Patents

Literature

80results about How to "Promote interpenetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electric resistance welding method

ActiveCN101318256APromote interpenetrationTightly boundWelding/soldering/cutting articlesResistance welding apparatusElectrical resistance and conductanceWelding power supply

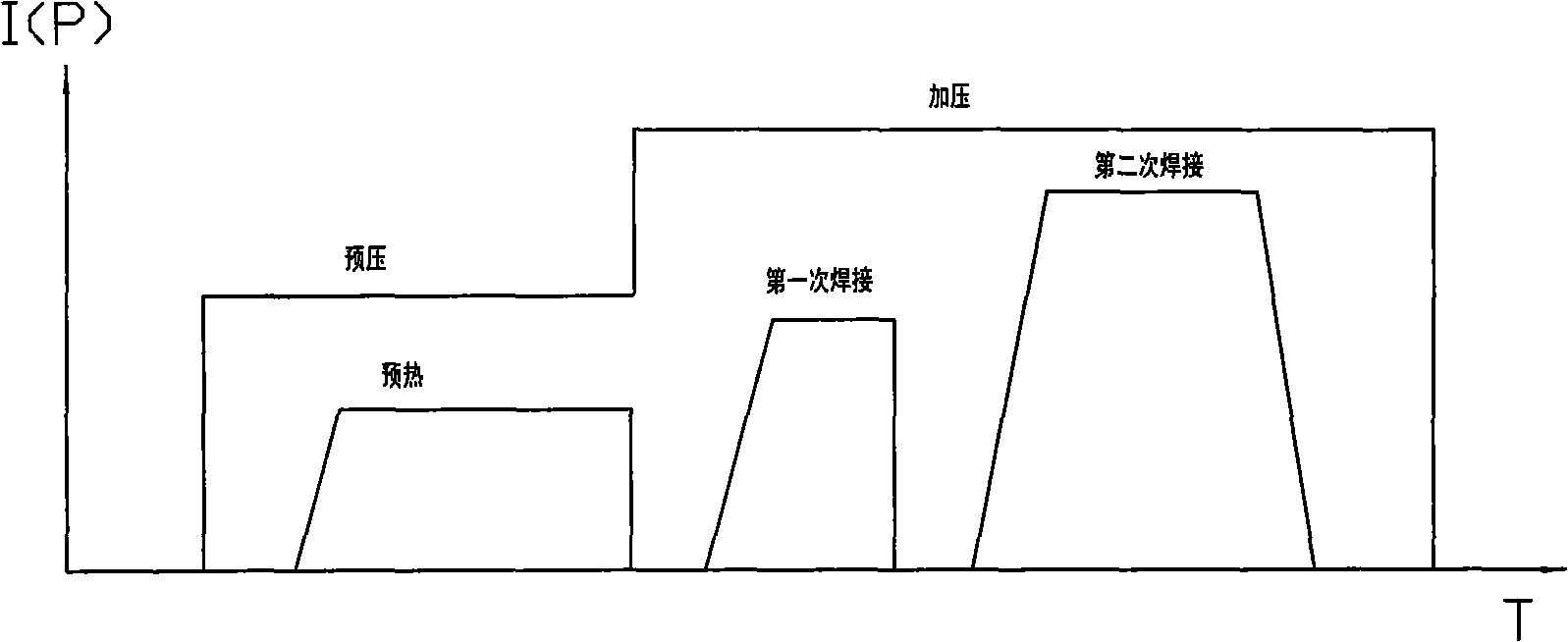

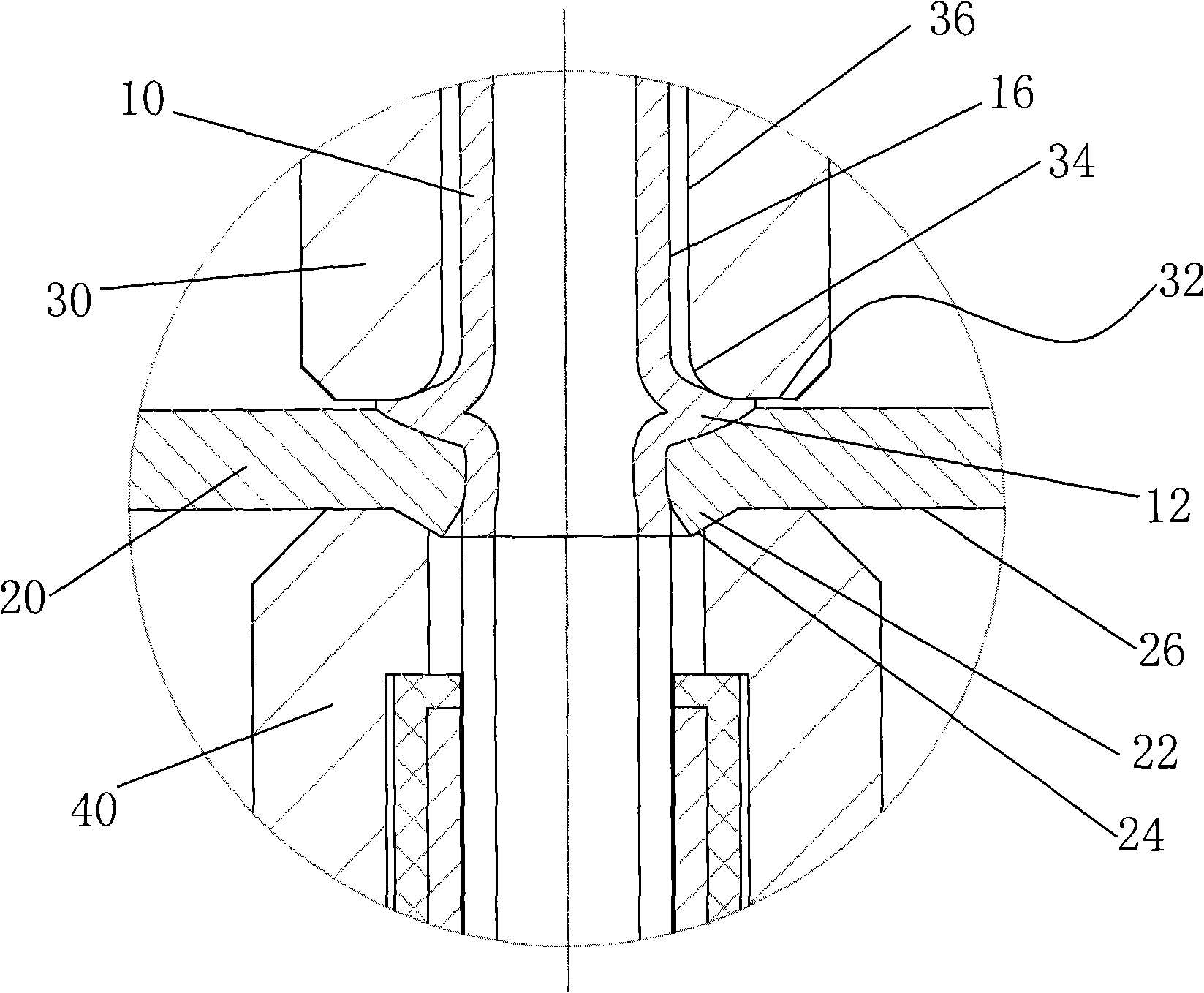

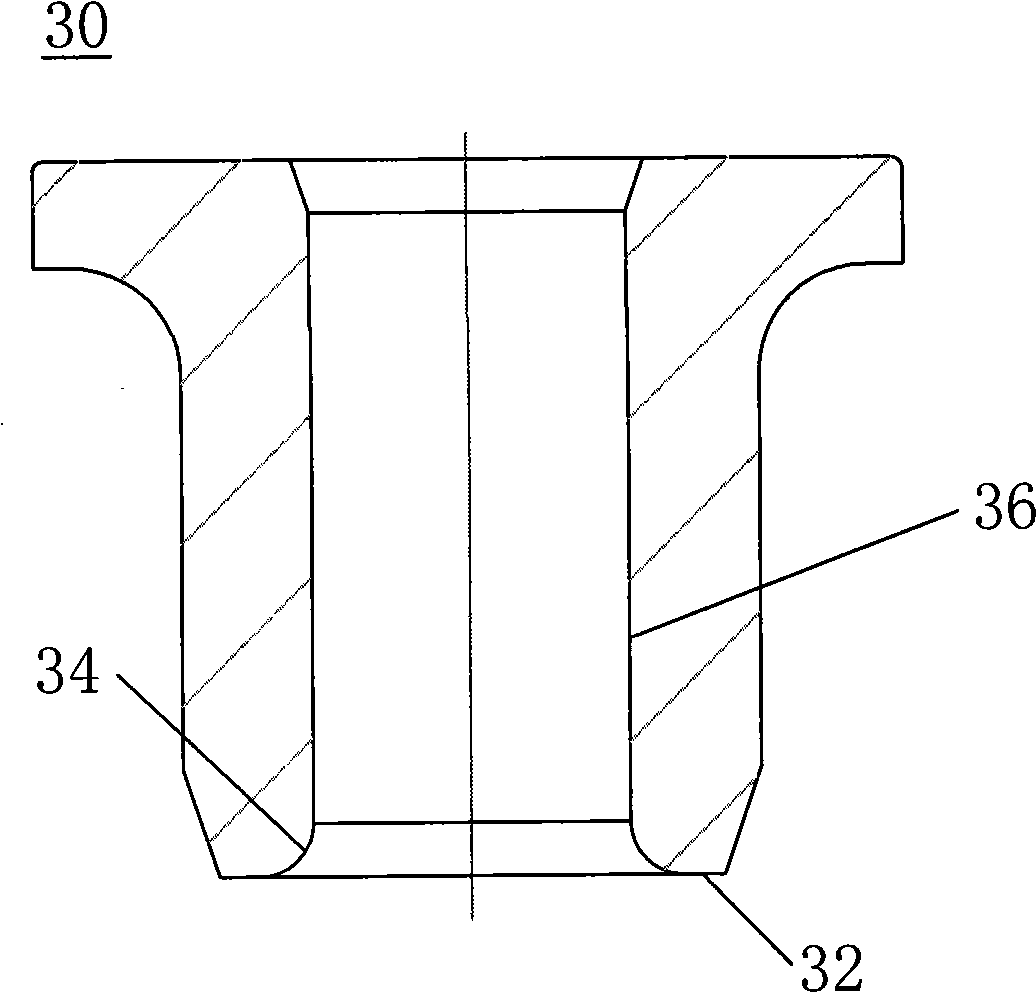

The invention discloses a resistance welding method for welding the copper or copper alloy and the steel or steel alloy, which adopts general principles of the resistance welding to carry out the spot welding or the loop projection welding of the copper or the copper alloy and the steel or the steel alloy to obtain complete liquid phase nuggets by using the technique of applying pulse currents and pressures by sections on special electrode tips of the resistance welding and a special welding power, and the real welding can be realized, wherein, the welding power provides direct current for welding and the discharging time is 110ms to 280ms, the maximum current is 36KA to 280KA, the current frequency before the rectification is 1000Hz, 1200Hz or 1500Hz, the welding current between work pieces and the electrode tips is the direct current, and the pressure is 1 to 5.9Kgf / cm<2>.

Owner:HERON INTELLIGENT EQUIP CO LTD

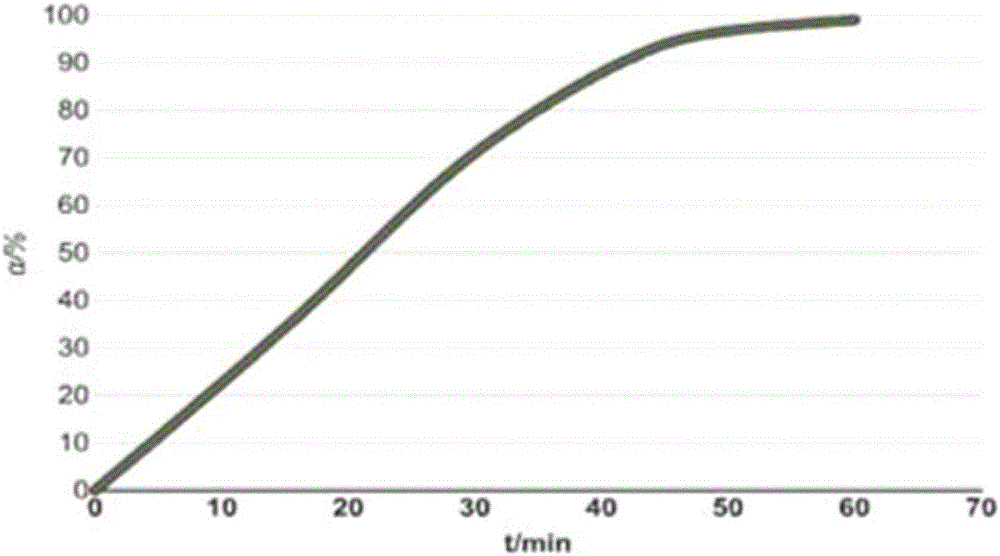

Preparation method of benzoin product

InactiveCN103288609AHigh yieldQuality improvementOrganic compound preparationCarbonyl compound preparationPtru catalystPotassium cyanide

The invention relates to the technical field of organic synthesis and particularly relates to a preparation method of a benzoin product. The preparation method is characterized by taking benzaldehyde as a reaction raw material, sodium cyanide or potassium cyanide as a catalyst and water as a reaction solvent. The preparation method comprises the steps of adding an efficient cationic surfactant, a phase transfer catalyst, a dispersant and inorganic salt into a reaction mixing system, heating up to 60-70 DEG C, carrying out thermal reaction for 1.5h-3.0h, cooling to room temperature after the thermal reaction to obtain a solid-liquid mixture of reaction products, filtering the mixture to separate out a solid product, washing the solid product by an ethanol solution to remove surface impurities, and drying to obtain the white granular benzoin crystal product with the melting point being above 133 DEG C, and the purity being above 99.0%. The product yield is high.

