Feed with hydrolyzed protein and preparation method of feed

A technology of hydrolyzed protein and feed, which is applied in the field of feed with hydrolyzed protein and its preparation, which can solve the problems that protein cannot be absorbed, and achieve the effects of reducing air pollution, simple and practical production process, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

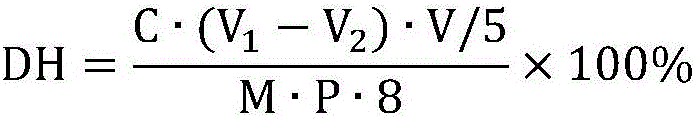

Embodiment 1

[0045] Add 150kg of whey powder, 500kg of soybean protein, 250kg of lard, and 150kg of soybean oil into 2000kg of water. The temperature is controlled between 50-60°C and the pH value is about 7.0. Add 5kg of emulsifier, stir, and add 1.5kg of neutral protease , papain 1.5kg, lipase 1.0kg, stir, homogeneous refinement by homogenizer, pressure about 29-35MPa, then enter emulsifier for processing, emulsifier rotor speed is about 1200r / min, in static grinding, After strong and reciprocating hydraulic shearing, friction, centrifugal extrusion, liquid flow collision and other comprehensive effects are formed in the reasonably narrow gap between the movable grinding plate and the propeller blade, it takes about 90 minutes to spray the semi-finished material The drying tower is spray-dried to become powder, and the dried product is sieved, measured, and packaged. Its degree of hydrolysis is 13.7%.

Embodiment 2

[0047] Put 50kg of whey powder, 160kg of coconut oil, 290kg of palm oil, and 500kg of soybean meal into a 2000kg aqueous solution with a pH value of 6.5-7.5. The temperature is controlled at about 60°C. Add 10kg of emulsifier, stir, and add 1.5kg of Bacillus subtilis. Papain 1.5kg, bromelain 1.0kg, stirred, homogenized and refined by a homogenizer, the pressure is about 40-45MPa, and then enters the emulsifier for processing. The rotor speed of the emulsifier is about 18000r / min. After the combined effect of strong and reciprocating hydraulic shearing, friction, centrifugal extrusion, and liquid flow collision is formed in the reasonably narrow gap between the moving grinding discs, the material is circulated in the container through the circulation tube. , which lasted about 300 minutes, the semi-finished material was spray-dried through a spray drying tower to become a powder, and the dried product was sieved, measured, and packaged. Its degree of hydrolysis is 8.7%.

Embodiment 3

[0049] Put 150kg of whey powder, 195kg of coconut oil, 200kg of palm oil, and 440kg of wheat protein into 2000kg of aqueous solution with a pH value between 1.5-3.0. Pepsin 5kg, stirred, and then enter the emulsification machine for processing, the rotor speed of the emulsification machine is about 2900r / min, forming strong, reciprocating hydraulic shearing, After the comprehensive effects of friction, centrifugal extrusion, liquid flow collision, etc., it takes about 120 minutes, and then enters the high-pressure homogenizer for homogenization, the pressure is about 20MPa, the material is refined, and the semi-finished product is spray-dried through the spray drying tower. Become a powder, dry the product, sieve, measure, and pack. Its degree of hydrolysis is 18.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com