Microwave catalytic activation rubber powder composition and preparation method therefor

A technology for activating rubber powder and microwave catalysis, which is applied in building structures, building components, building insulation materials, etc., can solve the problems of low rubber powder dosage and poor storage stability of rubber powder modified asphalt, reducing energy consumption, The effect of less heat loss and longer service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

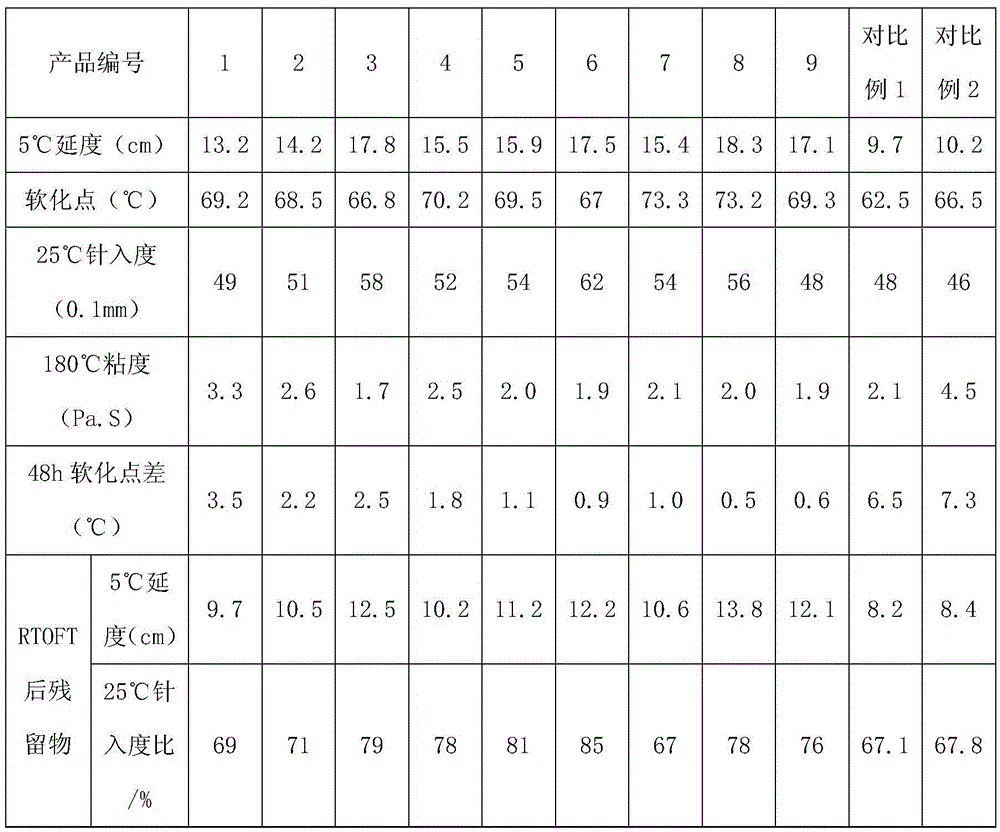

Examples

Embodiment 1-9

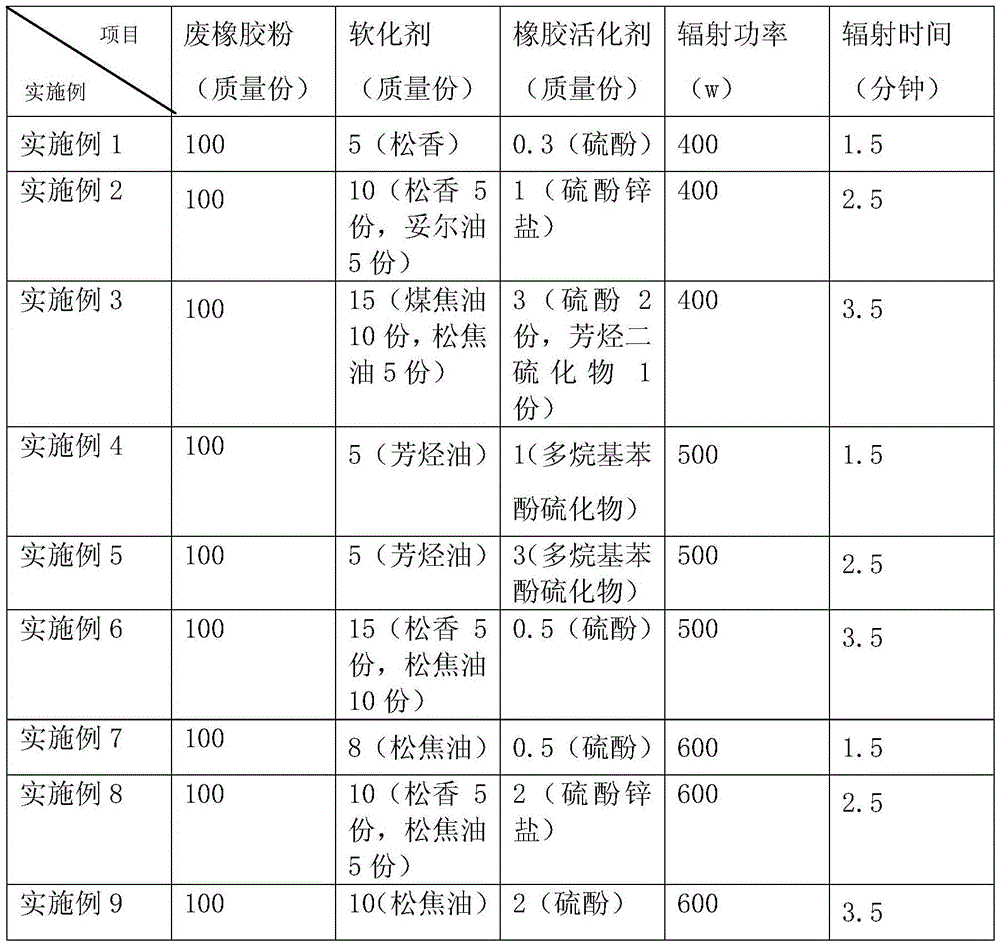

[0033] 1. Preparation of catalytically activated rubber powder composition

[0034] Prepare the catalytically activated rubber powder composition of Examples 1-9 according to the components listed in Table 1 and their consumption, premix