Owner:宁波市奉化南科新材料有限公司

Microwave catalytic activation rubber powder composition and preparation method therefor

InactiveCN105418964ASo as not to damageHigh affinityPlastic recyclingBuilding insulationsMicrowavePolymer science

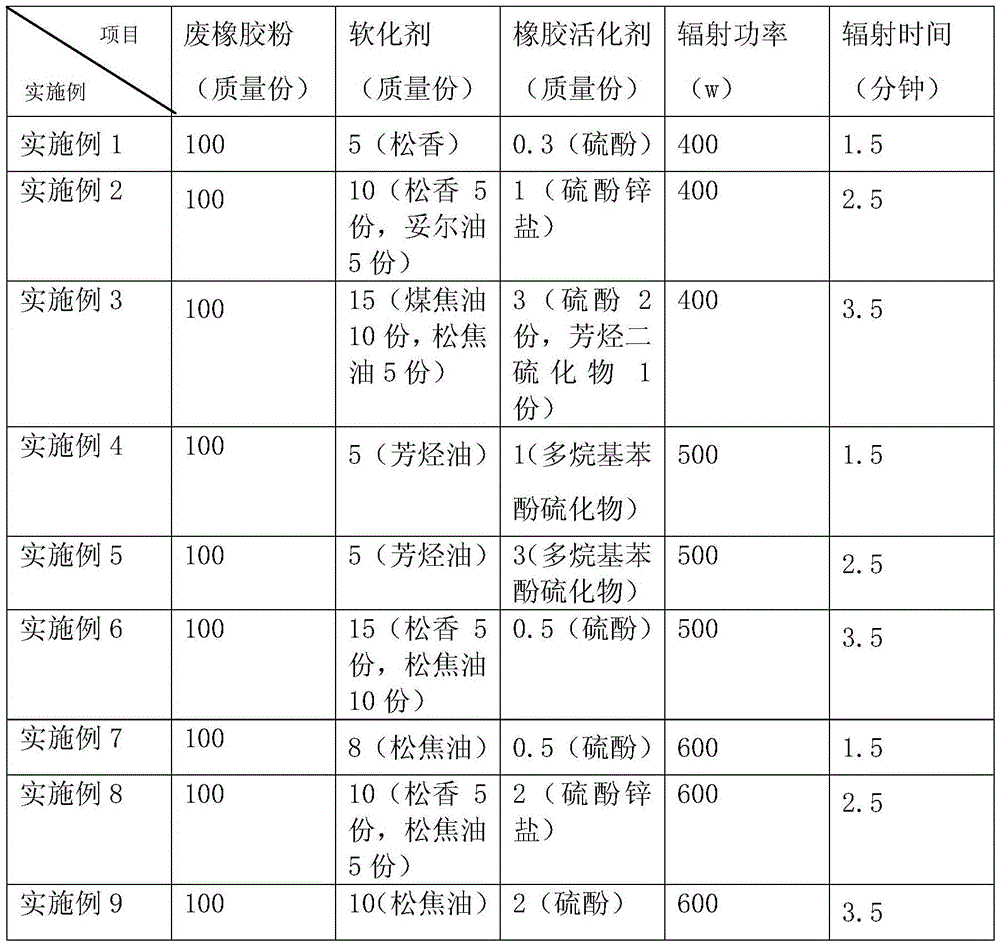

The invention relates to a microwave catalytic activation rubber powder composition and a preparation method therefor and belongs to the chemical technology field. The microwave catalytic activation rubber powder composition comprises 100 parts of waste rubber powder, 5-15 parts of softener and 0.3-2 parts of activator. By utilization of radiation effects of microwaves, S-S, C-S crossing bonds of waste tyre rubber powder are damaged fully selectively, thus the stereoscopic crossing net is fractured, the waste tyre rubber powder has a fluffy surface after microwave catalytic activation treatment, mutual permeability and the reaction activity of phase interfaces are raised, and therefore rubber powder composition and asphalt have compatibility.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

Light extinction type waterborne polyurethane emulsion and preparation method thereof

The invention discloses light extinction type waterborne polyurethane emulsion and a preparation method thereof. According to the light extinction type waterborne polyurethane emulsion, a novel raw material composition is adopted and has a cooperative effect to solve the problems of existing light extinction type waterborne polyurethane emulsion that the glossiness is relatively high, the rigidityis low, the water resistance is poor, the wearing resistance is poor and the like; meanwhile, the prepared polyurethane emulsion has no acetone residues and the performance of the emulsion is not influenced; a procedure is simple and convenient and industrial production is facilitated; in a reaction process, the polymerization or crosslinking degree of raw materials is relatively high, so that the quantity of double electric layers and the fluid volume of particles are ensured, the compatibility of the raw materials is improved, a relatively fine blending structure is formed and the wearing resistance is improved; meanwhile, latex particles with a relatively great grain diameter are generated by a produced polyurethane material; the surface of a membrane has relatively great roughness andhas good light extinction efficiency.

Owner:JIANGMEN CAIGE ENVIRONMENTAL PROTECTION TECH IND

Method for rapidly preparing cellulose DMAc (Dimethylacetylamide) /LiCl solution

The invention provides a method for rapidly preparing a cellulose DMAc (Dimethylacetylamide) / LiCl solution, which comprises the following steps of: performing decompressing evaporation for mixed cellulose and dimethylacetylamide DMAc during stirring under the conditions of vacuumizing at a temperature of not lower than 100 DEG C and extracting the distillate, then adding LiCl and introducing dimethylacetylamide of equal quantity with the distillate, continuously vacuumizing and stirring at a temperature of 100-155 DEG C till LiCl is completely dissolved, and extracting the distillate, stirring strongly and then deforming to prepare the transparent cellulose solution. The mass fraction of cellulose is 0.8-15% and the mass fraction of the LiCl is 1-12%. The preparation method of the technical scheme can be used for preparing the cellulose solution rapidly and effectively; and the prepared cellulose solution with homogeneous phase has smaller degree of degradation and is more suitable for industrial production.

Owner:EASTERN LIAONING UNIV +1

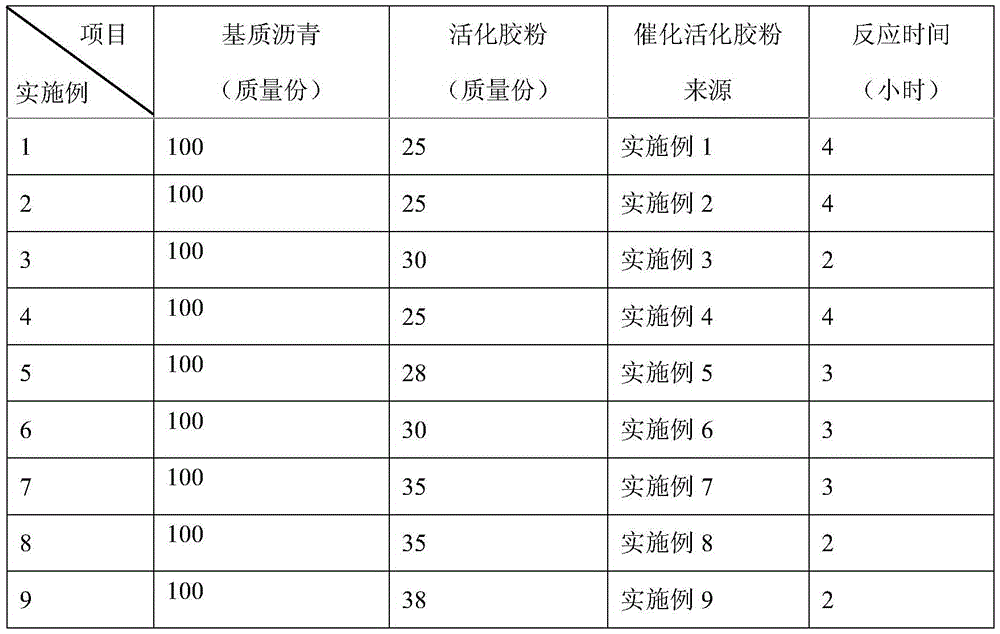

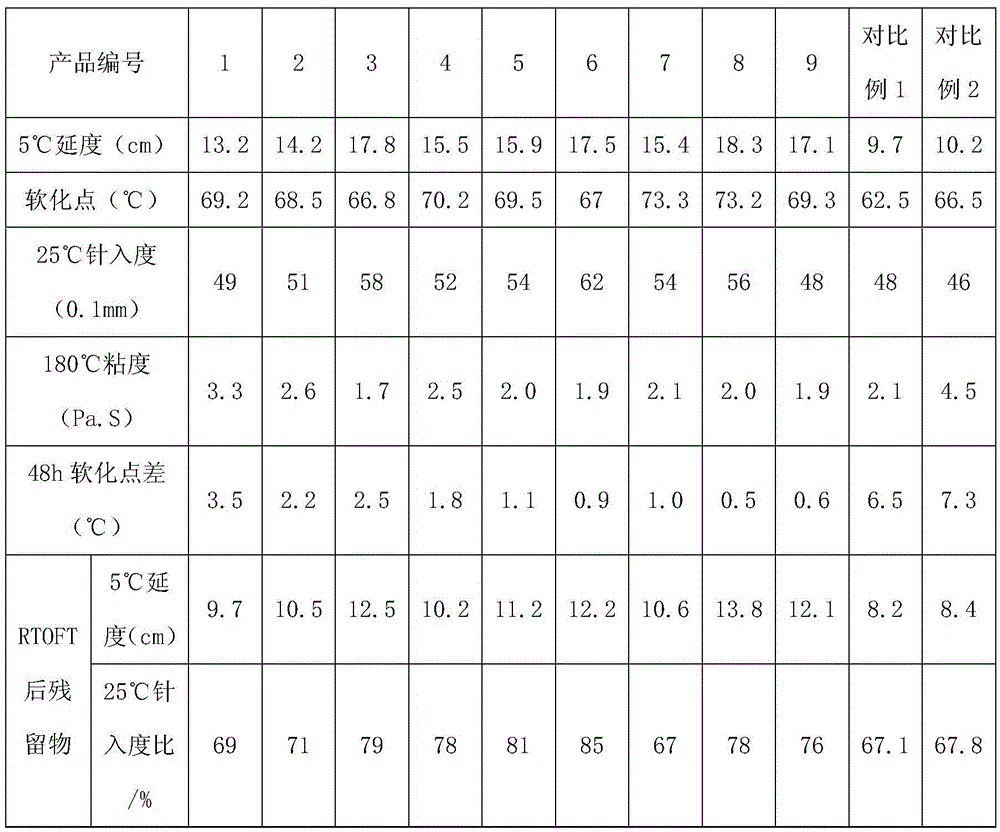

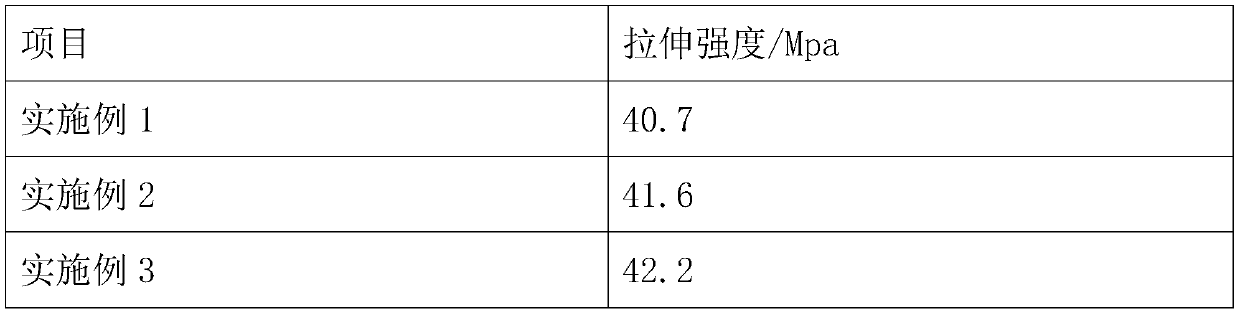

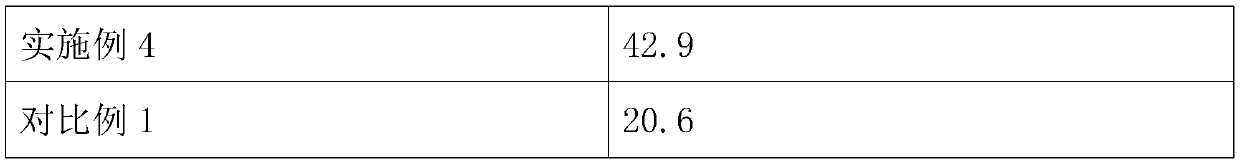

Low-viscosity crumb rubber modified asphalt and preparation method thereof

ActiveCN105482474ASo as not to damageHigh affinityPlastic recyclingBuilding insulationsPolymer scienceButt joint

The invention relates to low-viscosity crumb rubber modified asphalt and a preparation method thereof, and belongs to the technical field of chemistry. The low-viscosity crumb rubber modified asphalt is prepared from the following components in parts by weight: 100 parts of matrix asphalt, 25-35 parts of modified crumb rubber and 0.25-0.5 part of a crosslinking agent, wherein the modified crumb rubber comprises 100 parts of waste car crumb rubber, 5-15 parts of softener and 0.3-2 parts of an activating agent. According to the preparation method, the viscosity of crumb rubber modified asphalt can be reduced, the difficulty for producing, delivering, agitating and paving the crumb rubber modified asphalt can be reduced, and the pavement paved by the crumb rubber modified asphalt is easy to compact. Continuous butt joint production is selected in the whole process, namely continuous butt joint is adopted for 'crumb rubber A-crumb rubber B-modified asphalt', little heat is lost, and energy consumption of the whole process is reduced.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

Composite adhesive for single-sided film reinforced little glue mica tape and preparation method thereof

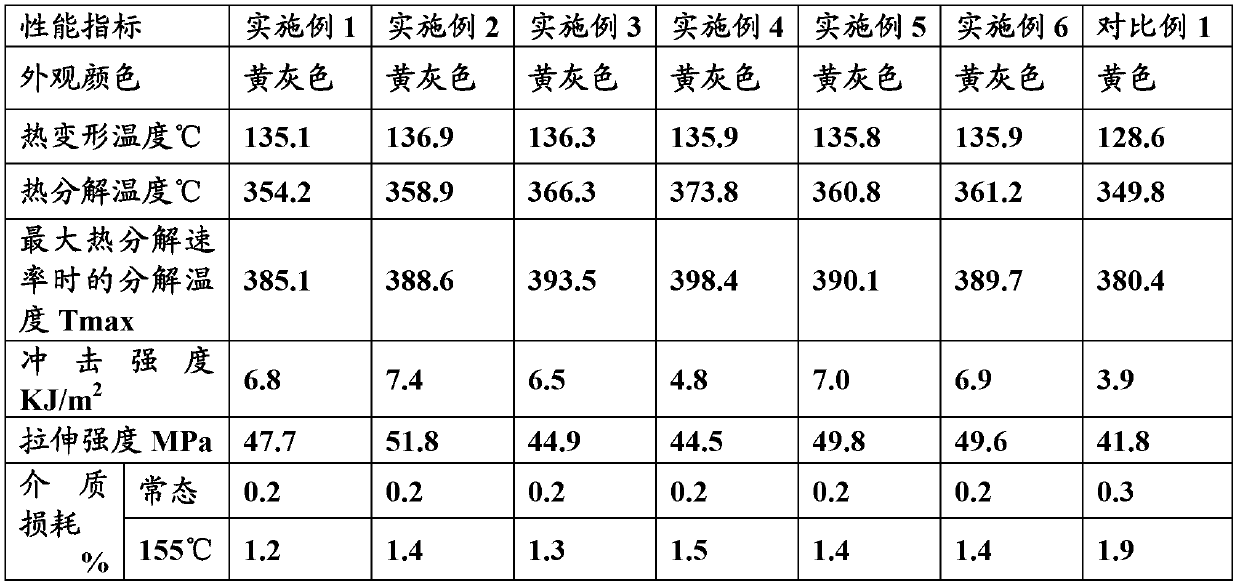

ActiveCN103131373AGood adhesionPromote interpenetrationNon-macromolecular adhesive additivesLayered productsAdhesiveMass ratio

The invention relates to a composite adhesive for a single-sided film reinforced little glue mica tape and a preparation method thereof. The composite adhesive comprises the following raw materials: 1-20 parts of organic nano montmorillonite, 100-500 parts of bisphenol A type epoxy resin, 100-400 parts of acetone and 50-200 parts of toluene, wherein the organic nano montmorillonite is obtained by performing an aqueous solution ion exchange organic reaction on nano montmorillonite and alkyl methyl ammonium salt for 2 to 12 hours; and the mass ratio of the feeding amount of nano montmorillonite to the feeding amount of alkyl methyl ammonium salt is 1:0.2-1. The composite adhesive is high in compatibility with mica paper, and the adhesion force between the mica paper and the substrate film can be improved. In addition, the composite adhesive is simple in preparation process, low in cost and high in mechanical strength, the condensate formed by matching with epoxy-acid anhydride type VPI paint has high thermal deformation temperature, high impact strength, high tensile strength and low dielectric loss and can be expected to be widely applied to the fields of insulated mica products and the like.

