Patents

Literature

42 results about "Oxide dispersion-strengthened alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxide dispersion strengthened alloys (ODS) consist of a metal matrix with small oxide particles dispersed within it. They are used for high temperature turbine blades and heat exchanger tubing. Alloys of nickel are the most common but work is being done on iron aluminum alloys. ODS steels are used in nuclear applications.

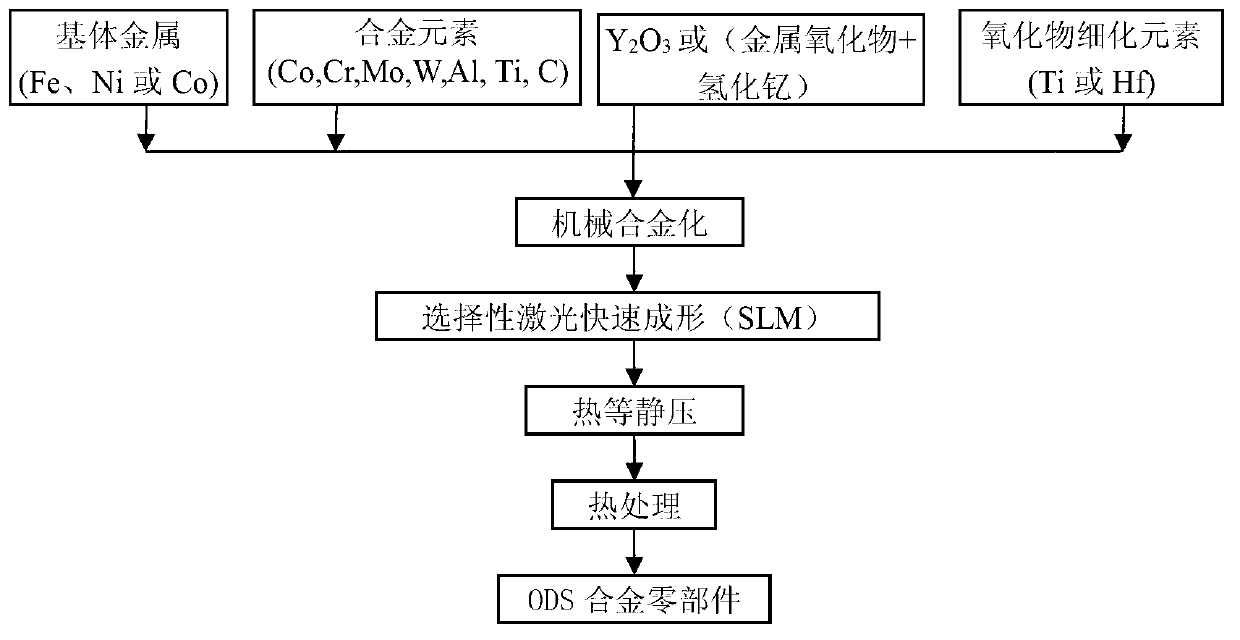

Method for preparing oxide dispersion strengthened alloy by rapid forming

InactiveCN103008657AHigh densitySmall particle sizeAdditive manufacturingIncreasing energy efficiencyOxide dispersion-strengthened alloySoftware design

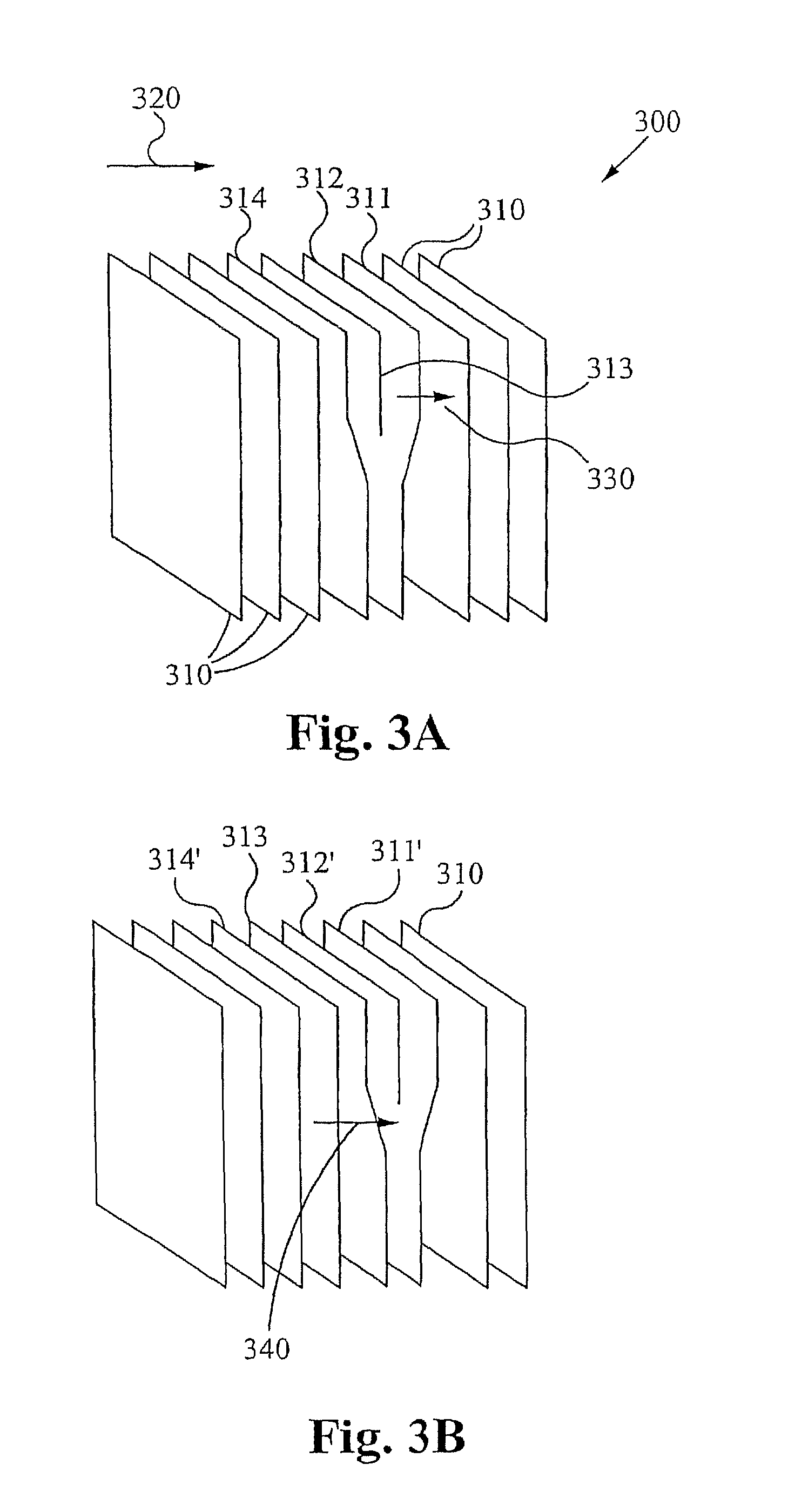

The invention belongs to the technical field of high-temperature alloy near net shape forming and discloses a method for preparing oxide dispersion strengthened alloy by rapid forming. The method includes: using the mechanical alloying process to obtain oxide dispersion strengthened alloy powder, using CAD (computer-aided design) software to design a three-dimensional solid model of an ODS (oxide dispersion strengthened) alloy part, subjecting the three-dimensional model to layering and slicing to disperse the three-dimensional model into a series of two-dimensional layers, smelting the ODS alloy powder layer by layer according to slicing information to obtain a laser rapidly formed blank in a needed shape, eliminating residue pores in the laser rapidly formed blank by means of hot isostatic pressing, and optimizing structure property by means of subsequent annealing or solid solution and aging heat treatment to obtain an ODS alloy part in a complex shape. Wrap packaging or fixture moulds are not needed, the complexity of shapes of parts is unlimited, and alloy components and structures are easy to control. The prepared ODS alloy is small in oxide dispersed phase, and products are high in compactness and excellent in comprehensive mechanical property.

