Preparation method of mulberry leaf oolong tea

A production method and technology of oolong tea, applied in tea treatment before extraction, etc., can solve the problems of insufficient aroma and sweetness of oolong tea, different process parameters, and large differences in contents, etc. Reaction, soup color yellow-green bright effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

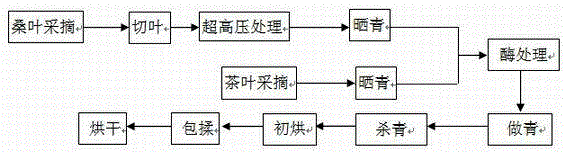

Image

Examples

Embodiment Construction

[0010] Follow the steps below to make mulberry leaf oolong tea:

[0011] (1) In the morning when the weather is fine, pick 20kg of mulberry leaves in the 3rd to 5th leaf positions that are free from pests and diseases and pollution-free.

[0012] (2) Remove the stems from the mulberry leaves, and cut them into strips about 2 cm wide and 3 cm long.

[0013] (3) Ultra-high pressure treatment: The mulberry leaves are vacuum-packed and placed in an ultra-high pressure container, and treated at a temperature of 25-30°C and a pressure of 500Mpa for 12 minutes.

[0014] (4) A total of 5kg of tea leaves were picked from 2-4 leaves.

[0015] (5) Sun-drying: spread the tea leaves and mulberry leaves after ultra-high pressure treatment on a bamboo sieve, and dry them until the leaves are soft and lose about 15% of their weight. The drying time is about 2 hours.

[0016] (6) Enzyme treatment: mix immobilized cellulase (50000U / g), pectinase (100000U / g), papain (200000U / g) at a mass rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com