Owner:SUZHOU TAIHU ELECTRIC ADVANCED MATERIAL CO LTD

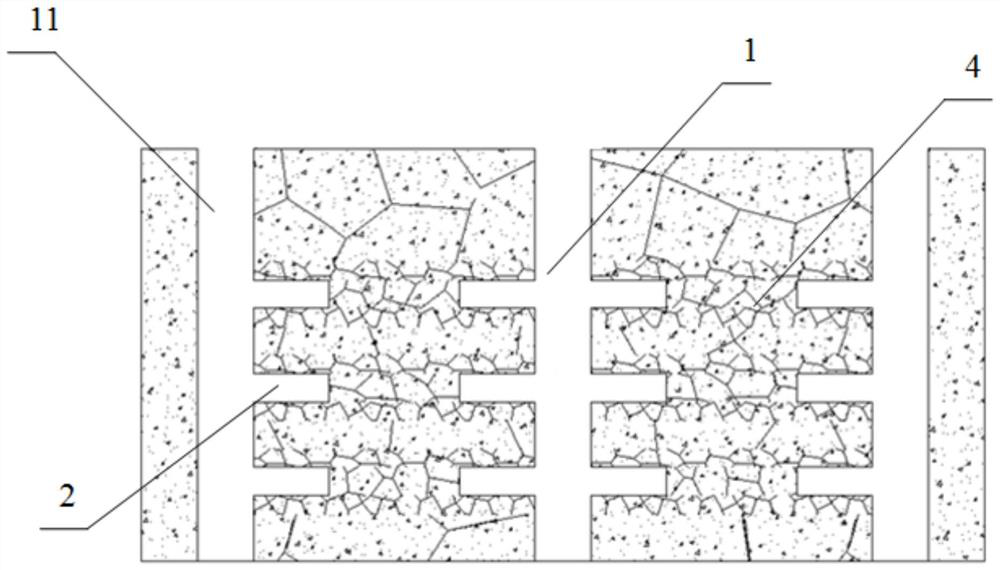

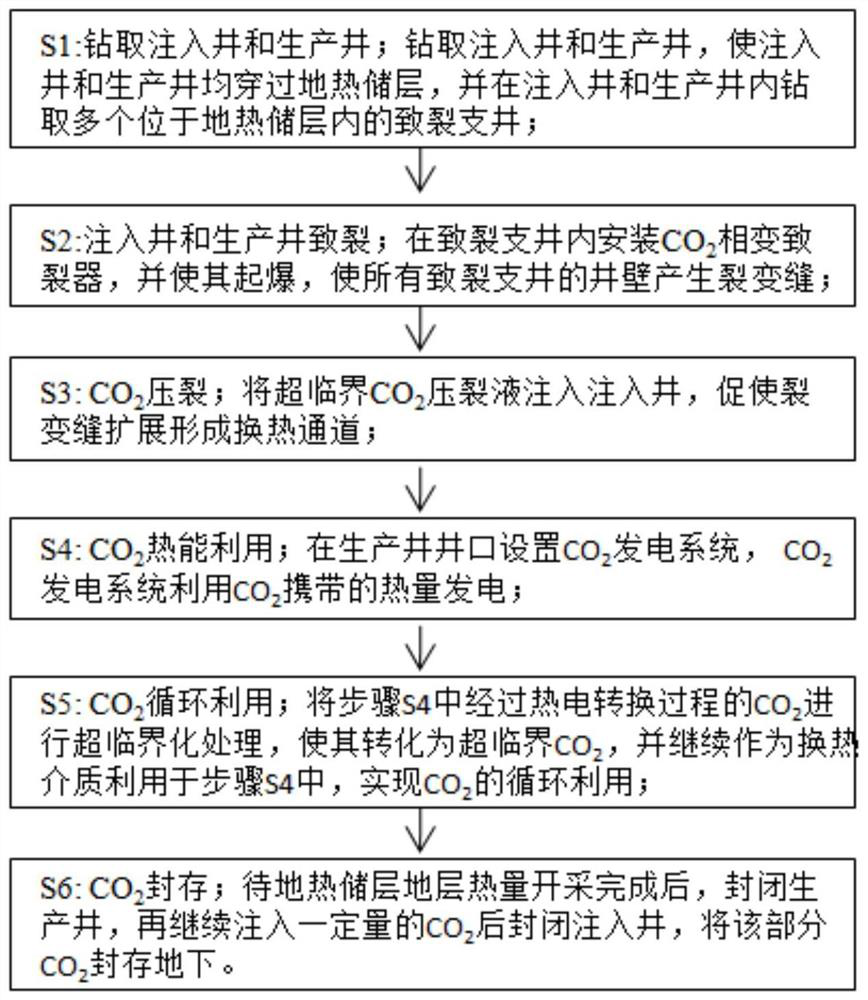

Deep geothermal exploitation method based on carbon dioxide medium

ActiveCN114033346AHigh cracking efficiencyUniform seamGeothermal energy generationFluid removalThermodynamicsFracturing fluid

The invention provides a deep geothermal exploitation method based on a carbon dioxide medium. The deep geothermal exploitation method comprises the following steps that S1, an injection well and a production well are drilled; S2, the injection well and the production well are fractured; S3, CO2 fracturing is carried out; S4, CO2 heat energy utilization is carried out; S5, cyclic utilization of CO2 is carried out; and S6, CO2 storage is carried out. The method is advantaged in that CO2 is adopted as a fracturing medium and a heat exchange medium, pressure loss and fracturing difficulty in the flowing process of fracturing fluid can be reduced by taking CO2 as the fracturing medium, the heat exchange area of a heat storage stratum can be increased, intercommunication of a micro-fracture network system is promoted, and the reservoir transformation time is saved; meanwhile, CO2 serves as a heat exchange medium, the heat extraction capacity of a heat storage stratum can be improved, a large amount of CO2 can be stored in the underground deep part in the heat exchange process and after heat exchange, and carbon peak reaching and carbon neutralization can be achieved easily.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Mold cutting edge repair welding process

InactiveCN104209639ASimple welding processSave man hoursArc welding apparatusWelding/soldering/cutting articlesParent materialElectric heating

The invention relates to a mold cutting edge repair welding process. The mold cutting edge repair welding process comprises the following steps: S1, making preparations before welding; S11, drying a welding rod; S12, opening a break; S13, cleaning; S2, preheating: putting a mold into an electric heating furnace, uniformly heating to 250-450 DEG C, and taking the mold out; S3, welding: fixing a mold parent material onto a workbench, and welding by adopting low current gas arc and vertical short arc operation, reverse welding and uniform filling, and jointing during layered staggered welding; S4, heating and preserving heat: putting the welded mold back into the electric heating furnace for heating till the temperature is up to 150-300 DEG C, preserving heat for 25-35 minutes, and the performing furnace cooling; S5, assembling after welding: trimming a welding area, forming a gap, assembling the mold on a machine tool, performing trial production, and detecting a product. The mold cutting edge repair welding process has the advantages of simple machining process, short period, low cost and long service life after repair welding.

Owner:AEROSPACE WANXIN SCI & TECH CHENGDU

Ceramic blank and manufacturing method thereof

The invention provides a ceramic blank and a manufacturing method thereof, and relates to the technical field of ceramics, the ceramic blank includes 80-120 parts by weight of a based blank, 10-20 parts by weight of an enhancer and 1-5 parts by weight of an additive; the production process of the ceramic blank comprises the following steps: 1) making mud, 2) making a wet blank, and 3) drying the blank. Through the improvement of raw materials and production methods, the prepared ceramic blank has good chemical stability and good mechanical strength, and the prepared ceramic blank also has good toughness and shaping property, is anti-falling and not easy to break, has low production cost, long service life and wide application range, and is worthy of promotion.

Owner:玉林龙升建筑装饰工程有限公司

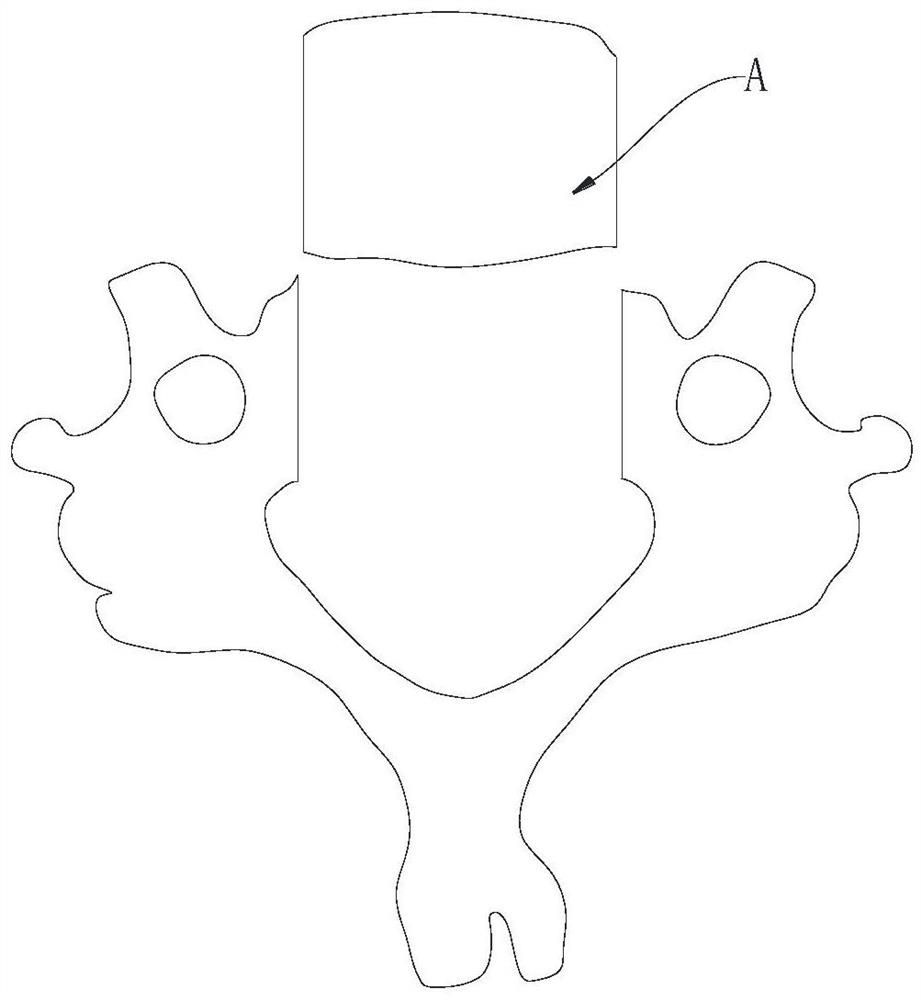

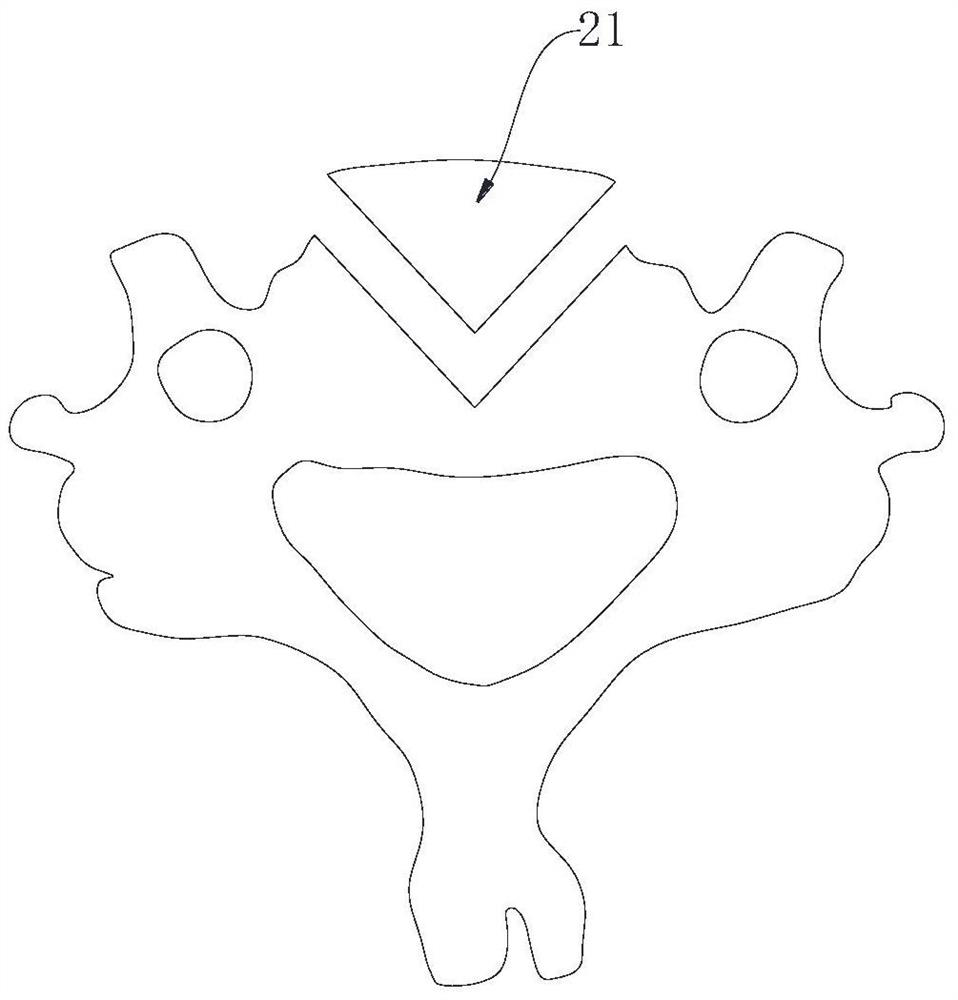

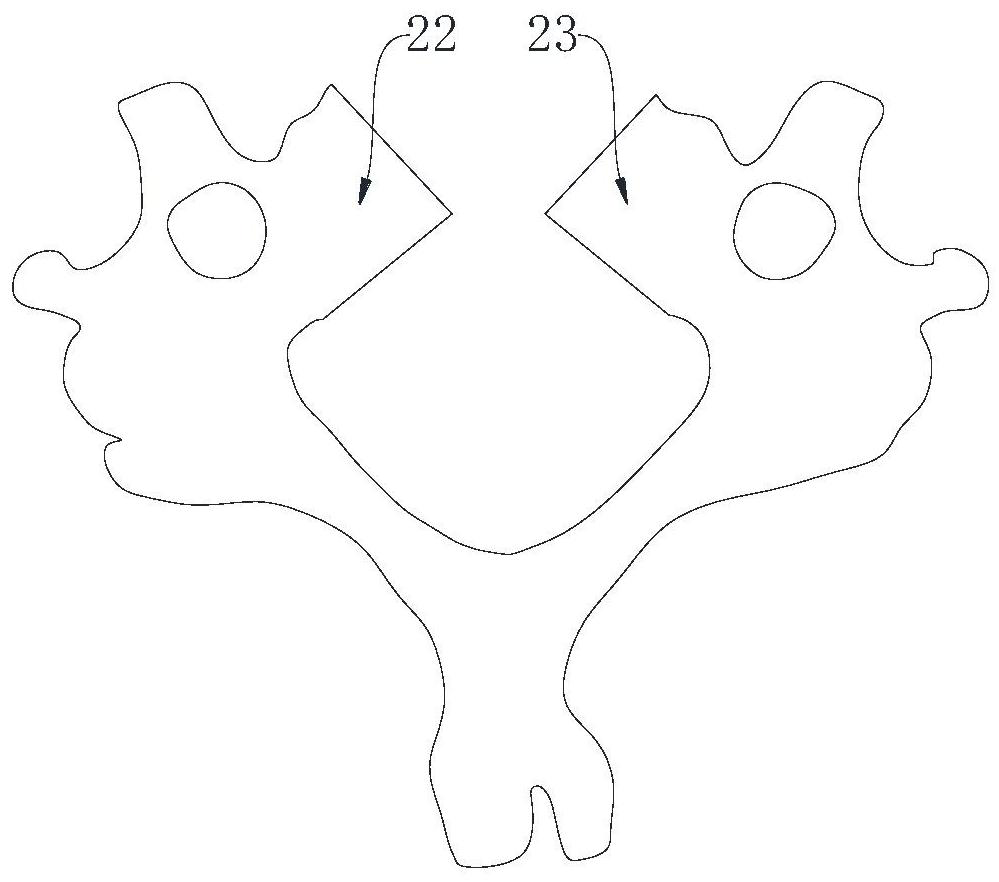

Intervertebral fusion fixator for X-shaped excision decompression vertebroplasty of vertebral body