Owner:UNIV OF SCI & TECH BEIJING

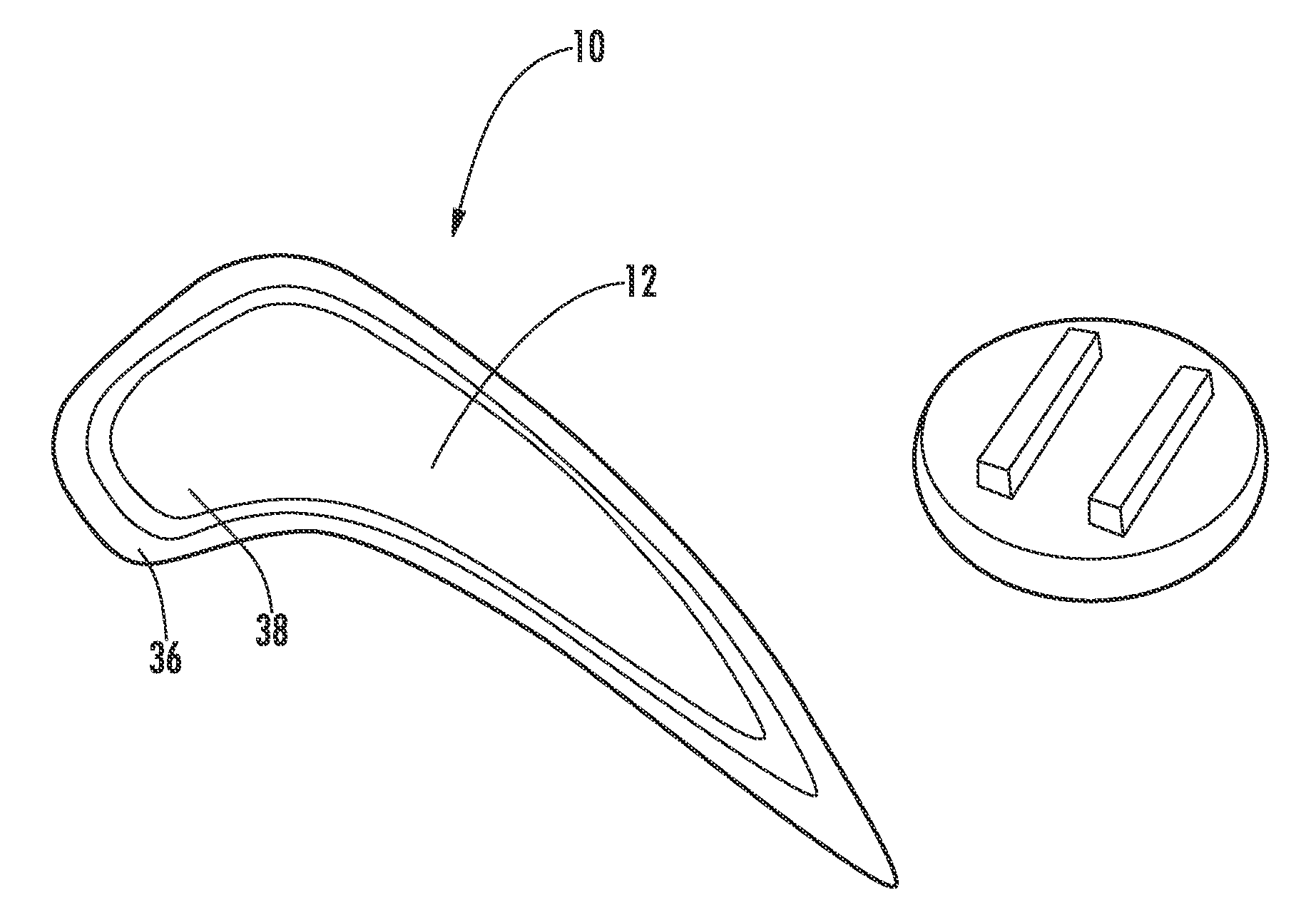

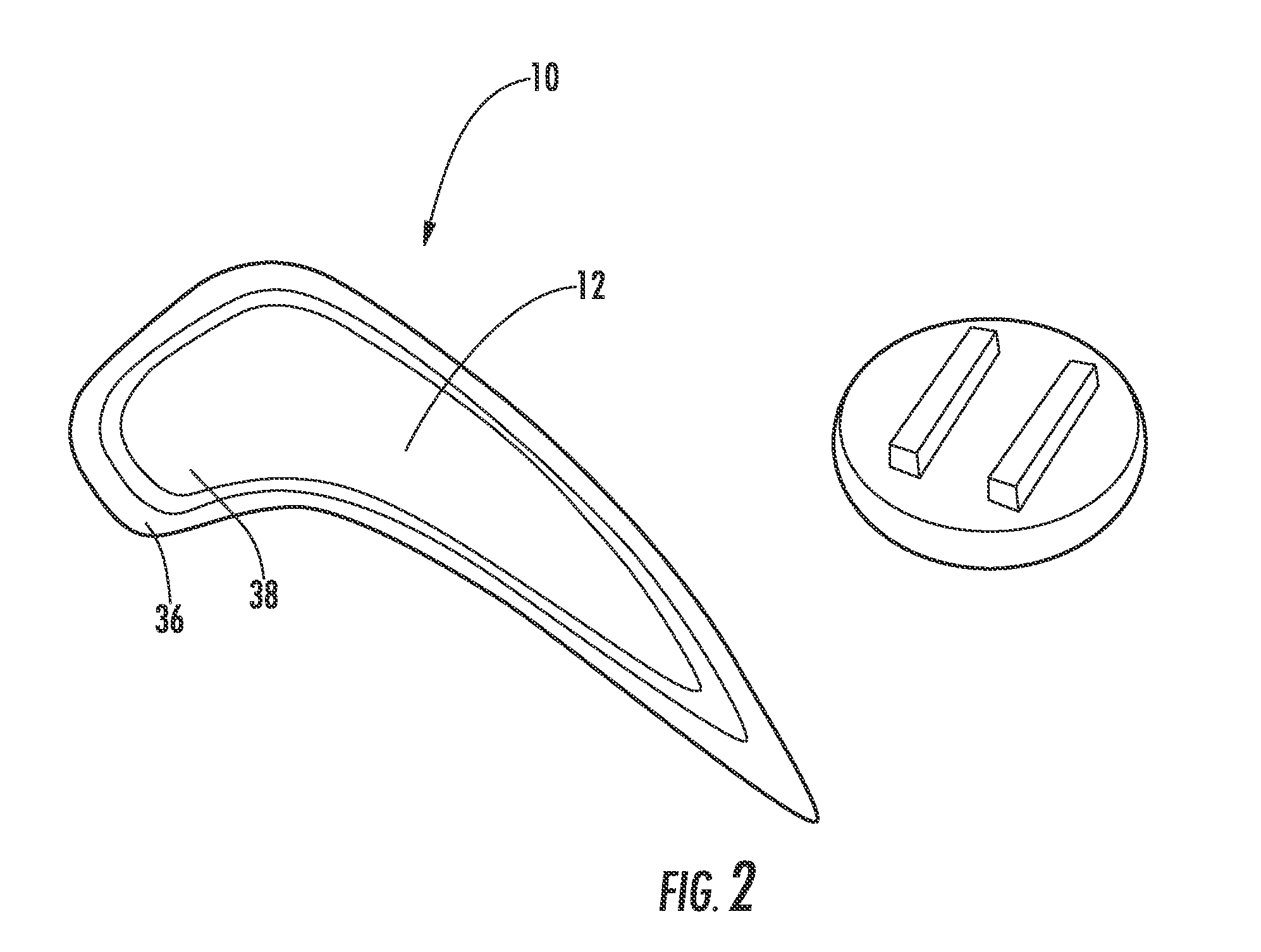

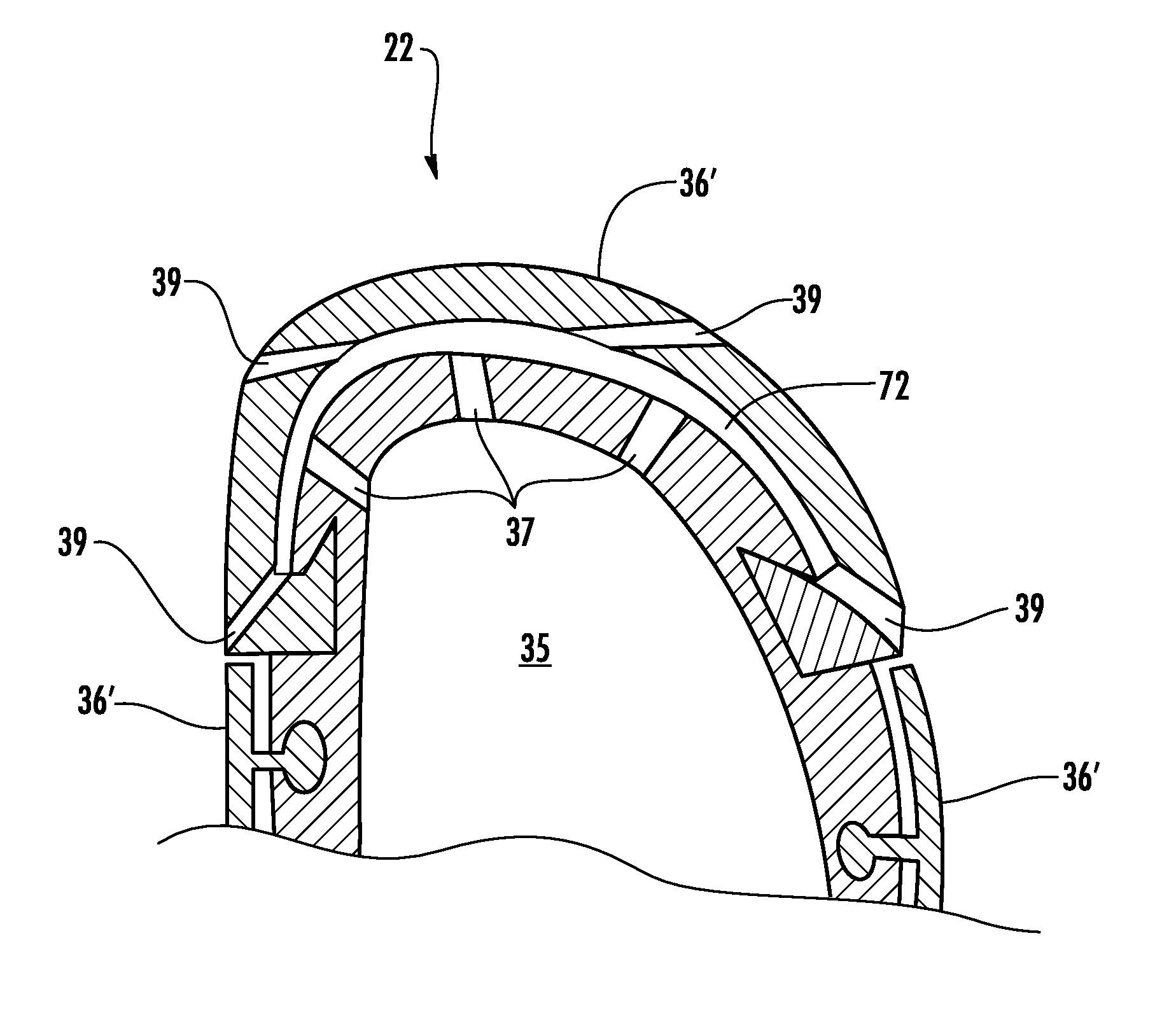

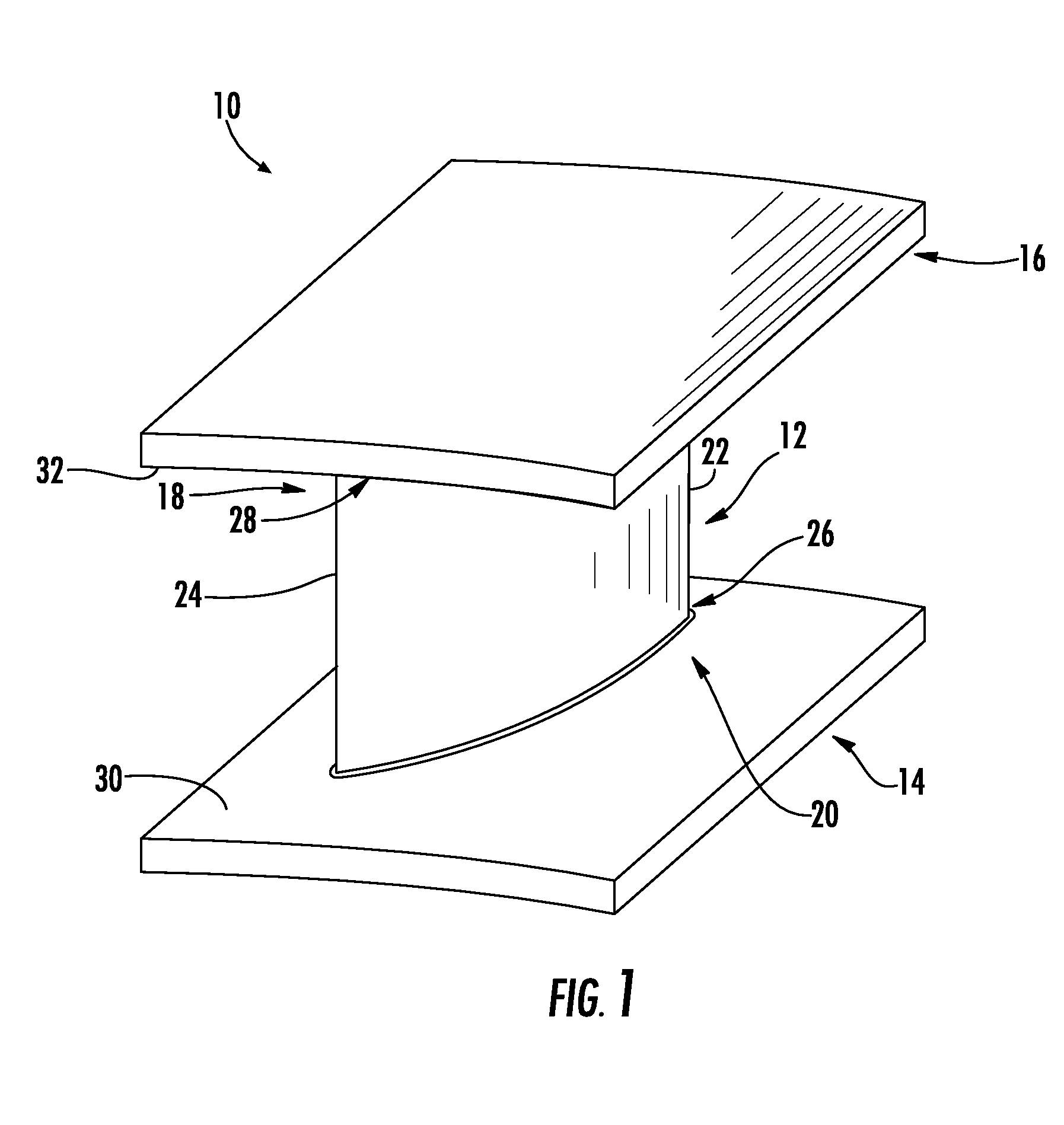

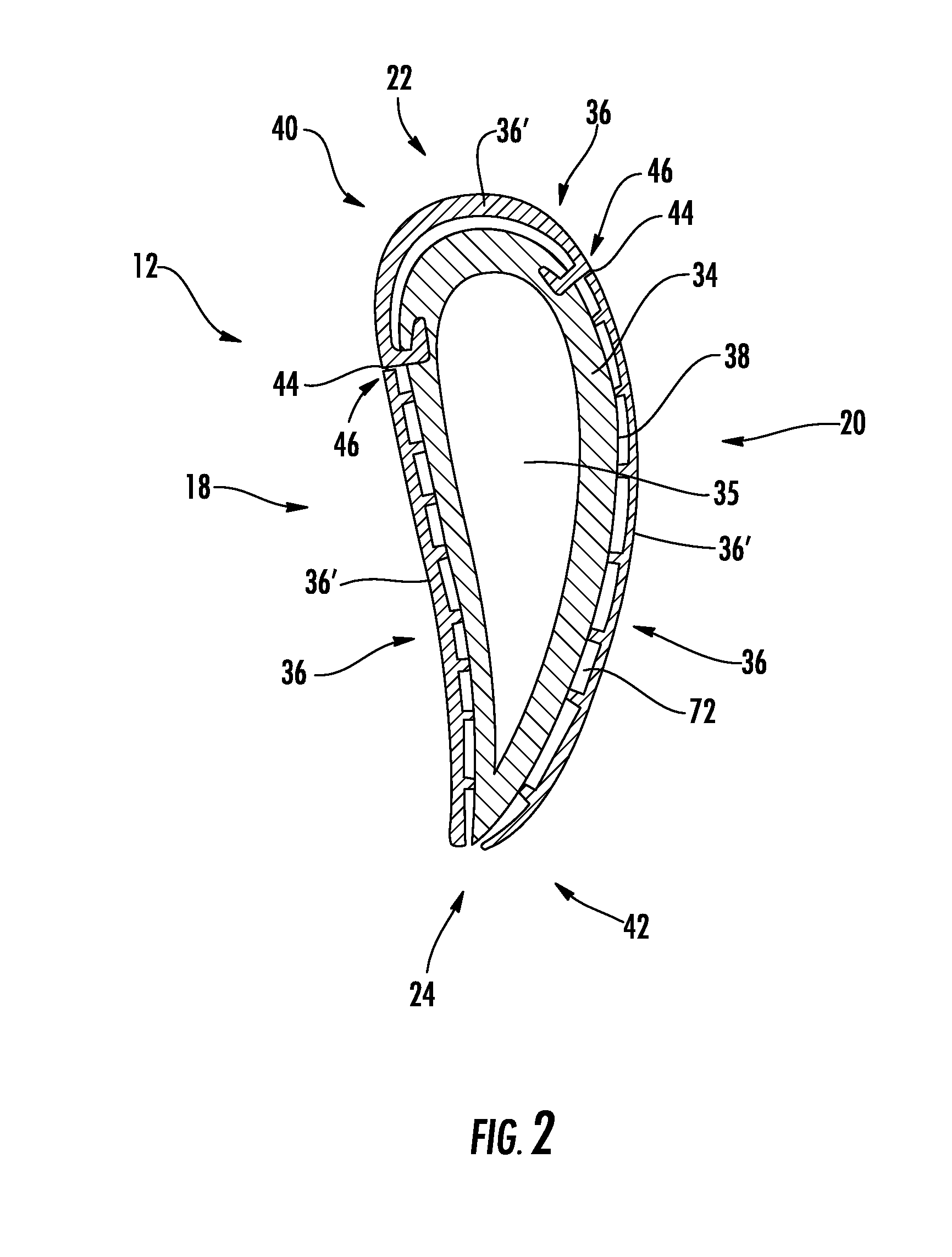

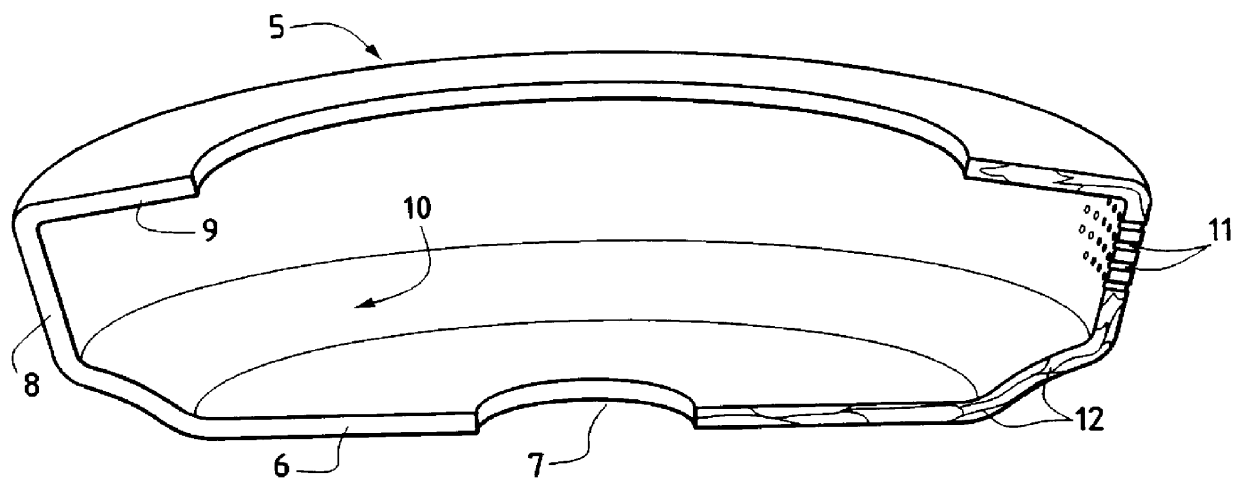

Turbine blade squealer tip

InactiveUS20120034101A1Improve efficiencyLess cooling fluidsPropellersRotary propellersSelective laser meltingMulti material

A turbine blade having a squealer tip coupled to a radially outer end of the turbine blade that is usable in a gas turbine engine is disclosed. The squealer tip may require less cooling air and may therefore be more efficient than conventional configurations. The squealer tip may be formed from one or more materials such as oxide dispersion strengthened alloys and FeCrAl alloys. The squealer tip may be formed from a plurality of segmented tips extending radially outward and spaced apart from each other. For example, the squealer tip may be formed from two rails extending radially outward and spaced apart from each other. The two rails may be formed from outer and inner rails that each form a continuous ring. The squealer tip may be attached to the tip with a transient liquid phase bond or an additive manufacturing process, such as, a selective laser melting process.

Owner:SIEMENS ENERGY INC

Methods for forming oxide dispersion-strengthened alloys

ActiveUS20150093279A1TurbinesAdditive manufacturing apparatusOxide dispersion-strengthened alloyVolumetric Mass Density

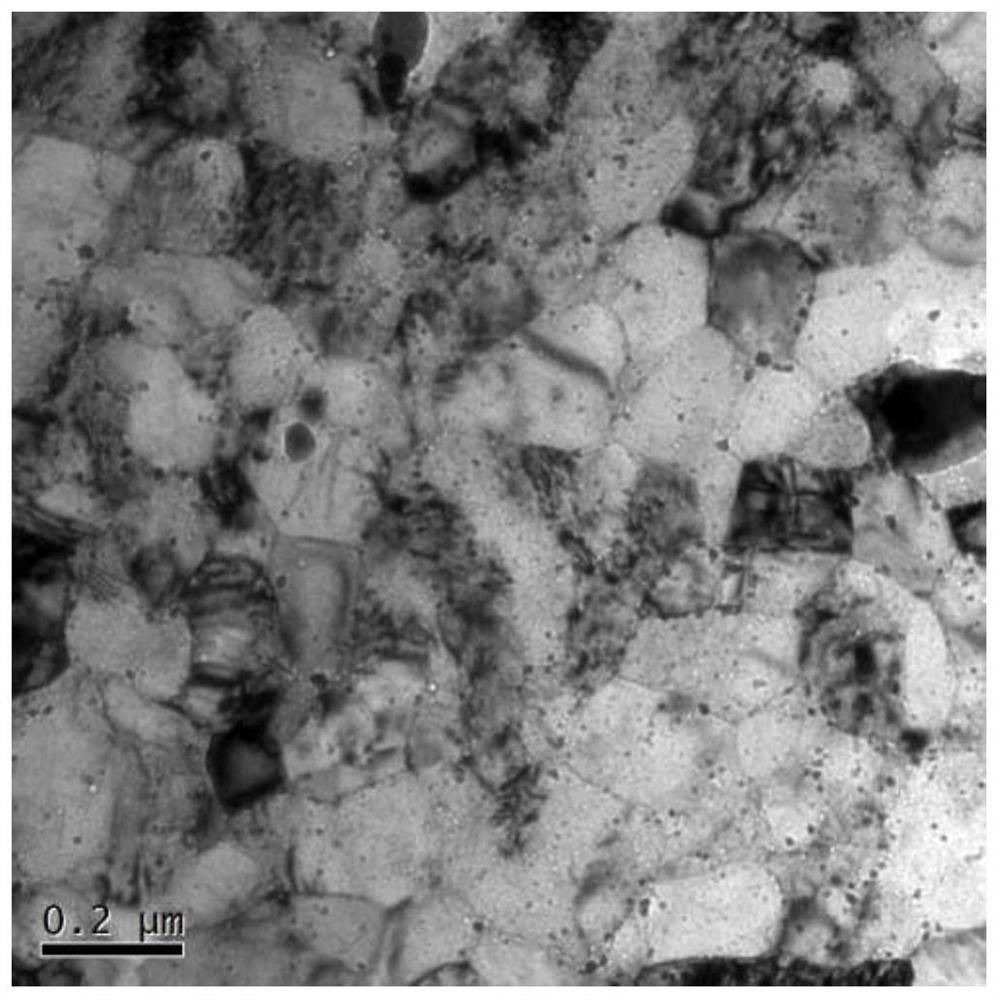

In accordance with an exemplary embodiment, a method of forming a oxide dispersion-strengthened alloy metal includes the steps of providing, in a powdered form, an oxide dispersion-strengthened alloy composition that is capable of achieving a dispersion-strengthened microstructure, directing a low energy density energy beam at a portion of the alloy composition, withdrawing the energy beam from the portion of the powdered alloy composition, and cooling the portion of the powdered alloy composition at a rate greater than or equal to about 106° F. per second, thereby forming the oxide dispersion-strengthened alloy metal.

Owner:HONEYWELL INT INC

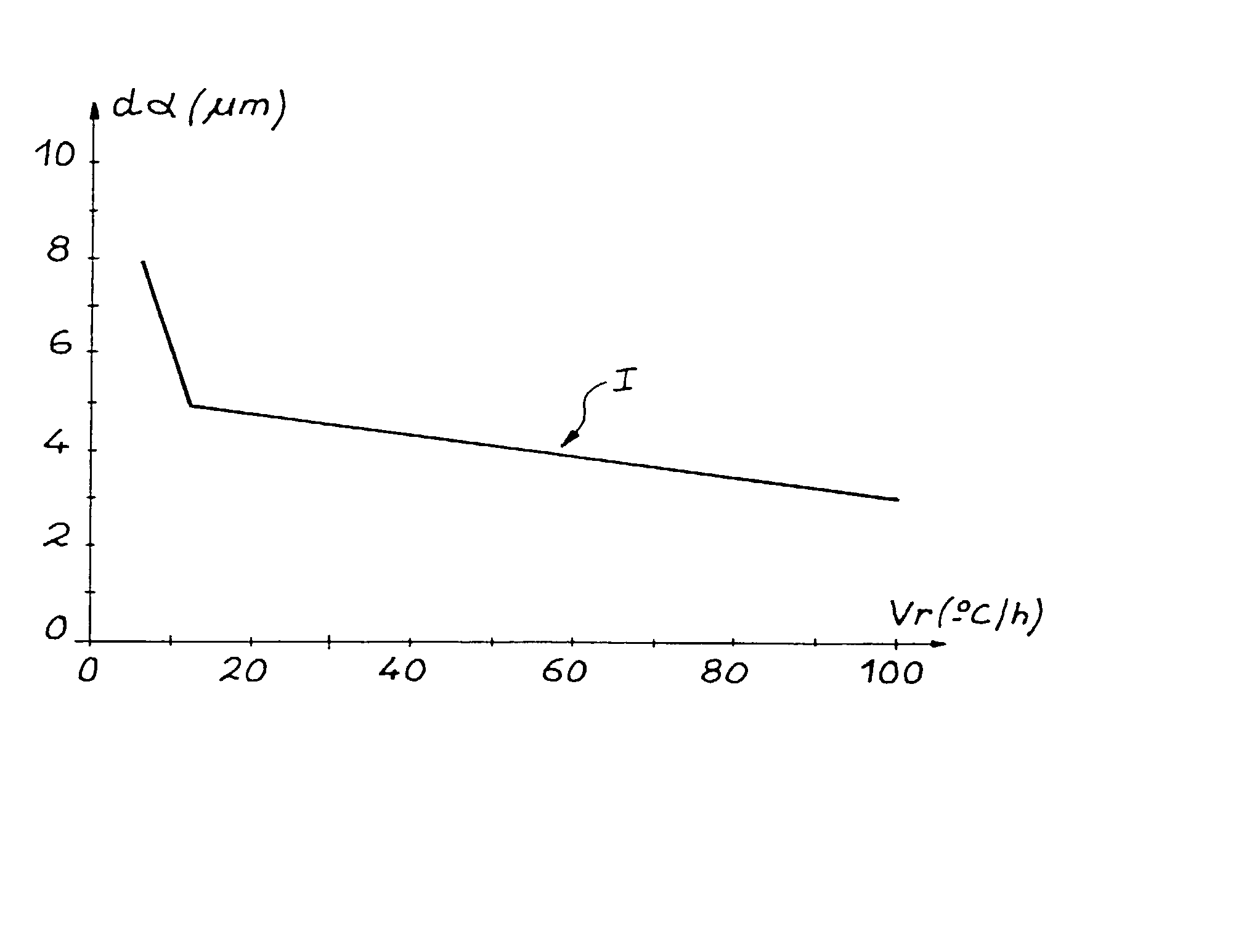

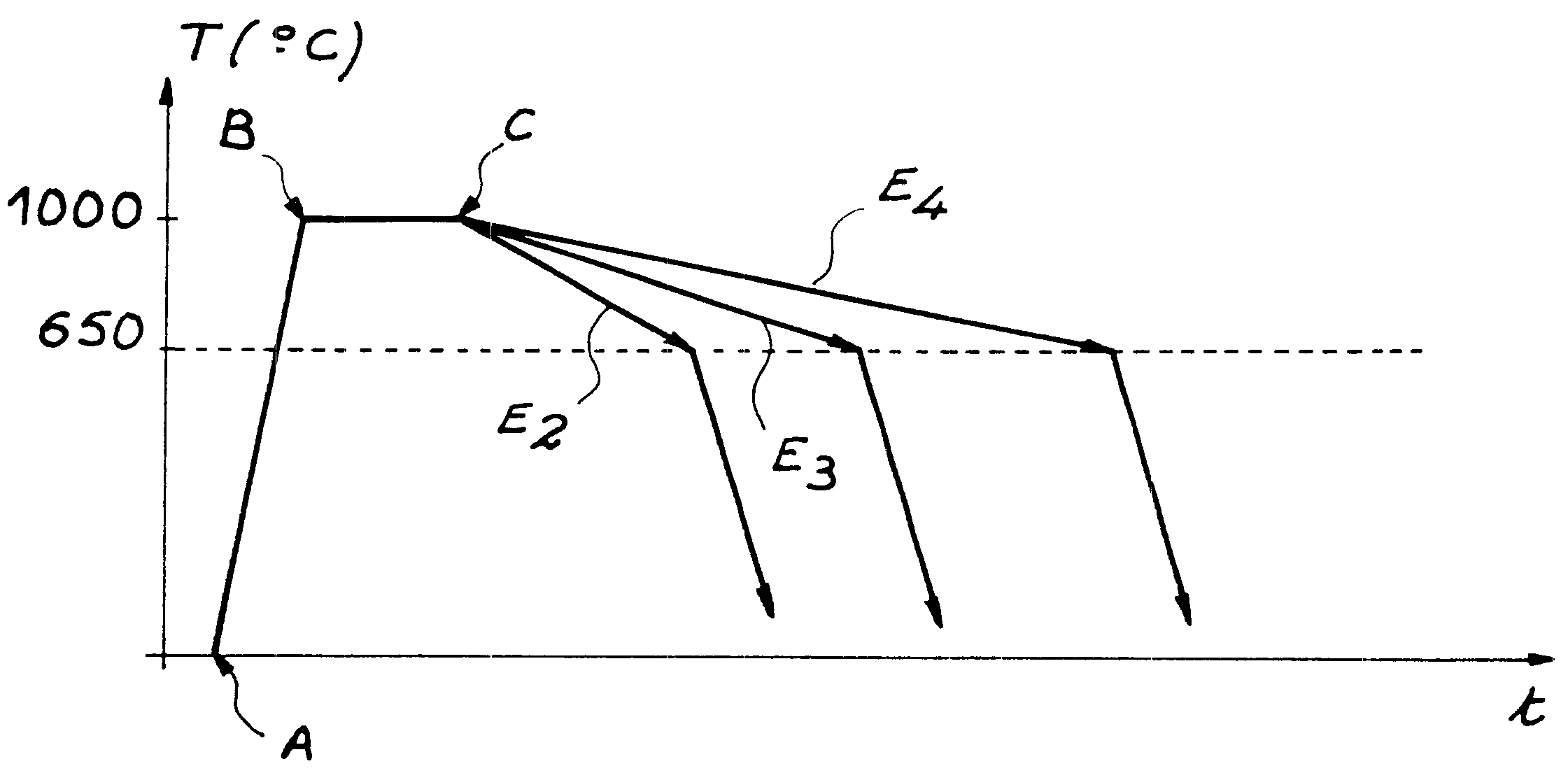

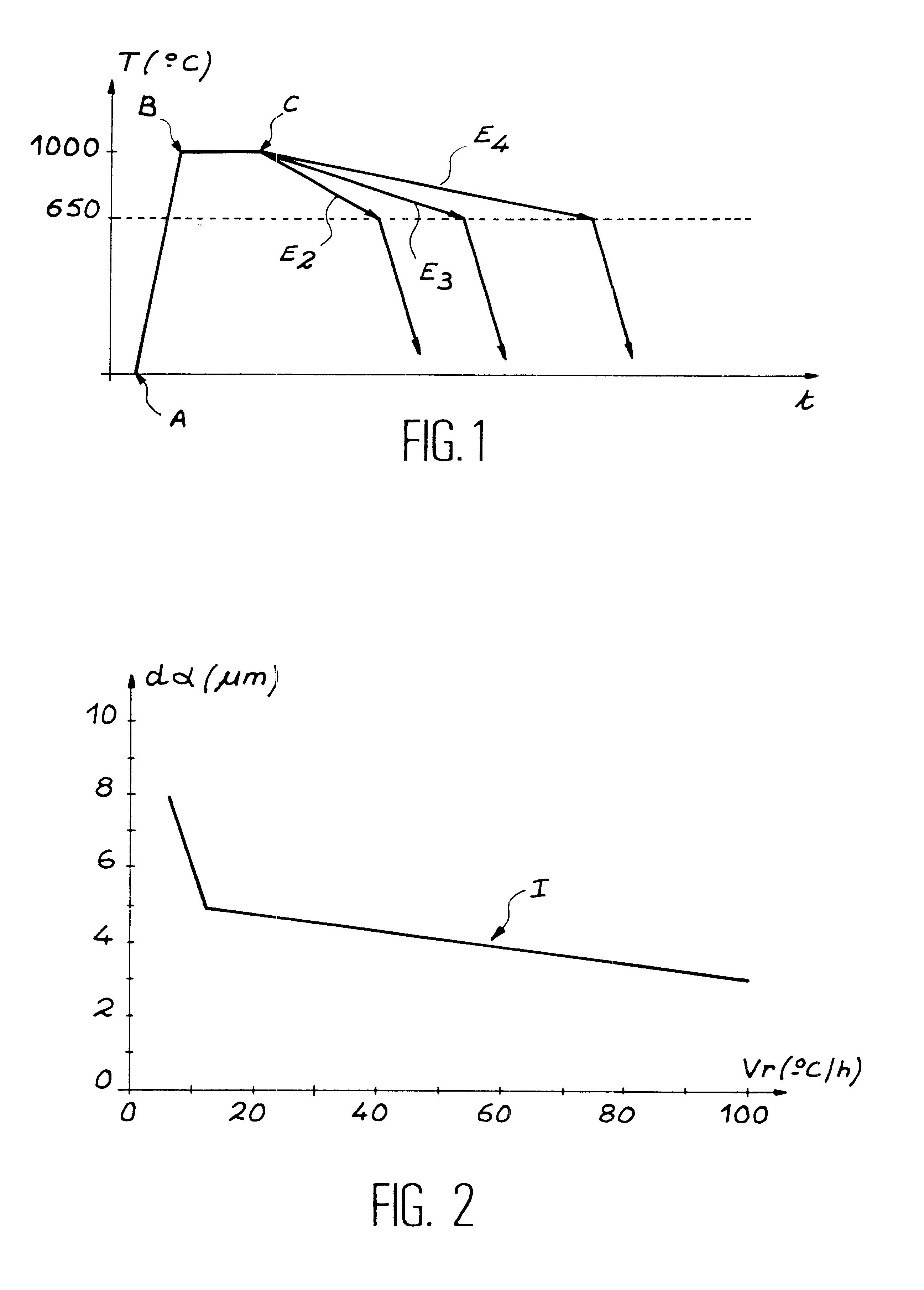

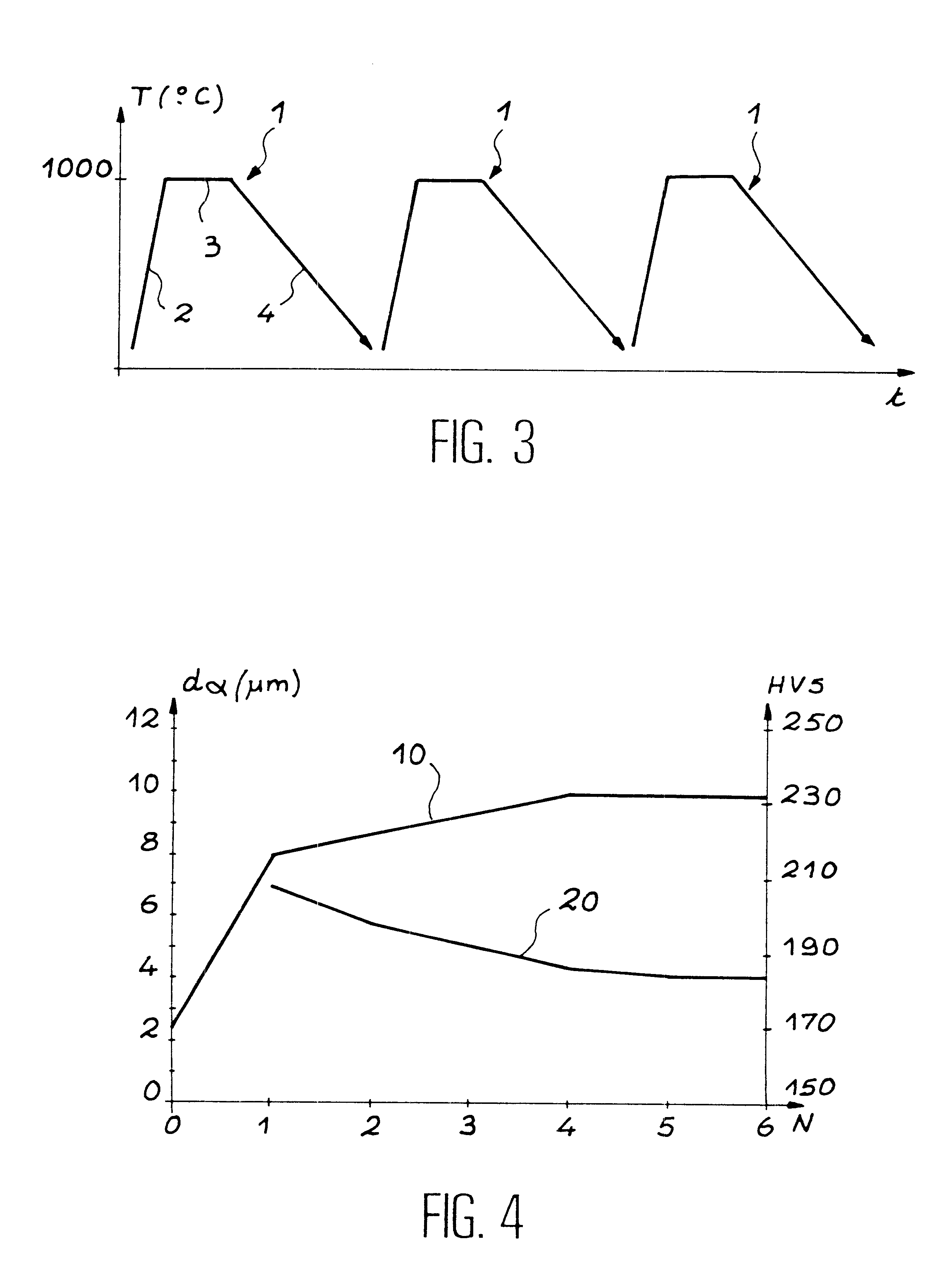

Method of manufacturing a ferritic-martensitic, oxide dispersion strengthened alloy

