Machining method and machining device of bi-metal roller sleeve and bi-metal roller sleeve

A processing method and processing device technology, applied in the field of bimetal roll sleeves, can solve the problems of incomplete bonding, gaps in the bonding layer, impurities in the bonding layer, etc., and achieve the effects of complete bonding, uniform fusion transition layer, and good mutual penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Please refer to Figure 1 to Figure 3 , the processing method of a kind of bimetal roll sleeve of present embodiment, this processing method comprises the following steps:

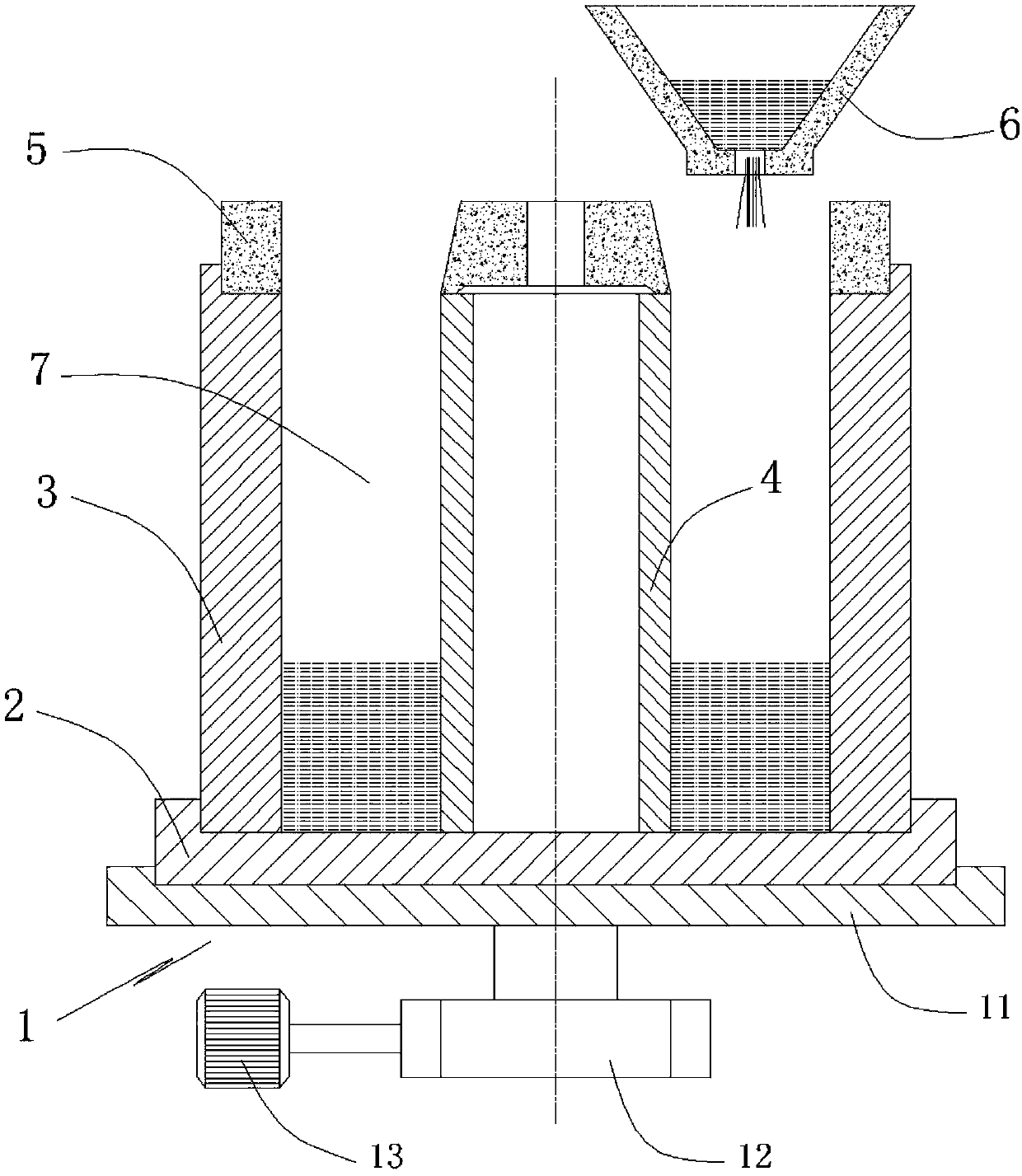

[0047] The rotating mechanism 1, the casting base plate 2 and the outer steel mold 3 for processing the bimetal roll sleeve are prepared in advance, the casting base plate 2 is fixed on the rotating mechanism 1, and the outer steel mold 3 is installed on the casting base plate 2. Wherein, the rotating mechanism 1 includes a turntable 11 , a reducer 12 and a motor 13 , the turntable 11 drives the casting base plate 2 to rotate under the drive of the motor 13 , and the speed of rotation can be adjusted by the reducer 12 .