ActiveCN111888056AReduce work delaysShorten the fusion success rateSpinal implantsBone chamberRetainer

The invention discloses an intervertebral fusion fixator, relates to the field of medical instruments, and aims to provide a fusion fixator which is matched with anterior cervical approach vertebral X-shaped excision decompression vertebroplasty and can shorten the bone crawling substitution distance, shorten the fusion time and increase the bone grafting fusion success rate. According to the technical scheme, the intervertebral fusion fixator for X-shaped excision decompression vertebroplasty of the vertebral body comprises a fusion fixing body and screws, the fusion fixing body is provided with three bone grafting cavities, the horizontal section of the first bone grafting cavity is in a fan shape, the outer sides of the two radiuses of the fan shape are the second bone grafting cavity and the third bone grafting cavity respectively, a fixing blocking piece is arranged above or below the arc edge of the fan shape, the fixing blocking piece is provided with a through hole and the first screw, and the first screw is used for being implanted into a replantation bone block; and fixing holes are formed in the arc edge of the first bone grafting cavity, and screws used for implanting residual vertebral bodies on the two sides and adjacent normal vertebral bodies are arranged in the fixing holes. The intervertebral fusion fixator is suitable for the anterior cervical approach vertebral X-shaped excision decompression vertebroplasty.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

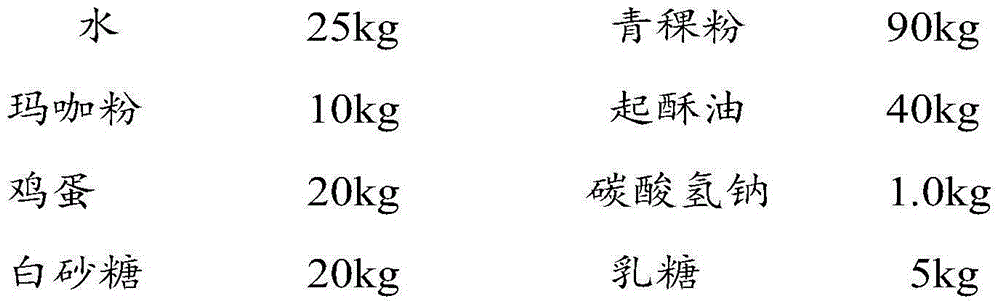

Highland barley maca biscuit and preparation method thereof

InactiveCN105230752AGreat tasteGive full play to the health benefitsDough treatmentBakery productsSodium bicarbonateTrace element

The invention provides a highland barley maca biscuit and a preparation method thereof. The highland barley maca biscuit is prepared by taking the following raw materials in parts by weight: 10-20 parts of maca powder, 80-90 parts of highland barley powder, 35-40 parts of shortening, 20-25 parts of sweetening agent, 15-20 parts of eggs, 0.6-1.0 part of sodium bicarbonate and 20-25 parts of water. The preparation method comprises the following steps: forming a premixed solution after heating and dissolving the sweetening agent and the shortening, cooling and standing by; mixing and uniformly stirring the maca powder and the highland barley powder, adding the sodium bicarbonate, the premixed solution and the eggs in turn, kneading and forming a dough; standing by the dough for 1-2min, performing the steps of pressing mould shaping and baking, and then cooling, thereby acquiring the highland barley maca biscuit. The highland barley maca biscuit according to the embodiment of the invention has the advantages of organic combination of the highland barley in Tibetan area and maca, unique, sweet, smooth and fine taste, pure natural, complete nutritional ingredients rich in various amino acids and trace elements, and more benefit in absorption of human body.

Owner:QINGHAI XIHAI ZHIYUAN BIOTECH CO LTD

Shock-resisting and breaking-proof ceramic for daily use and preparation method thereof

The invention discloses shock-resisting and breaking-proof ceramic for daily use and a preparation method thereof. The ceramic is prepared from the following raw materials in parts by weight: 20 to 30parts of kaolin, 10 to 20 parts of silicon dioxide, 10 to 20 parts of feldspar, 5 to 15 parts of bamboo charcoal powder, 3 to 10 parts of talcum powder, 5 to 15 parts of zirconium boride, 10 to 15 parts of fructus gardeniae, 3 to 7 parts of tetraethyl orthosilicate, 3 to 5 parts of oxidized polyethlene wax, 5 to 15 parts of epoxy resin and 1 to 3 parts of a silane coupling agent. The shock-resisting and breaking-proof ceramic for daily use, disclosed by the invention, has the advantages of simple production technology, no pollution in a technological process, low raw material cost, fine microstructure crystal grains and high wear-resisting strength of a product; the prepared shock-resisting and breaking-proof ceramic for daily use has high shock-resisting performance and good mechanical strength and is durable.

Owner:福建省德化汇远陶瓷有限公司

Preparation method of benzoin product

InactiveCN103288609BHigh yieldQuality improvementOrganic compound preparationCarbonyl compound preparationPtru catalystPotassium cyanide

The invention relates to the technical field of organic synthesis and particularly relates to a preparation method of a benzoin product. The preparation method is characterized by taking benzaldehyde as a reaction raw material, sodium cyanide or potassium cyanide as a catalyst and water as a reaction solvent. The preparation method comprises the steps of adding an efficient cationic surfactant, a phase transfer catalyst, a dispersant and inorganic salt into a reaction mixing system, heating up to 60-70 DEG C, carrying out thermal reaction for 1.5h-3.0h, cooling to room temperature after the thermal reaction to obtain a solid-liquid mixture of reaction products, filtering the mixture to separate out a solid product, washing the solid product by an ethanol solution to remove surface impurities, and drying to obtain the white granular benzoin crystal product with the melting point being above 133 DEG C, and the purity being above 99.0%. The product yield is high.

Owner:宁波市奉化南科新材料有限公司

Polycarbonate synthesis process

A polycarbonate synthesis process comprises steps as follows: S1, a raw material mixing stage: melt isosorbide and dialkyl carbonate are stirred and uniformly mixed in a raw material mixing tank; S2, an ester exchange reaction stage: a tower reactor located behind the raw material mixing tank is taken as an ester exchange reactor, and released hydroxyl and aryl reaction products can be removed continuously; S3, a pre-polymerization reaction stage: a kettle pre-polycondensation reactor is arranged behind the ester exchange reactor, a pre-polymerization product is generated in the pre-polycondensation reactor, and meanwhile, released hydroxyl and aryl reaction products are removed continuously; S4: a polycondensation reaction stage: a hydraulic driven horizontal disk polycondensation reactor located behind the pre-polymerization reactor performs microwave processing on a pre-polycondensation product, and the pre-polycondensation product is subjected to polycondensation to form polycarbonate melts. The released hydroxyl and aryl reaction products are removed continuously, so that reaction balance is pushed in the positive direction, the pre-polycondensation product is heated through microwaves in the polycondensation stage, and the reaction rate can be effectively increased.

Owner:NINGBO ZHETIE DAPHOON CHEM

Amino-terminated aqueous polyurethane dispersion and preparation method thereof

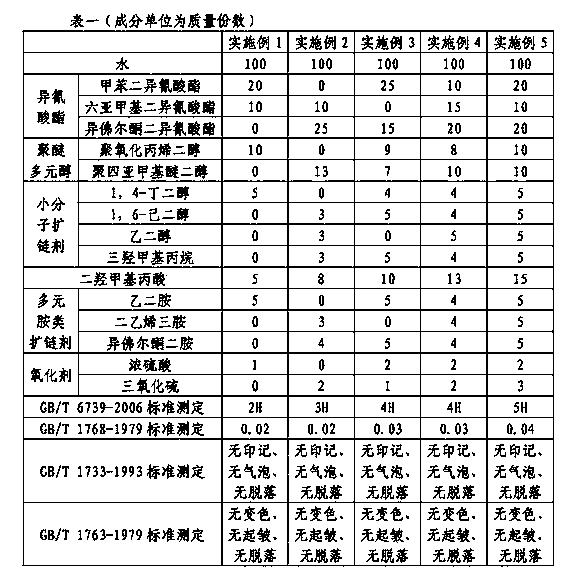

ActiveCN104211898AImprove responsePromote interpenetrationPolyurea/polyurethane coatingsPolyurethane dispersionPolyol

The invention discloses an amino-terminated aqueous polyurethane dispersion. The amino-terminated aqueous polyurethane dispersion comprises, by mass, 100 parts of water, 30-50 parts of isocyanate, 10-20 parts of polyether polyol, 5-20 parts of a micro-molecular chain extender, 5-15 parts of a hydrophilic chain extender, 5-15 parts of a polyamine chain extender and 1-5 parts of an oxidant. The amino-terminated aqueous polyurethane dispersion has the advantages of high hardness, good wear resistance and excellent water resistance.

