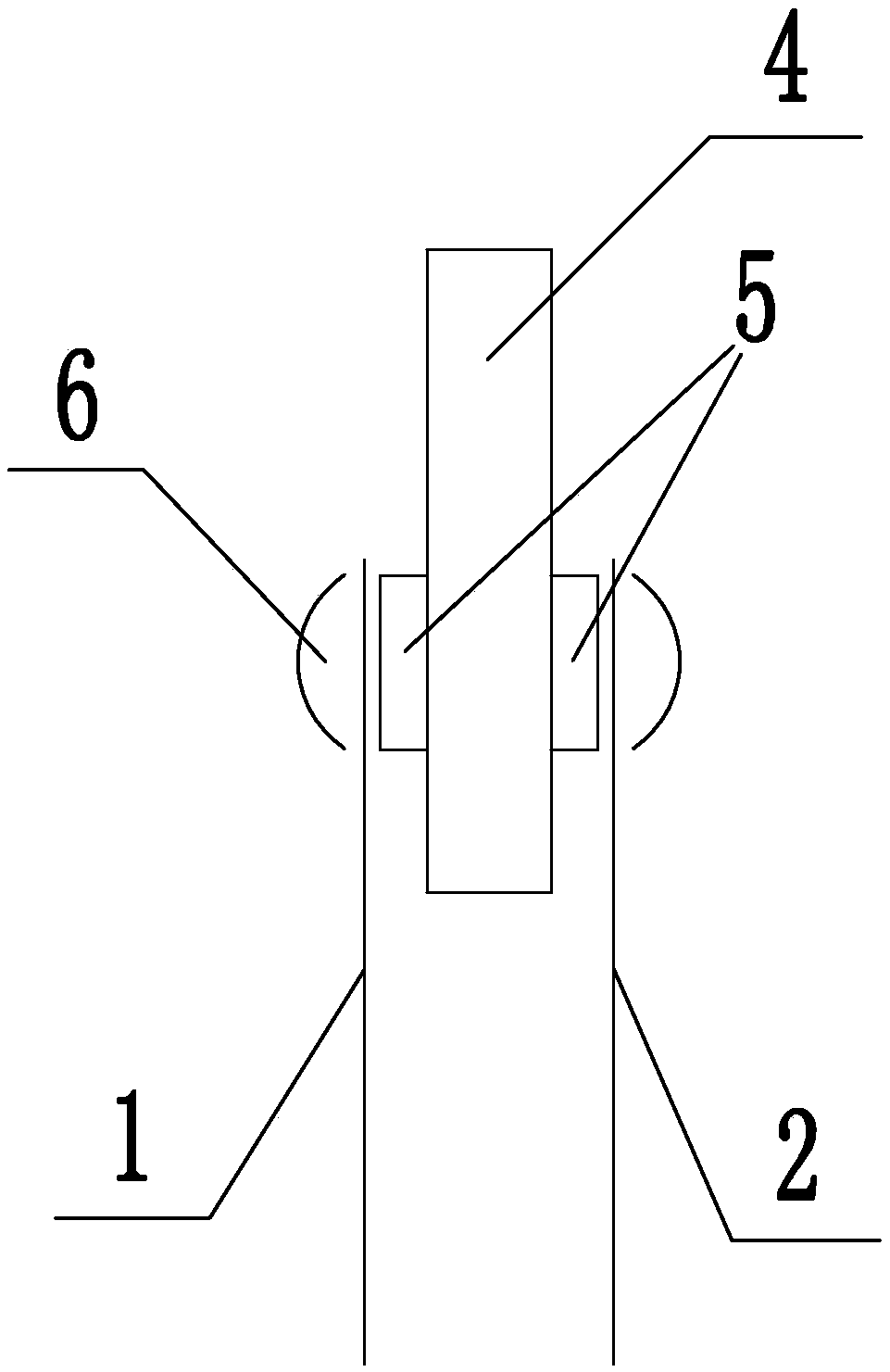

Electro-thermal push bar for electronic thermostat of engine

InactiveCN102536418AExtended service lifeSimple structureCoolant flow controlMachines/enginesElectricityControl power

The invention discloses an electro-thermal push bar for an electronic thermostat of an engine, which comprises a push bar body. A heating element is disposed inside the push bar body and comprises a magnesium oxide stick, an electric heating wire and a high-temperature wire, wherein the electric heating wire is wound on the magnesium oxide stick, two ends of the electric heating wire are connected through the high-temperature wire, and the high-temperature wire extends out of the push bar body to be connected with a control power source. The heating element and the push bar inside the electronic thermostat are integrated, so that deformation and even breakage of the heating element under the action of external force is avoided, the service life of the heating element of the electronic thermostat is prolonged, and the engine is guaranteed to operate within a proper temperature range for long. In addition, a conventional sheet heater for the electronic thermostat is changed into a stick heater, and the stick heater compared with the sheet heater has the advantages of no crisping, no deformation and no breakage, is longer in service life and further is simple in structure. Therefore, the internal structure of the electronic thermostat is simpler, and manufacturing cost and difficulty can be reduced.

Owner:乐清市海狮电热电器制造有限公司

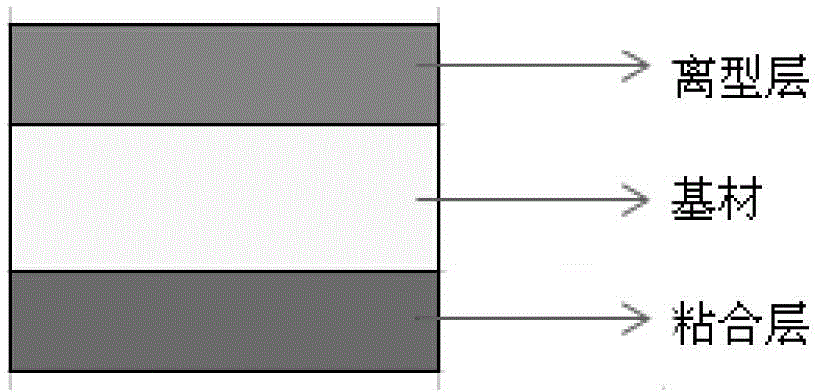

High temperature resistant release adhesive tape as well as preparation method and use of adhesive tape

ActiveCN104629640ANo meltingNo embrittlementLamination ancillary operationsFilm/foil adhesivesThin membraneSilicone tape

The invention discloses a high temperature resistant release adhesive tape as well as a preparation method and the use of the adhesive tape. The high temperature resistant release adhesive tape is composed of a release layer, a substrate and an adhesive layer, wherein the release layer and the adhesive layer are formed on the substrate in a coating or spray-coating manner; the substrate is a thin film prepared from the mixed material of PA6 and PA66, or PA6, or PA66 as a major material. The preparation method comprises the following steps: firstly, preparing the substrate from the mixed material of PA6 and PA66, or PA6, or PA66 as the major material; secondly, treating the thin film by use of a corona treater to reduce the surface energy; thirdly, forming the release layer and the adhesive layer on the corresponding release surface and adhesive surface of the thin film in a coating or spray-coating manner respectively; and finally, slitting and curling, and packaging to obtain a finished product. The high temperature resistant release adhesive tape is low in cost, and capable of bearing the use temperature within the range of 150 to 220 DEG C without melting, embrittlement, breakage and the like. The high temperature resistant release adhesive tape can be widely applied to composite materials, and to the fields of bicycle frame five-way part wrapping, the difficult corner mold stripping parts of other pipe fittings, vacuum-pumping process sealing adhesive tapes in the electronic industry and the like.