[0048] Fix the inner steel core 4 on the casting base plate 2, form a casting space 7 between the inner steel core 4 and the outer steel mold 3, place the casting sand mold 5 on the outer steel mold 3 and the inner steel core 4, adjust the casting cup 6 position so that the liquid...

Embodiment 2

[0057] Please refer to Figure 4 to Figure 6 , a processing device for a bimetallic roll sleeve of the present embodiment is used in the processing method described in Embodiment 1. The processing device includes: a rotating mechanism 1, a casting base plate 2, an outer steel mold 3 and a casting cup 6, and the rotating mechanism 1 is fixedly installed at a predetermined location, the casting bottom plate 2 is detachably embedded on the rotating mechanism 1, and the outer steel mold 3 is detachably installed on the casting bottom plate 2. Wherein, the rotating mechanism 1 includes a turntable 11 , a reducer 12 and a motor 13 , the turntable 11 drives the casting base plate 2 to rotate under the drive of the motor 13 , and the speed of rotation can be adjusted by the reducer 12 .

[0058] The position of the casting cup 6 is adjustable and erected above the outer steel mold 3. When casting, an inner steel core 4 is fixed on the casting bottom plate 2, and the position of the ca...

Embodiment 3

[0065] Please refer to Figure 7 to Figure 9, a kind of bimetallic roll sleeve of this embodiment is made by using the processing method described in Embodiment 1. The bimetallic roll sleeve includes: an inner steel core 4 and a roll jacket 8, and the inner steel core 4 is a prefabricated ordinary steel pipe. The roll jacket 8 is a high-speed steel alloy jacket cast-in-place on the outside of the inner steel core 4 . When the roll jacket 8 is cast-in-place, the molten alloy steel and the molten steel on the outer wall of the inner steel core 4 infiltrate each other to form a molten transition layer 9 .