Owner:上海巴德富实业有限公司

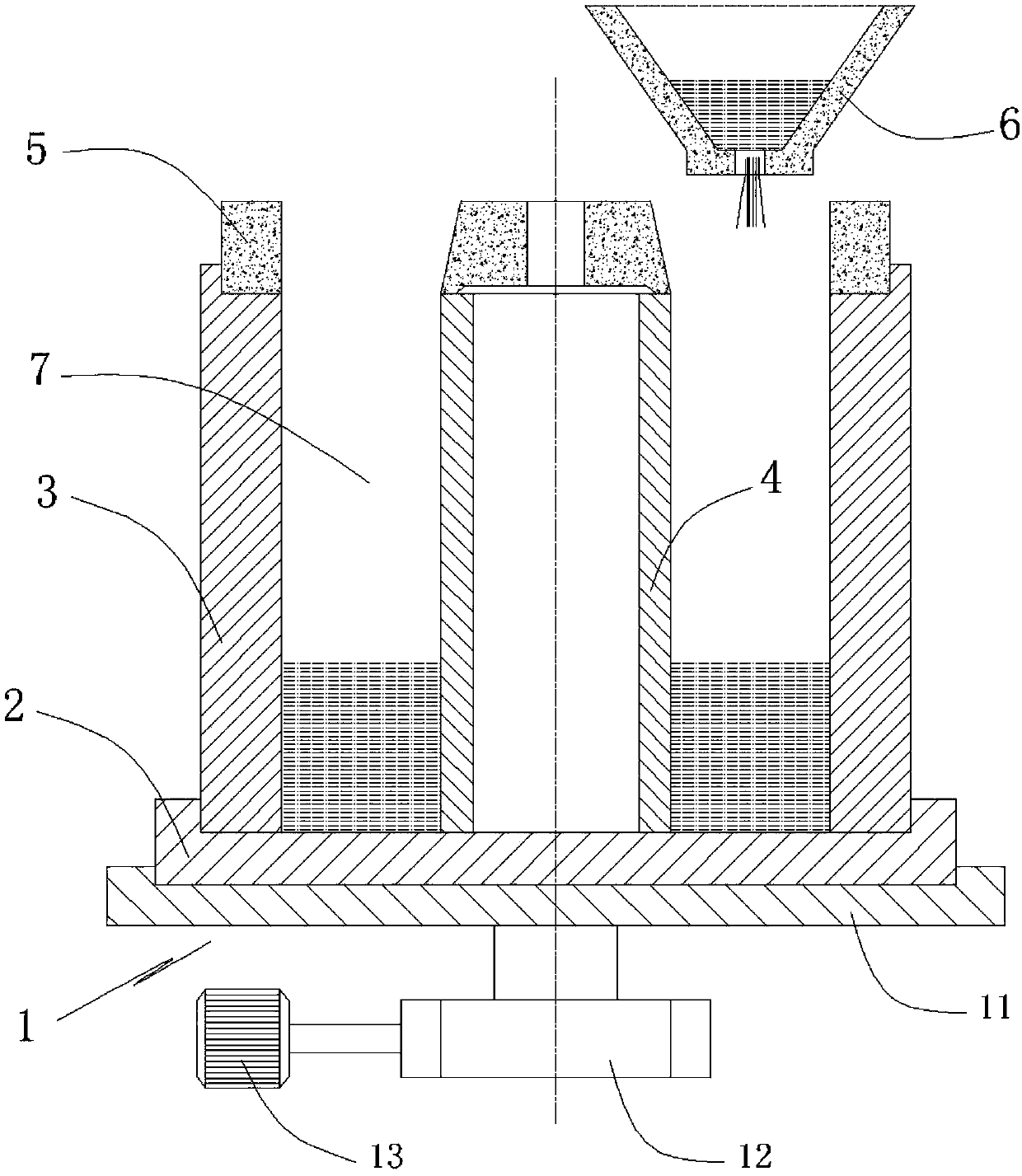

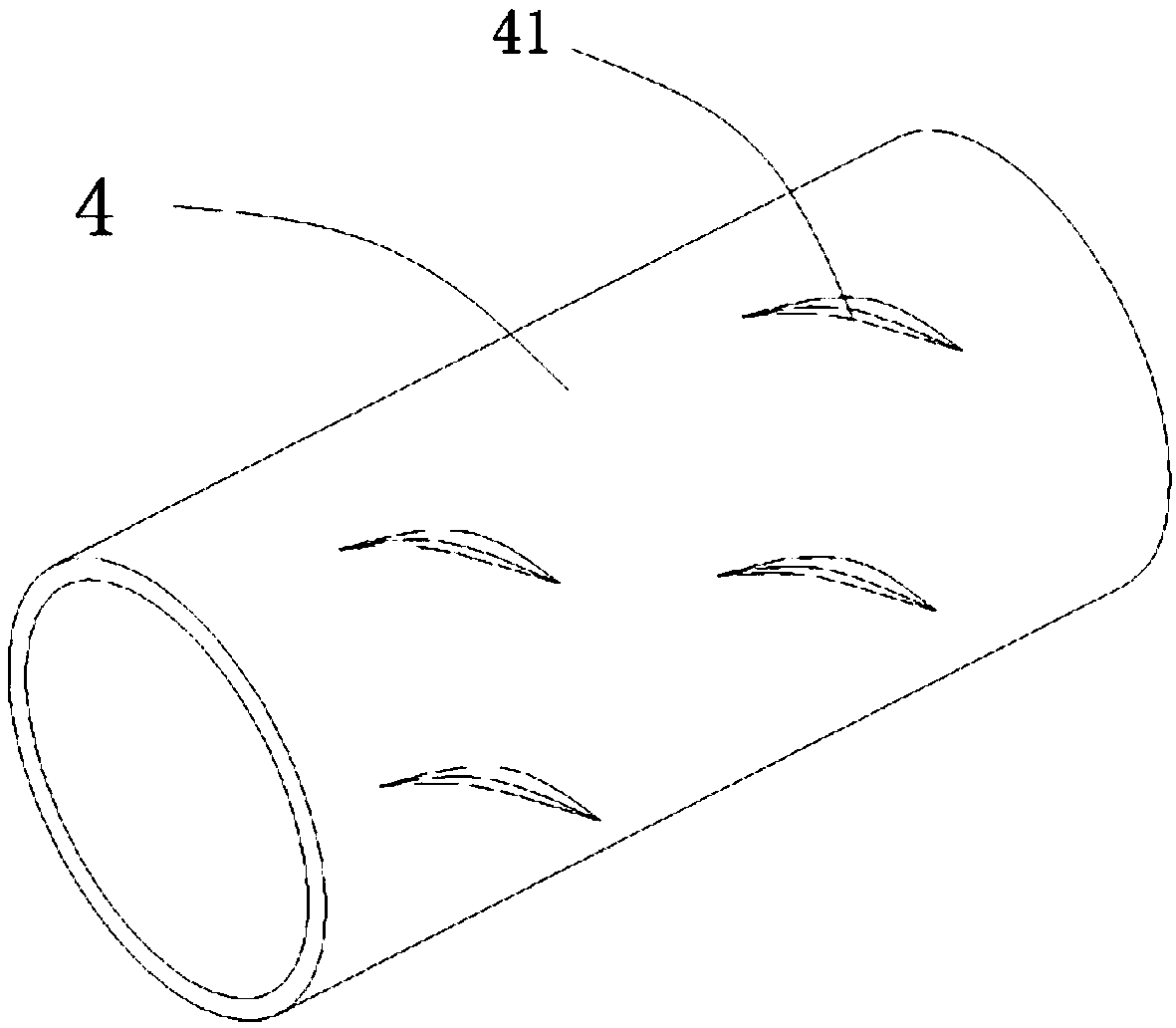

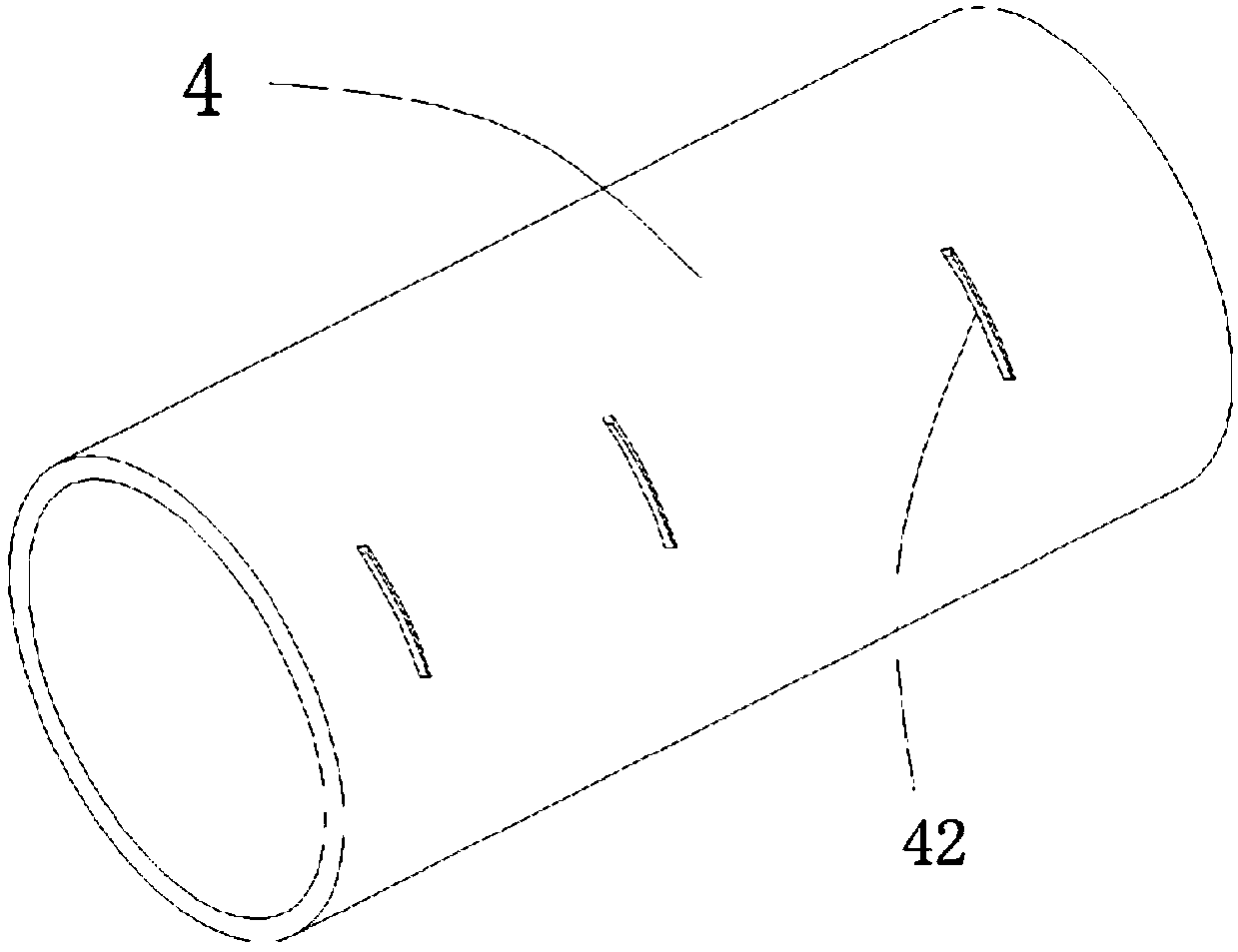

Machining method and machining device of bi-metal roller sleeve and bi-metal roller sleeve

InactiveCN109513902APromote partial meltingPromote perfect fusionFurnace typesHeat treatment furnacesSuperalloyTransition layer

The invention discloses a machining method of a bi-metal roller sleeve. The machining method of the bi-metal roller sleeve includes the following steps that a rotating mechanism, a casting bottom plate and an outer steel mold used for machining the bi-metal roller sleeve are prepared in advance; an inner steel core is fixed to the casting bottom plate, and a casting space is formed between the inner steel core and the outer steel mold; the rotating mechanism is started, the rotating speed of the rotating mechanism is set to be 25-75 r / min, a casting cup is opened, alloy steel liquid is injected into the casting space, and the roller outer sleeve is formed after the alloy steel liquid is cooled. The invention further discloses a machining device used for the method and the bi-metal roller sleeve machined and produced through the method. In this way, according to the roller outer sleeve manufactured in a cast-in-place manner, due to the fact that when the high temperature alloy steel liquid is combined with the inner steel core in the cast-in-place process, part of the structure of the outer wall of the inner steel core can be melted, thus combination of the alloy steel liquid and the inner steel core is firmer, interinfiltration between the two is more sufficient, and a perfectly combined transition layer is formed.

Owner:湖南四昉新材料有限公司

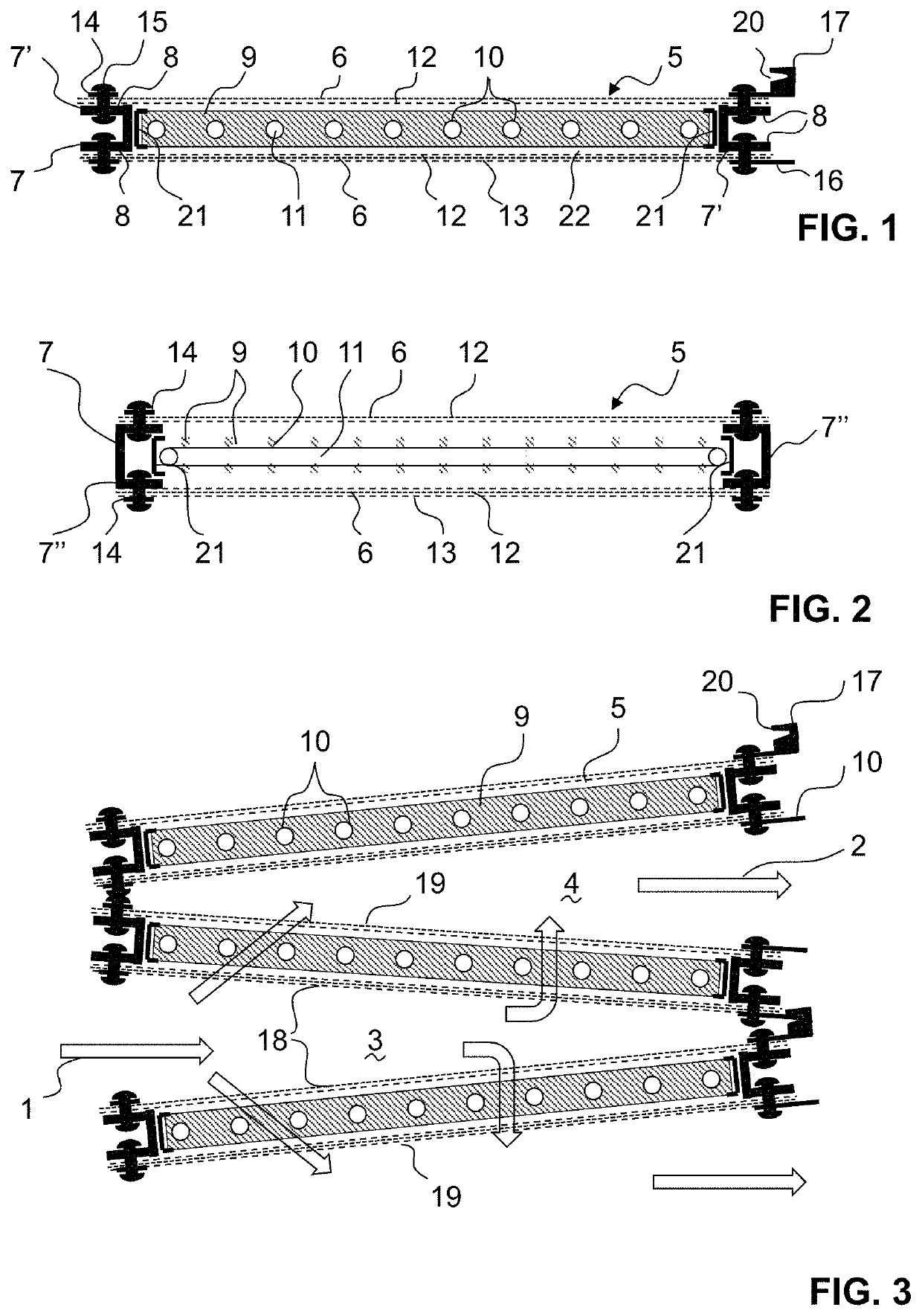

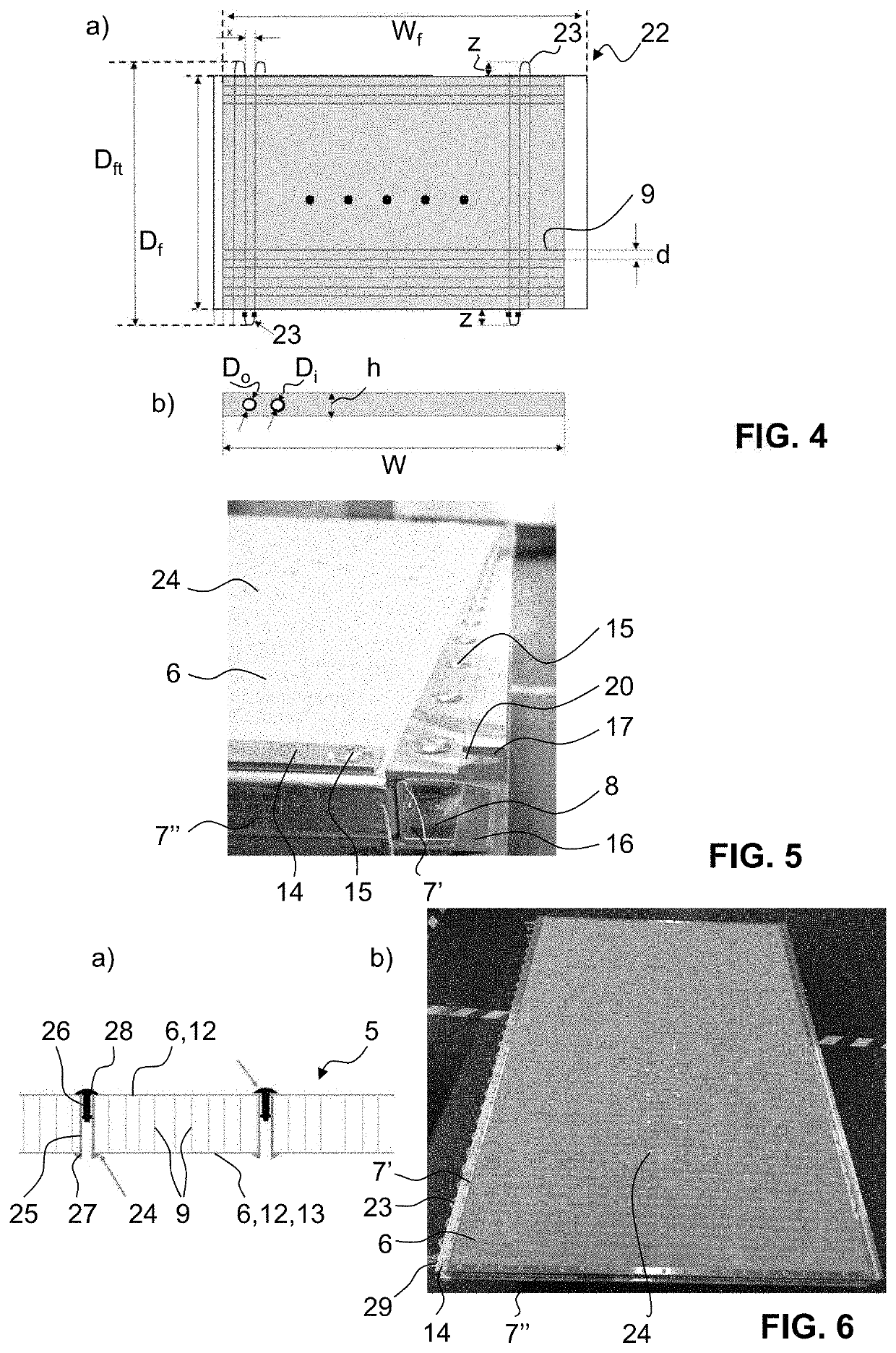

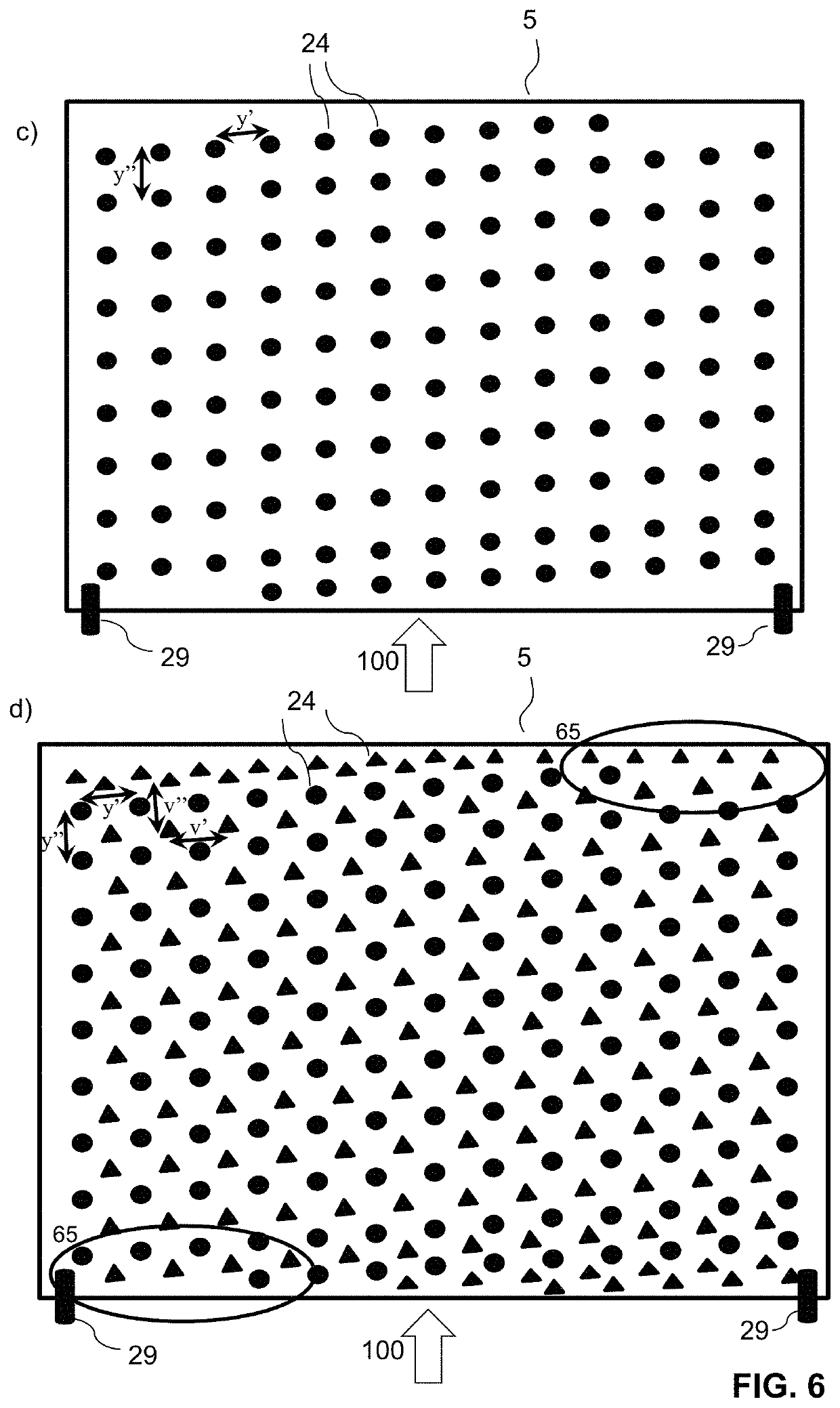

Low-pressure drop structure of particle adsorbent bed for improved adsorption gas separation process