InactiveUS20030116239A1Optical rangefindersNuclear energy generationNeutron irradiationOxide dispersion-strengthened alloy

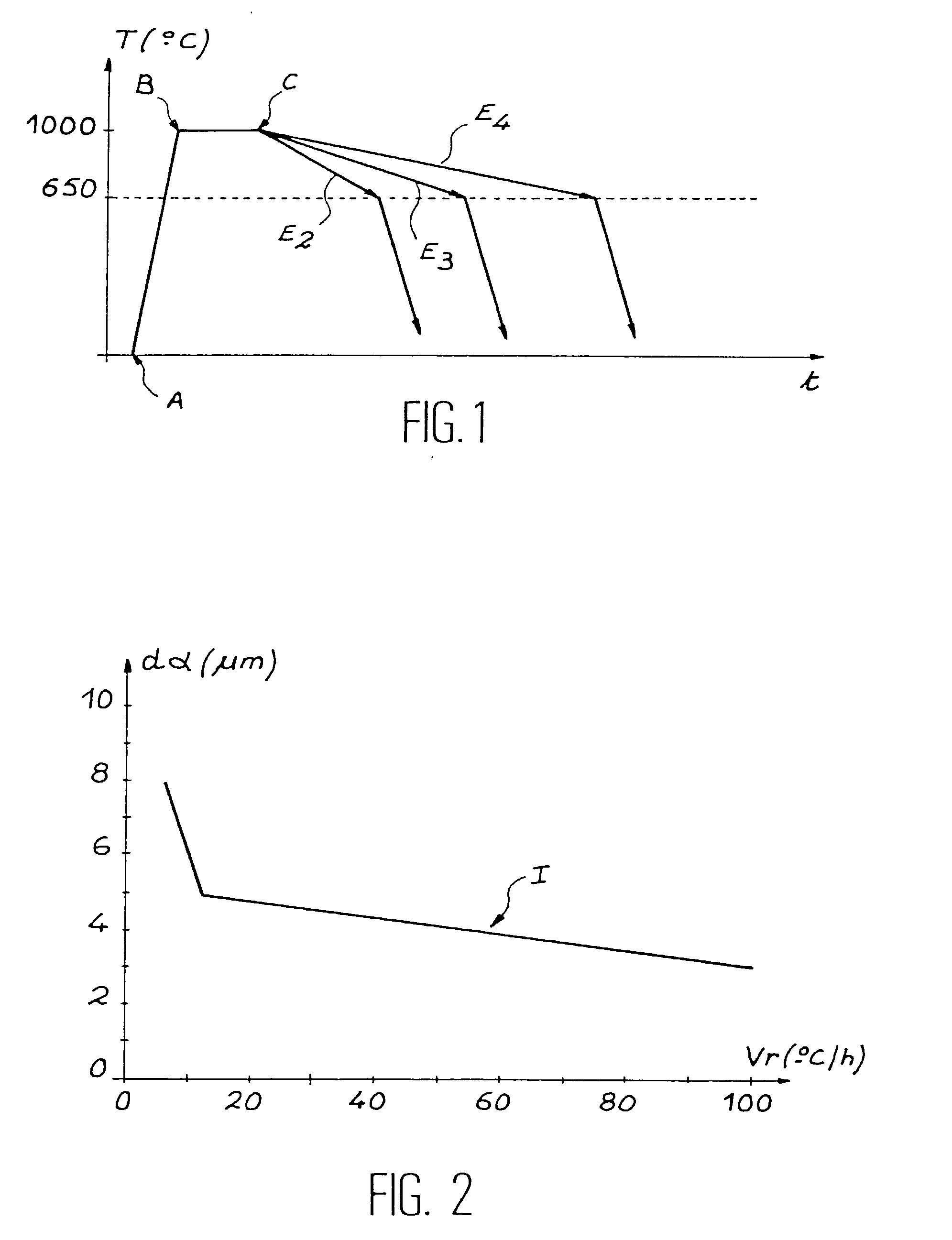

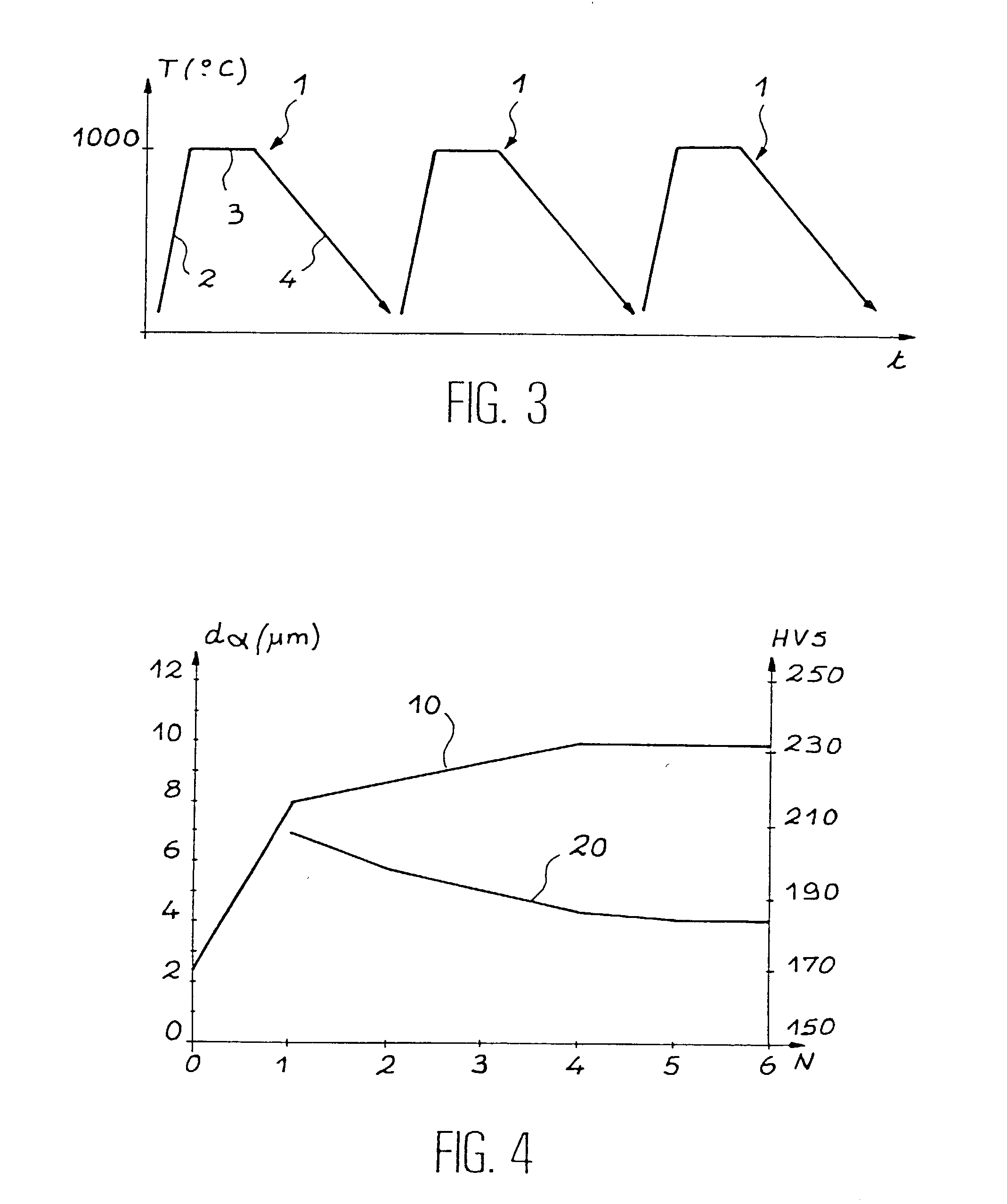

This invention relates to a method of manufacturing an improved ferritic or martensitic alloy based on iron and chromium strengthened by a dispersion of oxides, commonly called an Oxide Dispersion Strengthened or ODS alloy, and, more particularly to a method of manufacturing a ferritic or martensitic ODS alloy with large grains based on iron and chromium which has a single phase ferritic or martensitic matrix having an isotropic microstructure and a grain size that is sufficient to guarantee mechanical strength compatible with a use of this alloy at high temperature and / or under neutron irradiation. According to the invention, the method comprises slow cooling of an austenite at a cooling rate less than or equal to the critical cooling rate for transformation of this austenite into ferrite.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Method of forming oxide dispersion strengthened alloys

ActiveUS8821786B1Optimize allocationMaterial nanotechnologyMolten spray coatingNanoparticleOxide dispersion-strengthened alloy

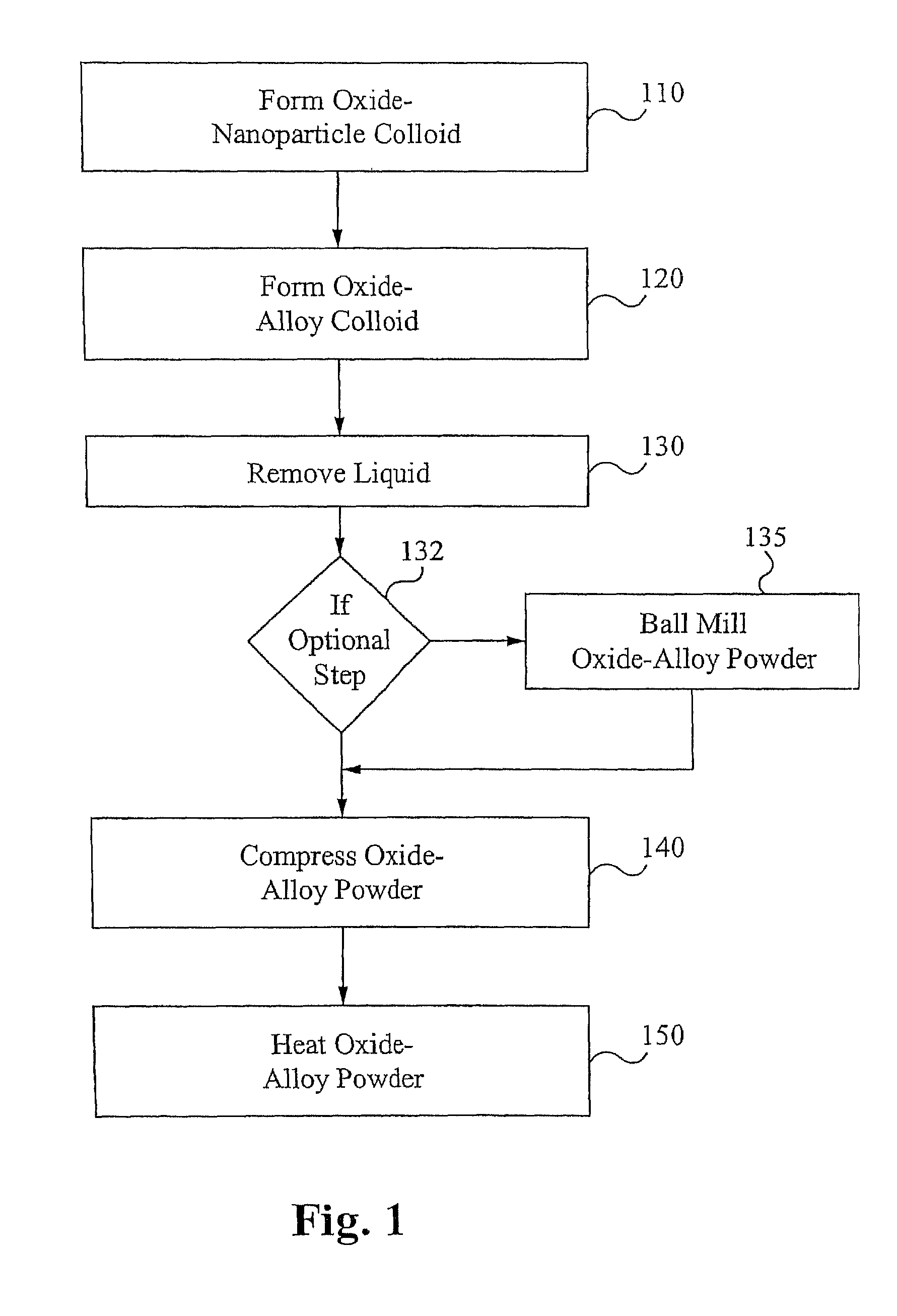

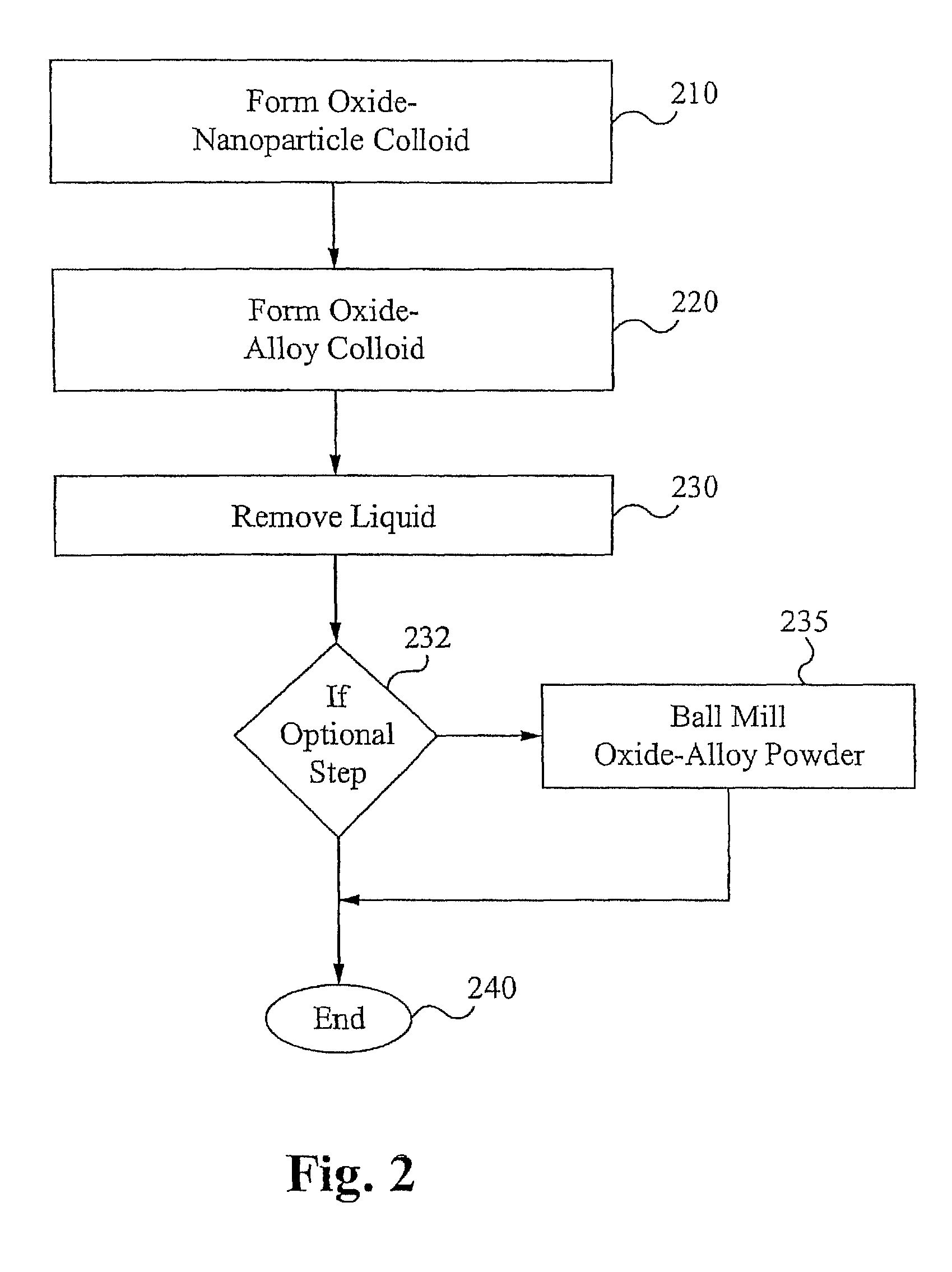

A method of forming an oxide-dispersion strengthened alloy and a method for forming an oxide-alloy powder where the oxide-nanoparticles are evenly distributed throughout the powder. The method is comprised of the steps of forming an oxide-nanoparticles colloid, mixing the oxide-nanoparticles colloid with alloy-microparticles forming an oxide-alloy colloid, drying the oxide-alloy colloid solution to form an oxide-alloy powder, applying pressure to the oxide-alloy powder, and heating the oxide-alloy powder to a sintering temperature. The oxide-nanoparticles are sized to be between 1-10 nanometers in diameter. The ratio of oxide-nanoparticles to alloy-microparticles should be 1-5% by weight. Heating of the oxide-alloy powder can use a spark plasma sintering process.

Owner:SDC MATERIALS +1

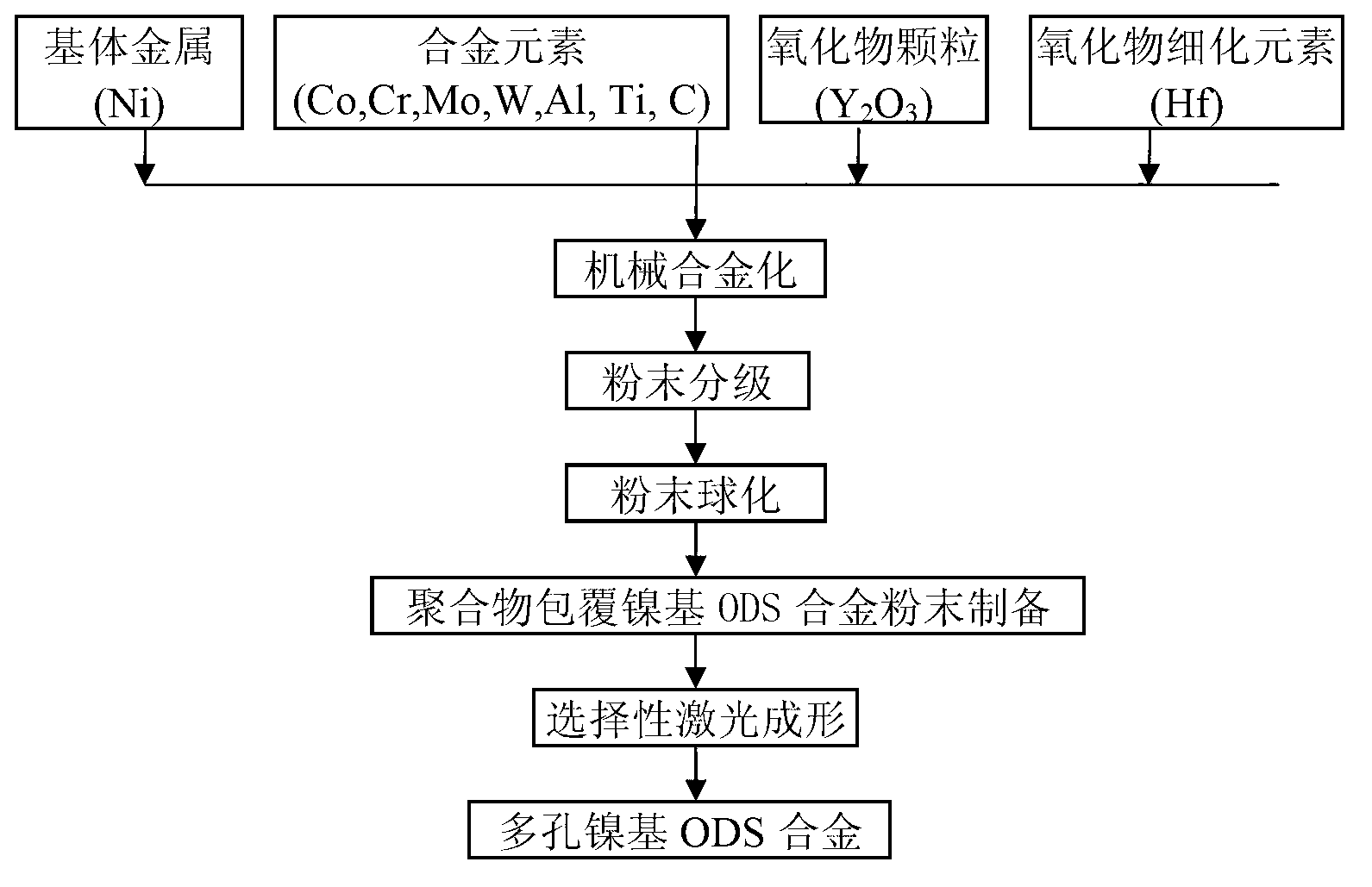

Method for near-net shaping of porous Ni-based ODS (oxide dispersion strengthening) alloy

ActiveCN103060591AIncrease profitNo limit to complexityAdditive manufacturing apparatusIncreasing energy efficiencyKneader reactorOxide dispersion-strengthened alloy

A method for the near-net shaping of a porous Ni-based ODS alloy belongs to the technical field of porous alloy high-temperature preparation. The method comprises the following steps: adopting a mechanical alloyage technology to obtain oxide dispersion reinforced alloy powder, and carrying out grading and plasma spheroidization of Ni-based ODS alloy powder to obtain spherical Ni-based ODS alloy powder having uniform particle sizes; carrying out heating stirring of the Ni-based ODS alloy powder with a thermoplastic polymer in a kneader to obtain polymer coated Ni-based ODS alloy powder; designing a three-dimensional solid model of an Ni-based ODS alloy part through adopting CAD software, carrying out layering slicing treatment of the three-dimensional model to discretize into a series of two-dimensional layers used for the rapid shaping process control; and scanning the Ni-based ODS alloy powder layer by layer according to slice information to obtain a porous Ni-based ODS alloy body. The method is suitable for preparing complex-shape porous metals used under high temperature, corrosion and oxidation resistance conditions, and the porous Ni-based ODS alloy has the characteristics of high high-temeprature strength, and strong porosity and pore size designability.