Owner:厦门新旺新材料科技有限公司

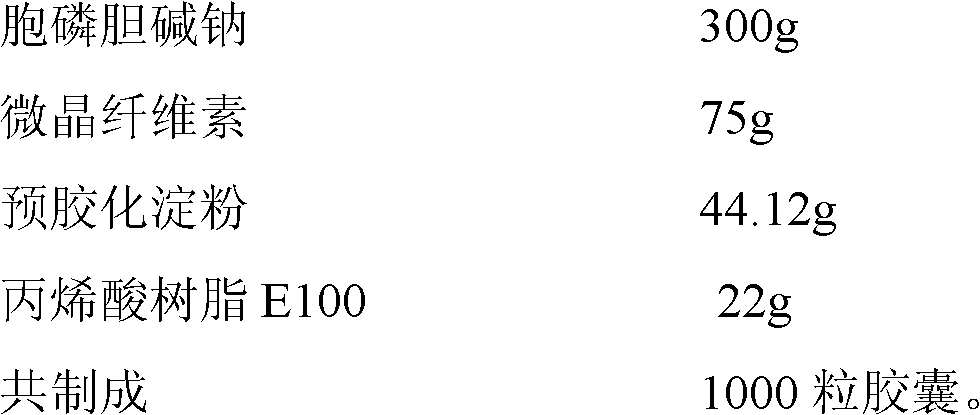

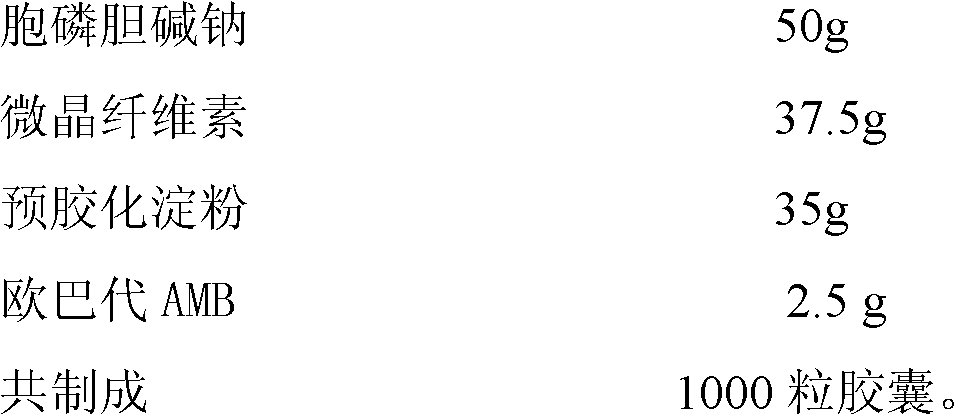

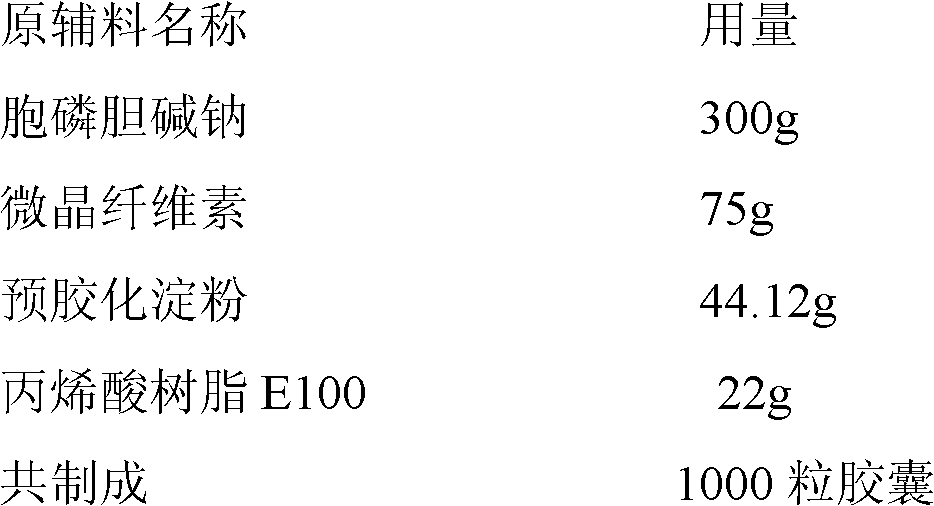

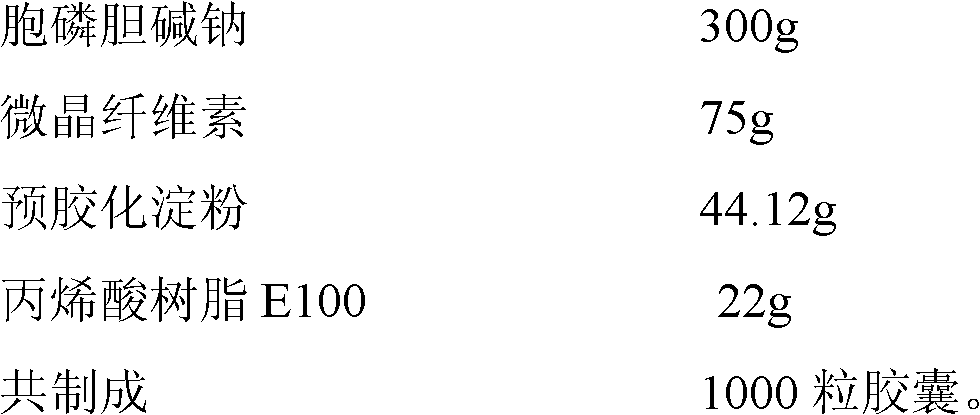

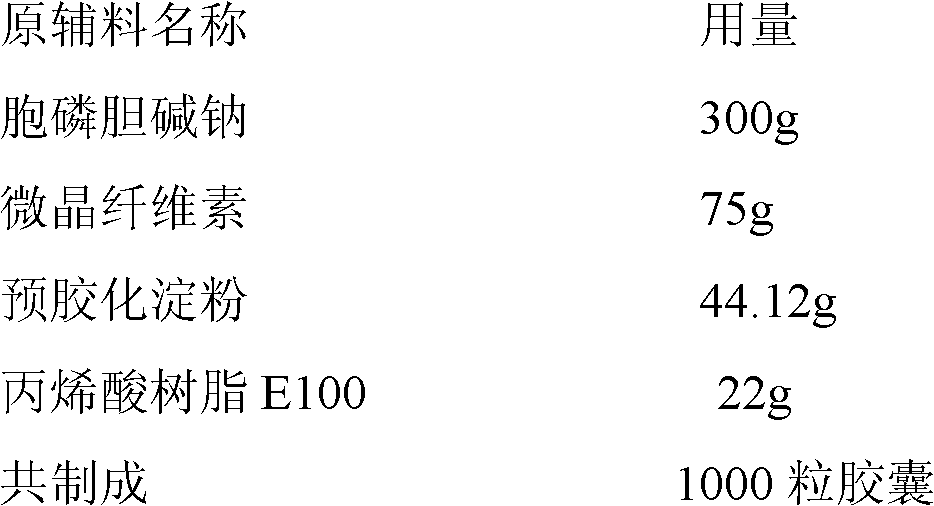

Moisture-proof coating citicoline sodium capsule and preparation method thereof

ActiveCN102525997AGood granularityGood disintegrationOrganic active ingredientsNervous disorderCiticoline sodiumMoisture absorption

The invention provides a moisture-proof coating citicoline sodium capsule and a preparation method thereof. The citicoline sodium capsule is composed of a capsule casing and quick-release moisture-proof micro pills or granules. All components in each capsule containing citicoline sodium quick-release moisture-proof micro pills or granules by percentage are 40% to 70% of citicoline sodium, 10% to 30% of microcrystalline cellulose, 10% to 30% of pregelatinized starch and 2% to 10% of moisture-proof coatings. The moisture-proof micro pills or granules are obtained by being extruded and rounded or pressed and granulated to be coated with moisture-proof coatings. The citicoline sodium capsule is good in moisture-proof function and resolves the problems that the capsule is prone to absorb waterdue to the fact that citicoline sodium is strong in moisture absorption, the capsule casing is prone to be fragile, and the like.