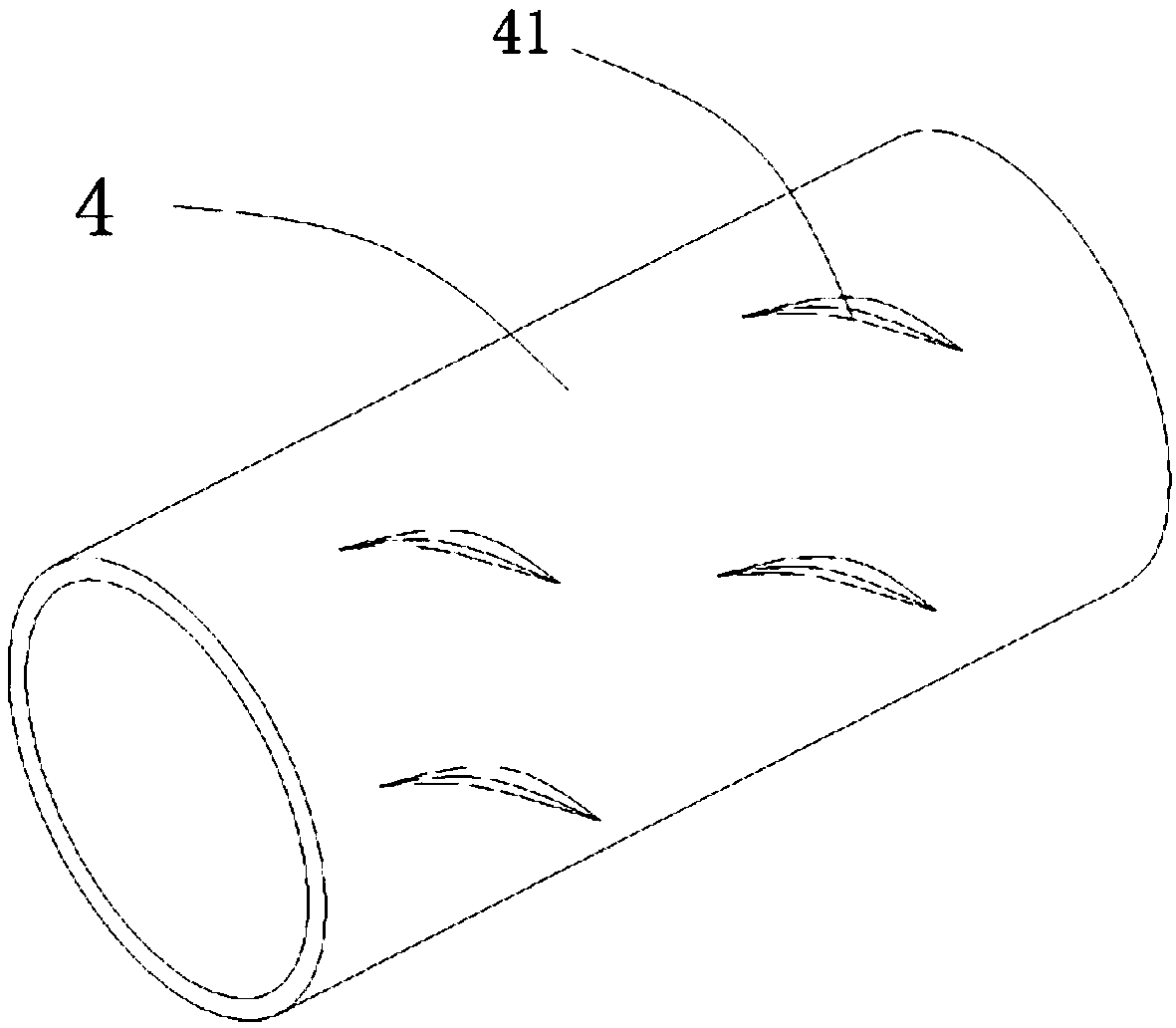

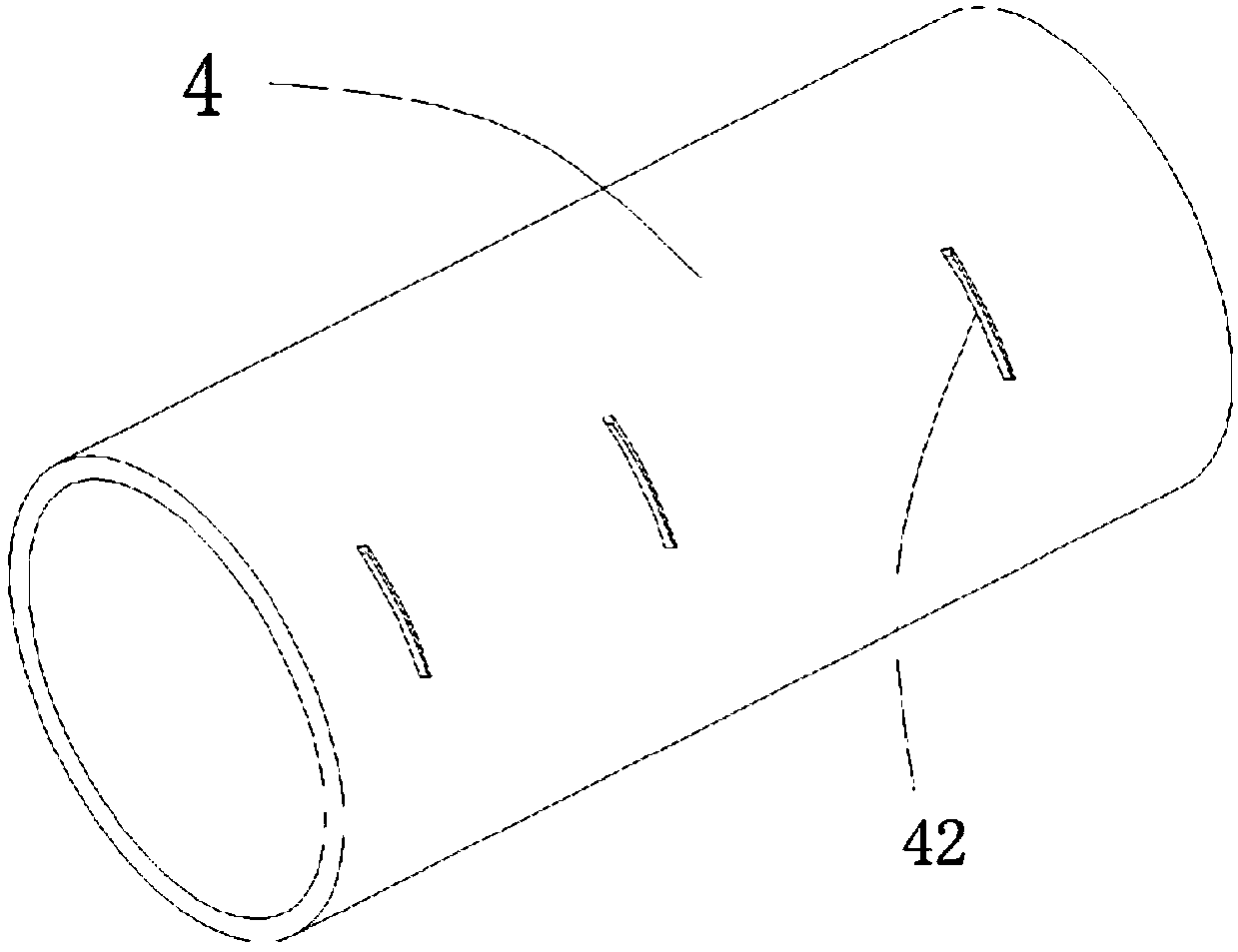

[0066] Preferably, the outer peripheral surface of the inner steel core 4 is provided with convex ribs 41 or grooves 42, and the protruding height of the convex ribs 41 is 1 / 30-1 / 20 of the wall thickness of the inner steel core 4, or the concave depth of the groove 42 It is 1 / 30-1 / 20 of the wall thickness of the inner steel core 4.

[0067] Still preferably, the roll jacket 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com