Owner:UNIV OF SCI & TECH BEIJING

Method of manufacturing a ferritic-martensitic, oxide dispersion strengthened alloy

InactiveUS6485584B1Optical rangefindersFuel elementsNeutron irradiationOxide dispersion-strengthened alloy

This invention relates to a method of manufacturing an improved ferritic or martensitic alloy based on iron and chromium strengthened by a dispersion of oxides, commonly called an Oxide Dispersion Strengthened or ODS alloy, and, more particularly to a method of manufacturing a ferritic or martensitic ODS alloy with large grains based on iron and chromium which has a single phase ferritic or martensitic matrix having an isotropic microstructure and a grain size that is sufficient to guarantee mechanical strength compatible with a use of this alloy at high temperature and / or under neutron irradiation. According to the invention, the method comprises slow cooling of an austenite at a cooling rate less than or equal to the critical cooling rate for transformation of this austenite into ferrite.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

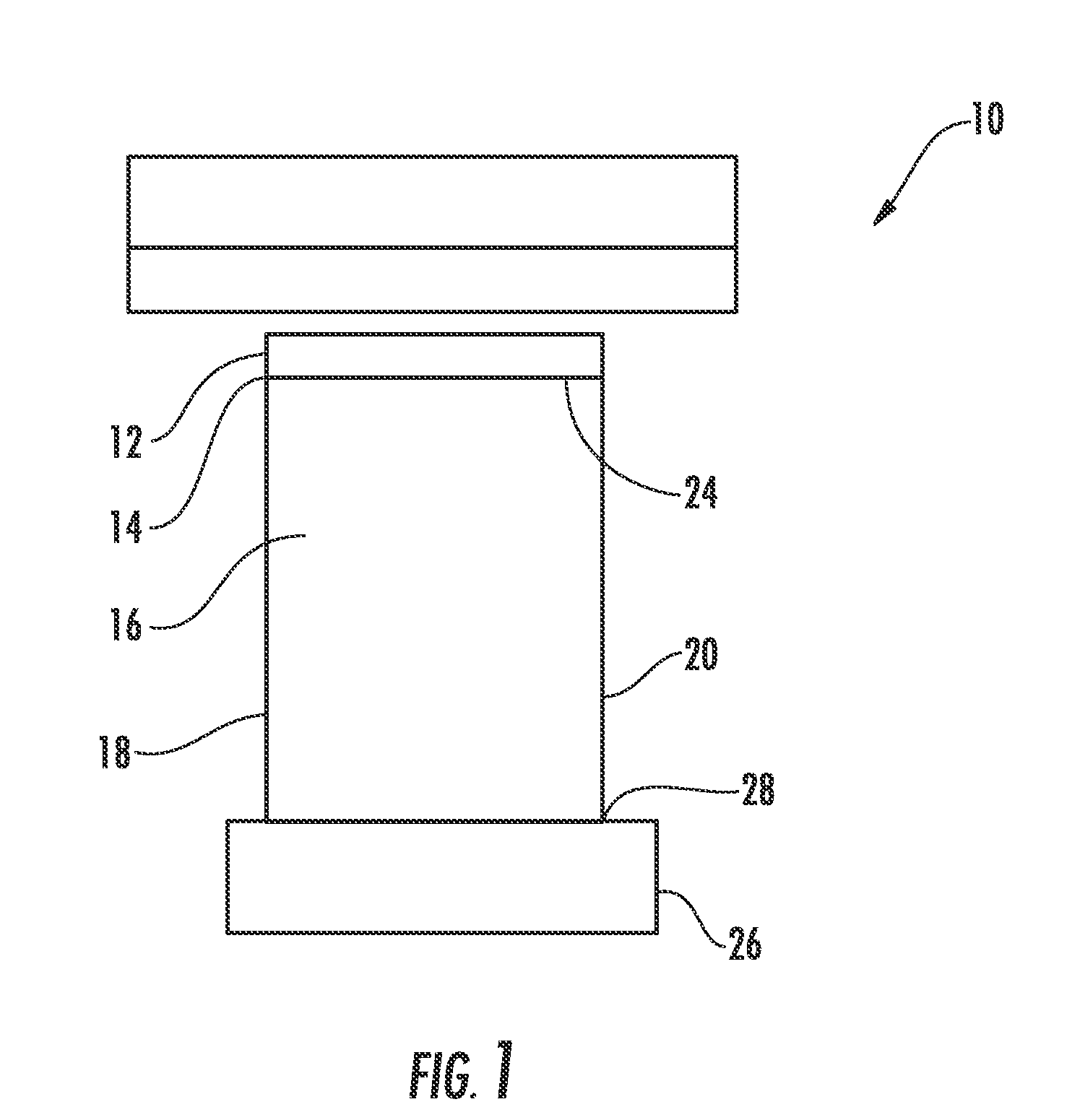

Turbine vane with high temperature capable skins

A turbine vane assembly includes an airfoil extending between an inner shroud and an outer shroud. The airfoil can include a substructure having an outer peripheral surface. At least a portion of the outer peripheral surface is covered by an external skin. The external skin can be made of a high temperature capable material, such as oxide dispersion strengthened alloys, intermetallic alloys, ceramic matrix composites or refractory alloys. The external skin can be formed, and the airfoil can be subsequently bi-cast around or onto the skin. The skin and the substructure can be attached by a plurality of attachment members extending between the skin and the substructure. The skin can be spaced from the outer peripheral surface of the substructure such that a cavity is formed therebetween. Coolant can be supplied to the cavity. Skins can also be applied to the gas path faces of the inner and outer shrouds.

Owner:SIEMENS ENERGY INC

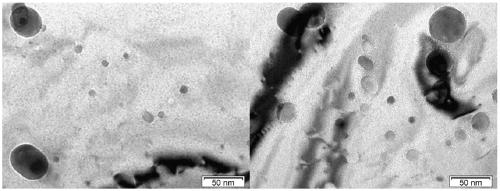

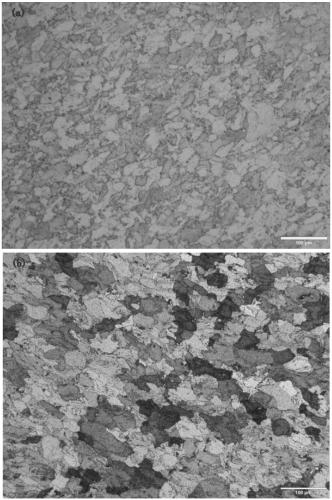

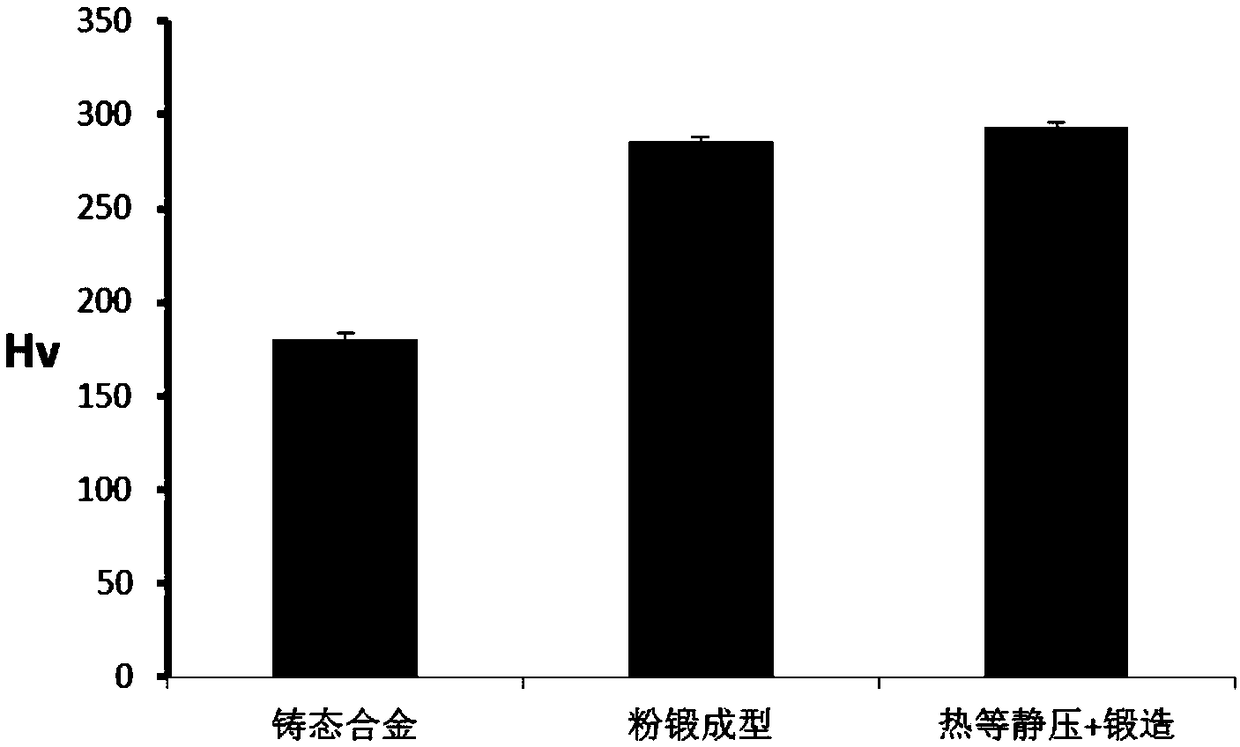

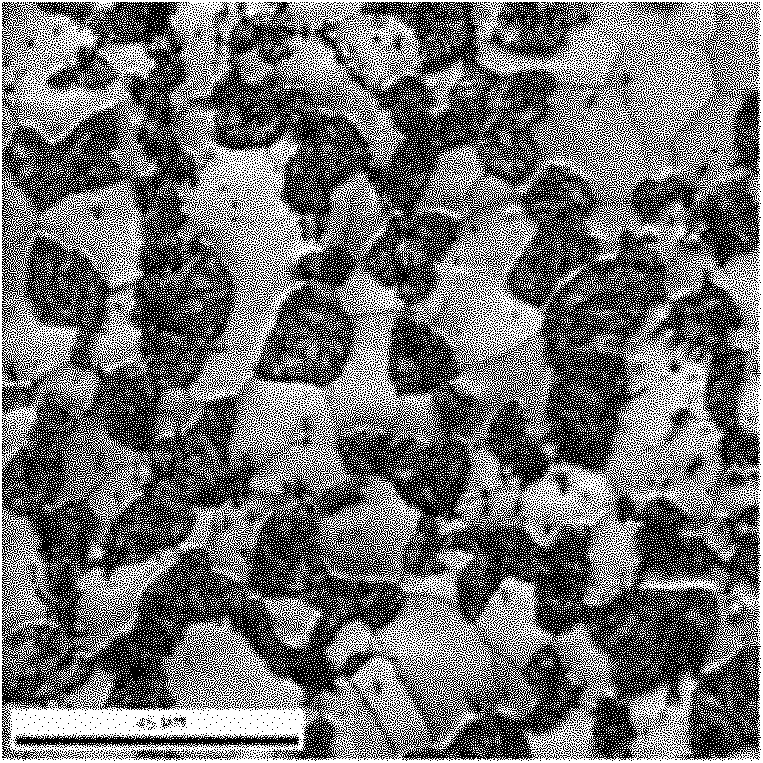

Method for preparing oxide dispersion strengthened alloy through powder forging

The invention aims at providing a preparation method for oxide dispersion strengthened alloy with the advantages that the process is simple; the efficiency is high; the product performance is excellent and stable. The method has the concretely steps of performing pretreatment on alloy powder; charging the alloy powder subjected to pretreatment into a low-carbon steel coating sleeve; after vacuum pumping degassing, performing welding sealing; performing alloy heat curing directly by using a powder forging process; after the coating sleeve is removed, obtaining the oxide dispersion strengthenedalloy with good performance. The alloy has the uniform tissue; fine second phase particles are dispersed and distributed. The alloy pretreatment method comprises the following steps of mixing iron-based or nickel-based pre-alloy powder and 0.1 to 1.0 weight percent of Y2O3 powder; performing mechanical ball milling to obtain yttrium-containing alloy powder; or performing treatment by an inner oxidization method to obtain the yttrium-containing alloy powder. The method directly uses powder forging so that the oxide dispersion strengthened alloy is directly shaped to obtain the oxide dispersionstrengthened alloy with high intensity and good plasticity; the preparation efficiency is greatly improved; the work cost is reduced.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Oxide dispersion-strengthening ferrite steel with bicrystal structure and production method thereof

InactiveCN102127713AImprove toughnessBalance strengthOxide dispersion-strengthened alloyRoom temperature

The invention relates to oxide dispersion-strengthening ferrite steel with a bicrystal structure, compirisng the following components of Cr, W, Ti, Y2O3 and the balance of Fe. A preparation method of the oxide dispersion-strengthening ferrite steel with the bicrystal structure comprises the following steps of: uniformly mixing Fe-Cr-W prealloy powder and ball milled powder according to a certain proportion; placing the mixed powder into a steel capsule for degassing and seal welding; then thermally canned-forging, solidifying and molding; and carrying out thermal treatment. The ferrite steel with excellent mechanical property at room temperature and high temperature can be produced through mixing powders in different proportions and controlling on solidifying and molding as well as the following thermal treatment. Oxide dispersion-strengthening alloy produced by the invention has the characteristic of the bicrystal structure, and the structure can simultaneously give the alloy higher strength and excellent toughness. The efficiency for producing the oxide dispersion-strengthening ferrite steel can be increased effectively, the process cost can be greatly saved, and the oxide dispersion-strengthening ferrite steel is beneficial to industrial production.

Owner:CENT SOUTH UNIV

Method for preparing alloy sheet

InactiveCN1702191AVacuum evaporation coatingSputtering coatingCrucibleOxide dispersion-strengthened alloy

A method for preparation of alloy sheet, relates to the improvement of preparation technique of a allay sheet. It aims to settle the problem of preparing sheet with intermetallic compound and metallic material difficult to creep. The method for preparation in the invention is as following: preparing material bar and substrate to evaporate; putting the material bar to evaporate into water-cooled copper crucible, equipping the substrate with pivot of substrate, evacuating the vacuum chamber to 1-5*10-3Pa; regulating heating substrate to given temperature; heating, evaporating separation layer charge bar, depositing separation layer; stopping depositing, heating and evaporating metallic alloy bar, depositing metallic alloy layer, stopping heating, taking out the substrate, and separating metallic alloy layer from the substrate to prepare alloy sheet. The apparent merit of the invention is characterized in that the thickness of prepared alloy sheet is controlled among from 0.005mm to 5mm, and the material of sheet can be not only alloy, but also pure metal, intermetallic compound, oxide strengthened dispersion alloy, and ceramic.

Owner:HARBIN INST OF TECH

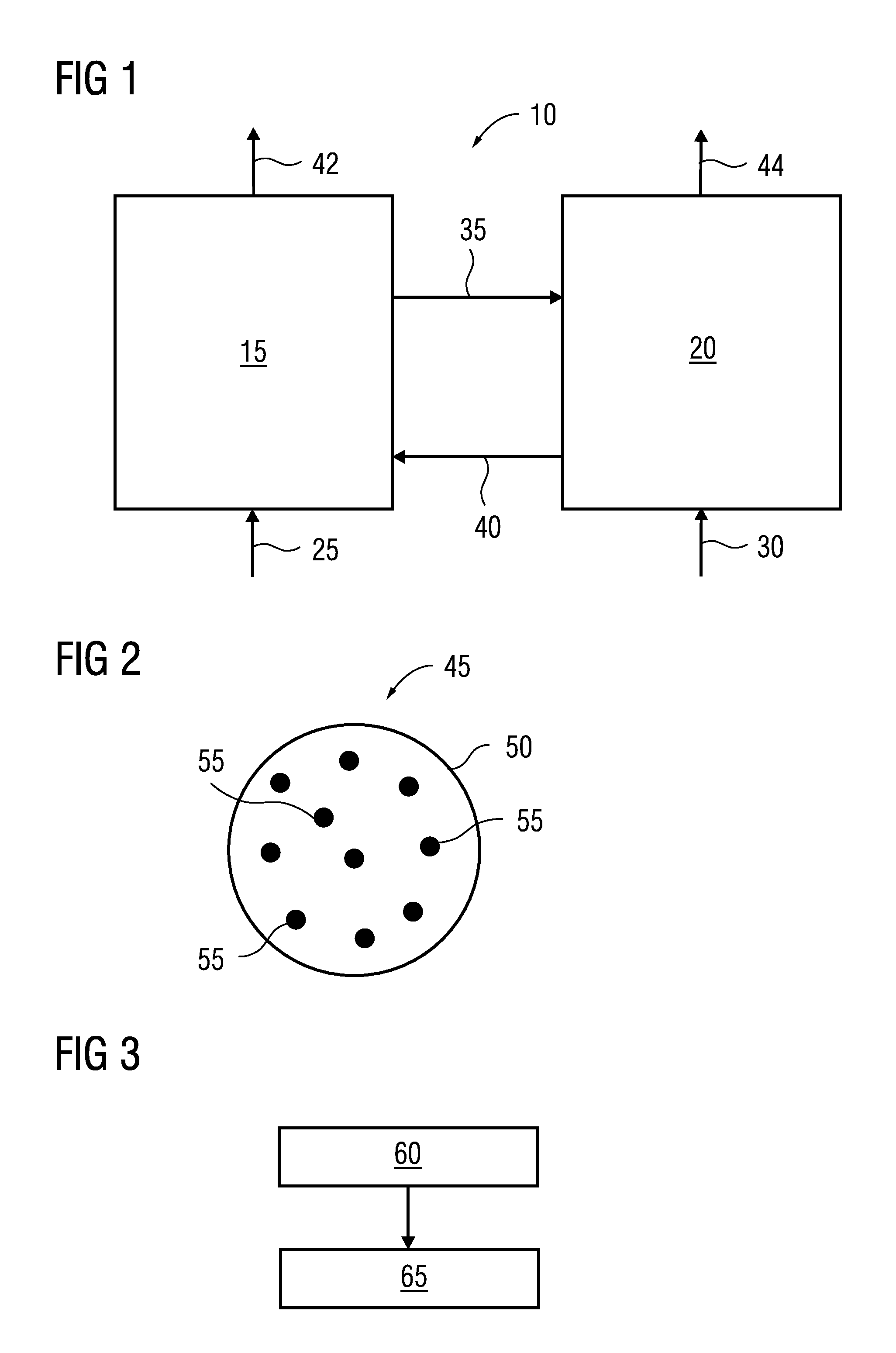

Chemical looping system

InactiveUS20130125462A1Easy to separateIncrease generationFluidized bed combustionGaseous fuelsNuclear engineeringCompound (substance)

A chemical looping system and a method of transferring oxygen therein are provided. The system has an air reactor adapted to receive air for oxidizing an oxygen carrier, a fuel reactor adapted to receive a fuel and the oxidized oxygen carrier for at least partially oxidizing the fuel by reducing the oxygen carrier to produce a gas. The oxygen carrier has oxide-dispersion-strengthened alloy particles.