Owner:QILU PHARMA CO LTD

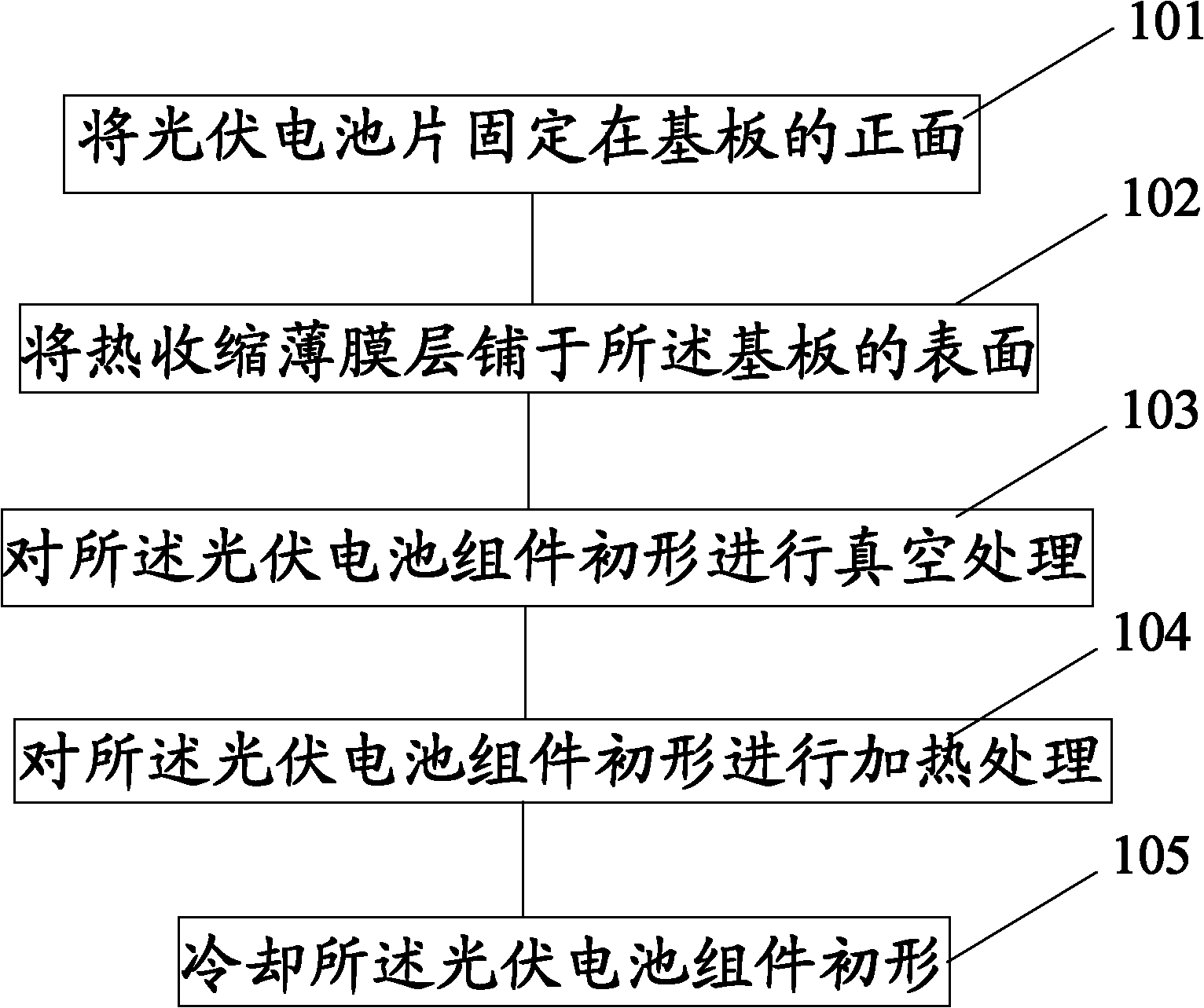

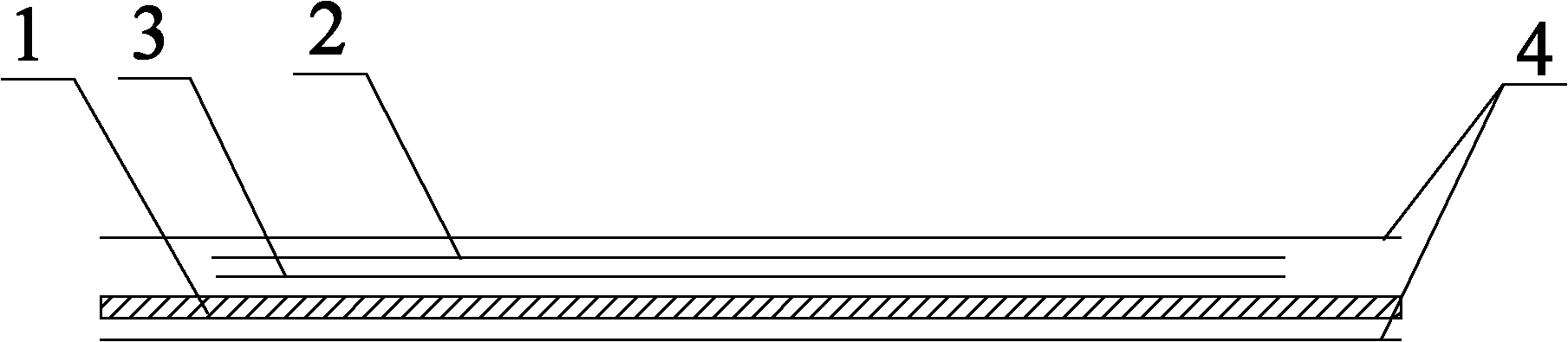

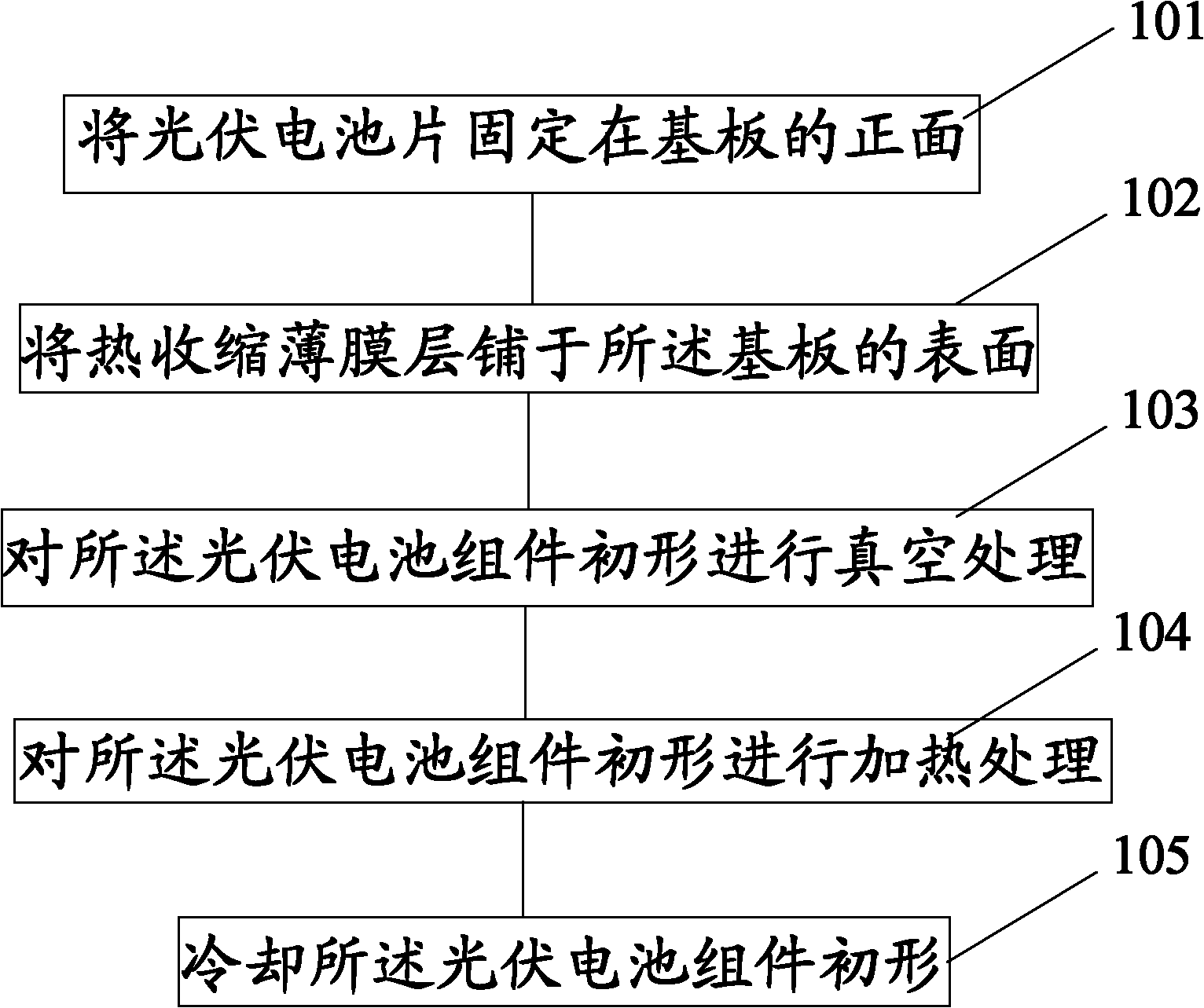

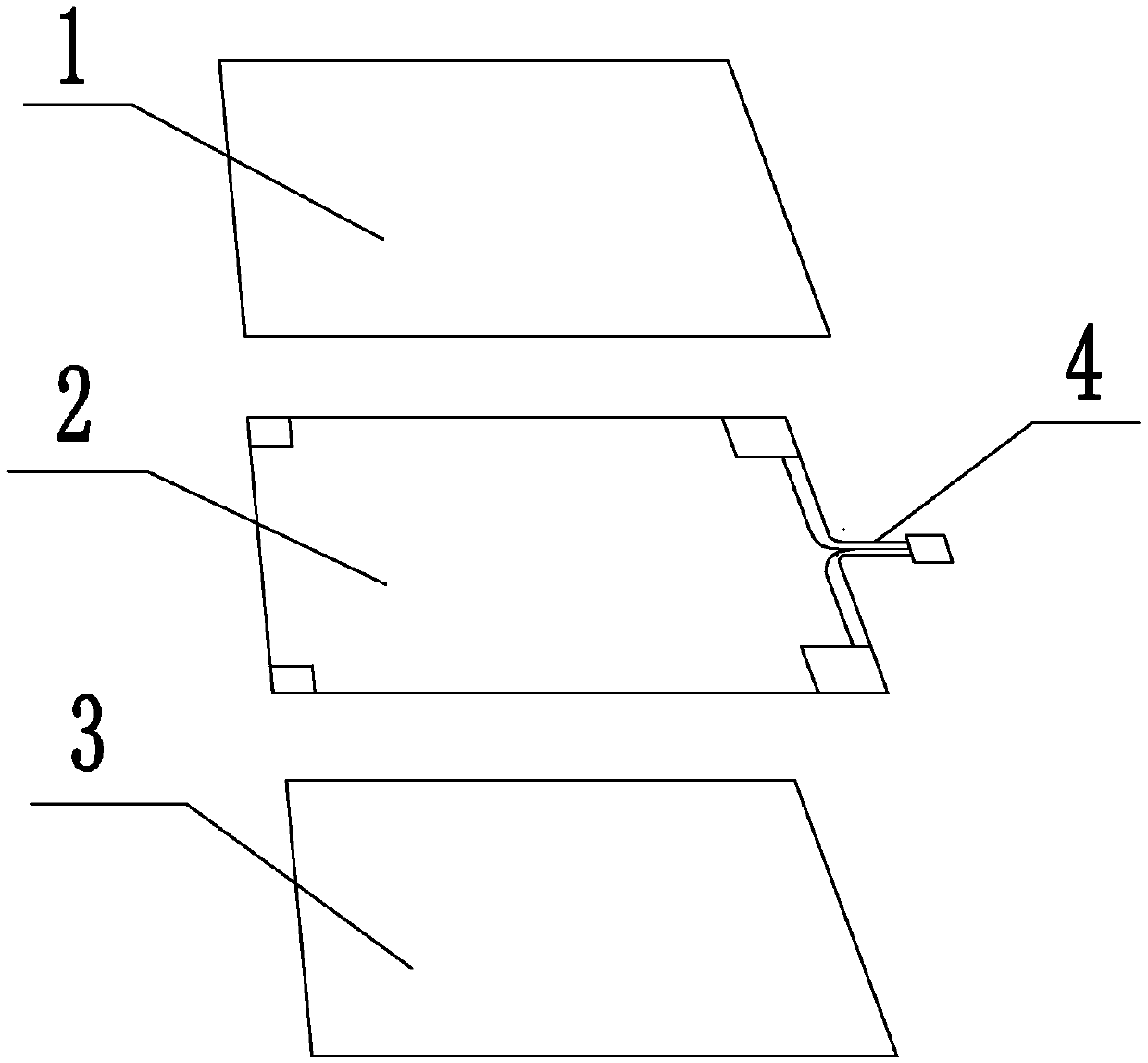

Photovoltaic battery component packaged by heat-shrinkable material and preparation method thereof

InactiveCN102082207AGood weather resistanceImprove sealingFinal product manufactureSynthetic resin layered productsEngineeringPhotovoltaic power generation

The invention relates to the technical field of photovoltaic power generation, and discloses a method for preparing a photovoltaic battery component. The method comprises the following steps of: fixing a photovoltaic battery plate on the front surface of a substrate; laying a heat-shrinkable film layer on the surface of the substrate to form the original shape of the photovoltaic battery component; performing vacuum treatment on the original shape of the photovoltaic battery component; performing heat treatment on the original shape of the photovoltaic battery component; and cooling the original shape of the photovoltaic battery component to obtain the photovoltaic battery component. The preparation process of the solar photovoltaic battery component is simple, and low in cost, and has a wide application range. The invention also discloses the photovoltaic battery component prepared by the method.