ActiveUS11007470B2Promote interpenetrationSolve Porosity InsufficiencyGas treatmentDispersed particle separationSorbentDesorption

Owner:CLIMEWORKS

High-efficiency yield-increase wear-resistant polymer coated fertilizer for strawberries and preparation method thereof

InactiveCN104649813AIncrease profitImprove water retentionBio-organic fraction processingAnimal corpse fertilisersPolyvinyl alcoholWear resistant

The invention relates to a high-efficiency yield-increase wear-resistant polymer coated fertilizer for strawberries, which is prepared from the following raw materials in parts by weight: 0.3-0.6 part of hydroxymethyl cellulose sodium, 34-38 parts of rice bran, 33-35 parts of tobacco leaf powder, 60-65 parts of fruit peel, 43-46 parts of bamboo shoot shell, 21-24 parts of feather meal, 33-37 parts of rape seed cake, 15-18 parts of potassium chloride, 1-2 parts of borax, 0.02-0.04 part of Laetiporus sulphureus, 40-44 parts of cattle manure, 7-10 parts of calcium magnesia phosphate fertilizer, 18-24 parts of ammonium dihydrogen phosphate, 20-25 parts of urea, 0.5-1.0 part of zirconia, 6-9 parts of effective microorganisms, 11-14 parts of modified bamboo fiber, 3-5 parts of polyvinyl alcohol, 3-4 parts of diatomite, 2-3 parts of nano carbon, 1-2 parts of zinc sulfate, 0.2-0.4 part of polyoxyethylene fatty amine, 0.1-0.3 part of sodium persulfate, 3-4 parts of styrene, 0.1-0.2 part of 2-hydroxyethyl acrylate, 2-3 parts of acrylamide and a right amount of water. The high-efficiency yield-increase wear-resistant polymer coated fertilizer for strawberries has the advantages of high water retention property and high adsorptivity, and enhances the quality of the strawberries.

Owner:HEXIAN CHANGJIU AGRI DEV

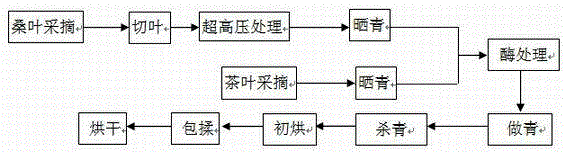

Preparation method of mulberry leaf oolong tea

InactiveCN104431065AFacilitated releasePromote interpenetrationPre-extraction tea treatmentFlavorCellulose

The invention discloses a preparation method of mulberry leaf oolong tea. The preparation method comprises the following steps: picking mulberry leaves, cutting the mulberry leaves, carrying out ultrahigh pressure treatment, picking tea leaves, carrying out sun withering, carrying out enzyme treatment, carrying out green making, carrying out fixation and primarily drying. The preparation method has the advantages that by virtue of the ultrahigh pressure treatment, some cells are broken and the release of endogenous substances in the mulberry leaves is promoted, so that the preparation method is conducive to the reduction of the herbal flavor of the mulberry leaves and to the promotion of following enzymatic reaction. With the addition of a complex enzyme preparation, the decomposition of substances such as cellulose and protein into various soluble sugars and amino acids as well as the release of aroma substances can be promoted, the herbal smell of the mulberry leaves is remarkably eliminated, the aroma of the mulberry tea is enhanced and the taste of the tea is improved. By adding the tea leaves in the process of carrying out the green making on the mulberry leaves, the fermentation of the mulberry leaves is promoted by virtue of polyphenol substances and polyphenol oxidase in the tea leaves, so that the unique quality and aroma of the oolong tea are generated. The oolong tea prepared by the invention has the green appearance, is in the form of a screw, compact and uniform in texture, and has the fragrance of flowers when the tea is dried; and after being brewed, the oolong tea has the brightly yellow and green soup color, and tastes refreshing and mellow.

Owner:JIANGXI SERICULTURE & TEA RES INST

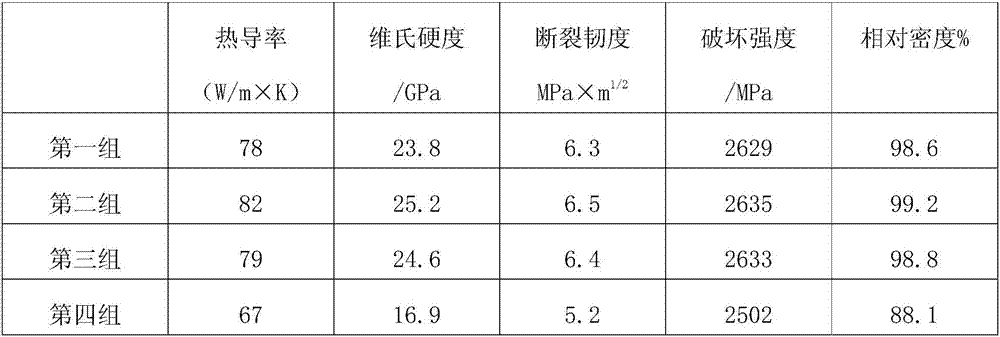

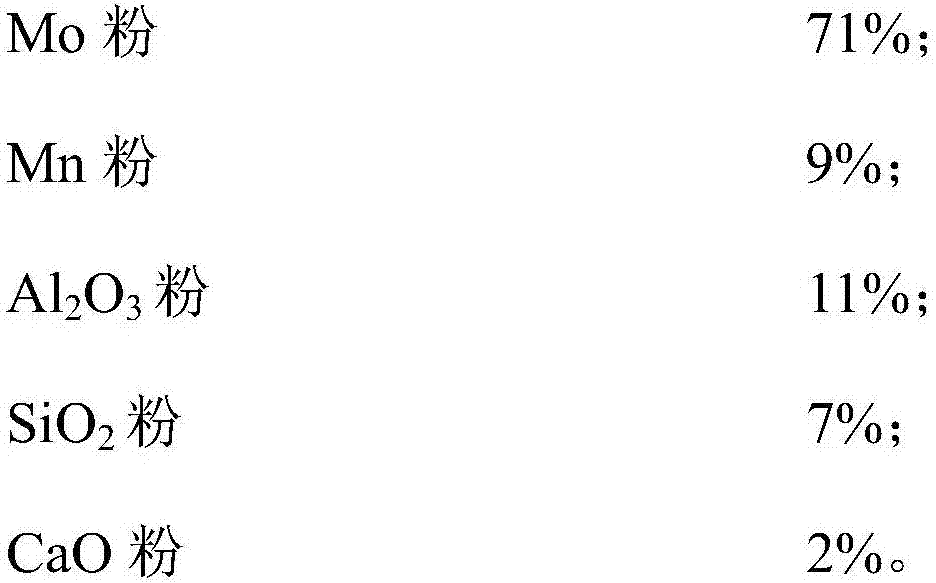

Ceramic metallizing paste and preparation method and application thereof

The invention relates to a ceramic metallizing paste and a preparation method and application thereof. The ceramic metallizing paste comprises the following components by mass percent: 71-73% of Mo powder, 8-13% of Mn powder, 9-11% of Al2O3 powder, 7-9% of SiO2 powder and 1.1-3% of CaO powder. All the powder in the formula are mixed and then ground to obtain the granularity of 0.5-1.3 [mu]m, and then a roll-pressing technology is adopted for paste making to obtain the fine and smooth paste with uniform ingredients and small granularity. The ceramic metallizing paste is subjected to metallizing sintering at 1,330-1,350 DEG C to realize good interinfiltration with ceramic, so that the energy consumption is reduced. When the end surface of ceramic is coated with the prepared ceramic metallizing paste, a metallized layer formed after sintering is continuous and compact, the sealing strength reaches 300 MPa or above, which is far higher than the industrial standard, the air tightness of a weld meets the demands, and favorable economical benefits and a wide application prospect are achieved.

Owner:BEIJING BOE VACUUM ELECTRONICS CO LTD

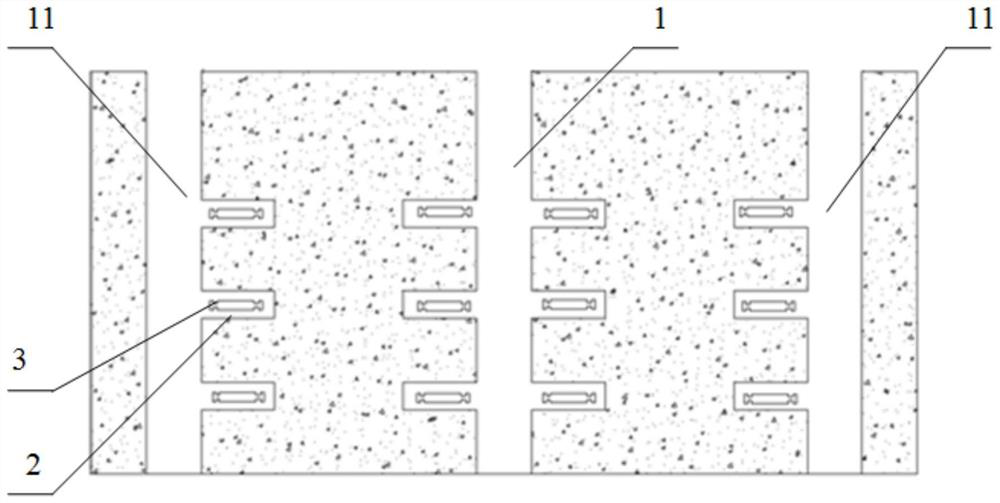

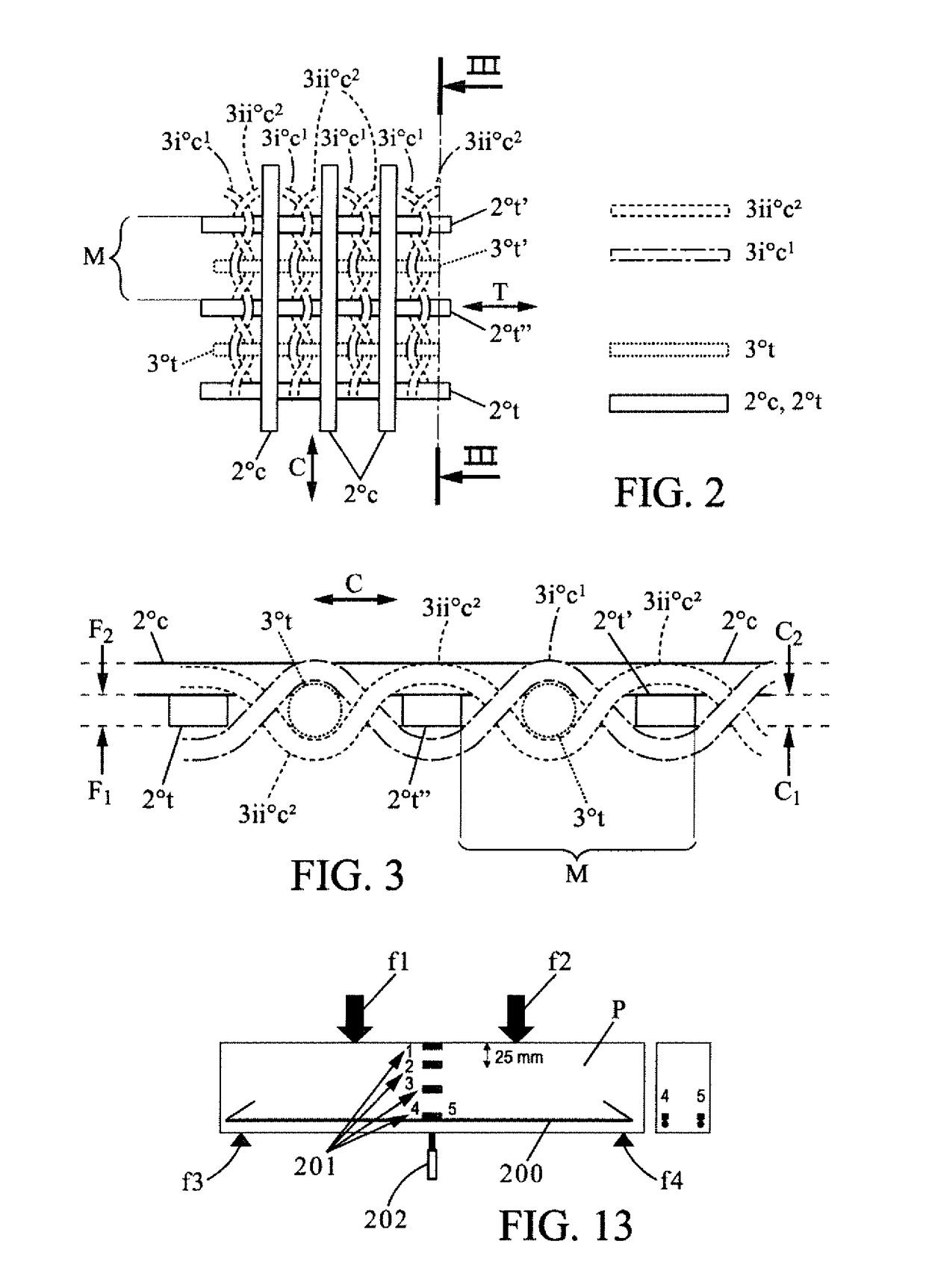

Low-pressure drop structure of particle adsorbent bed for improved adsorption gas separation process