Owner:SIEMENS AG

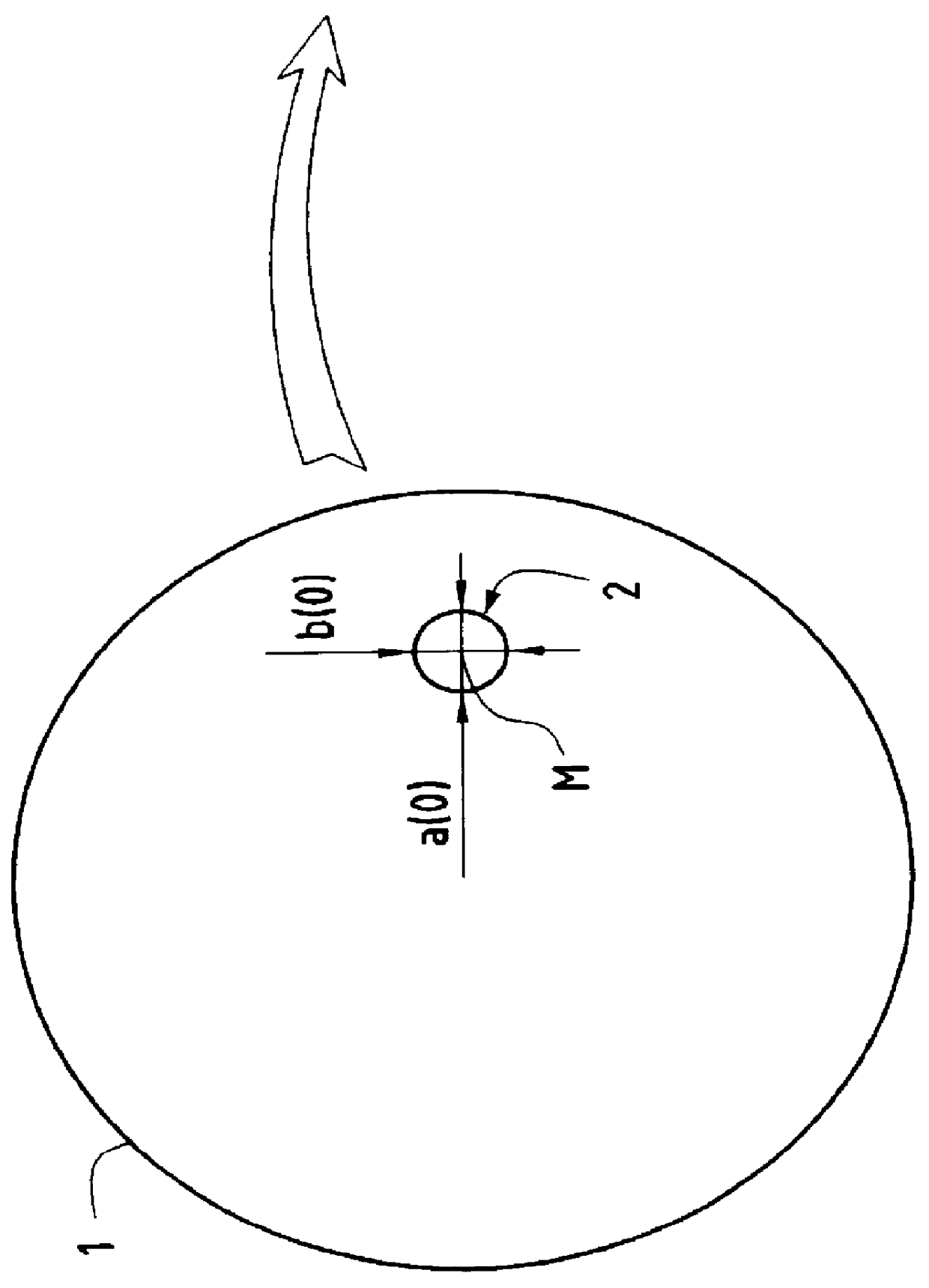

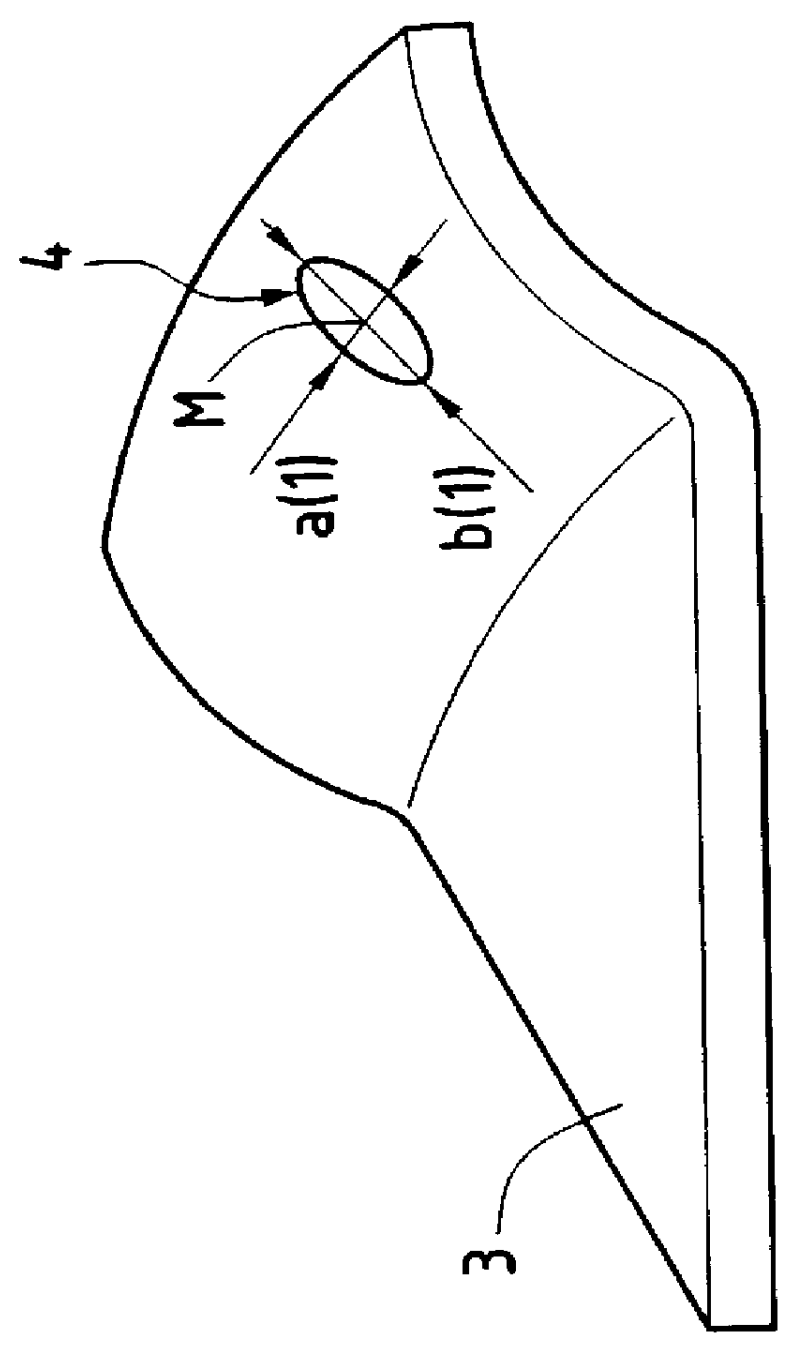

Process for manufacturing an article made of an oxide-dispersion-strengthened alloy

InactiveUS6042662AHigh strengthIncrease pressureGlass making apparatusMetal-working apparatusAbnormal grain growthOxide dispersion-strengthened alloy

This process makes it possible to manufacture articles of any shape by stamping, in which articles the matrix of the alloy has to have a coarse-grained structure. According to the invention, a partial hot-forming operation is carried out by stamping a blank made of an oxide-dispersion-strengthened alloy, especially a nickel-based alloy, having an initial ultrafine-grained structure, in order to form a shaped component, this shaped component is subjected to a secondary recrystallization heat treatment so as to develop an abnormal grain growth, and then a new hot-forming operation is carried out by stamping in order to give the recrystallized shaped component the final shape of the article.

Owner:SEVA

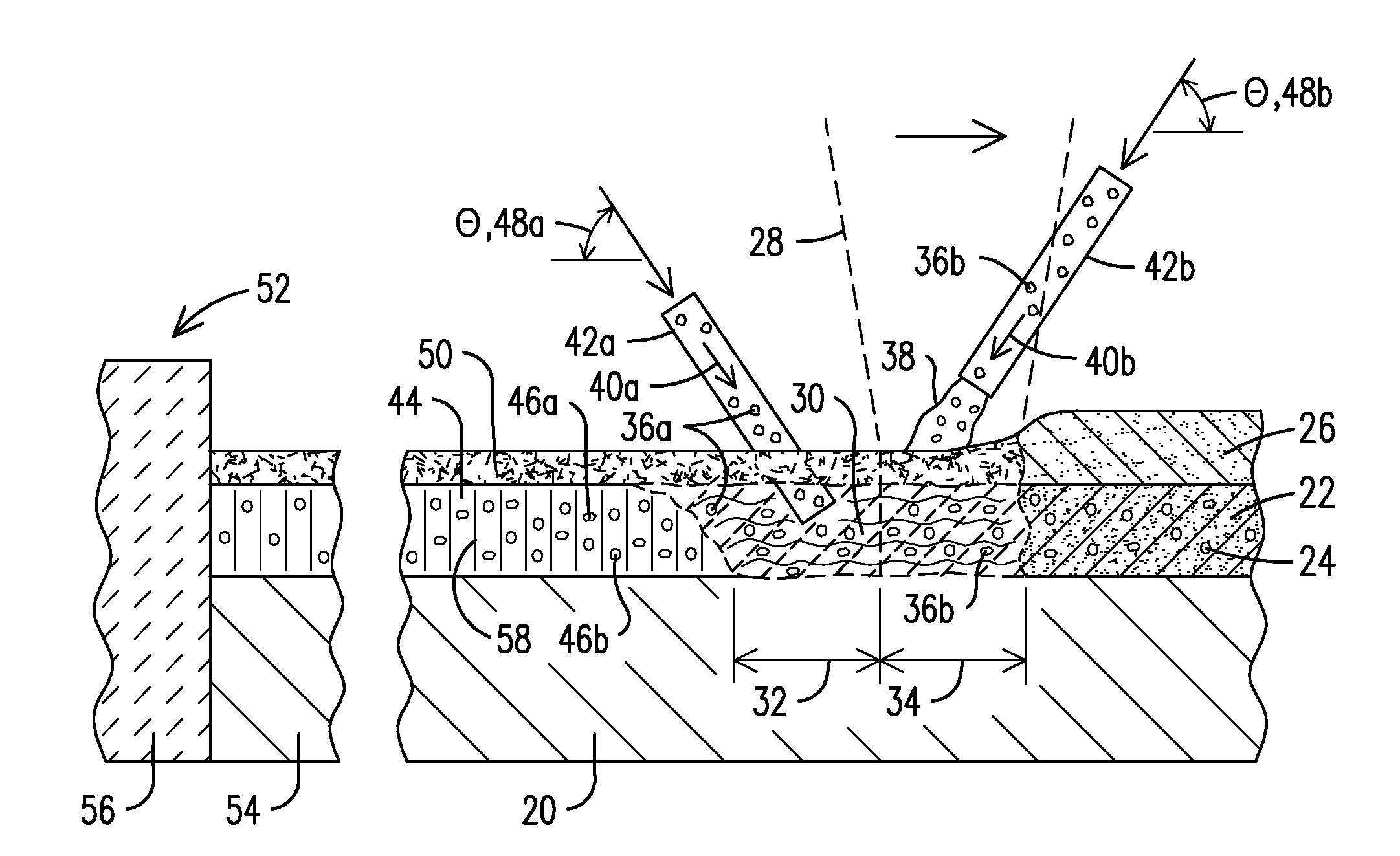

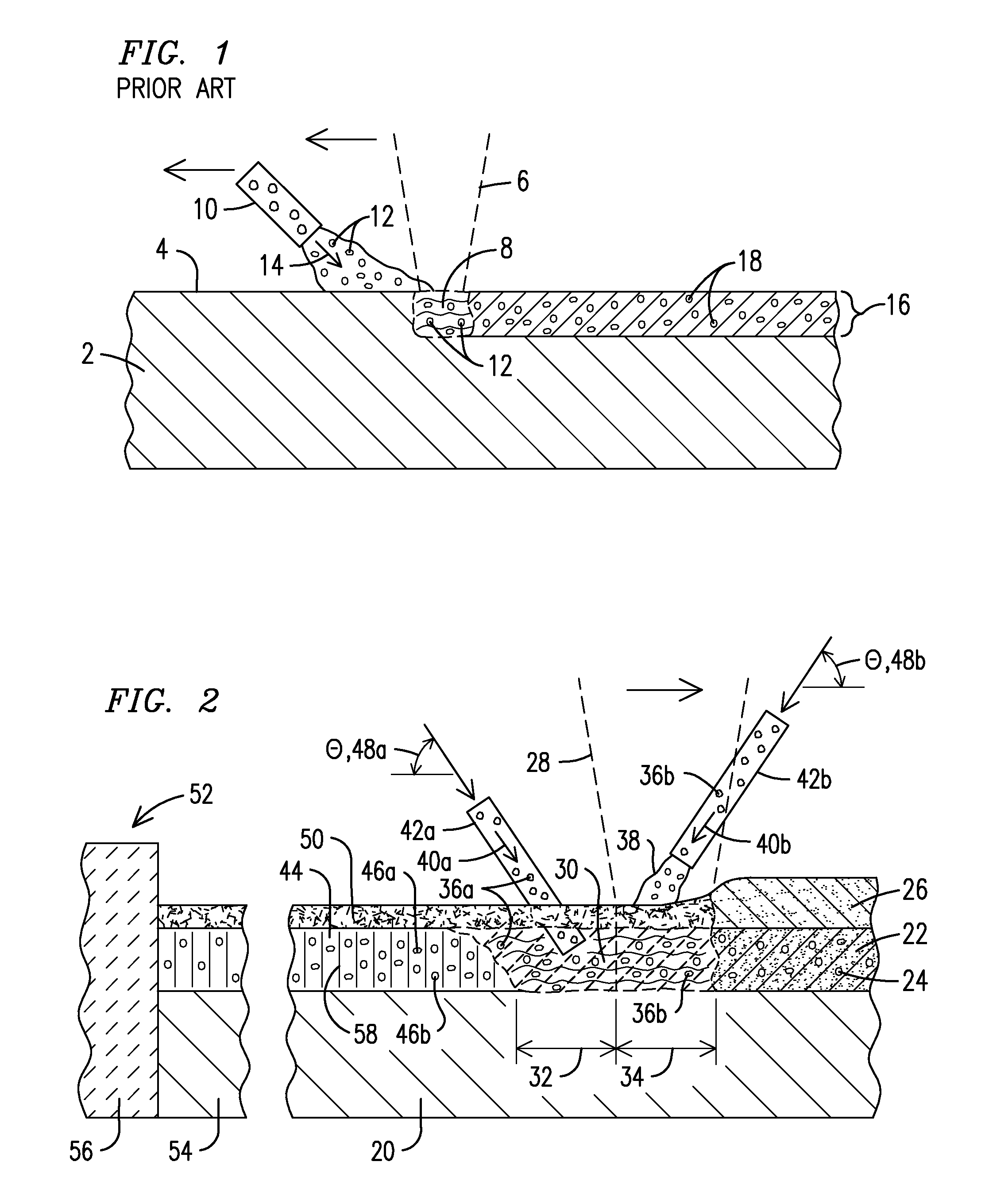

Method to form oxide dispersion strengthended (ODS) alloys

ActiveUS20160215364A1Electron beam welding apparatusLaser beam welding apparatusOxide dispersion-strengthened alloyMaterials science

Method for forming an oxide dispersion strengthened alloy. An alloy material (24) is melted with an energy beam (28) to form a melt pool (30) in the presence of a flux material (26), and particles (36) of a metal oxide are directed into the melt pool such that the particles are dispersed within the melt pool. Upon solidification, an oxide dispersion strengthened alloy (44) is formed as a layer bonded to an underlying substrate (20) or as an object contained on a removable support.

Owner:SIEMENS ENERGY INC

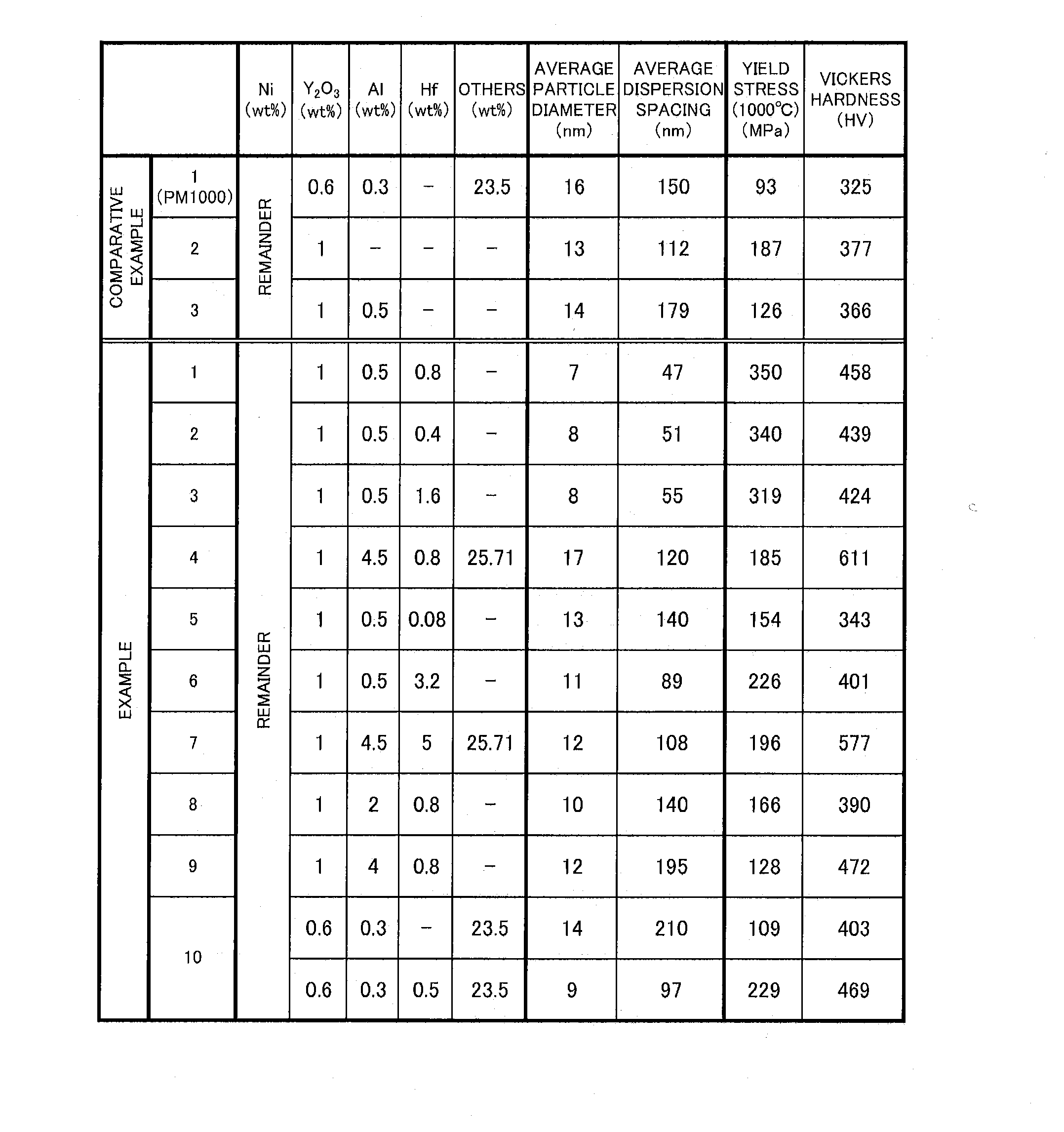

Oxide-dispersion-strengthened alloy

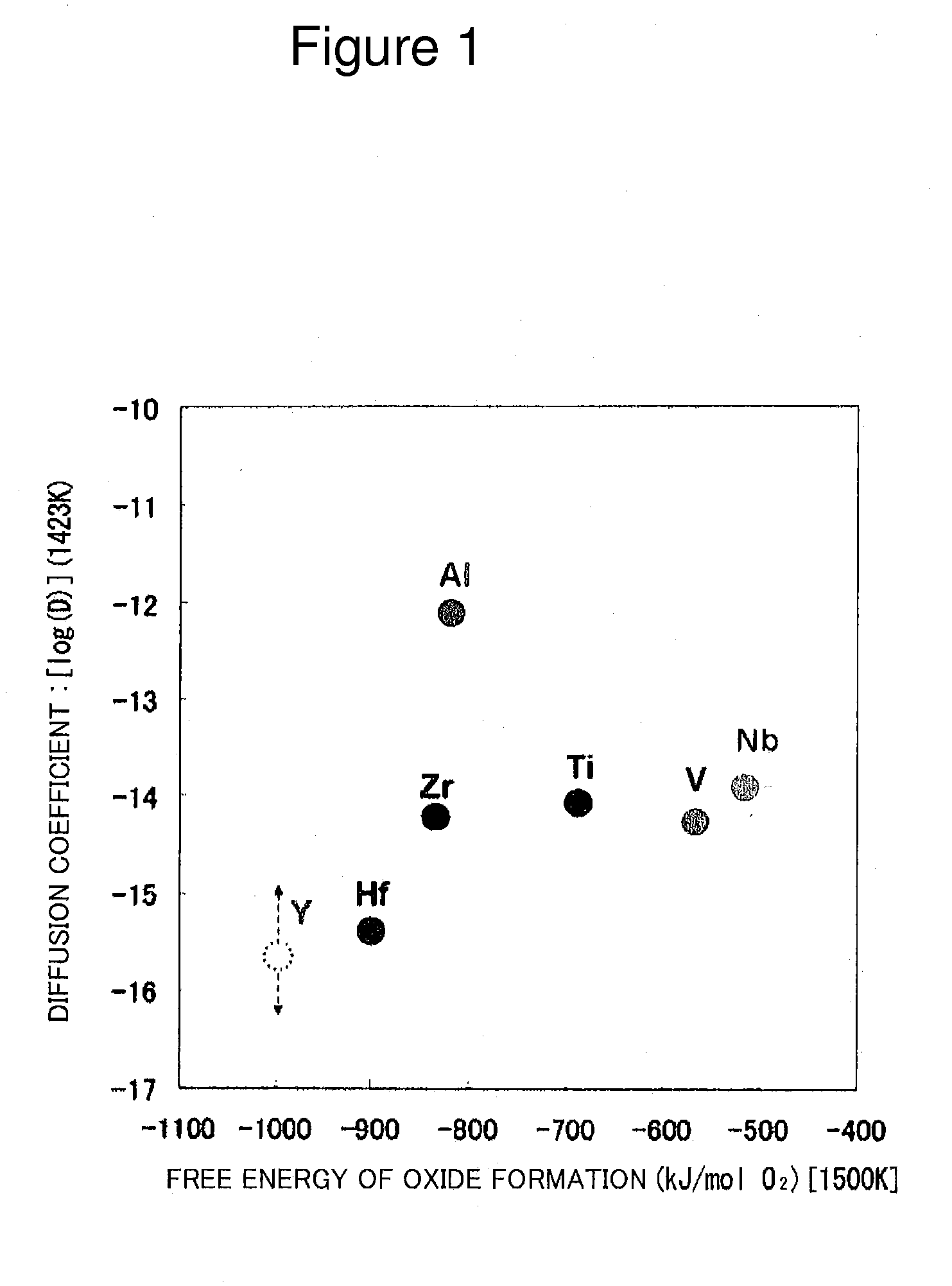

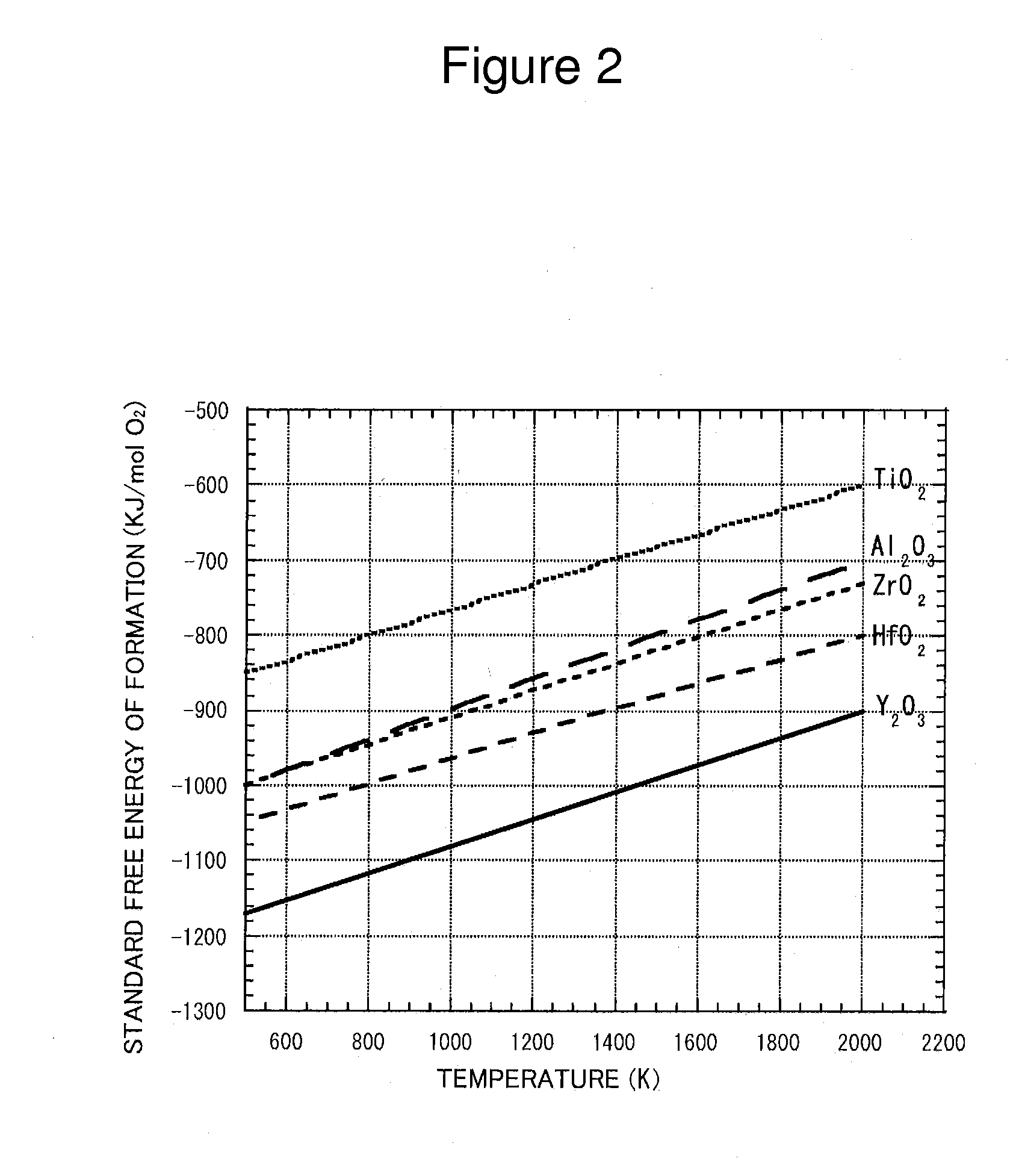

InactiveUS20110142711A1High temperature strengthImprove corrosion resistanceOxide dispersion-strengthened alloyHafnium

The present invention provides an oxide dispersion strengthened alloy in which even with aluminum contained, the particle diameter and dispersion spacing of the oxide are decreased, and the strength at high temperature, the high temperature oxidation and the corrosion resistance can be improved. An oxide dispersion strengthened alloy being a nickel-base alloy containing aluminum, hafnium, and yttrium oxide, wherein a complex oxide of the yttrium oxide and hafnium oxide is dispersed in a matrix of the nickel-base alloy, with the aluminum contained.