Owner:YINGLI ENERGY CHINA

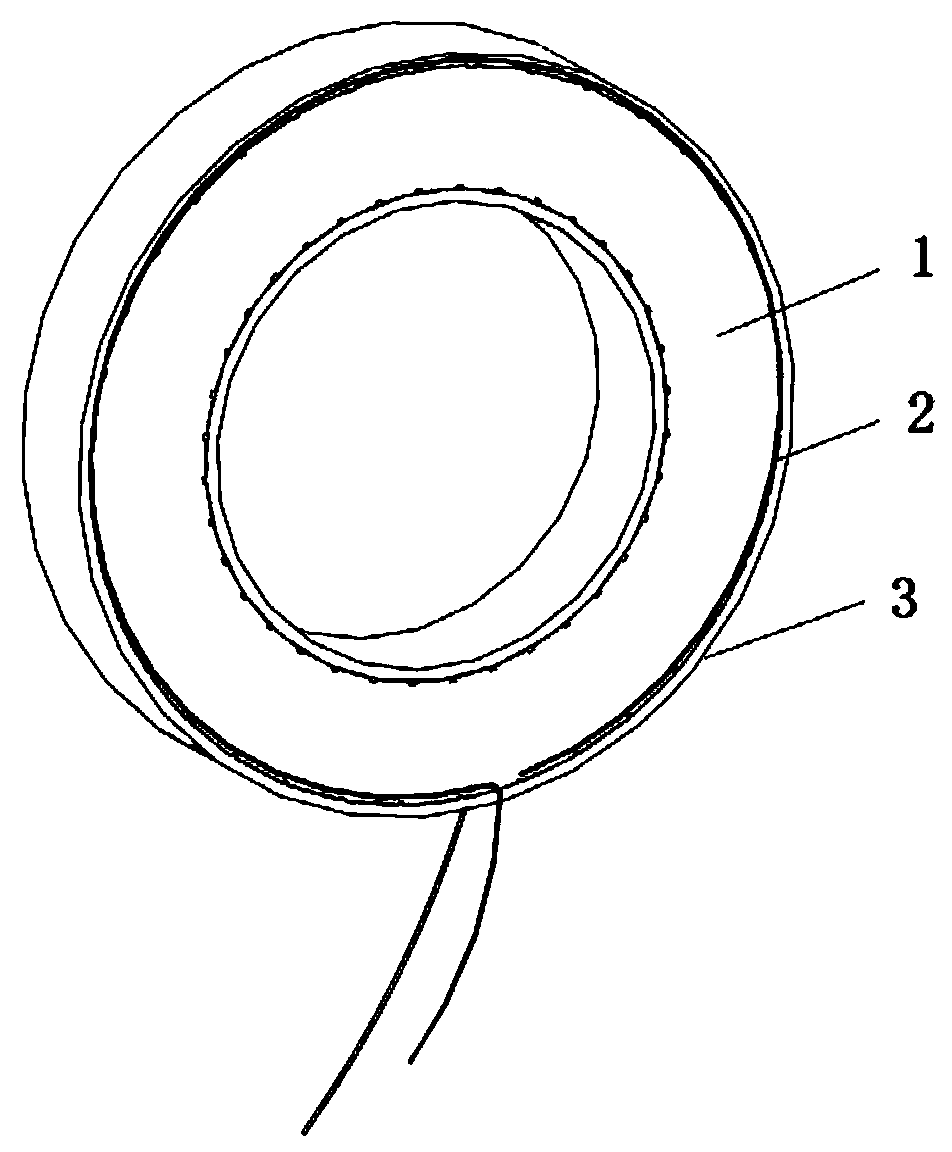

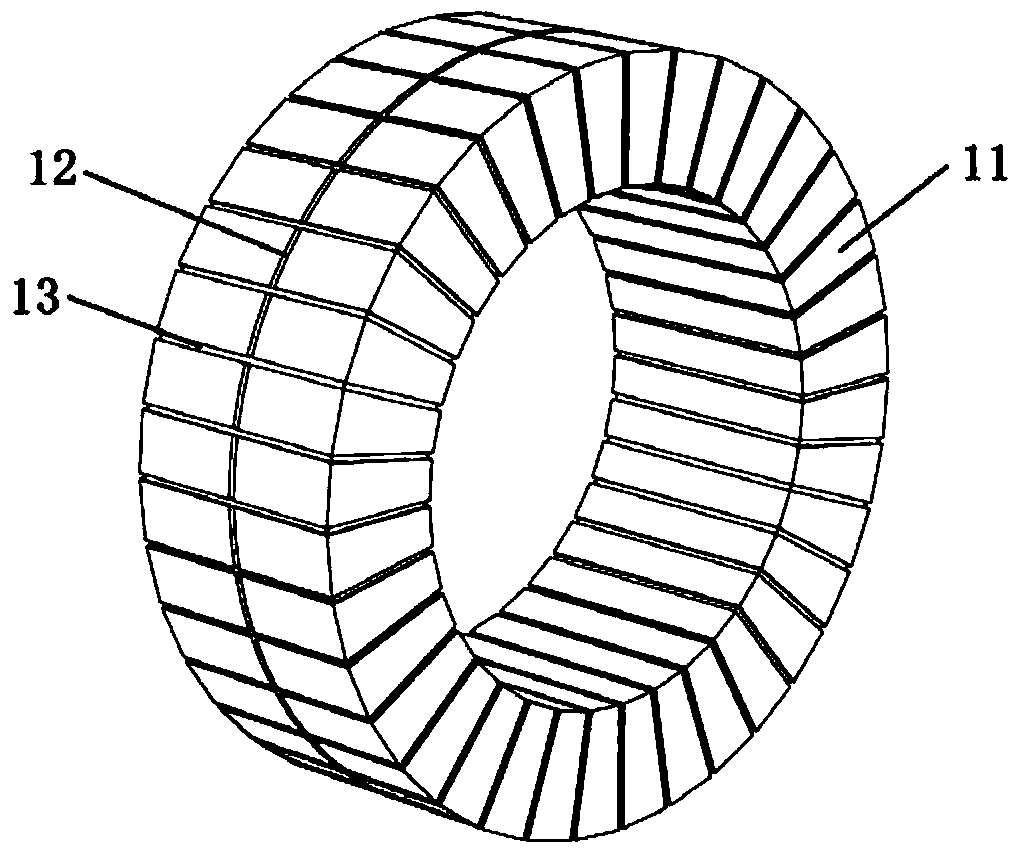

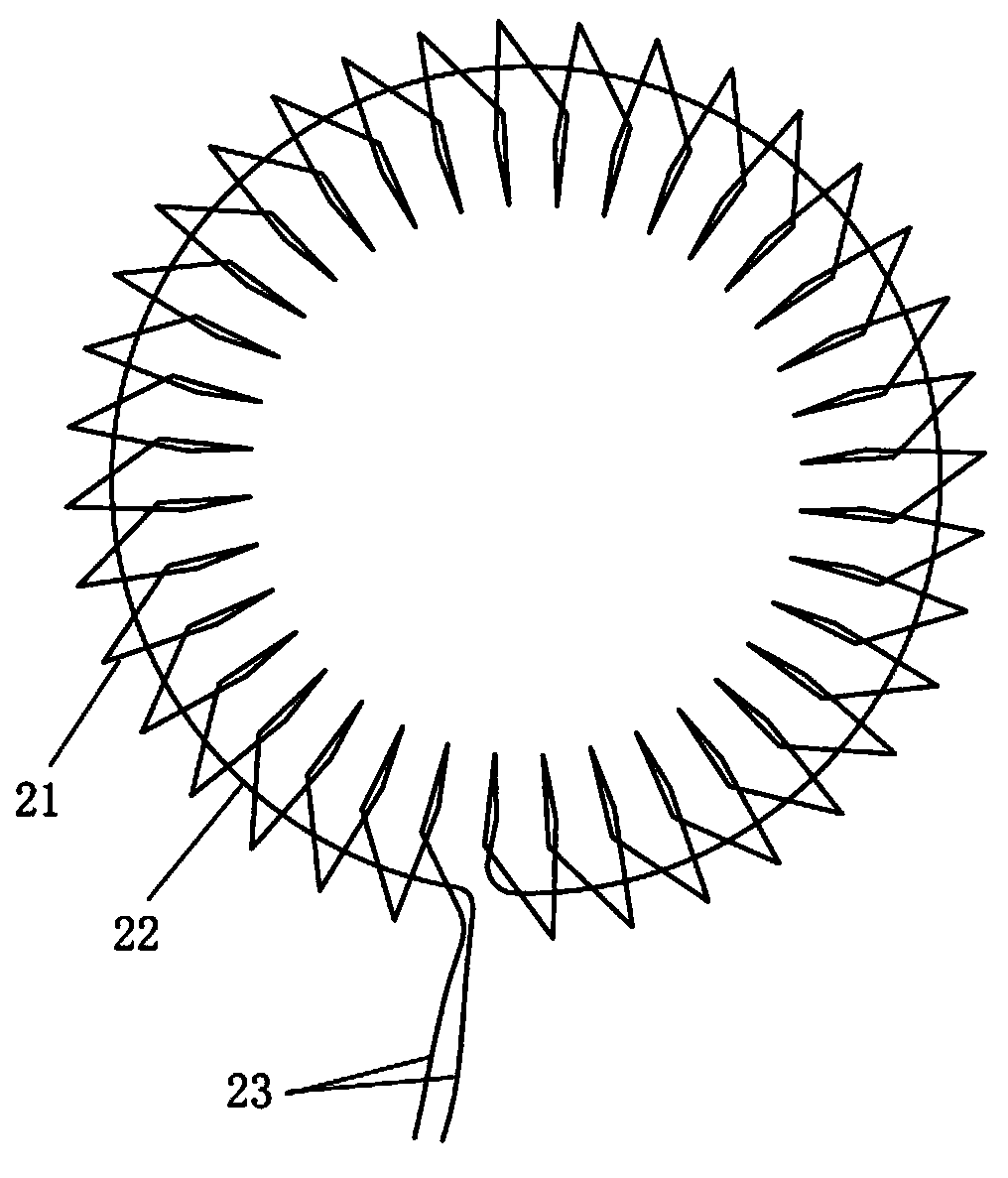

Low-temperature current transformer coil

InactiveCN104200979AGuaranteed Dielectric StrengthNo embrittlementTransformersTransformers/inductances coils/windings/connectionsConductor CoilElectrical and Electronics engineering

The invention discloses a low-temperature current transformer coil. The low-temperature current transformer coil mainly comprises a low-temperature glue inner frame (1), a low-temperature insulated wire turn (2) and a low-temperature glue outer frame (3), wherein the low-temperature glue inner frame (1) is arranged in the center of the low-temperature current transformer coil, and adopts a hollow ring-shaped structure; the low-temperature insulated wire turn (2) is formed by uniform winding in the radial direction of the low-temperature glue inner frame (1) of low temperature resistant insulation varnished wire; the head and tail lead wires (23) of the low-temperature insulated wire turn (2) are clung to the outer wall of the low-temperature glue inner frame (1), and are led out from a wire return groove (12) in the outer wall of the low-temperature glue inner frame (1); the low-temperature glue outer frame (3) is ring-shaped, and wraps the low-temperature insulated wire turn (2) and the low-temperature glue inner frame (1) except the lead wires (23).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

Shock-resisting and breaking-proof ceramic for daily use and preparation method thereof

The invention discloses shock-resisting and breaking-proof ceramic for daily use and a preparation method thereof. The ceramic is prepared from the following raw materials in parts by weight: 20 to 30parts of kaolin, 10 to 20 parts of silicon dioxide, 10 to 20 parts of feldspar, 5 to 15 parts of bamboo charcoal powder, 3 to 10 parts of talcum powder, 5 to 15 parts of zirconium boride, 10 to 15 parts of fructus gardeniae, 3 to 7 parts of tetraethyl orthosilicate, 3 to 5 parts of oxidized polyethlene wax, 5 to 15 parts of epoxy resin and 1 to 3 parts of a silane coupling agent. The shock-resisting and breaking-proof ceramic for daily use, disclosed by the invention, has the advantages of simple production technology, no pollution in a technological process, low raw material cost, fine microstructure crystal grains and high wear-resisting strength of a product; the prepared shock-resisting and breaking-proof ceramic for daily use has high shock-resisting performance and good mechanical strength and is durable.

Owner:福建省德化汇远陶瓷有限公司

Low-temperature-resistant ceramic tile and preparation method thereof

The invention discloses a low-temperature-resistant ceramic tile and a preparation method thereof. The ceramic tile is prepared from the following raw materials in parts by weight: 36-48 parts of sepiolite, 21-33 parts of firestone, 15-20 parts of limestone, 10-15 parts of construction waste, 8-16 parts of hill sand, 18-26 parts of modified clay, 16-28 parts of alunite, 4-8 parts of a sludge dry powder, 24-36 parts of kyanite, 5-10 parts of a straw powder, 3-5 parts of calcium chloride, 2-4 parts of chromic oxide, and 9-17 parts of a caustic-burned magnesia powder. The ceramic tile has good low temperature resistance, can be used for a long time under a low temperature condition of below -5 DEG C, does not generate brittle rupture, and has the advantages of high strength, good water resistance, strong anti-erosion ability, good weather resistance, and long service life.