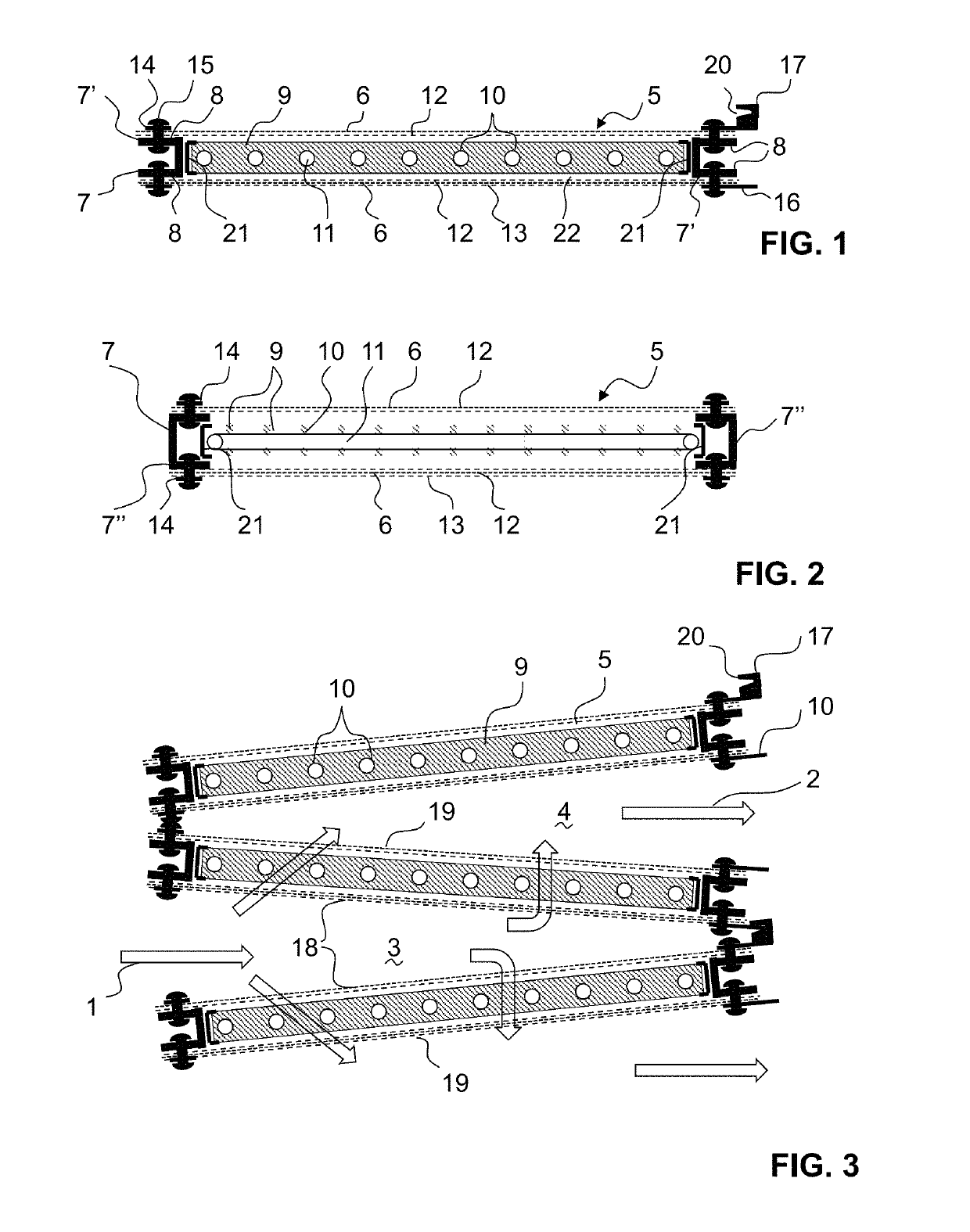

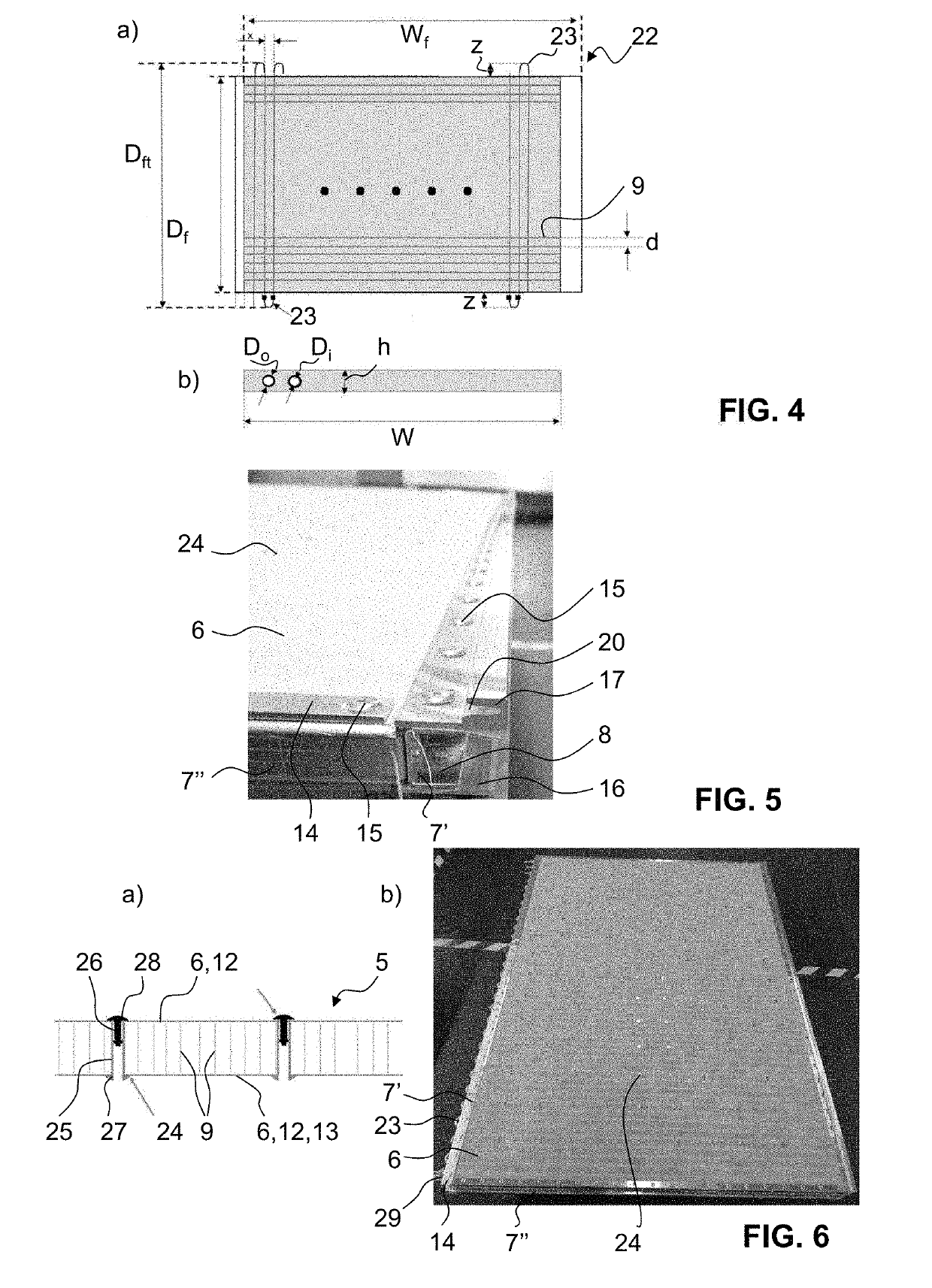

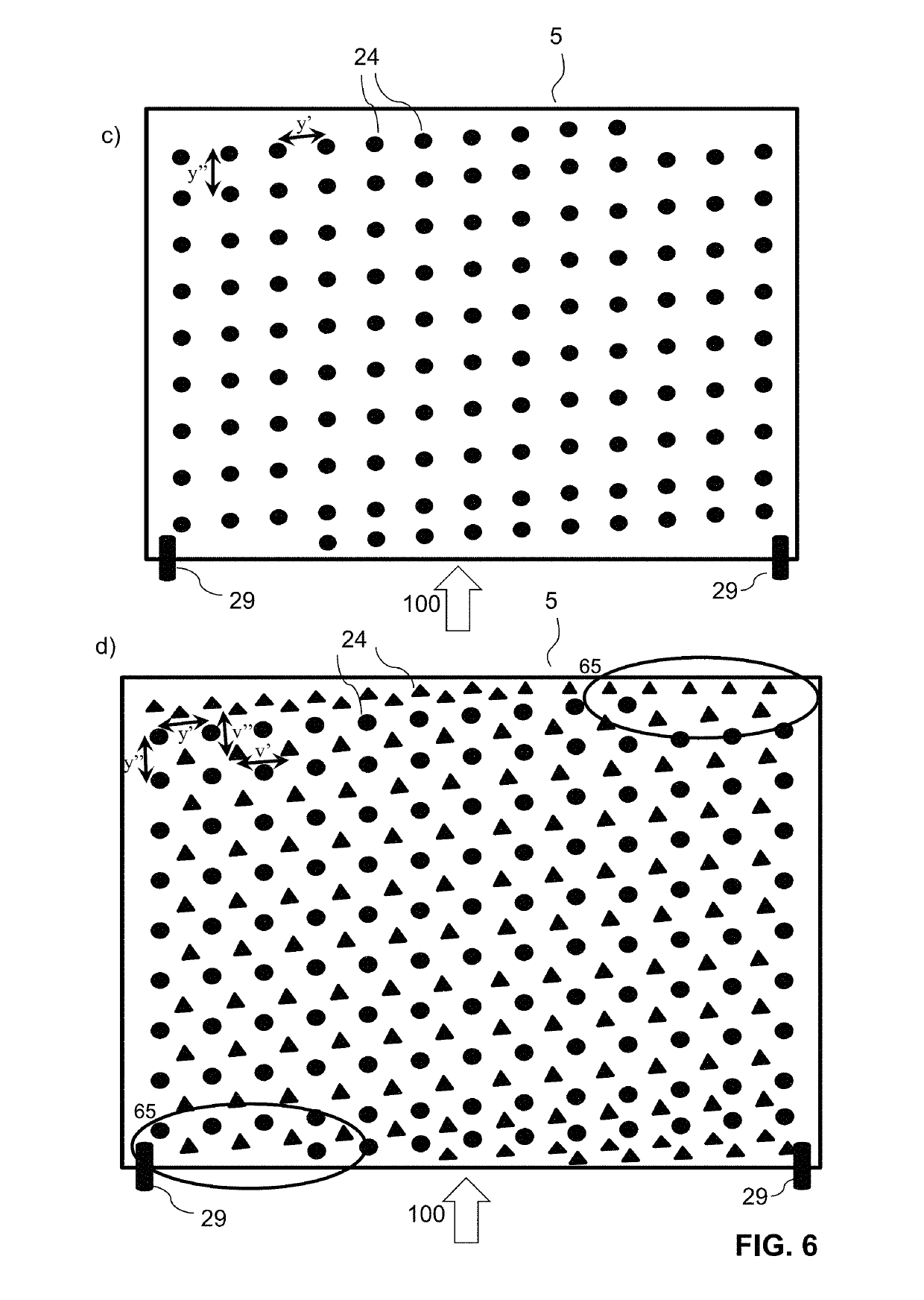

ActiveUS20190255480A1Improve corrosion resistanceLight structureGas treatmentDispersed particle separationParticulatesSorbent

A gas separation unit for the separation of a first gas from a mixture containing said first gas as well as further gases by a cyclic adsorption / desorption process using a loose particulate sorbent material for gas adsorption. The particulate sorbent material is arranged in at least two stacked layers (5) that are mounted on a stiff rectangular circumferential frame (7). A plurality of tubes (11) is provided for a heat exchange fluid within the frame (7). The tubes (11) are in thermal contact with a plurality of sheets (9) of metal which are arranged essentially perpendicular to a main plane of the frame (7) and perpendicular to the tubes (11). The sheets (9) extend in a continuous manner between a first pair of mutually parallel metal profiles (7′) and are provided with a plurality of holes (10) through which the plurality of tubes (11) penetrate.

Owner:CLIMEWORKS

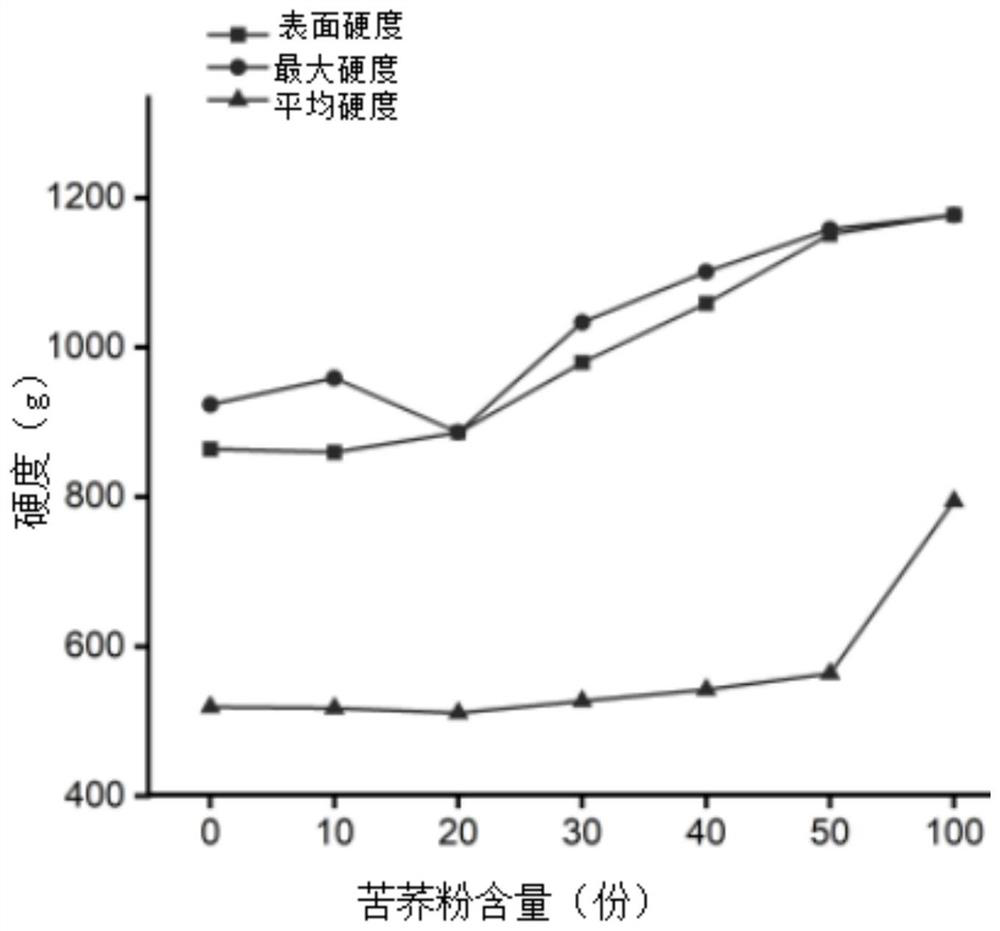

Tartary buckwheat biscuit and preparation method thereof

PendingCN113575644ACrispy tasteWith tartary buckwheat aromaDough treatmentBaking processesBiotechnologySUGAR/WATER

The invention discloses a tartary buckwheat biscuit and a preparation method thereof, and belongs to the technical field of food processing. The tartary buckwheat biscuit comprises the following components in parts by weight: tartary buckwheat flour, wheat flour, yolk liquid, butter, sweet water, table salt, baking soda and a composite leavening agent. The preparation method of the tartary buckwheat biscuits comprises the following steps: mixing sweet water, table salt, baking soda and a composite leavening agent to obtain a first mixture; whipping egg yolk liquid and butter, adding the first mixture, performing stirring to obtain a second mixture, and performing heating; stirring the tartary buckwheat flour, the wheat flour and the second mixture to form dough, and then preparing a cake blank; putting the biscuit blanks into an oven, baking with an upper fire of 130-150 DEG C and a lower fire of 160-170 DEG C, then baking with an upper fire of 180-190 DEG C and a lower fire of 200-210 DEG C, and then baking with an upper fire of 150-160 DEG C and a lower fire of 170-180 DEG C to obtain the tartary buckwheat biscuits. The tartary buckwheat biscuit is crisp in taste, not bitter and high in flavone and phenol content.

Owner:YANGTZE UNIVERSITY

Medium carbon steel quenching treatment process capable of reducing quenching cracking

InactiveCN111378822AAdd depthSpeed up coolingSolid state diffusion coatingQuenching agentsPolyethylene glycolBoriding

The invention discloses a medium carbon steel quenching treatment process capable of reducing quenching cracking, and relates to the technical field of quenching media. The medium carbon steel quenching treatment process comprises the following steps of (1) pretreatment: adding a medium carbon steel workpiece into a resistance furnace, heating to 400-460 DEG C, keeping the temperature for 30-40 minutes, adding into a polyethylene glycol composite water solution for impregnating, carrying out primary ultrasonic treatment, taking out, and drying to constant weight; and (2) quenching treatment:adding the pretreated medium carbon steel workpiece into the resistance furnace for heating and heat preservation, then rapidly transferring the medium carbon steel workpiece into a first salt bath tank for isothermal treatment for 35-40 min, then rapidly transferring the medium carbon steel workpiece into a second salt bath tank for isothermal treatment for 30-35 min, then transferring the mediumcarbon steel workpiece into a quenching medium for quenching, and carrying out secondary ultrasonic treatment at the same time, finally, cleaning and drying to constant weight to obtain the product.The medium carbon steel workpiece is treated through the first salt bath tank and the second salt bath tank, a boriding layer can be formed on the surface of the medium carbon steel in a permeating mode, and the hardness of the surface of the medium carbon steel workpiece is greatly improved.