Owner:HOKKAIDO UNIVERSITY

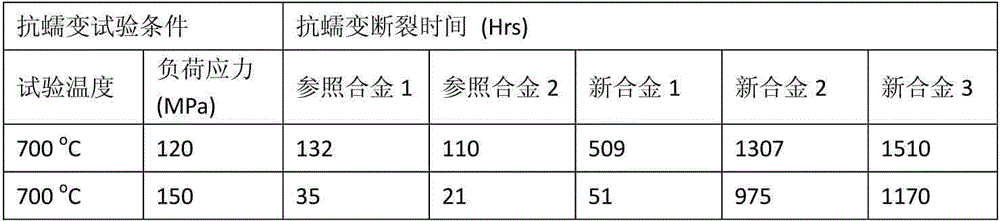

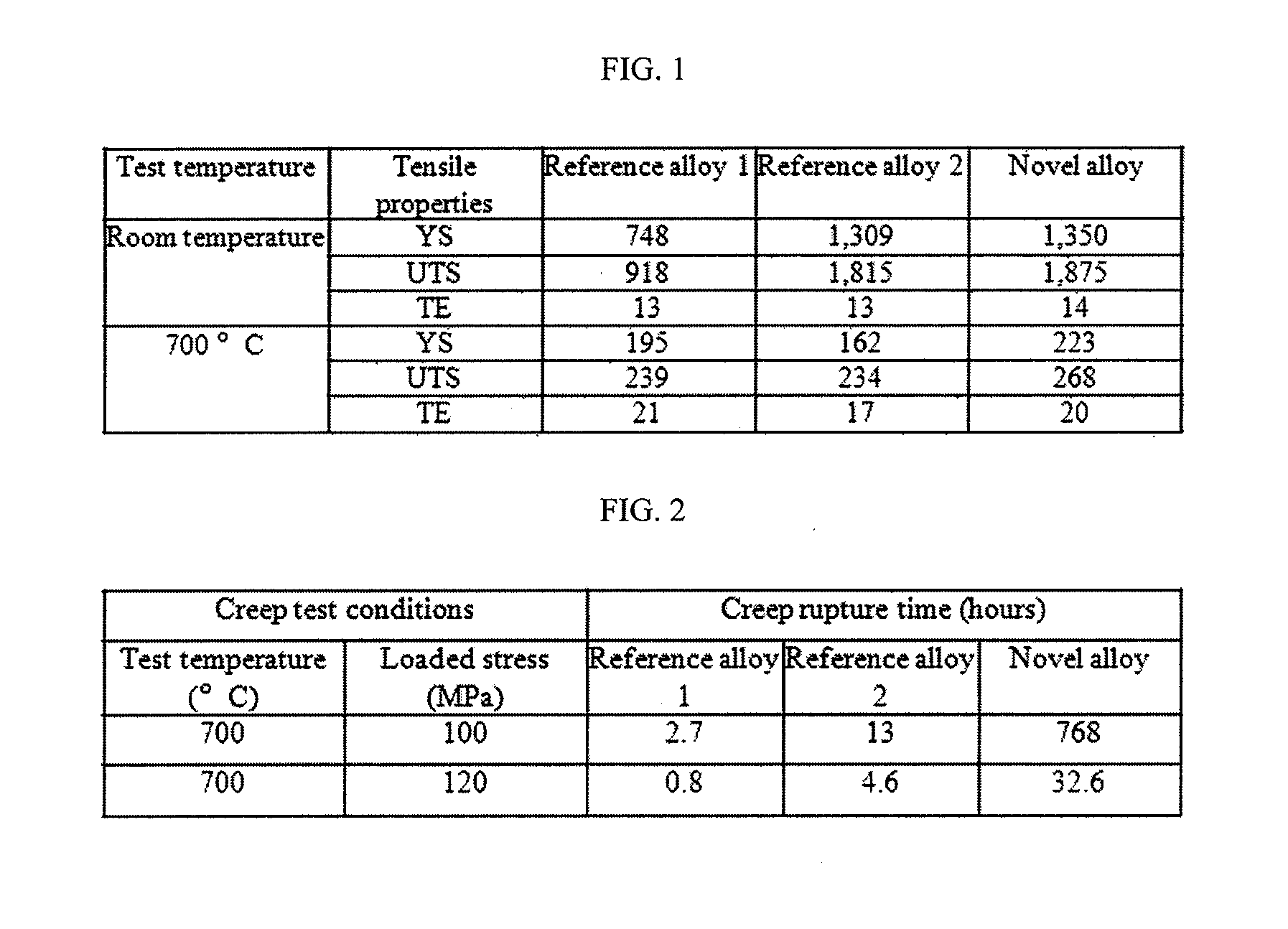

Ferritic oxide dispersion strengthened alloy with enhanced room temperature and high temperature strength and manufacturing method thereof

The invention relates to a ferritic oxide dispersion strengthened alloy with enhanced room temperature and high temperature strength containing Cr in a range of from 12 to 20wt%, Y2O3 in a range of from 0.1 to 0.5wt%, W 0.1 to4wt%, Mo 0.5 to 2 wt%, Ti 0.1 to 0.3 wt%, and Zr 0.02 to 0.3 wt%, and Fe, and a manufacturing method thereof. The ferritic oxide dispersion strengthened alloy is advantageous in that under the 700-degree temperature condition, the anti-tensioning performance is good, the alloy can be used for the supercritical steam generator part (rotor wings, and shafts) used for the thermal power, airplane engine part (circular discs, and effusers), and sodium-cooled fast reactor and other nuclear power system reactor core structural parts such as nuclear coating tube, conduits, conductors, and end plugs).

Owner:KOREA ATOMIC ENERGY RES INST +1

Method for preparing oxide dispersion strengthen (ODS) high-temperature alloy pipe

InactiveCN102758181ASmall sizeEvenly distributedOptical rangefindersNuclear energy generationElectron beam physical vapor depositionGas phase

The invention relates to a method for preparing an oxide dispersion strengthen (ODS) high-temperature alloy pipe. The problems that in prior methods for preparing nuclear fuel cladding ODS alloy pipes, the process is complex, the efficiency is low and pipes with various diameters and various wall thicknesses are difficult to obtain are solved. The method comprises steps of cleaning the outer surface of a base pipe; conducting preparation work before electron beam physical vapor deposition; and depositing the ODS high-temperature alloy pipe. By the aid of the method, ODS high-temperature alloy pipes with various diameters and various wall thicknesses are prepared. The method can be applied to preparation of nuclear fuel cladding materials of supercritical water reactor in a nuclear power system and preparation of other components which are used under high-temperature environments.

Owner:HARBIN INST OF TECH

Method for synthesizing nano oxide particle dispersion strengthened alloy in in-situ mode

ActiveCN109175391ASimple methodReduce processAdditive manufacturing apparatusTransportation and packagingManufacturing technologyOxide dispersion-strengthened alloy

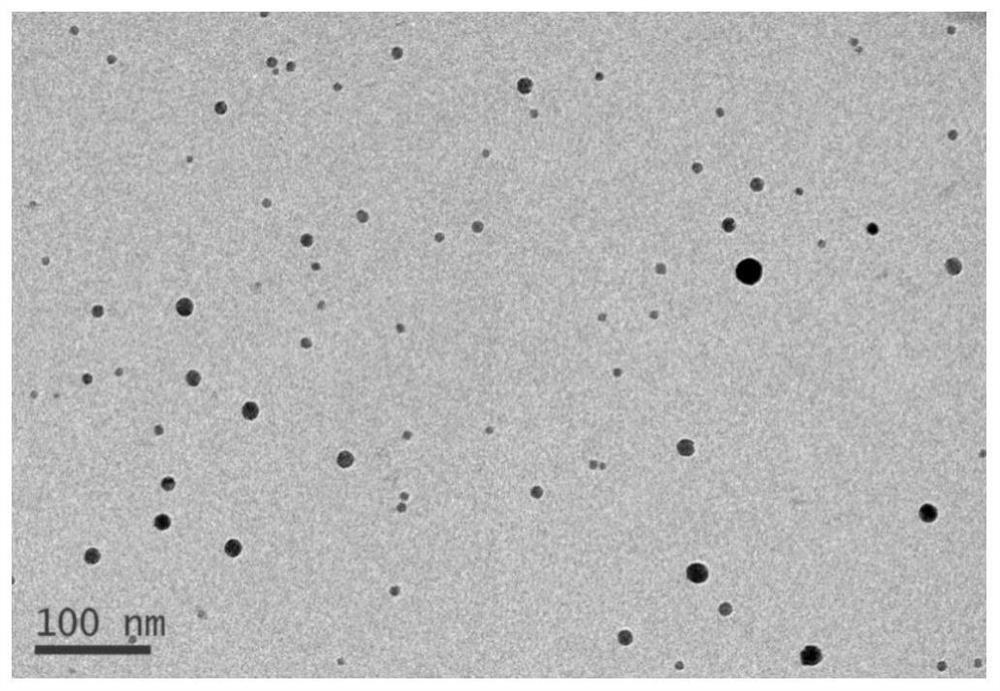

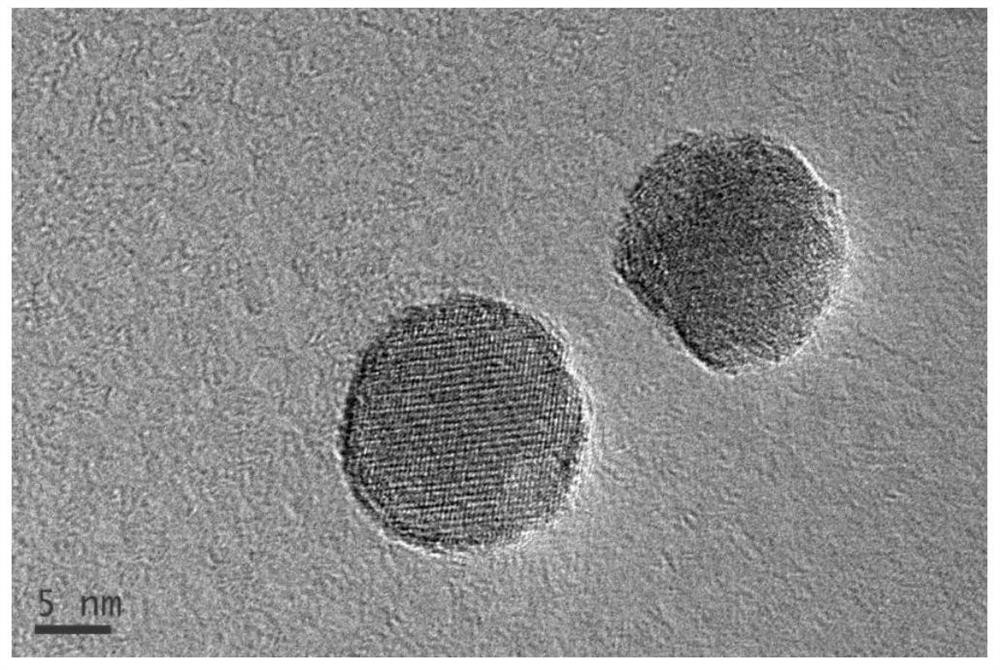

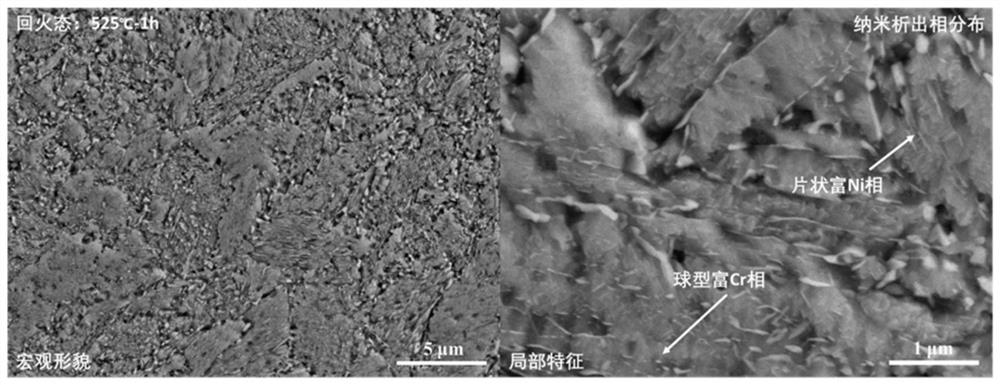

The invention discloses a method for synthesizing nano oxide particle dispersion strengthened alloy in an in-situ mode. The method comprises the following steps that (1) alloy is designed to enable the alloy to contain elements capable of forming oxides; (2) alloy powder is prepared, wherein in the preparation process of the alloy powder, the oxygen content in the alloy powder is increased; and (3) a metal additive manufacturing technology is utilized, so that the oxide forming elements and the oxygen element are combined to form dispersed nano oxide particles in the localized solidification process of the alloy so as to obtain the nano oxide particle dispersion strengthened alloy. According to the method, the process and the period for preparing the nano oxide dispersion strengthened alloy can be reduced and shortened, the nano oxide particles are separated out in situ and are uniformly distributed in an alloy matrix, and meanwhile, a columnar crystal organizational structure can be prepared in situ, so that the formation of pores in the subsequent heat treatment process is guaranteed to be avoided.