Owner:安徽省亚欧陶瓷有限责任公司

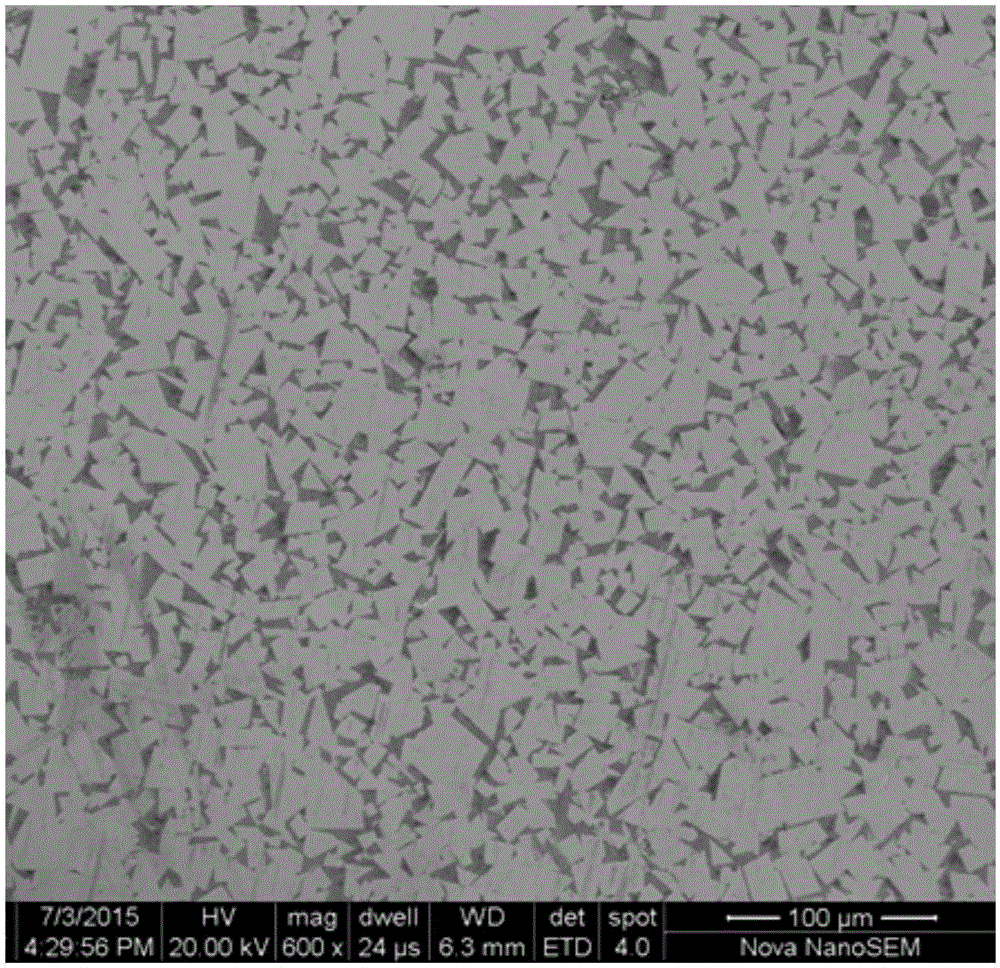

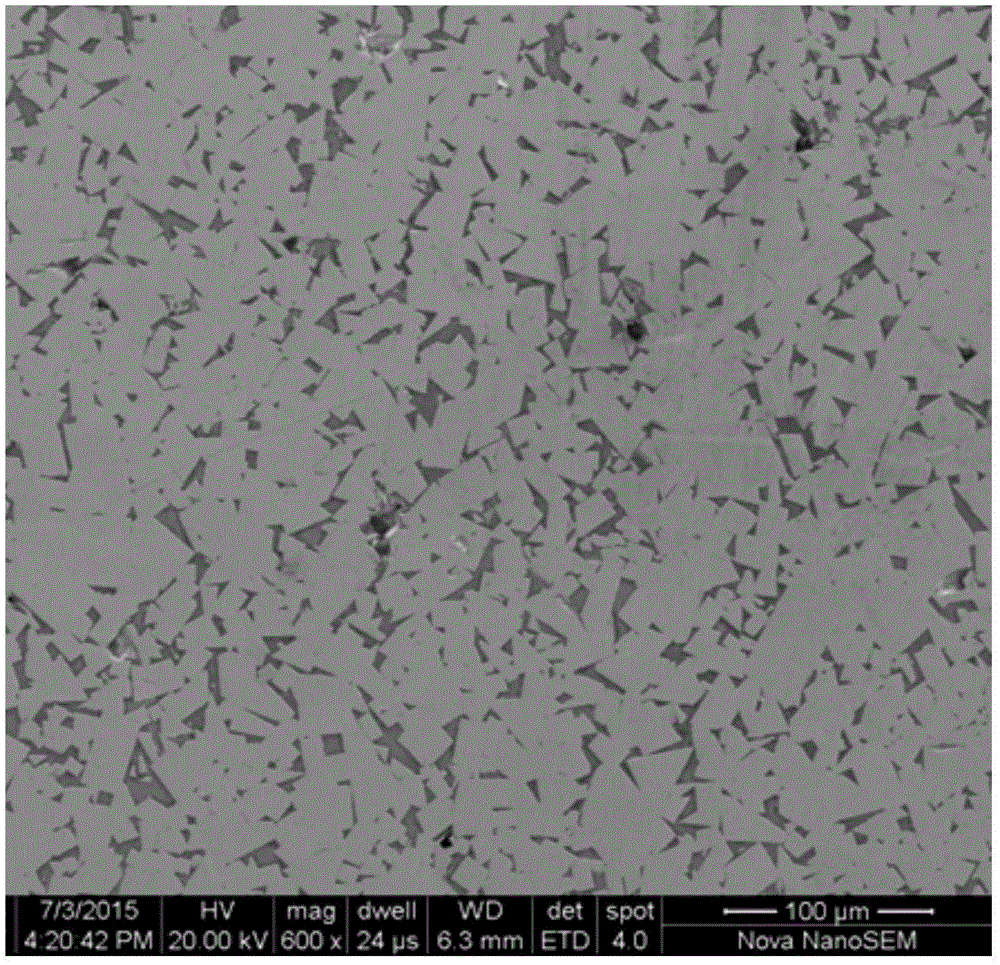

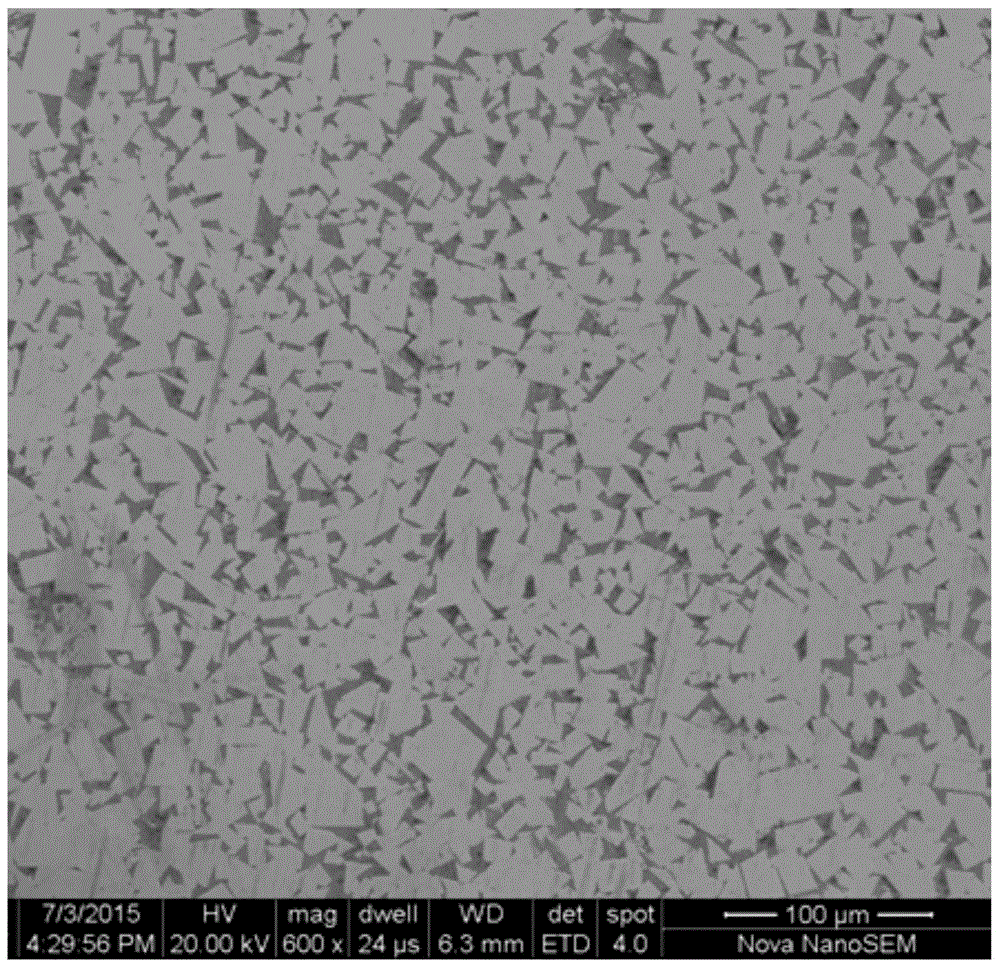

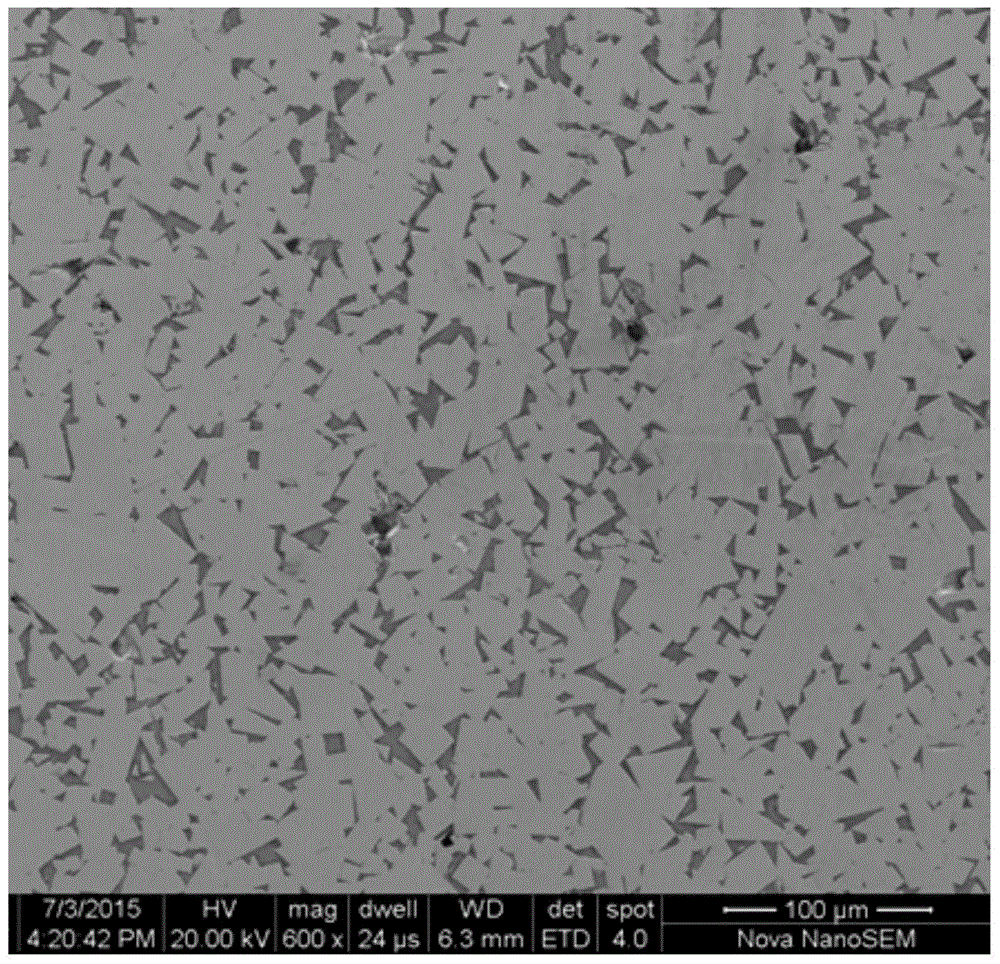

Method for preparing hard alloy through stability regulation and control

The invention provides a method for preparing hard alloy through stability regulation and control and belongs to the technical field of hard alloy material and powder metallurgy. The method includes the steps that firstly, round hard alloy bars are prepared, the two round hard alloy bars are taken and are vertical up and down, the ends of the two round hard alloy bars are adjacent, and the two round hard alloy bars are sequentially arranged in a vertical floating region of a zone melting furnace and vacuumized; the operating power is set to be 60%-95% of the total power, the power is increased to the set power within 20-30 minutes, after the contact ends of the round hard alloy bars form the beam-shaped stable molten state, the round hard alloy bar on the lower side descends, and the round hard alloy bar on the upper side descends synchronously till the round hard alloy bar on the upper side is taken out and serves as the hard alloy bar obtained after zone melting; and the hard alloy bar obtained after zone melting is arranged in a vacuum heat treatment furnace or a carbonizing oven, the carbonization atmosphere such as methane or carbon monoxide is injected, heat is preserved for 1-3 hours at the temperature ranging from 900 DEG C to 1,100 DEG C, the hard alloy bar is cooled to the room temperature along with the furnace, and then a super-coarse grain hard alloy bar is obtained. The super-coarse grain hard alloy with the excellent performance can be prepared.

