Ceramic blank and manufacturing method thereof

The technology of a ceramic body and a manufacturing method, which is applied in the field of ceramics, can solve the problems of poor appearance of the body, non-wear resistance of the ceramic body, and easy aging and cracking, and achieve good surface smoothness, increased hardness, and improved strength. plasticity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

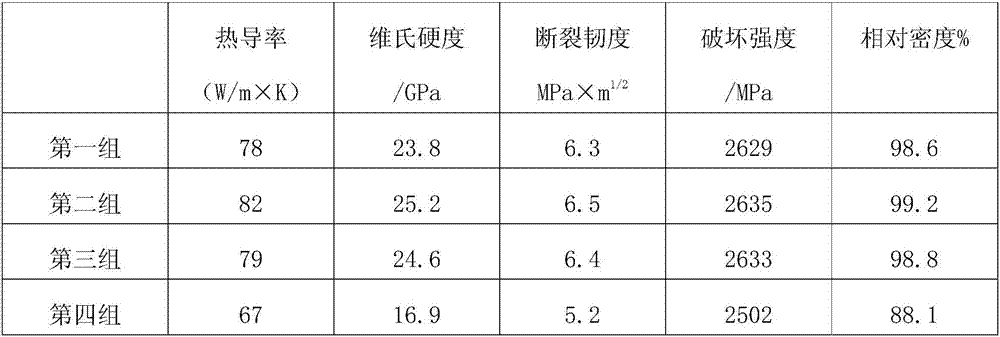

Examples

Embodiment 1

[0039] A kind of ceramic green body provided by the present embodiment comprises 80 parts by weight of basic blanks, 10 parts by weight of reinforcing agents and 1 part by weight of auxiliary agents; wherein, the basic blanks are composed of the following raw materials by weight: 35 parts by weight of diopside , 15 parts of quartz, 10 parts of silicon dioxide, 10 parts of potassium feldspar, 8 parts of zirconium boride, 5 parts of hydroxypropyl methylcellulose, 5 parts of vanadium carbide and 10 parts of absolute ethanol; the reinforcing agent consists of the following parts by weight Composition of raw materials: 30 parts of bentonite, 5 parts of nano silica gel, 5 parts of tungsten disulfide, 5 parts of ABS resin, 1 part of rosin and 1 part of zinc oxide; the auxiliary agent is composed of the following raw materials by weight: 20 parts of aluminum oxide, magnesium oxide 5 parts, talcum powder 10 parts, styrene-butadiene rubber 5 parts and polyethylene glycol 4 parts.

[004...

Embodiment 2

[0056] A kind of ceramic green body provided by the present embodiment comprises 100 parts by weight of a base material, 15 parts by weight of a reinforcing agent and 3 parts by weight of an auxiliary agent; wherein, the base material consists of the following raw materials by weight: 45 parts by weight of diopside , 18 parts of quartz, 12 parts of silicon dioxide, 12 parts of potassium feldspar, 10 parts of zirconium boride, 7 parts of hydroxypropyl methylcellulose, 6 parts of vanadium carbide and 18 parts of absolute ethanol; the reinforcing agent consists of the following parts by weight Composition of raw materials: 38 parts of bentonite, 7 parts of nano-silica gel, 7 parts of tungsten disulfide, 7 parts of ABS resin, 3 parts of rosin and 3 parts of zinc oxide; the auxiliary agent is composed of the following raw materials by weight: 28 parts of aluminum oxide, magnesium oxide 8 parts, talcum powder 15 parts, styrene-butadiene rubber 10 parts and polyethylene glycol 6 parts...

Embodiment 3

[0073] A kind of ceramic green body provided by the present embodiment comprises 120 parts by weight of base material, 20 parts by weight of reinforcing agent and 5 parts by weight of auxiliary agent; wherein, the base material is made up of the following raw materials by weight: 65 parts by weight of diopside , 20 parts of quartz, 15 parts of silicon dioxide, 15 parts of potassium feldspar, 12 parts of zirconium boride, 10 parts of hydroxypropyl methylcellulose, 8 parts of vanadium carbide and 25 parts of absolute ethanol; the reinforcing agent consists of the following parts by weight Composition of raw materials: 45 parts of bentonite, 10 parts of nano silica gel, 10 parts of tungsten disulfide, 10 parts of ABS resin, 5 parts of rosin and 5 parts of zinc oxide; the auxiliary agent is composed of the following raw materials by weight: 35 parts of aluminum oxide, magnesium oxide 12 parts, 20 parts of talcum powder, 15 parts of styrene-butadiene rubber and 7 parts of polyethyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com