Owner:BEIHANG UNIV

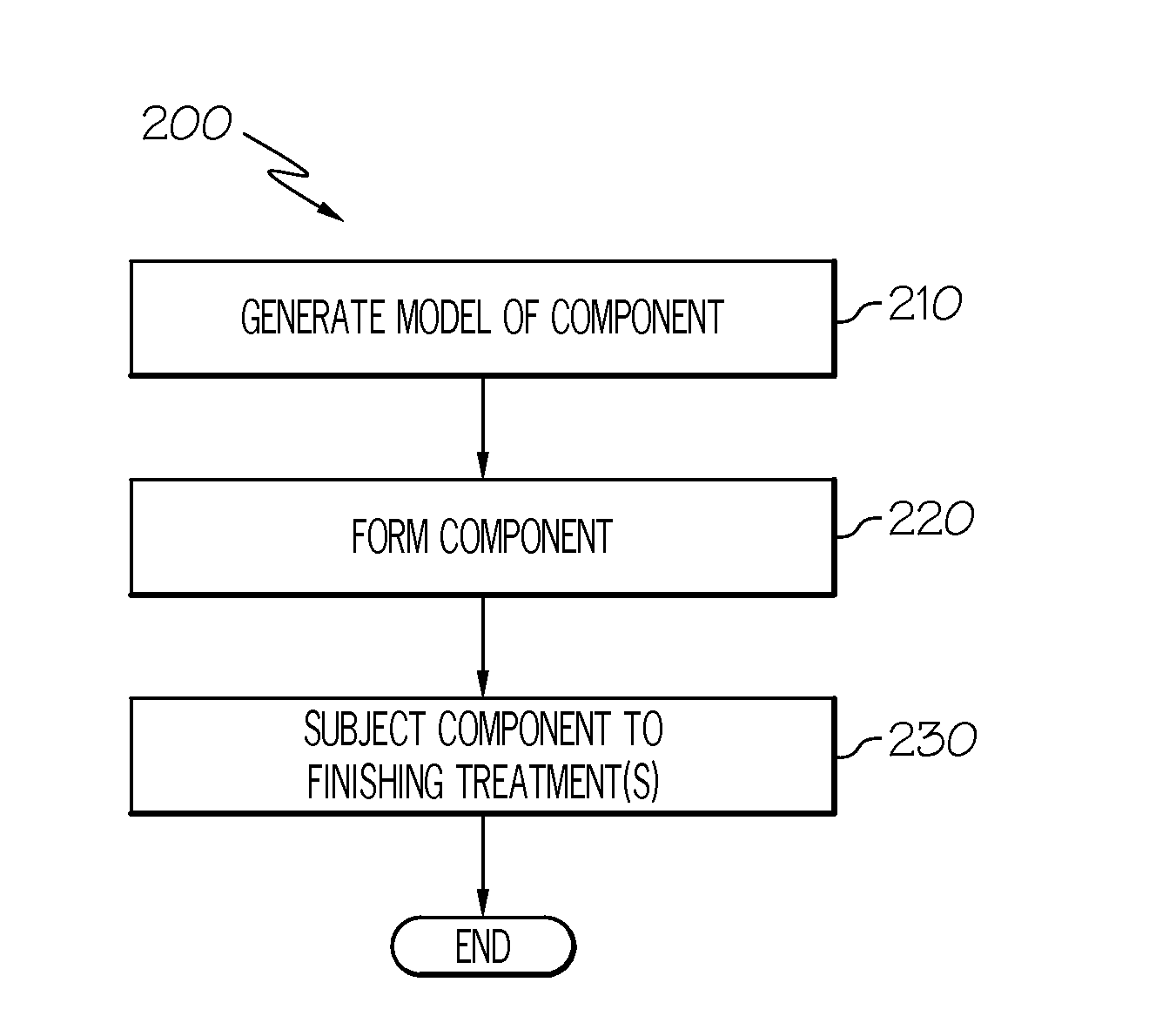

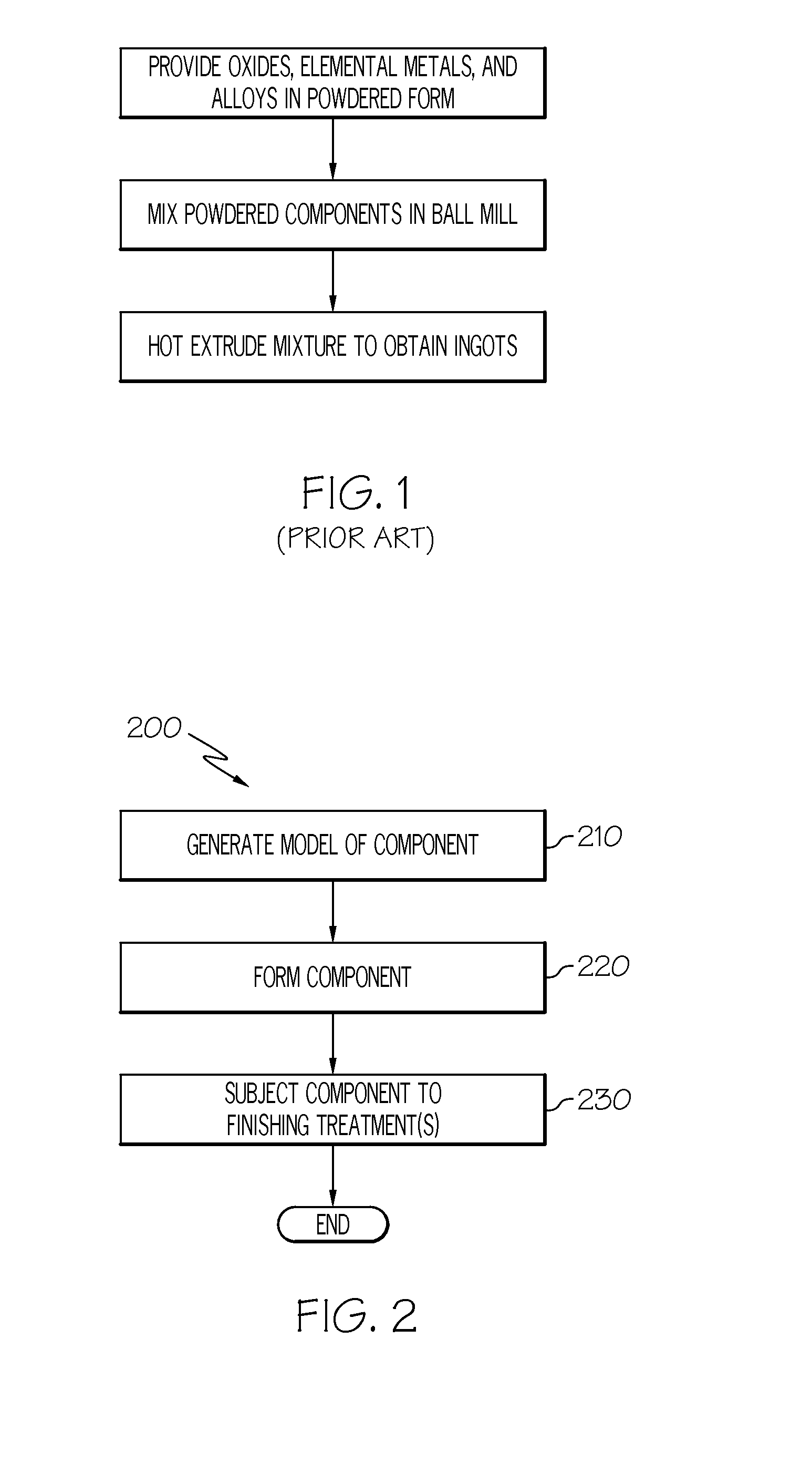

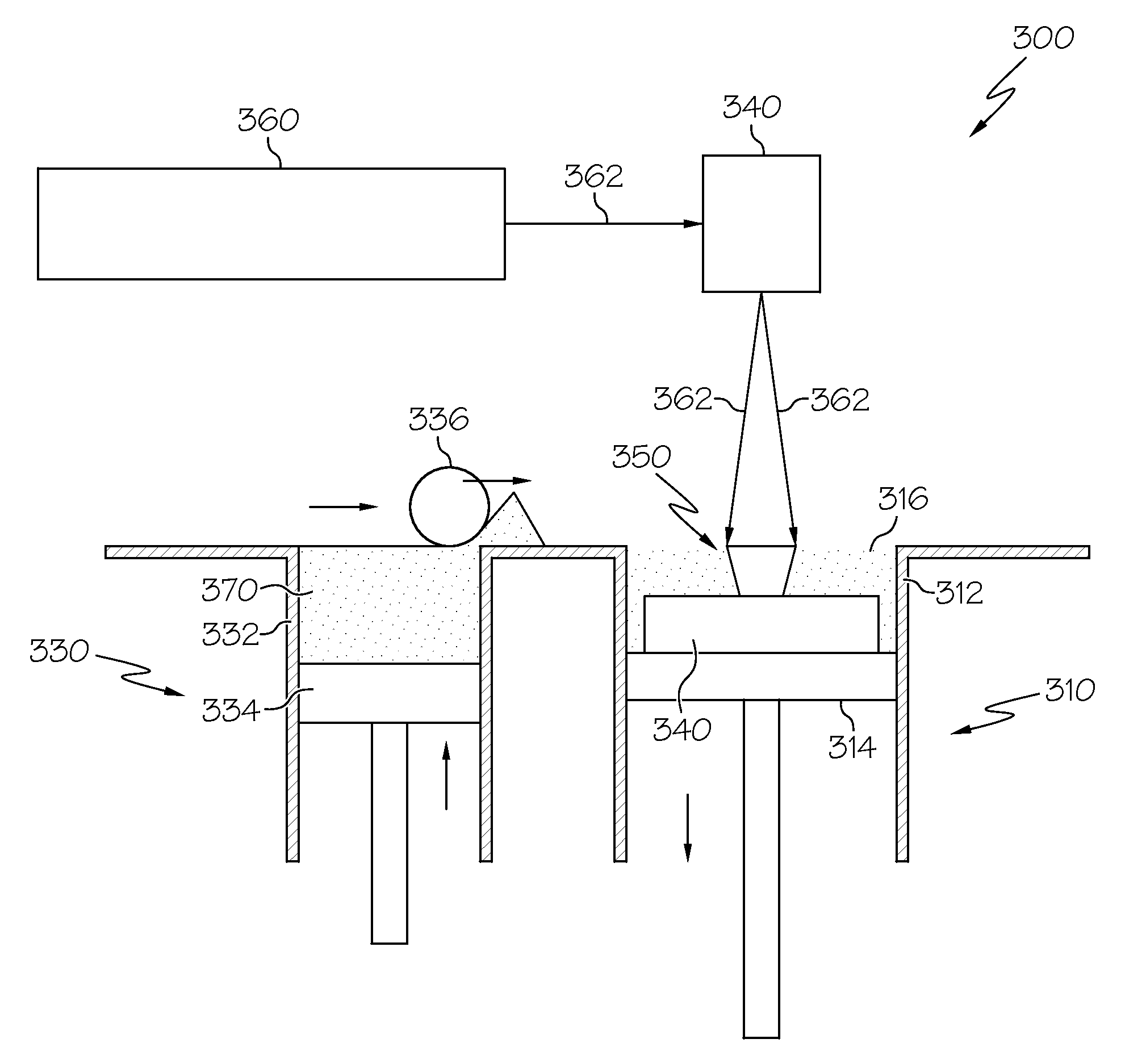

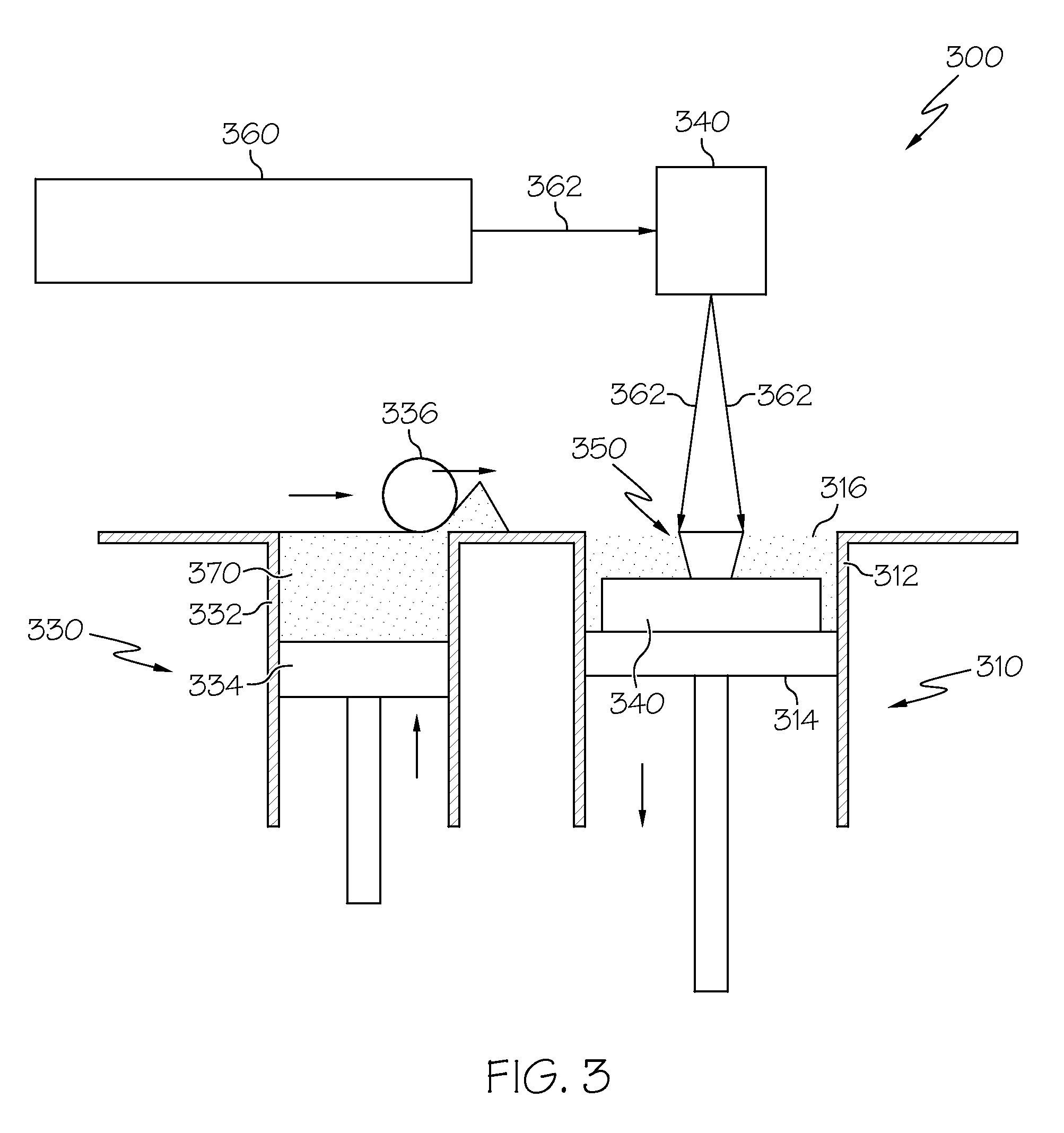

Methods for forming oxide dispersion-strengthened alloys

In accordance with an exemplary embodiment, a method of forming a oxide dispersion-strengthened alloy metal includes the steps of providing, in a powdered form, an oxide dispersion-strengthened alloy composition that is capable of achieving a dispersion-strengthened microstructure, directing a low energy density energy beam at a portion of the alloy composition, withdrawing the energy beam from the portion of the powdered alloy composition, and cooling the portion of the powdered alloy composition at a rate greater than or equal to about 106° F. per second, thereby forming the oxide dispersion-strengthened alloy metal.

Owner:HONEYWELL INT INC

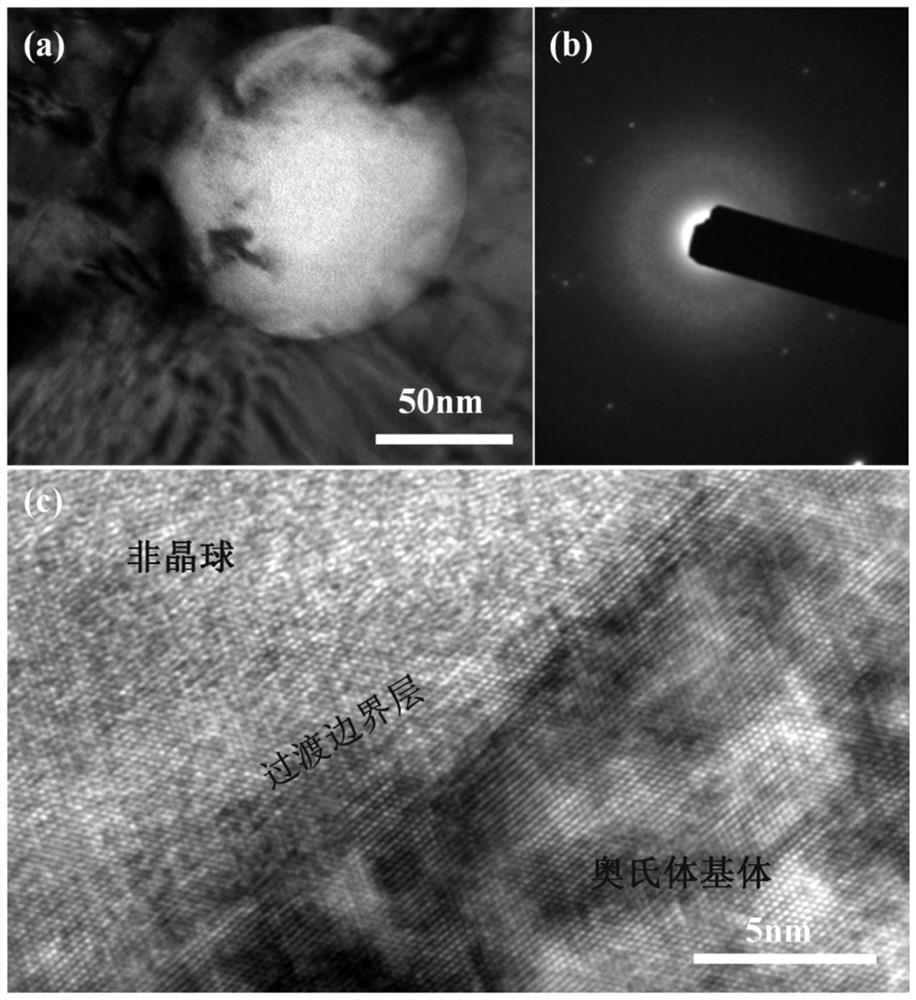

Method for preparing nano spherical oxide dispersion strengthening phase

ActiveCN112170854AHigh tensile strengthHigh elongationOxide dispersion-strengthened alloyAlloy composite

The invention relates to a method for preparing a nano spherical oxide dispersion strengthening phase, and provides a method for preparing the nano spherical oxide dispersion strengthening phase by adopting micron oxide for the first time. Firstly, nano oxide / matrix alloy composite powder with a completely amorphous structure is prepared by taking the micron oxide as a raw material and adopting astaged mechanical ball milling method. According to the preparation method, ball milling is carried out at the first stage, so that the oxide is subjected to crushing and structural transformation, nanocrystallization and complete amorphization are realized, and composite powder in which the nano oxide with a complete amorphous structure is uniformly distributed in matrix alloy powder is prepared;and in the second stage, the composite powder obtained in the first stage and the remaining matrix alloy powder are subjected to ball milling and evenly mixed. Then, the prepared powder is sequentially subjected to hot forming, hot rolling and heat treatment, and the nano spherical oxide dispersion strengthened alloy is obtained. According to the method, the dispersion strengthening effect of anoxide phase can be obviously improved, and the room-temperature and high-temperature mechanical properties of the alloy are obviously improved. The method is simple, the production efficiency is high,the prepared alloy is excellent in performance, and the strength and plasticity of the alloy are obviously superior to those of the same type of alloy.

Owner:CENT SOUTH UNIV

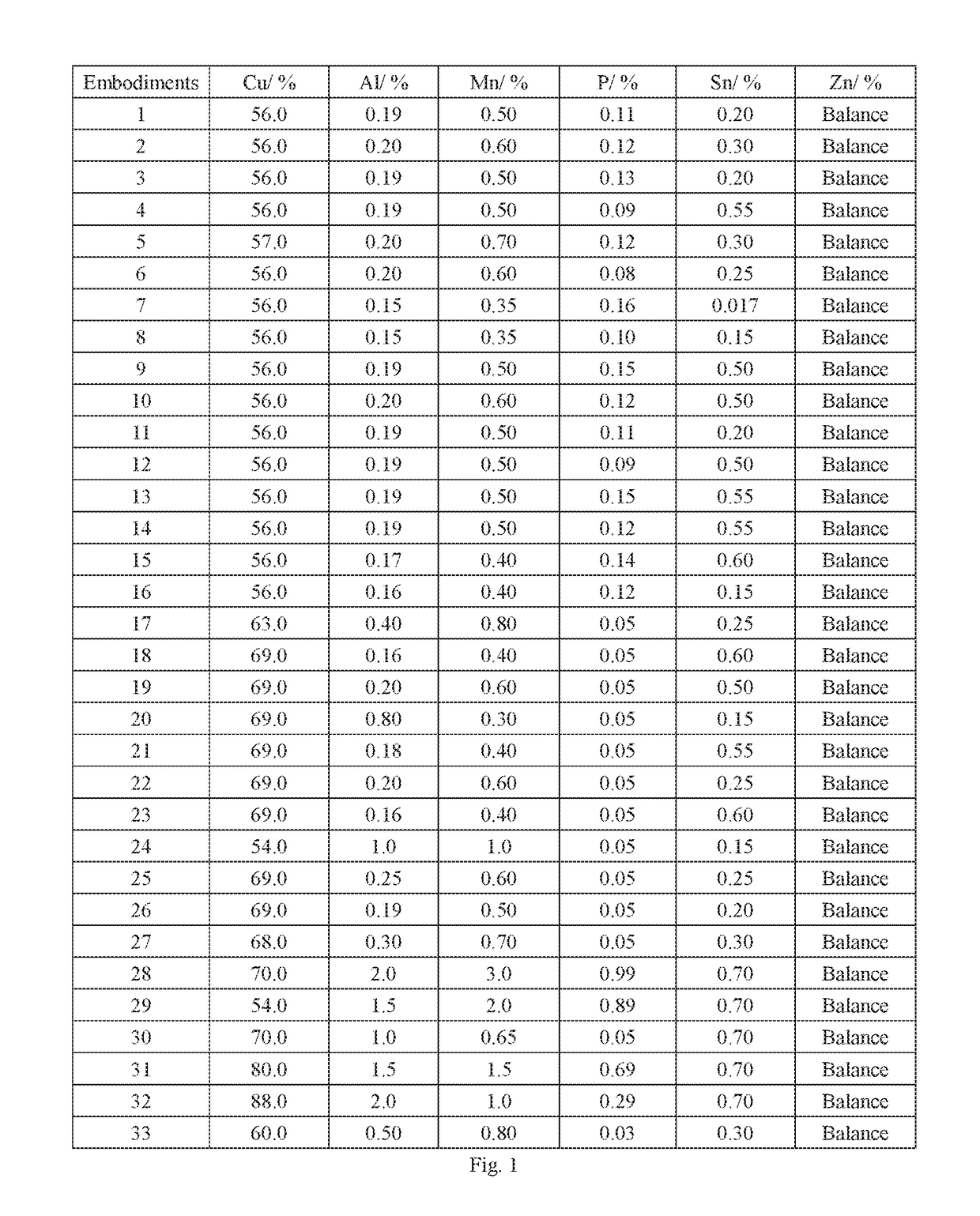

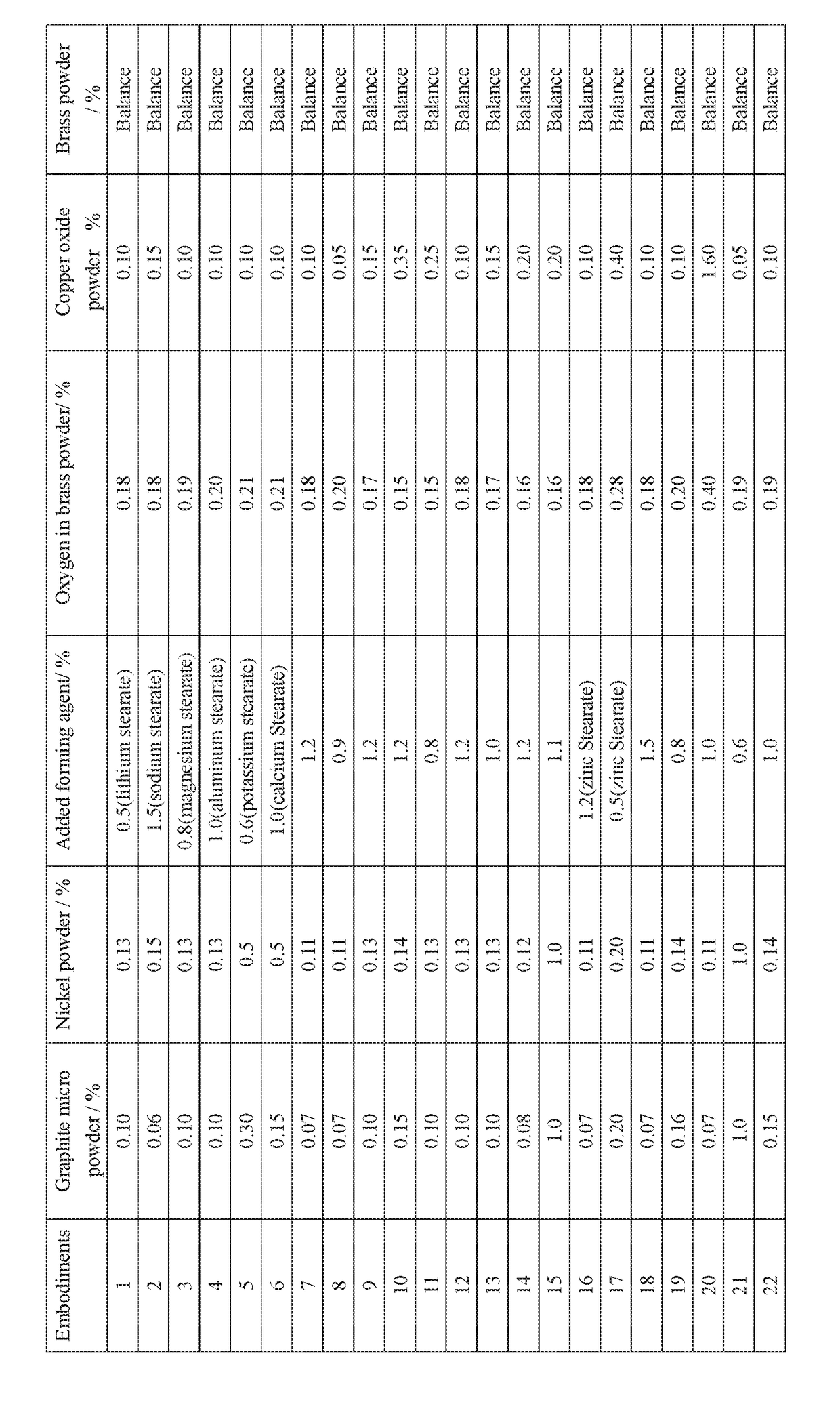

Oxide dispersion-strengthened alloy (ODS), lead-free and free-cutting brass and producing method thereof

ActiveUS20180355459A1Improve cooling effectImprove interface strengthTransportation and packagingMetal-working apparatusOxide dispersion-strengthened alloyManganese

Oxide dispersion-strengthened alloy (ODS), lead-free and free-cutting brass and producing method thereof The mass percent of components in the brass are: 52.0%-90.0% of copper, 0.001%-0.99% of phosphorus, 0.15%-0.70% of tin, 0.25%-3.0% of manganese, 0.15%-0.90% of aluminum, 0.10%-1.5% of nickel, 0.191%-0.90% of oxygen, and 0.06%-0.80% of carbon, the ratio of aluminum to oxygen not exceeding 27:24, with the balance being zinc and inevitable impurities, wherein lead is not more than 0.08%. The brass is produced by a powder metallurgy method: brass powder, copper oxide powder, and graphite micro powder are mixed evenly; 0.001%-1.5% of a forming agent is added and mixed evenly with the mixture; and then molded by compression, and sintering are performed before post-treatment.