Owner:BEIJING UNIV OF TECH

High-temperature-resisting and anti-freezing cable sheath material and preparation method thereof

InactiveCN107325418AEasy to prepareLow costPlastic/resin/waxes insulatorsInsulated cablesCross-linked polyethyleneCorrosion resistant

The invention discloses a high-temperature-resisting and anti-freezing cable sheath material and a preparation method thereof, and relates to the field of cable sheaths. The sheath material is prepared from the following raw materials: cross-linked polyethylene, nitrile butadiene rubber, epoxy resin, polyester fibers, sodium acetonate, nano calcium carbonate, modified bauxite, polyphenylene sulfone resin, 2-amino-5-(p-methoxyphenyl)-1, a lubricant, a flame retardant, an anti-freezing agent and an adhesive. The preparation method of the high-temperature-resisting and anti-freezing cable sheath material comprises the following steps: carrying out three times of mixing on the raw materials and then carrying out vulcanization treatment. The cable sheath material disclosed by the invention is simple and convenient to prepare and low in cost; a finished-product cable sheath has excellent physicochemical properties and has the characteristics of high temperature resistance, cold freezing resistance and corrosion resistance; the cable sheath material is long in service life, has a wide application field and is suitable for popularization and application.

Owner:HEFEI ZEJUN ELECTRICAL EQUIP CO LTD

Tile paint

The invention relates to the technical field of chemical materials, and specifically relates to a tile paint. The tile paint is composed of the following components in parts by weight: 200 to 300 parts of quartz sand, 20 to 100 parts of deionized water, 80 to 100 parts of styrene-acrylic emulsion, 0.2 to 1 part of hydroxyethyl cellulose HEC, 4 to 20 parts of titanium dioxide, 0.8 to 2 parts of thickening agent, 5 to 15 parts of glycol, 0.2 to 1 part of organic silicon defoaming agent, 6 to 15 parts of alcohol ester-12, and 0.8 to 1.5 parts of benzoic acid antiseptic. The invention aims to provide a tile paint with an ideal performance.

Owner:赵明贵

Method for smell removal, disinfection and stain resistance process on fabric

InactiveCN103061108AEfficient decompositionNo brittle deteriorationFibre treatmentResistance ProcessHydroxyapatites

The invention discloses a method for a smell removal, disinfection and stain resistance process on a fabric. The method comprises coating a smell-removal, disinfection and stain-resistant complex agent on the surface of a fabric, and carrying out drying, wherein the smell-removal, disinfection and stain resistant complex agent comprises a TiO2-hydroxyapatite photocatalytic composite nanomaterial. The method can effectively and economically perform photocatalyst effects.

Owner:湖州诺普医疗科技有限公司

Regenerating method of cleaning waste liquor of hydrocarbon cleaner

InactiveCN102978049AReduce pollutionLow priceDetergent mixture composition preparationTreatment with plural serial refining stagesLiquid wasteDistillation

The invention provides a regenerating method of cleaning waste liquor of a hydrocarbon cleaner, and in particular relates to a method for purifying a hydrocarbon cleaner from hydrocarbon cleaner cleaning waste liquor. The method is characterized by comprising the steps of: 1, adding the hydrocarbon cleaner cleaning waste liquor in a container, slowly adding industrial sulphuric acid of 98 percent, fully stirring for 20-30min, standing for 2-3h, and layering due to different densities; 2, extracting supernatant as a basic material, feeding to an organic distillation device, recycling the purified hydrocarbon cleaner by negative pressure distillation, and incinerating residues in the distillation kettle; and 3, separating waste acid containing grease, dust and water at the lower layer, and mixing into the wastewater for treating. The regenerating method is used for regenerating cleaning waste liquor, has a considerable economic benefit, is capable of reducing environment pollution, and accords with the environmental protection idea. The recycled and regenerated hydrocarbon cleaner is satisfied in test and plant using effects, and can completely replace a hydrocarbon cleaner product for use.

Owner:DALIAN DONGTAI INDAL WASTE TREATMENT

A method for preparing cemented carbide with stability control

The invention provides a method for preparing hard alloy through stability regulation and control and belongs to the technical field of hard alloy material and powder metallurgy. The method includes the steps that firstly, round hard alloy bars are prepared, the two round hard alloy bars are taken and are vertical up and down, the ends of the two round hard alloy bars are adjacent, and the two round hard alloy bars are sequentially arranged in a vertical floating region of a zone melting furnace and vacuumized; the operating power is set to be 60%-95% of the total power, the power is increased to the set power within 20-30 minutes, after the contact ends of the round hard alloy bars form the beam-shaped stable molten state, the round hard alloy bar on the lower side descends, and the round hard alloy bar on the upper side descends synchronously till the round hard alloy bar on the upper side is taken out and serves as the hard alloy bar obtained after zone melting; and the hard alloy bar obtained after zone melting is arranged in a vacuum heat treatment furnace or a carbonizing oven, the carbonization atmosphere such as methane or carbon monoxide is injected, heat is preserved for 1-3 hours at the temperature ranging from 900 DEG C to 1,100 DEG C, the hard alloy bar is cooled to the room temperature along with the furnace, and then a super-coarse grain hard alloy bar is obtained. The super-coarse grain hard alloy with the excellent performance can be prepared.

Owner:BEIJING UNIV OF TECH

Deodorant, antibacterial and anti-fouling complexing agent for fabric

InactiveCN103031707AEfficient decompositionNo brittle deteriorationFibre treatmentHydroxylapatiteDeodorant

The invention discloses a deodorant, antibacterial and anti-fouling complexing agent for fabric which comprises a TiO2-hydroxylapatite photocatalytic composite nanomaterial. With the adoption of the technical scheme, a photocatalyst effect can effectively exert a function economically and efficiently.

