Amino-terminated aqueous polyurethane dispersion and preparation method thereof

A technology of polyurethane dispersion and water-based polyurethane, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of increased molecular weight of water-based polyurethane, low molecular weight of water-based polyurethane, difficult cross-linking reaction, etc., to improve compatibility, mutual The effect of good permeability and simplified processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

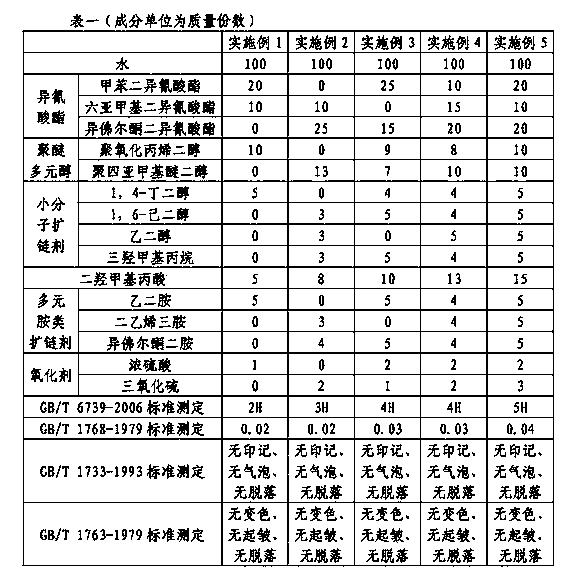

Examples

preparation example Construction

[0032] The preparation method of amino-terminated aqueous polyurethane dispersion of the present invention comprises the following steps:

[0033] a: Weigh the raw materials according to the above ratio for later use;

[0034] b: Add polyether polyol, small molecule chain extender, and hydrophilic chain extender into the reactor, react at normal pressure and 100-120°C for 0.5-2 hours, and vacuumize and dehydrate;

[0035] c: Lower the temperature in the reactor to 40-80°C, add isocyanate until the reaction is complete;

[0036] d: filling nitrogen into the mixture in step c, and adding an oxidizing agent, and reacting at 50-70° C. for 1-3 hours.

[0037] e: Stir the mixture obtained in step d continuously at 40-60°C, add water to gradually disperse it, and add polyamine chain extender under the protection of nitrogen, and react for 2-6 hours;

[0038] f: Stir the mixture obtained in step e at 30-50° C. at a speed of 200-500 rpm for 2-5 hours to disperse the mixture uniformly...

Embodiment 1

[0042] The amino-terminated aqueous polyurethane dispersion of the present invention comprises water, toluene diisocyanate, hexamethylene diisocyanate, polyoxypropylene glycol, 1,4-butanediol, dimethylol propionic acid, ethylenediamine and concentrated sulfuric acid , the contents of the above components are calculated in parts by mass: water: 100 parts; toluene diisocyanate: 20 parts; hexamethylene diisocyanate: 10 parts; polyoxypropylene glycol: 10 parts; Alcohol: 5 parts; Dimethylol propionic acid: 5 parts; Ethylenediamine: 5 parts; Concentrated sulfuric acid: 1 part.

[0043] The preparation method of hydroxyl-terminated water-based polyester resin of the present invention comprises the following steps:

[0044] a: Weigh the raw materials according to the above ratio for later use;

[0045] b: Add polyoxypropylene glycol, 1,4-butanediol, and dimethylol propionic acid into the reaction kettle, react at normal pressure and 100°C for 0.5 hours, and vacuumize and dehydrate;

...

Embodiment 2

[0052] The amino-terminated aqueous polyurethane dispersion of the present invention comprises water, hexamethylene diisocyanate, isophorone diisocyanate, polytetramethylene ether glycol, 1,6-hexanediol, ethylene glycol, trimethylol propane, dimethylolpropionic acid, diethylenetriamine, isophoronediamine and sulfur trioxide, the contents of the above components are calculated in parts by mass: water: 100 parts; hexamethylene diisocyanate: 10 parts; isophorone diisocyanate: 25 parts; polytetramethylene ether glycol: 13 parts; 1,6-hexanediol: 3 parts; ethylene glycol: 3 parts; trimethylolpropane: 3 parts dimethylolpropionic acid: 8 parts; diethylenetriamine: 3 parts; isophoronediamine: 4 parts; sulfur trioxide: 2 parts.

[0053] The preparation method of hydroxyl-terminated water-based polyester resin of the present invention comprises the following steps:

[0054] a: Weigh the raw materials according to the above ratio for later use;

[0055] b: Add polytetramethylene ether g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com