according to the above steps, and carry out under the microwave radiation power and radiation time listed in Table 1 Activation treatment to prepare catalytically activated rubber powder composition.

[0035] Table 1

[0036]

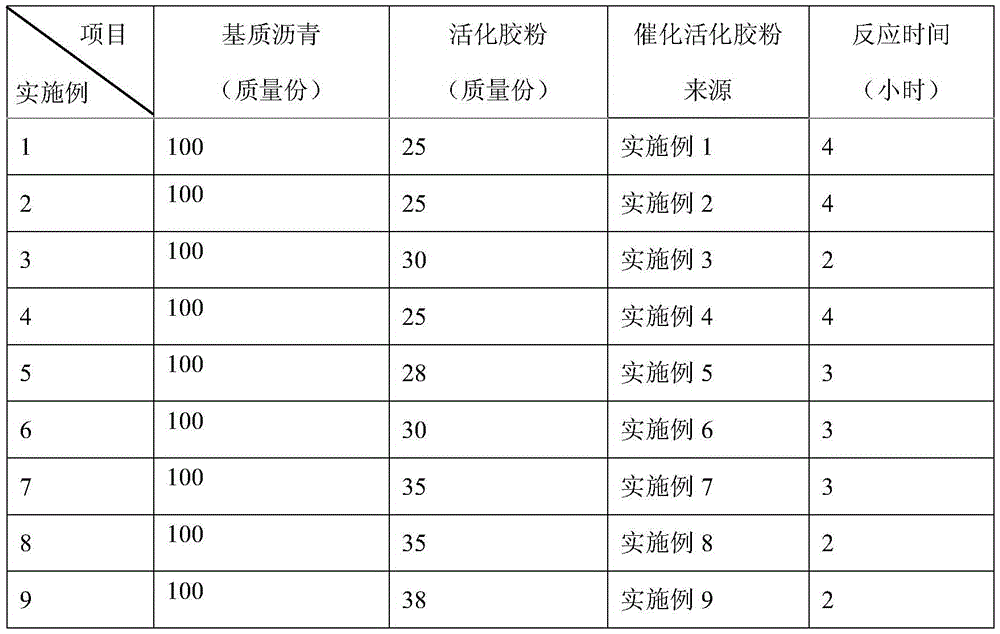

[0037] 2. Preparation of rubber powder modified asphalt

[0038] The modified asphalt was prepared by using the asphalt and the catalytically activated rubber powder composition prepared in Examples 1-9 according to the components and dosages listed in Table 2.

[0039] Table 2

[0040]

[0041] The preparation method of rubber powder modified asphalt is to heat the base asphalt to 185-190°C, add a certain proportion of the catalytically activated rubber powder composition prepared in Examples 1-9 to it, and he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com