Owner:湖州诺普医疗科技有限公司

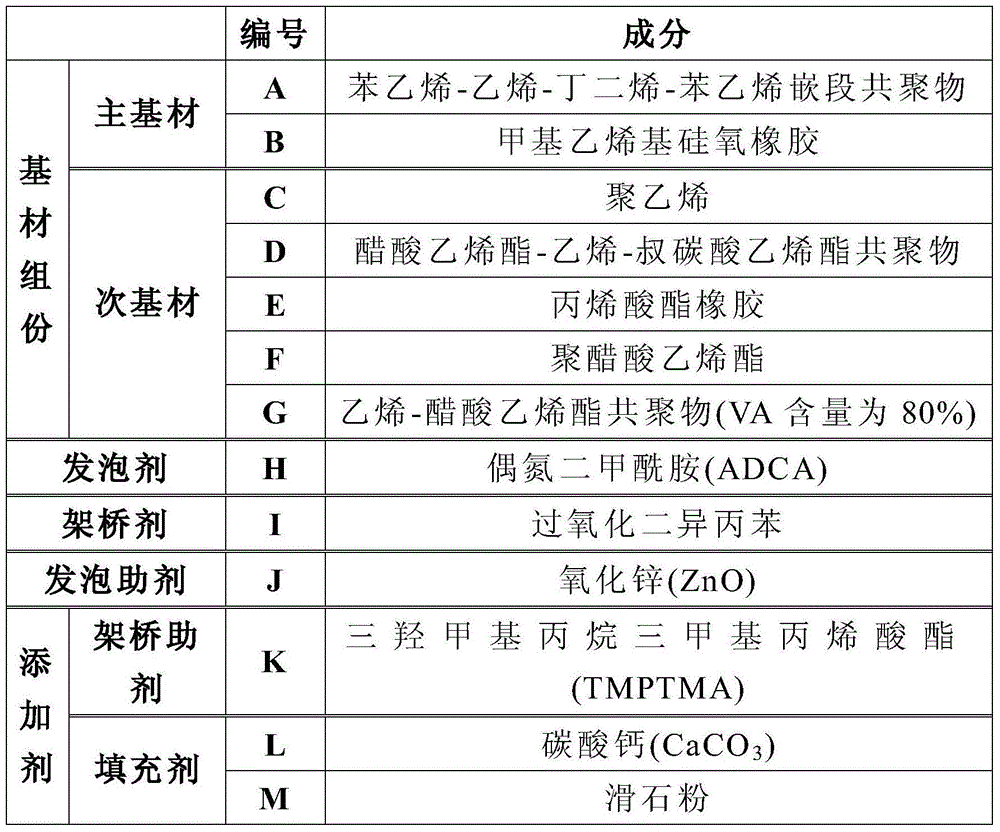

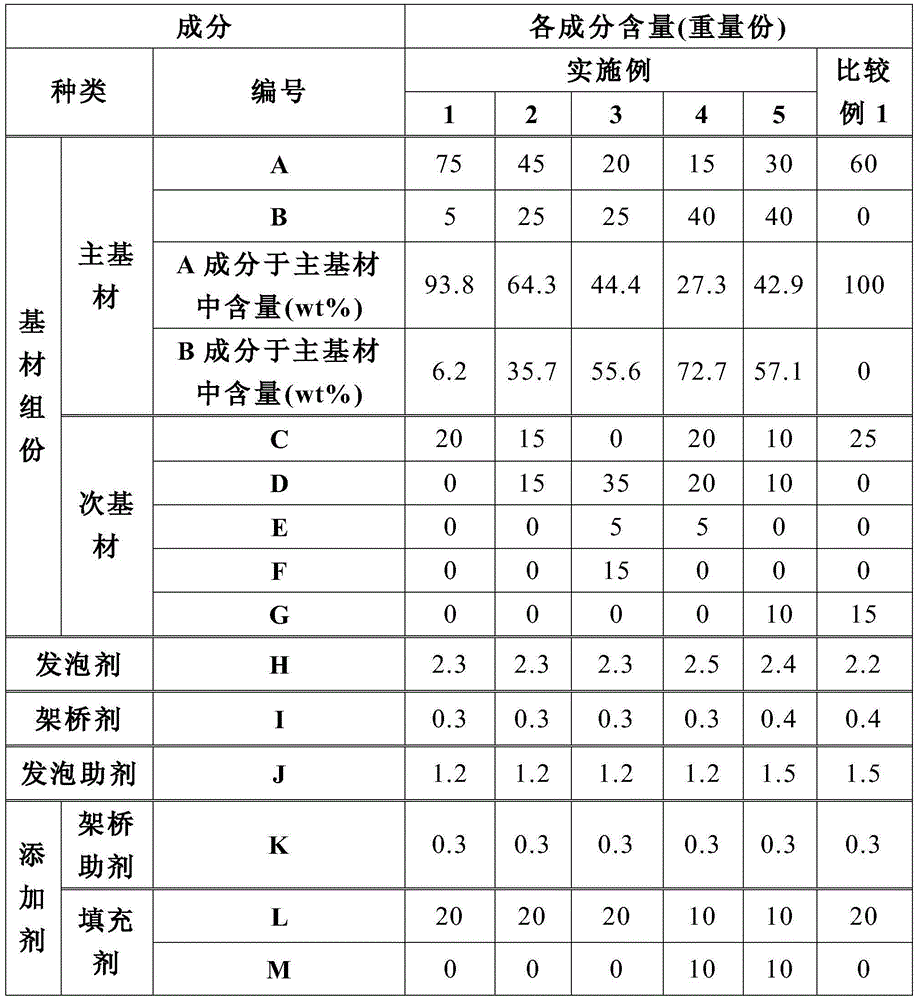

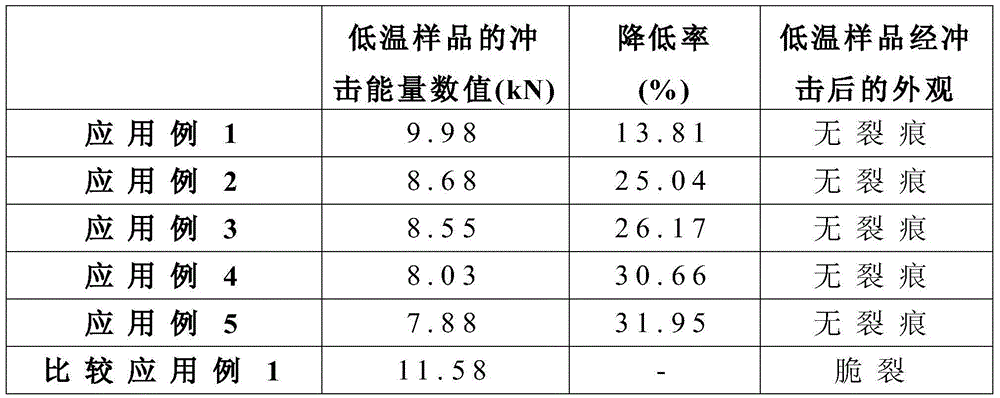

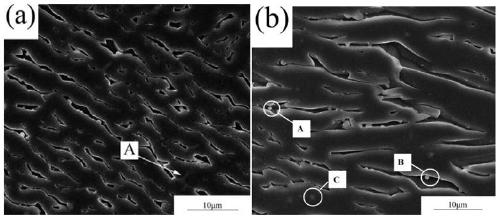

Composition for forming shock absorption foamed plastic

The invention provides a composition for forming shock absorption foamed plastic. The composition is prepared from a base material component, a foaming agent, a bridging agent and a foaming aid. The base material component comprises a main base material and an auxiliary base material. The main base material is prepared from a styrene-ethylene-butadiene-styrene segmented copolymer and silicone rubber. The auxiliary base material is prepared from a polymer. The polymer is an ethylene-vinyl acetate copolymer or polyethylene or a vinyl acetate-ethylene-vinyl versatate copolymer or polyacrylate rubber or polyvinyl acetate or a composition of the former substances. The shock absorption foamed plastic formed by the composition for forming the shock absorption foamed plastic in the following process is not subjected to brittle fracture when impacted in a low-temperature environment, and good shock absorption capacity is kept.

Owner:EVA GLORY INDAL

Flexible paint for plastics and preparation method of flexible paint

The invention discloses flexible paint for plastics and a preparation method of the flexible paint. The flexible paint for the plastics comprises the following raw materials in mass percent: 60-70% of solid thermoplastic acrylic resin, 15-20% of bisphenol F liquid epoxy resin, 3-5% of a leveling agent and the balance of ketone and ester solvents. The paint prepared by adopting the formula and method of the invention is applied to the coating of plastic fittings, the flexibility is greatly improved on the premise of guaranteeing that the paint has relatively good adhesive force after the coating and solidification, the plastic fittings do not have a brittle phenomenon, the use requirements are satisfied, the ketone and ester solvents are adopted, and the VOC (volatile organic compounds) emission can be effectively reduced and is extremely low, so that the flexible paint is completely in conformity with environmental protection standards.

Owner:东莞市瑞盟涂料有限公司

Bismuth brass alloy with good plasticity and corrosion resistance

ActiveCN110117736ABreaking the limit of bismuth contentEliminate or mitigate brittle effectsAlloyBismuth

The invention provides a bismuth brass alloy with good plasticity and corrosion resistance. The bismuth brass alloy is characterized by being prepared from, by mass, 58-75% of Cu, 0.02-2.5% of Bi, 0.02-1.8% of Mg, 0.05-1.5% of Zr, 0.02-0.3% of La, less than 0.5% of impurity elements and the balance Zn. The material is resistant to corrosion, bismuth brass scrap with the higher content can be adopted, and the alloy is good in machining performance and quite low in cost.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

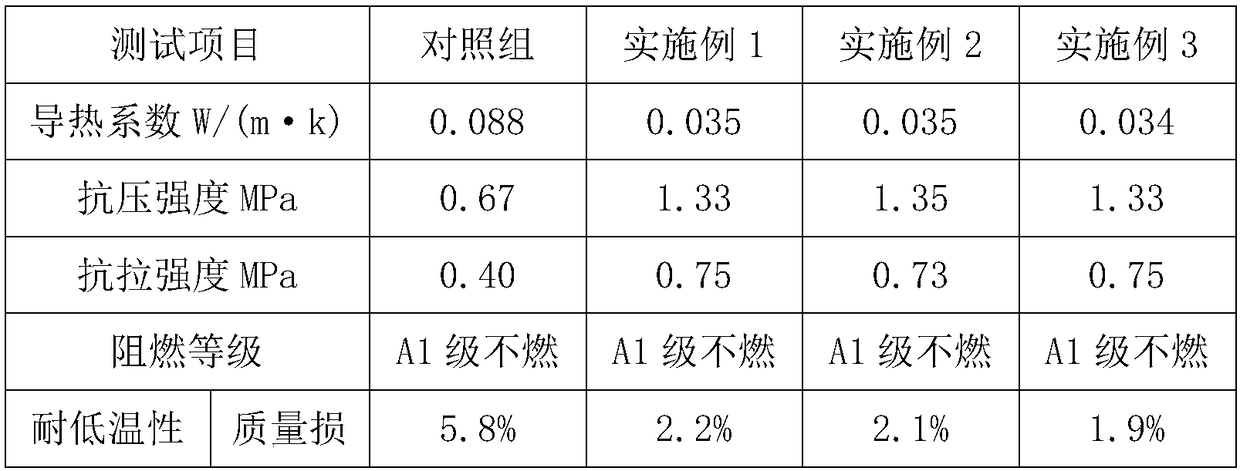

Anti-freezing anti-cracking cement foaming heat preservation board

The invention relates to the technical field of heat preservation construction materials, in particular to an anti-freezing anti-cracking cement foaming heat preservation board. The heat preservationboard is prepared from cement, coal dust, water glass, a cold-resistant flexibilizer, aluminum oxide fibers, a foaming agent, a foam stabilizer, a water reducer, an anti-freezing agent and water, wherein the cold-resistant flexibilizer is a novel material compound by various elastic materials, high-hardness fillers and the like. Cement is a mixture made by blending Portland cement with magnesium oxychloride cement according to a mass ratio of 8:1; the water reducer is a lignin water reducer or a poly-carboxyl water reducer or a melamine water reducer; the foaming agent is hydrogen peroxide; the foam stabilizer is calcium stearate; the anti-freezing agent contains propylene glycol butyl ether, glycol butyl ether acetate and diethylene glycol. The thermal conductivity of the heat preservation board is low, and the heat preservation performance is great. The cold-resistant anti-freezing performance of the materials is great, the tenacity is high, and the heat preservation board is not easily fractured at low temperature.

Owner:HEFEI LONGYANG AGRI TECH CO LTD

Preparation method of automobile fastener wire

InactiveCN111375649AImprove plastic deformation abilityImprove heat treatment effectMetallic material coating processesWire rodCar manufacturing

The invention belongs to the technical field of automobile manufacturing, and particularly relates to a preparation method of an automobile fastener wire. The preparation method provided by the invention comprises the steps of providing a low-carbon alloy steel wire, wherein the carbon content of the low-carbon alloy steel wire is 0.19 wt% to 0.21 wt%, and the boron content of the low-carbon alloysteel wire is 0.0005 wt% to 0.0030 wt%; sequentially carrying out acid pickling and phosphorization on the low-carbon alloy steel wire, and then carrying out first drawing treatment to obtain a firstdrawing product; carrying out spheroidizing annealing treatment on the first drawing product, and obtaining a spheroidizing annealing product, wherein the spheroidizing annealing treatment comprisesthe steps of heating the first drawing product to 710-730 DEG C in a protective atmosphere, and keeping the temperature for 5-8 hours; cooling to 540-560 DEG C at a speed of 20 DEG C / h, continuously cooling to 390-410 DEG C at a speed of 80 DEG C / h, and naturally cooling to normal temperature, wherein the protective atmosphere is methanol pyrolysis gas when the temperature is 550 DEG C or above, and the protective atmosphere is nitrogen when the temperature in the furnace is lower than 550 DEG C; and sequentially carrying out acid pickling and phosphorization on the spheroidizing annealing product, and carrying out second drawing treatment, wherein sodium nitrite is adopted as an accelerant for phosphorization.

Owner:DONGGUAN KELEE STEEL WIRE

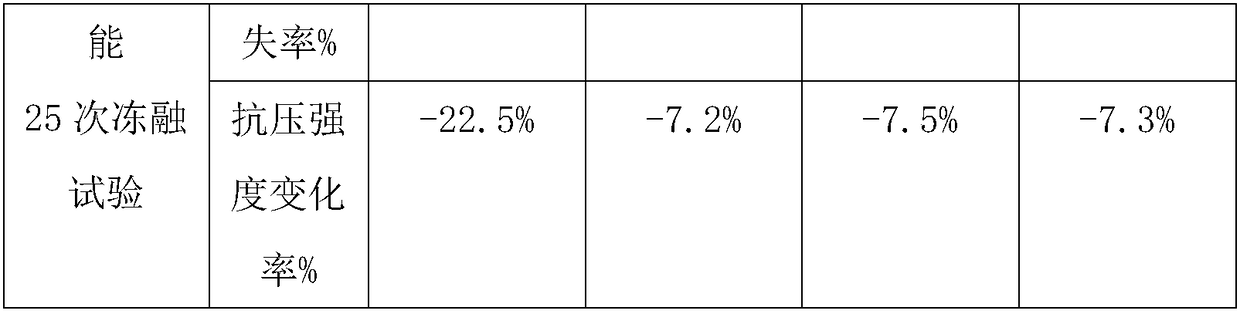

Waterproof and anti-freezing suspension type rubber sleeve cable used for water pump

InactiveCN107195366AWith water blocking effectStop deepFlexible cablesFlexible conductorsEngineeringThermal expansion

The invention discloses a waterproof and anti-freezing suspension type rubber sleeve cable used for a water pump. The cable comprises a cable core; the cable core consists of a heat tracing band and three insulating wire cores which surround the periphery of the heat tracing band; the hollow position of the cable core is filled with thermal expansion ointment; a lead plastic or aluminum plastic composite longitudinally-wrapping layer is arranged outside the cable core; a semi-conductive water-blocking expansion band is arranged outside the lead plastic or aluminum plastic composite longitudinally-wrapping layer; a chloroprene rubber outer sheath is arranged outside the semi-conductive water-blocking expansion band; and the exterior of the chloroprene rubber outer sheath is coated with anti-freezing coating. The waterproof and anti-freezing suspension type rubber sleeve cable has the characteristics of ice and snow attachment prevention, anti-freezing property under water, and corrosion resistance, wearing resistance, aging resistance, surface self-cleaning, high physical and mechanical properties, oil resistance, heat resistance, flame resistance, sunlight resistance, ozone resistance, acid and alkali resistance, chemical reagent resistance and the like.