Owner:马鞍山市鑫龙特钢有限公司

Feed with hydrolyzed protein and preparation method of feed

ActiveCN105961844AReduce pollutionLow investment costAnimal feeding stuffAccessory food factorsHydrolyzed proteinFeed processing

The invention belongs to the field of feed processing, and particularly relates to a feed with hydrolyzed protein and a preparation method of the feed. The preparation method provided by the invention comprises the following steps of adding prepared raw materials to water, performing heating, adjusting a pH value, adding an emulsifying agent, performing sufficient stirring, adding enzymes, and performing sufficient stirring; adding the obtained mixture to a homogenizing machine for homogenizing treatment; or adding the obtained mixture to an emulsifying machine for emulsifying treatment; or adding the obtained mixture to the homogenizing machine for homogenizing treatment, and then adding the homogenized mixture to the emulsifying machine for the emulsifying treatment; or adding the obtained mixture to the emulsifying machine for the emulsifying treatment, and then adding the emulsified mixture to the homogenizing machine for homogenizing treatment; and then drying obtained semi-finished products to obtain powder, so that the feed with hydrolyzed protein is obtained.

Owner:沈喆如

Automobile cooling pipe

InactiveCN107513242AImprove heat transfer effectPromote interpenetrationMachines/enginesEngine cooling apparatusTungstenHydrotalcite

The invention discloses an automobile cooling pipe, which is prepared from the following raw materials in parts by weight: 100 parts of ternary fluororubber, 5 to 8 parts of polyurethane pressure sensitive adhesive, 5 to 8 parts of nano simple substance tungsten, 20 to 30 parts of nano graphite fiber, 10 to 15 parts of nano potash feldspar, 4 to 6 parts of kaolin, 1 to 5 parts of magnesium oxide, 2 to 4 parts of hydrotalcite, 3 to 5 parts of calcium hydroxide, 1 to 3 parts of aluminum isopropoxide crosslinking agent, 0.5 to 1 part of silane coupling agent, and 5 to 10 parts of toluene. Nano simple substance tungsten, nano graphite fiber, and nano potash feldspar are added into the conventional raw materials of automobile cooling pipe to carry out modification so as to improve the heat transfer effect of automobile cooling pipe. The potash feldspar can effectively promote the penetration among raw materials, reduces the gaps, and improves the heat transfer performance.

Owner:莫小燕

High-strength wear-resistant bucket tooth for excavator and preparation process of high-strength wear-proof bucket tooth

InactiveCN107401194AReasonable ratioImprove wear resistanceSoil-shifting machines/dredgersWear resistantExcavator

The invention provides a high-strength wear-resistant bucket tooth for an excavator and a preparation process of the high-strength wear-resistant bucket tooth. The high-strength wear-resistant bucket tooth comprises an alloy steel body, a wear-resistant permeation layer and a corrosion-proof coating. The alloy steel body comprises 0.34-0.37% of C, 0.8-1.2% of Si, 0.65-0.7% of Mn, 0.3-0.45% of Mo, 2.8-3.3% of Cr, 0.25-0.28% of Ti, 0.1-0.15% of Ni, 0.18-0.2% of Y and the balance Fe and inevitable impurities. The wear-resistant permeation layer is an Al-Mo-La-Cr multi-component permeation layer. The corrosion-proof coating is an organic silicone resin composite coating. The element matching of the alloy steel body is reasonable, the hardness can reach over 300 HV, the impact toughness can reach 28 J / cm<2>, and in cooperation with the metal wear-resistant permeation layer, the abrasive resistance is improved greatly, the surface strength of the wear-resistant permeation layer can reach over 1,000 HV, the bonding force between the wear-proof permeation layer and the inner-layer alloy steel body and the outer-layer corrosion-proof coating is high, the stripping resistance is high, the hardness and strength of prepared products are high, and the high-strength wear-resistant bucket tooth is excellent in wear resistance and impact resistance and long in service life and has the high economic value and social benefits.

Owner:安徽省宁国市亚晨碾磨铸件有限责任公司

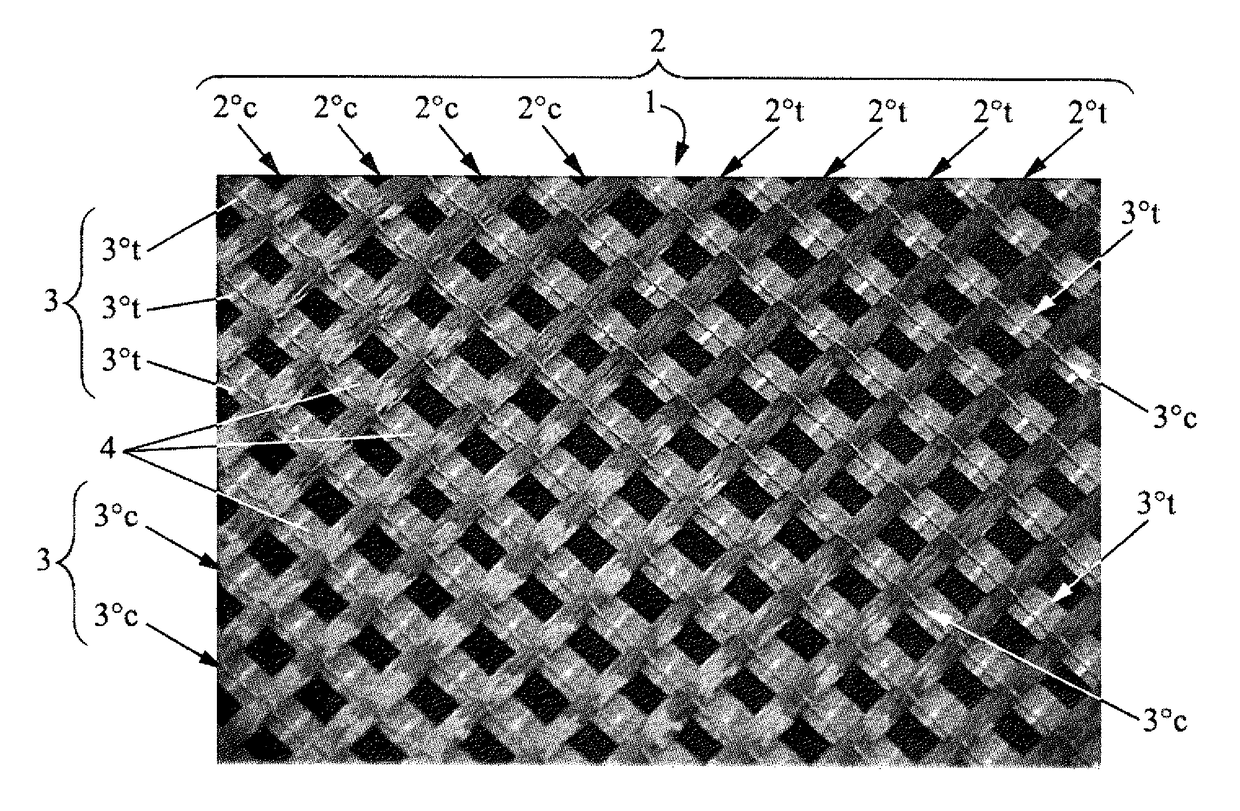

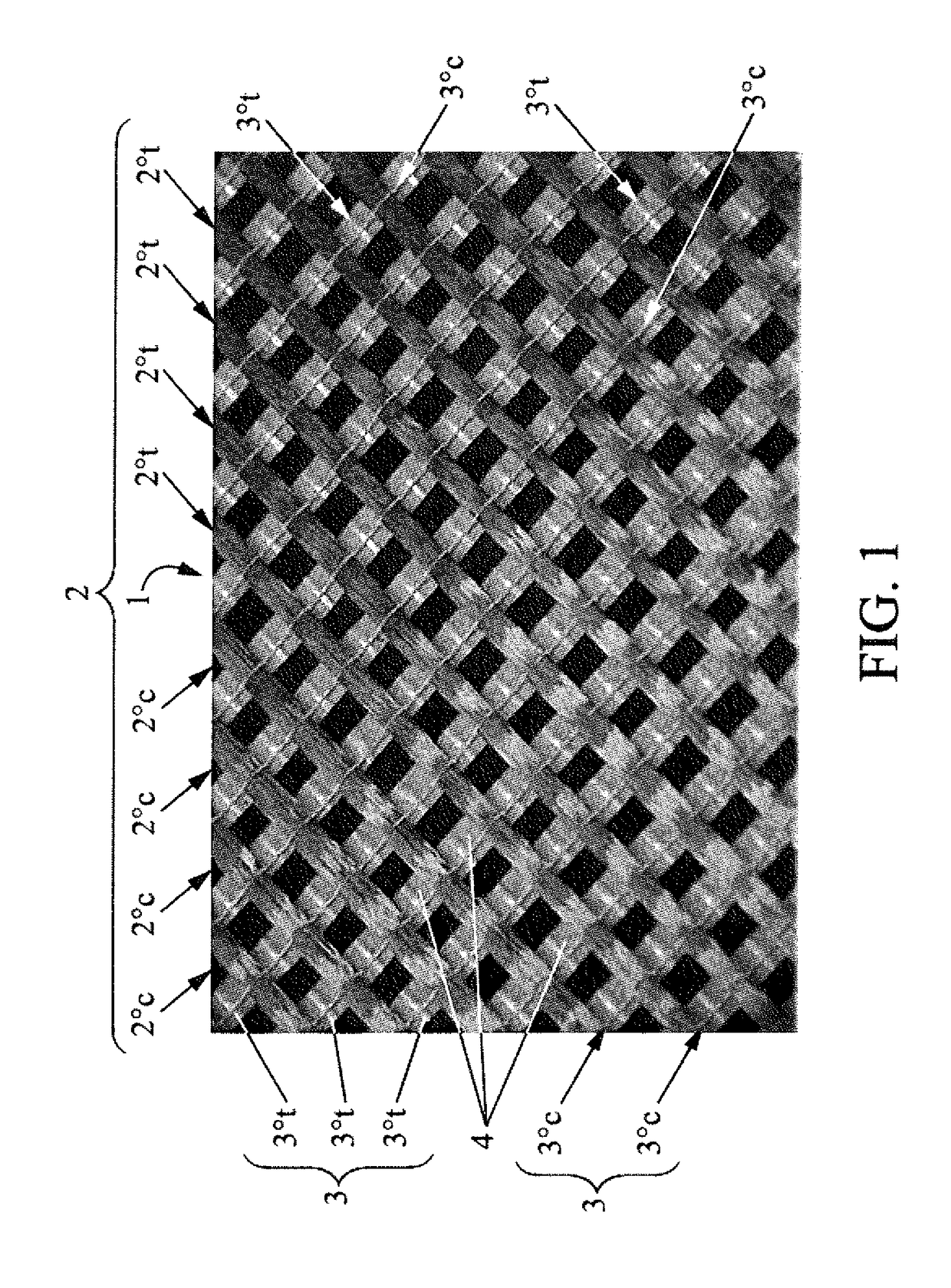

Composite system and consolidation method, in particular for structures made from reinforced concrete or masonry hardenable or hardened matrix and textile reinforcing mesh forming this system

ActiveUS20180230050A1Ensure dimensional stabilityMeet the requirements of mechanical propertiesBuilding repairsGauze-woven fabricsReinforced concreteRebar

The invention concerns a composite system for reinforcing, in particular, structures made from reinforced concrete or masonry comprising a curable or cured matrix and a textile reinforcement grid, and said two elements taken as such. The aim of the invention is for this system to make it possible to produce a cured composite structure having improved mechanical properties, both in the short term and in the long term (e.g. flexing behaviour, hardness, bending / compression resistance, durability, cohesion). This aim is achieved by the system of the invention in which the grid comprises at least one layer formed: —both from a framework consisting of flat warp yarns and weft yarns; —and from a network binding the framework; characterised in that the binding network is such that it ensures the geometric regularity and dimensional stability of the meshes of the framework, before the grid is applied to the structure to be reinforced. The invention also concerns a method for reinforcing, in particular, structures made from reinforced concrete or masonry, the composite structure obtained from this method, the dry and wet formulations of the curable matrix, and consolidated structures, in particular made from reinforced concrete or masonry.

Owner:PAREXGROUP SA

Environment-friendly porous ceramic tile and preparation method thereof

InactiveCN111517763ALow costBeautify the ecological environmentCeramic materials productionCeramicwareCompression moldingBrick

The invention discloses an environment-friendly porous ceramic tile and a preparation method thereof, belonging to the technical fields of waste treatment and building materials. The porous ceramic tile is prepared from the following raw materials in parts by mass: 35-45 parts of lake sludge, 30-40 parts of clamshells and 15-30 parts of fallen plant leaves. The preparation method comprises the following specific steps: mixing the lake sludge and the fallen plant leaves according to a certain ratio and carrying out uniform stirring to obtain a sludge mixture; crushing the clamshells, carrying out ball milling to obtain powder, weighing the clamshell powder according to a certain ratio, adding the clamshell powder into sludge slurry, and carrying out uniform stirring to obtain mixed slurry;carrying out sealed aging at room temperature for 12 hours, putting the aged mixed slurry into a brick making mold, and carrying out compression molding to obtain a green brick blank; putting the green brick blank into a kiln, carrying out preheating for a period of time, and conducting sintering according to a certain temperature schedule; and then performing air-cooling to room temperature alongwith the furnace so as to obtain the porous ceramic tile with an apparent density of 0.52-0.64 g / cm<3>, a porosity of 66.0-78.4% and compressive strength of 7.8-10.5 MPa. According to the invention,recycling of waste such as the lake sludge, the clamshells and the fallen plant leaves is achieved, environmental pollution is reduced, and the production cost of building materials is reduced.

Owner:朱义奎

Method for preparing insulating brick by utilizing sludge in lakes in central plains of China

InactiveCN111548184AImprove insulation performanceHigh compressive strengthCeramic materials productionCeramicwareBrickSludge

The invention discloses a method for preparing an insulating brick by utilizing sludge in lakes in central plains of China and belongs to the technical field of waste treatment and building materials.The insulating brick is prepared from the following raw materials in parts by mass: 45-55 parts of lake sludge; 10-15 parts of clamshell; 20-35 parts of coal cinder; and 5-15 parts of plant fallen leaves. The specific preparation method comprises the following steps of: mixing lake sludge and plant fallen leaves according to a certain ratio; the uniformly stirring the lake sludge and the plant fallen leaves to obtain sludge slurry; crushing clamshells and coal cinder; carrying out ball milling to obtain powder; weighing the clamshell powder and coal cinder powder according to a certain ratio;adding the sludge slurry; performing uniform stirring to obtain mixed slurry; carrying out sealed aging at room temperature for 24 hours; and carrying out compression molding on the slurry in a brickmaking mold to obtain a green brick blank; and putting the green brick blank into a kiln, after preheating the green brick blank for a period of time, sintering the preheated green brick blank according to a certain temperature system; and carrying out air cooling on the sintered green brick blank to room temperature along with the kiln to obtain the insulating brick. The porosity of the insulating brick is 18.0-27.3%; the compressive strength of the insulating brick is 21.0-27.5 MPa; the heat conductivity coefficient of the insulating brick is 0.38-0.51 W / (m.K); the reuse of wastes such as sludge, clamshells, coal cinder and plant fallen leaves in the lakes in the central plains of China is realized, environmental pollution is reduced, and the production cost of building materials is reduced.

Owner:朱义奎

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com