Forging method of high-temperature alloy fine-grained bars

A high-temperature alloy and fine-grained technology, which is applied in the field of forging, can solve problems such as insufficient carbide crushing, single deformation direction, and bar grain growth, so as to save strategic alloy resources, refine grain size, and grain size. The effect of uniform and fine tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

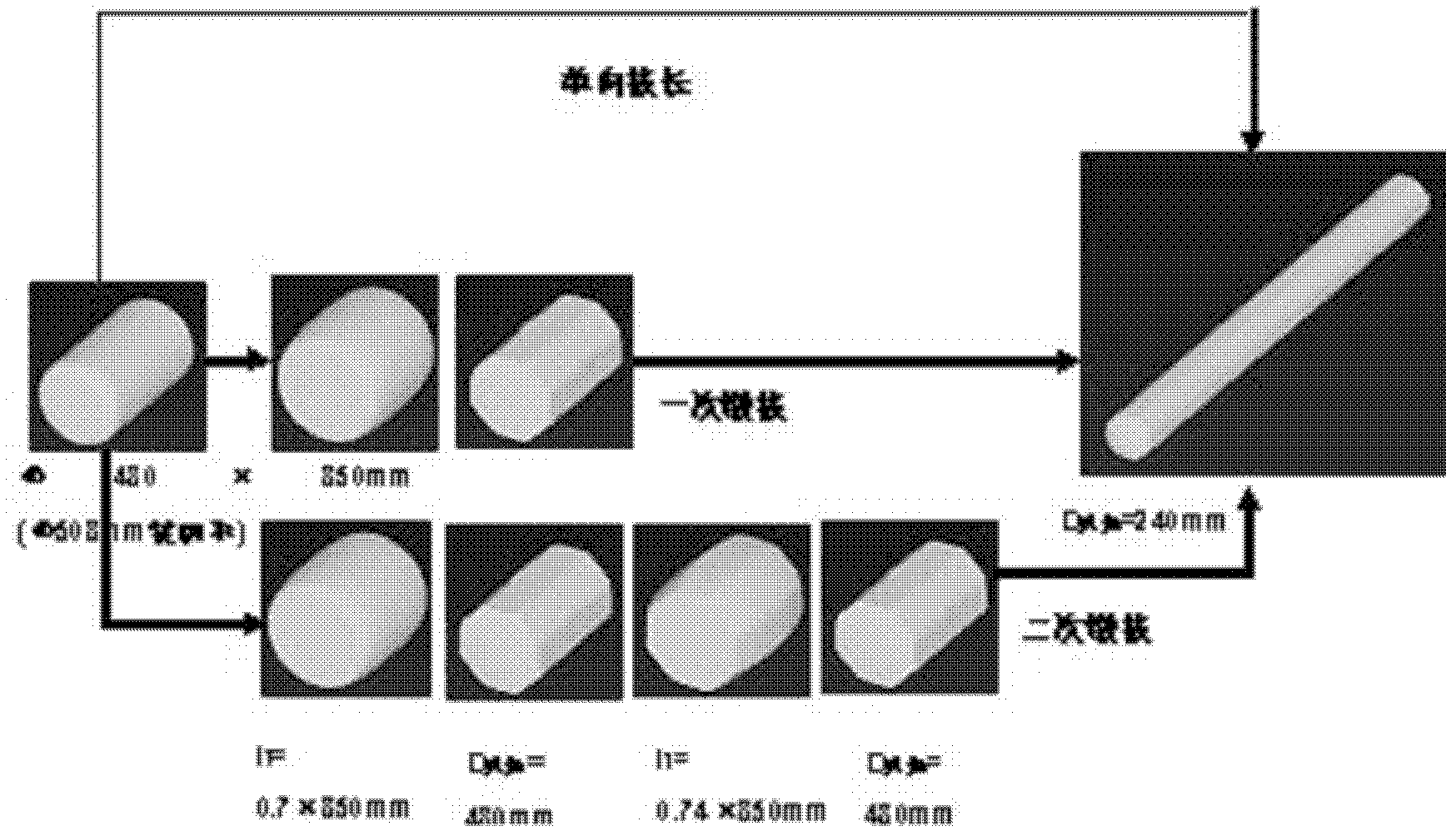

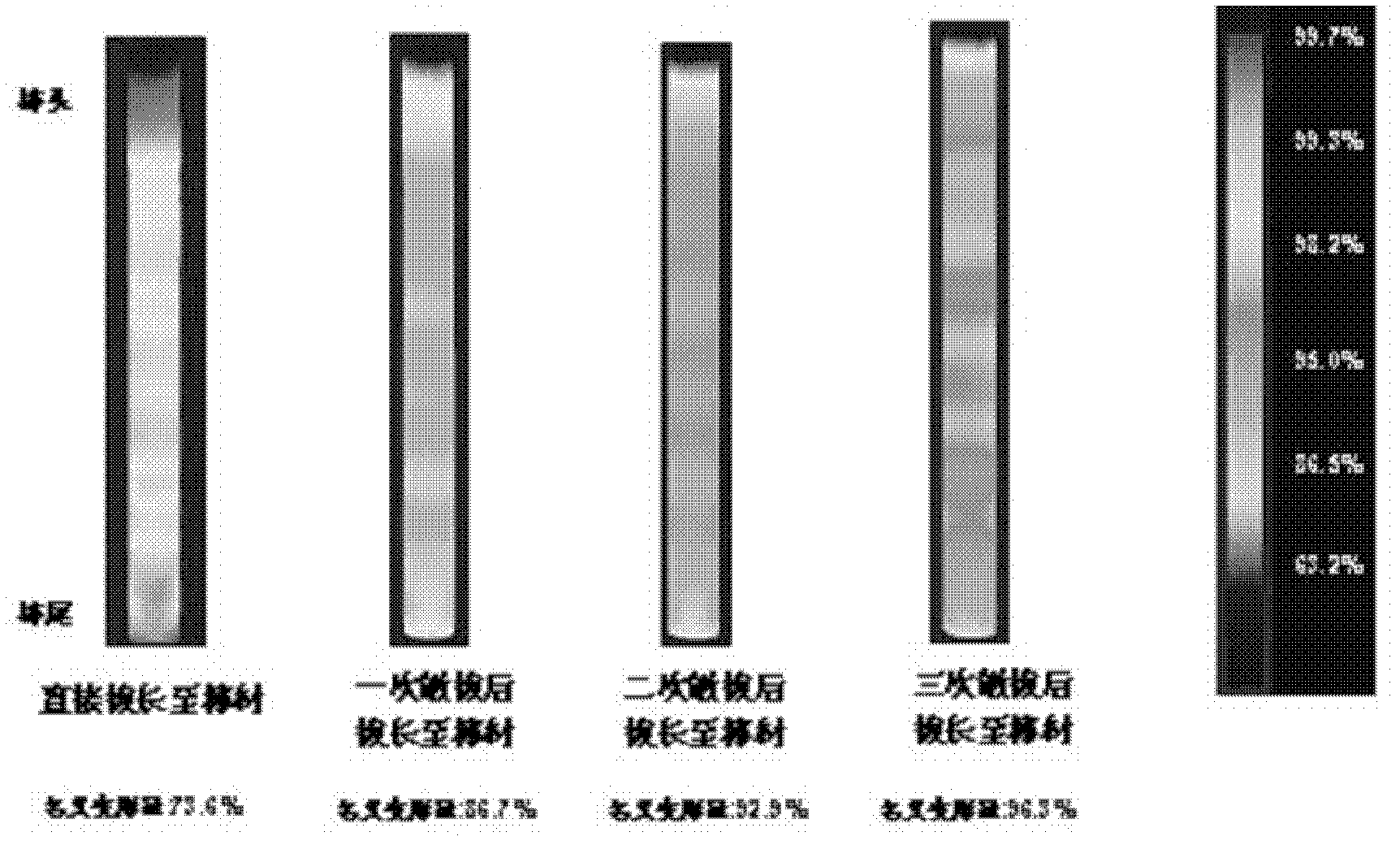

[0026] In the present invention, GH4169 alloy fine-grained rods are prepared by means of combined forming by upsetting, drawing and diameter forging. figure 1 shown. The Φ508mm GH4169 alloy ingot is vacuum induction melted (VIM)+vacuum consumable remelted (VAR) unidirectionally elongated bar, the surface is polished to Φ480mm, and the bar is drawn to Φ240mm in the fast forging machine; The bar blanked by upsetting and drawing process is Φ508mm GH4169 alloy ingot of VIM+VAR, the surface is polished to Φ480mm, and it is drawn to the original length after one-time upsetting with 30% deformation. After a second upsetting with 30% deformation, it is pulled out to the original length. Then continue unidirectional drawing to Φ240mm bar. figure 2 It is the finite element numerical calculation result of the relationship between multiple upsetting and drawing and deformation, which shows that the nominal value of the three billet opening methods is one-way drawing, one-time upsetting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com