Owner:JIANGSU HUAYA CABLE

Moisture-proof coating citicoline sodium capsule and preparation method thereof

ActiveCN102525997BGood granularityGood disintegrationOrganic active ingredientsNervous disorderCiticoline sodiumMoisture absorption

The invention provides a moisture-proof coating citicoline sodium capsule and a preparation method thereof. The citicoline sodium capsule is composed of a capsule casing and quick-release moisture-proof micro pills or granules. All components in each capsule containing citicoline sodium quick-release moisture-proof micro pills or granules by percentage are 40% to 70% of citicoline sodium, 10% to 30% of microcrystalline cellulose, 10% to 30% of pregelatinized starch and 2% to 10% of moisture-proof coatings. The moisture-proof micro pills or granules are obtained by being extruded and rounded or pressed and granulated to be coated with moisture-proof coatings. The citicoline sodium capsule is good in moisture-proof function and resolves the problems that the capsule is prone to absorb waterdue to the fact that citicoline sodium is strong in moisture absorption, the capsule casing is prone to be fragile, and the like.

Owner:QILU PHARMA CO LTD

Manufacturing method of electric heating push rod of electronic thermostat of engine

ActiveCN102528394BSimplify internal organizationReduce manufacturing difficultyThermostatEngineering

The invention discloses a manufacturing method of an electric heating push rod of an electronic thermostat of an engine, which comprises the following steps that: blanking: a hollow steel tube with the length being more than that of the push rod to be processed is cut off by a blanking machine; bottom welding: the bottom of the hollow steel tube is sealed; threading: a magnesium oxide rod or a magnesium oxide tube with the length being less than that of the push rod to be processed is selected, an electric heating wire is uniformly wound outside the magnesium oxide rod or inserted into the magnesium oxide tube; tube penetration: the magnesium oxide rod or the magnesium oxide tube is inserted into the hollow steel tube; filling: heat transfer powder is filled inside the hollow steel tube; tube reduction: the hollow steel tube is reduced through a tube reducing machine; polishing: the surface of the reduced steel tube is polished through a grinding machine; cutting: the steel tube with the surface being polished is cut off by the blanking machine according to the length of the push rod to be processed; and according to the electric heating push rod which is manufactured through the method, a sheet-type heating element of the electronic thermostat is arranged in the push rod, so that the heating element is prevented from deforming and being broken, and the service life of the heating element is ensured.

Owner:温州海得利电气有限公司

Technological method for welding low-temperature ductile iron and manganese steel plate

ActiveCN106270966AEasy to integrateGood weld shapeArc welding apparatusWelding/soldering/cutting articlesSheet steelManganese

The invention belongs to the technical field of welding, and particularly relates to a technological method for welding low-temperature ductile iron and a manganese steel plate. A NiFe-1 welding rod is selected, an MAG shielded welding technology is adopted, a low-temperature ductile iron material and the manganese steel plate are welded together in an intermittent welding manner, and the low-temperature ductile iron material, the manganese steel plate and the welding rod are not preheated before welding and are not subjected to heat treatment after welding. According to the welding technology, weld joint root fusion is good, weld joint appearance molding is good, and the surface is free of cracks and pores; the low-temperature ductile iron material is free of the phenomena of embrittlement and cracking; the quality of the manganese steel plate is not reduced; and energy consumption is reduced.

Owner:CHANGZHOU HUADE MACHINERY

Flame-retardant polypropylene film sealing bag used for graphene electrical heating film

The invention relates to a flame-retardant polypropylene film sealing bag used for a graphene electrical heating film. The flame-retardant polypropylene film sealing bag comprises the graphene electrical heating film and upper and lower flame-retardant polypropylene films, wherein the upper and lower flame-retardant polypropylene films sleeve the graphene electrical heating film. The short edge onone side of the graphene electrical heating film is connected with an insertion cable and used for being connected with a power supply. When the graphene electrical heating film is encapsulated withthe flame-retardant polypropylene films, the problems in the prior art are solved that a material for encapsulating the electrical heating film is poor in heat stability, high in smoke density duringcombustion, poor in shock resistance and environmentally unfriendly.

Owner:福建久信科技有限公司

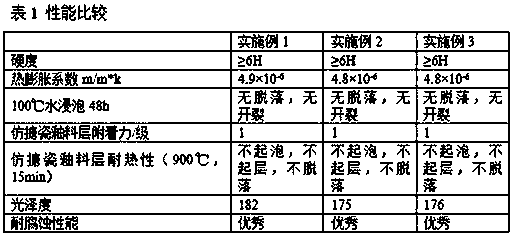

Enamel imitating ceramic product and preparation method thereof

The invention discloses an enamel imitating ceramic product and a preparation method thereof. The preparation method comprises the following steps: (1) preparing a ceramic matrix; (2) preparing enamelimitating glaze; (3) uniformly applying a layer of enamel imitating glaze to the surface of the ceramic matrix, putting in an oven, and baking for 5-10 minutes at 50-60 DEG C to obtain an enamel imitating ceramic product. The preparation method disclosed by the invention has the advantages of simple production technology, non-toxic and pollution-free process, low cost of raw materials, fine microstructure grains, uniform distribution of pores and high wear resistance and pressure resistance of product; by coating the surface of the ceramic matrix with a layer of enamel imitating glaze, the obtained ceramic product has the appearance and performance of enamel and the advantages of good heat resistance, high corrosion resistance and the like and thus is durable.

Owner:FUJIAN DEHUA XIEFA GUANGYANG POTTERY

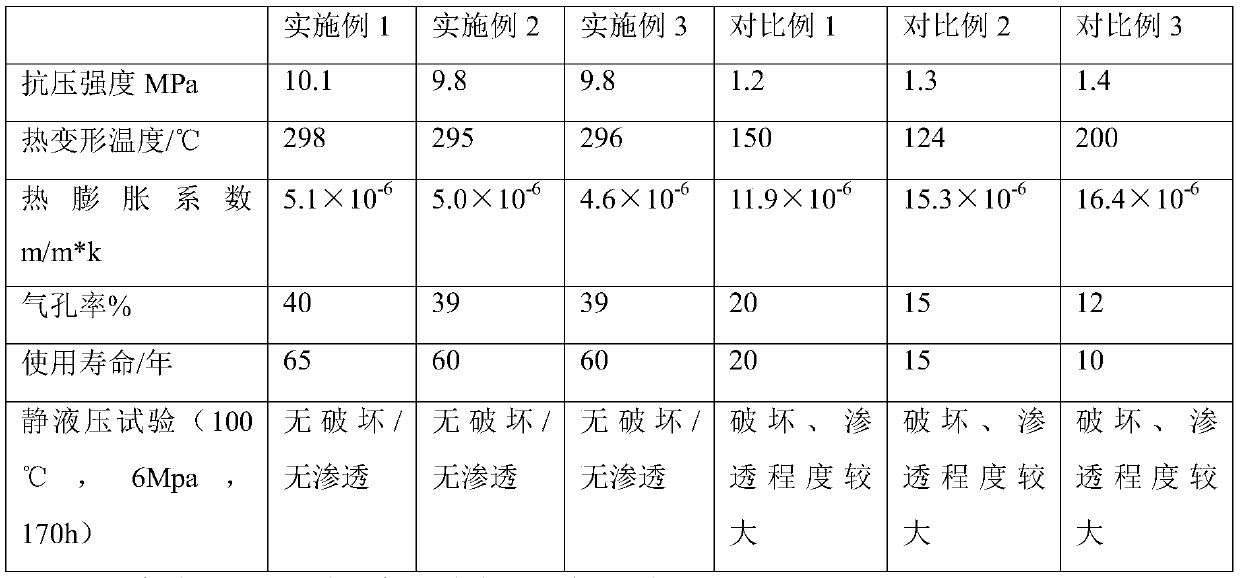

High-temperature-resistant and high-pressure-resistant PP-R composite pipe material and preparation method thereof

The invention discloses a high-temperature-resistant and high-pressure-resistant PP-R composite pipe material and a preparation method thereof. The pipe material comprises, by mass, 60-80 parts of polyethylene resin, 25-35 parts of epoxy resin, 5-10 parts of talc, 10-15 parts of methyl isobutyl ketone, 15-20 parts tea stalk powder, 10-15 parts of seaweed cellulose, 5-7 parts of decabromodiphenylethane, 5-10 parts of aluminum hydroxide, 3-6 parts of a crosslinking agent and 2-6 parts of a stabilizer. The production process is simple and free of toxins and pollutants, the grain size of the microstructure is fine, pores are evenly distributed, the compressive strength of the product is high, and the composite pipe has the advantages of good temperature resistance, high pressure resistance, strong corrosion resistance and the like, and is durable.

Owner:福建富华管业有限公司

High-polymer heat-resistant polyvinyl chloride based on multicomponent rare-earth heat stabilizer

The invention provides a high polymer heat-resistant polyvinyl chloride based on a multi-element rare earth heat stabilizer, the polyvinyl chloride includes high molecular weight polyethylene, trioctyl trimellitate, liquid barium zinc, a multi-element rare earth heat stabilizer and low Molecular polyethylene wax, wherein the preparation method of the multi-element rare earth heat stabilizer is: under an inert environment, add palladium chloride and triphenylphosphine into n-hexane, stir evenly, add 4-bromopropiophenone, and then drop three Phenyl lanthanum solution, continue to react after the dropwise addition, separate and purify to obtain the multi-element rare earth lanthanum palladium metal compound; add the multi-element rare earth lanthanum palladium metal compound into nitric acid and stir, and mix rapidly with the ethanol mixed solution of malic acid and salicylic acid, then drop Add sodium hydroxide aqueous solution, heat to react, vacuum filter, wash and dry to obtain multi-element rare earth heat stabilizer. The polyvinyl chloride prepared by the invention has a high degree of polymerization, good synergistic effect among various components, and can remarkably improve the heat resistance, mechanical properties, corrosion resistance and other properties of the polyvinyl chloride material.

Owner:SUZHOU WILDER IND & TRADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com