Owner:HUNAN TERRY NEW MATERIALS COMPANY

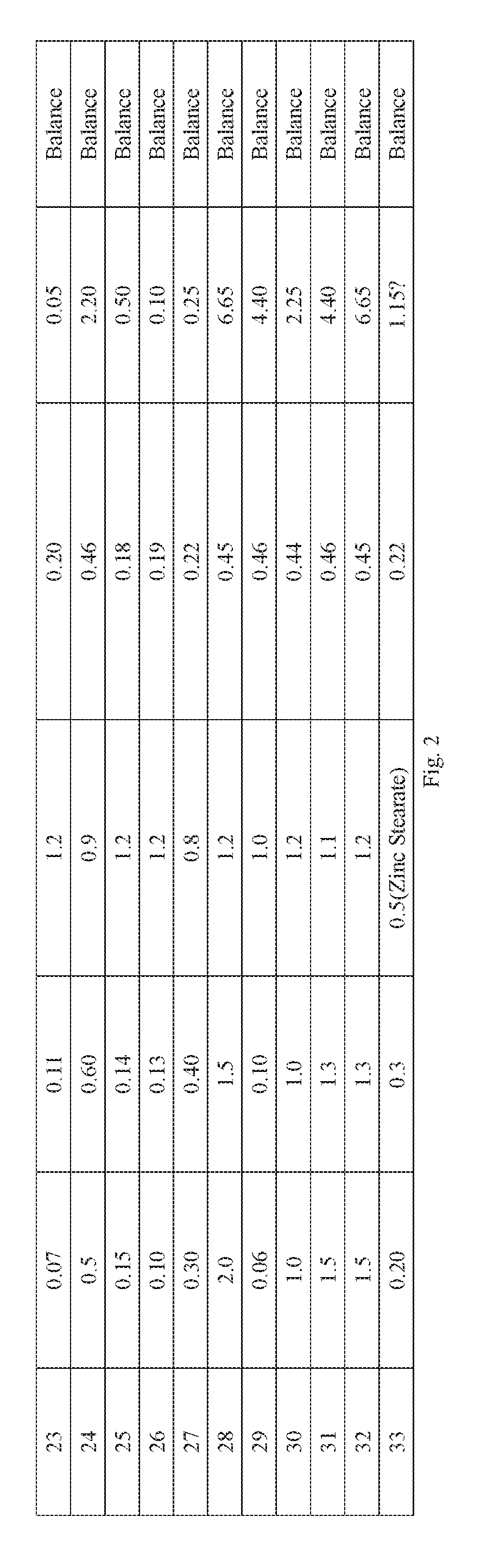

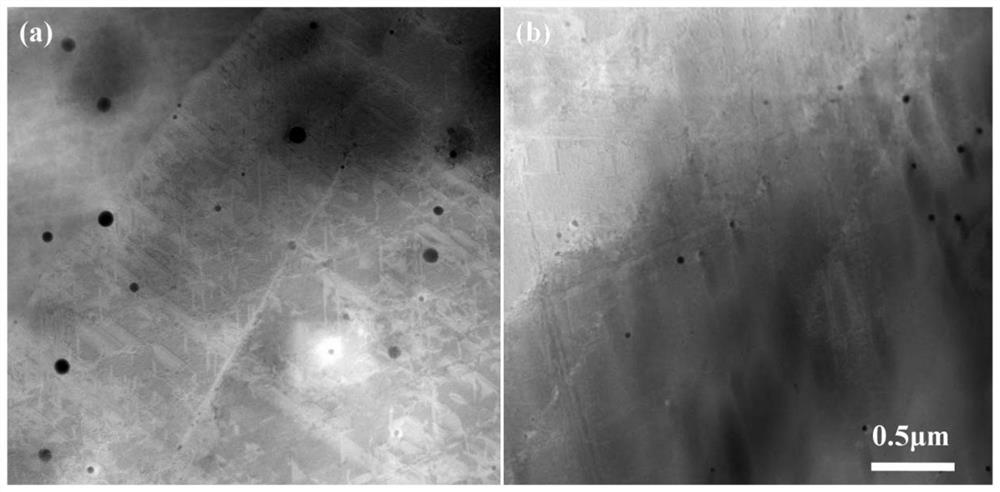

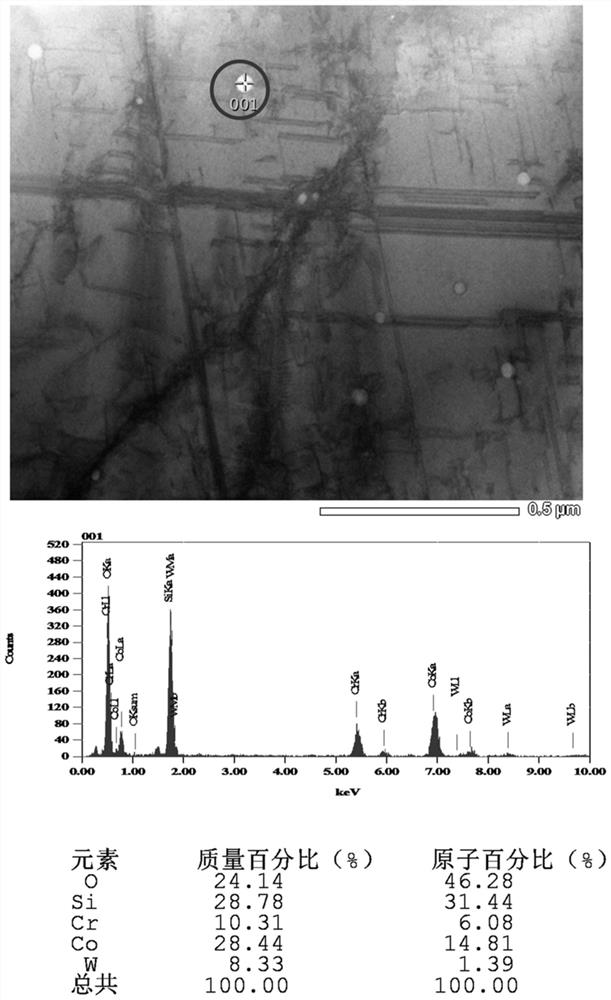

In-situ synthesis oxide dispersion strengthening CoCrW alloy and preparation method thereof

ActiveCN112322921AExtended service lifeImprove bindingAdditive manufacturing apparatusArtificial teethSelective laser meltingOxide dispersion-strengthened alloy

The invention provides a preparation method of an in-situ synthesis oxide dispersion strengthening CoCrW alloy. The preparation method comprises the following steps that CoCrW alloy powder is subjected to laser melting treatment in an inert gas atmosphere to obtain the in-situ synthesis oxide dispersion strengthening CoCrW alloy, wherein the oxygen content in the gas atmosphere is 200 ppm to 2, 000ppm, the CoCrW alloy powder contains Si element, and the weight content of the Si element in the CoCrW alloy powder ranges from 0.1% to 2%. According to the preparation method, because a spherical / nearly spherical nanometer oxide dispersion precipitation phase is synthesized in situ in the CoCrW alloy through a selective laser melting technology, and the phase is in an amorphous state, no latticematching problem exists between the phase and an interface of a CoCrW alloy matrix, and an interface transition layer is tightly combined. According to the in-situ synthesis oxide dispersion strengthening CoCrW alloy, a large number of oxide dispersion precipitation phases are uniformly distributed inside, the bonding capacity of the CoCrW alloy and ceramic is remarkably improved due to existenceof the oxide dispersion precipitation phases, the phenomena of cracks and ceramic collapse are avoided, and the service life of porcelain teeth is prolonged.

Owner:GUANGDONG INST OF NEW MATERIALS

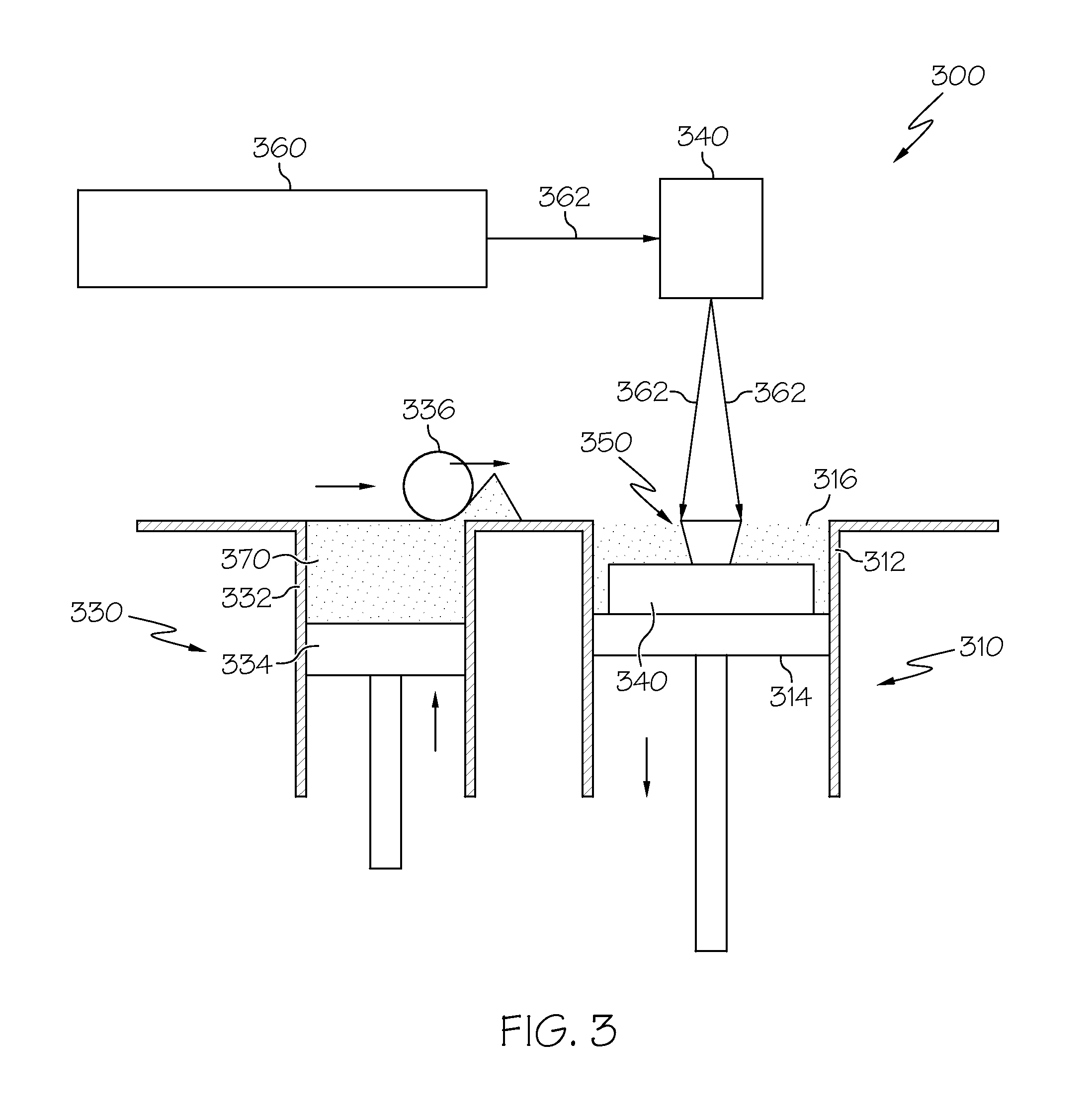

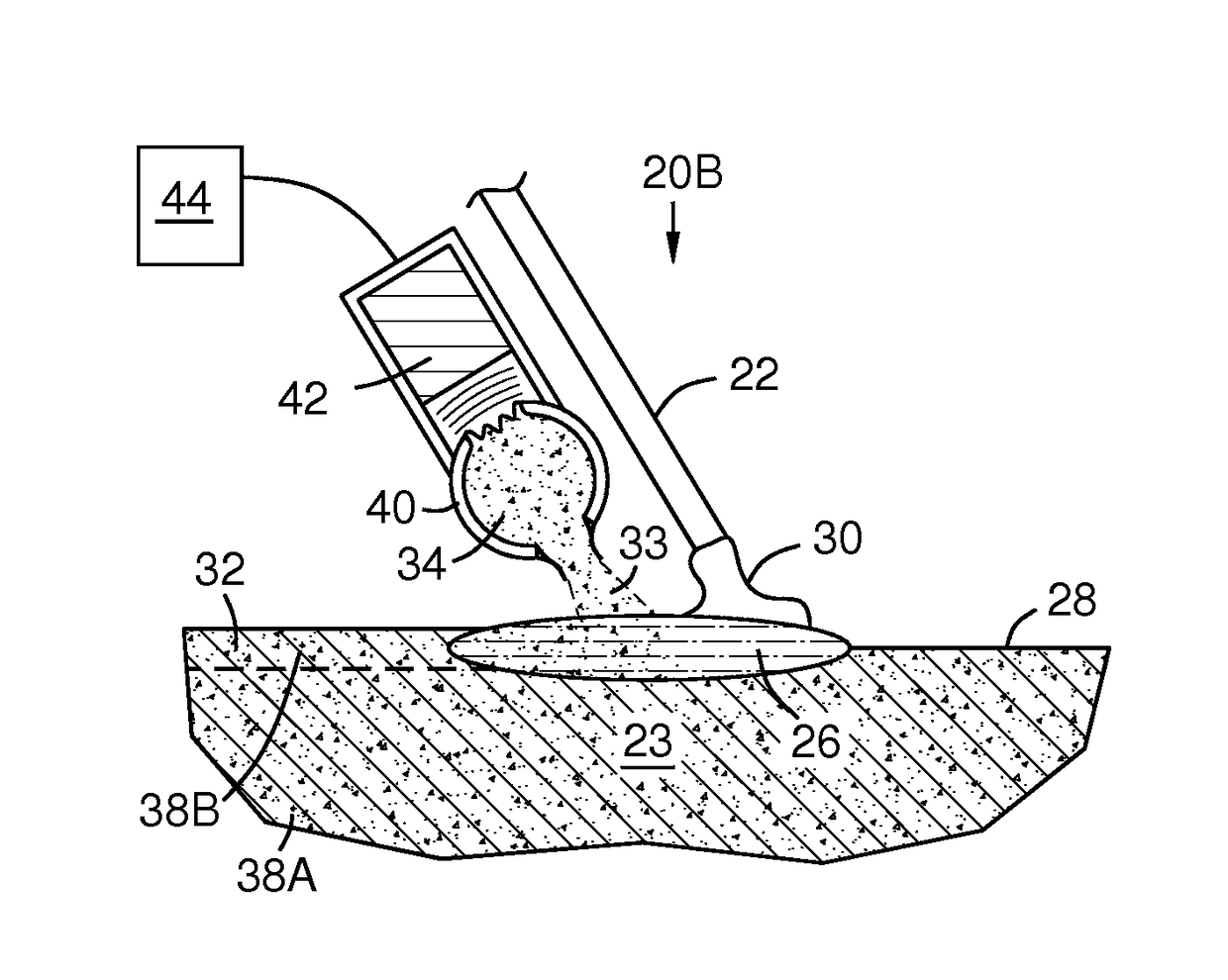

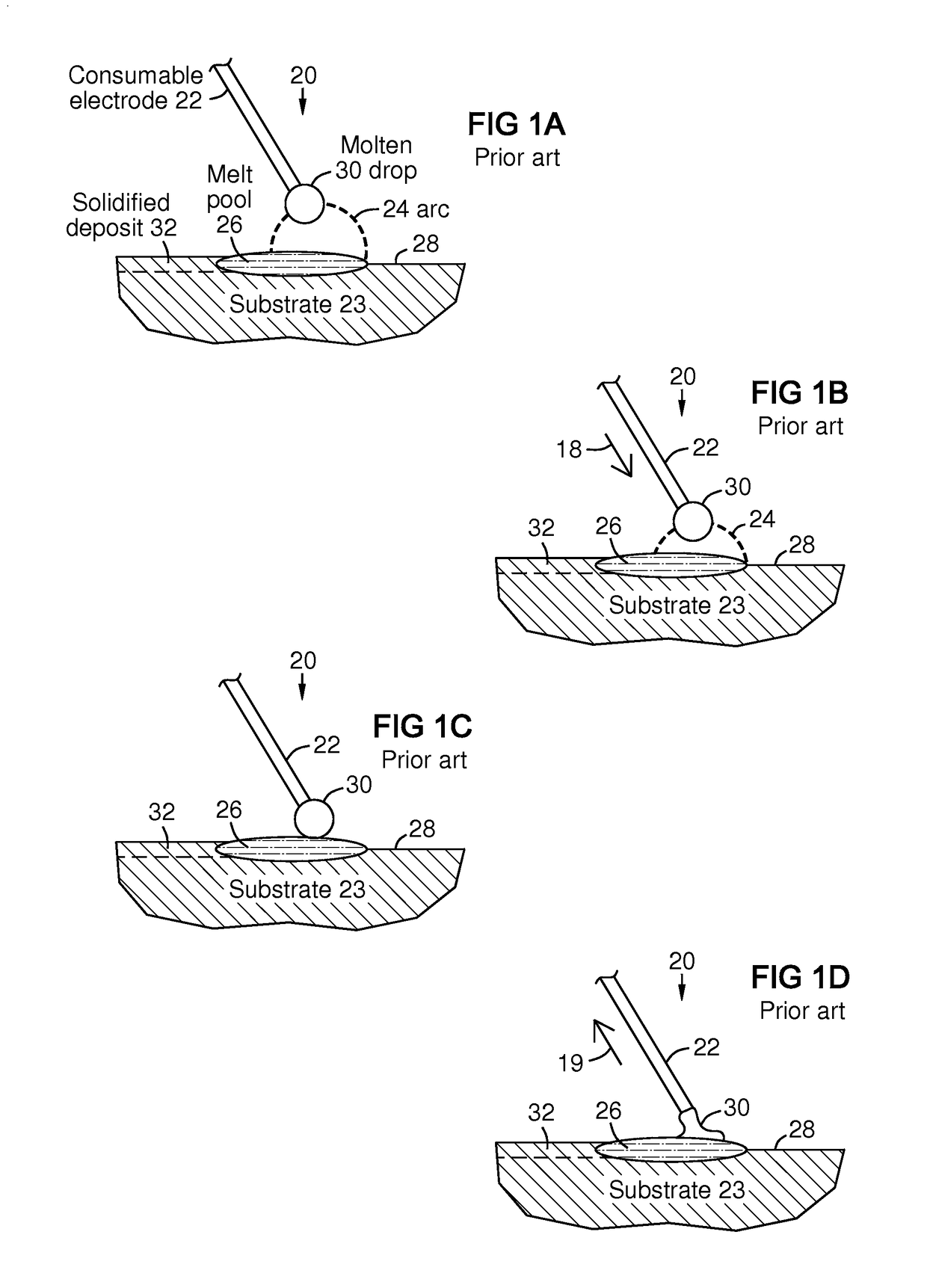

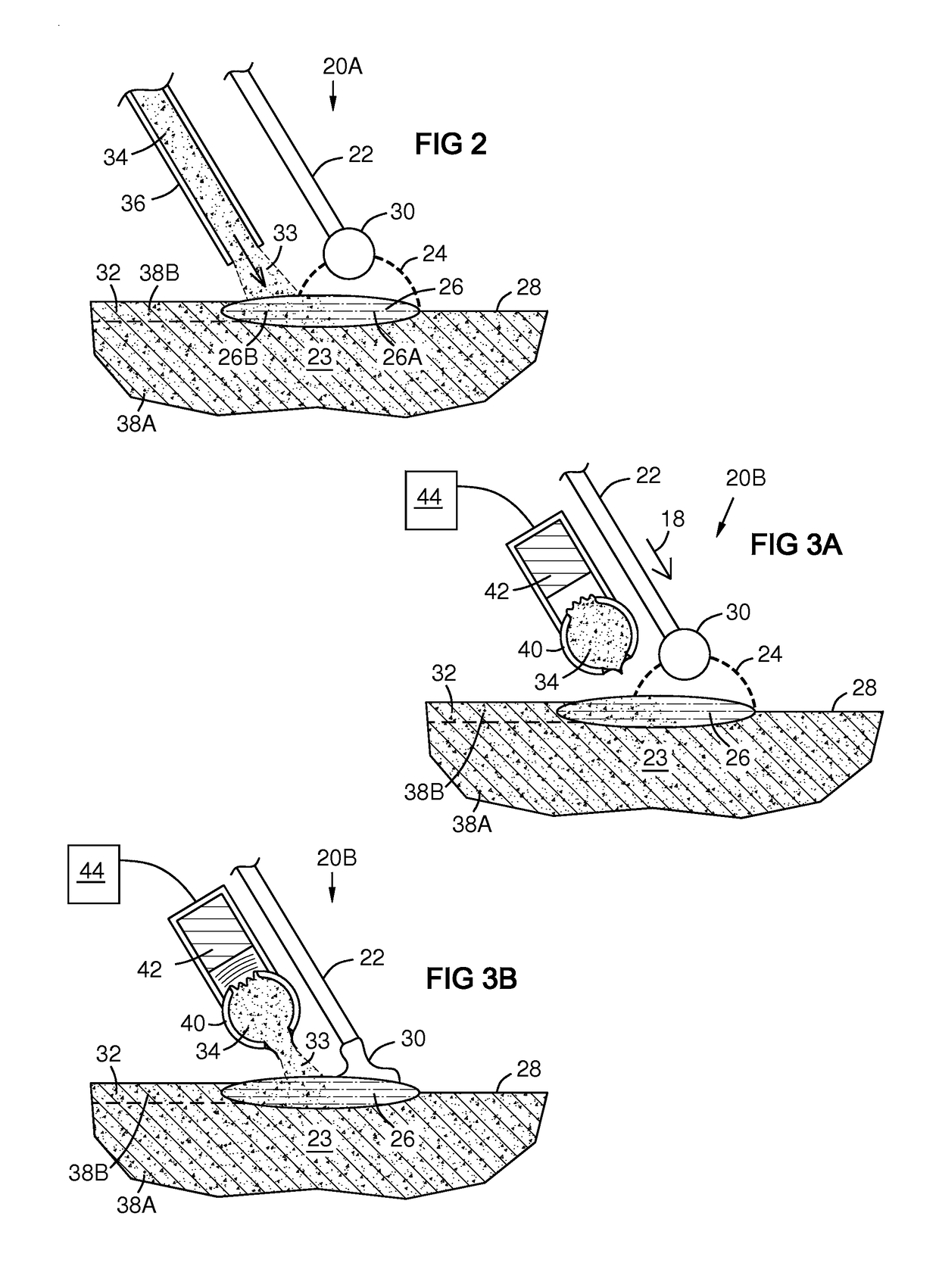

Formation and repair of oxide dispersion strengthened alloys by alloy melting with oxide injection

ActiveUS20170080508A1Evacuating shieldingMetallic material coating processesMetal alloyOxide dispersion-strengthened alloy

Melting energy exemplified by an arc (24) is delivered to a metal alloy material (22, 23), forming a melt pool (26). A metal oxide material (34) is delivered (33) to the melt pool and dispersed therein. The melting energy and oxide deliveries are controlled (44) to melt the alloy material, but not to melt at least most of the metal oxide material. The deliveries may be controlled so that the melting energy does not intercept the metal oxide delivery. The melting energy may be controlled to create a temperature of the melt pool that does not reach the melting point of the metal oxide. Deliveries of the melting energy and the oxide may alternate so they do not overlap in time. A cold metal transfer apparatus (22) and process (18, 19, 20) may be used for example in combination with an oxide particle pulse delivery device (42, 46).

Owner:SIEMENS ENERGY INC

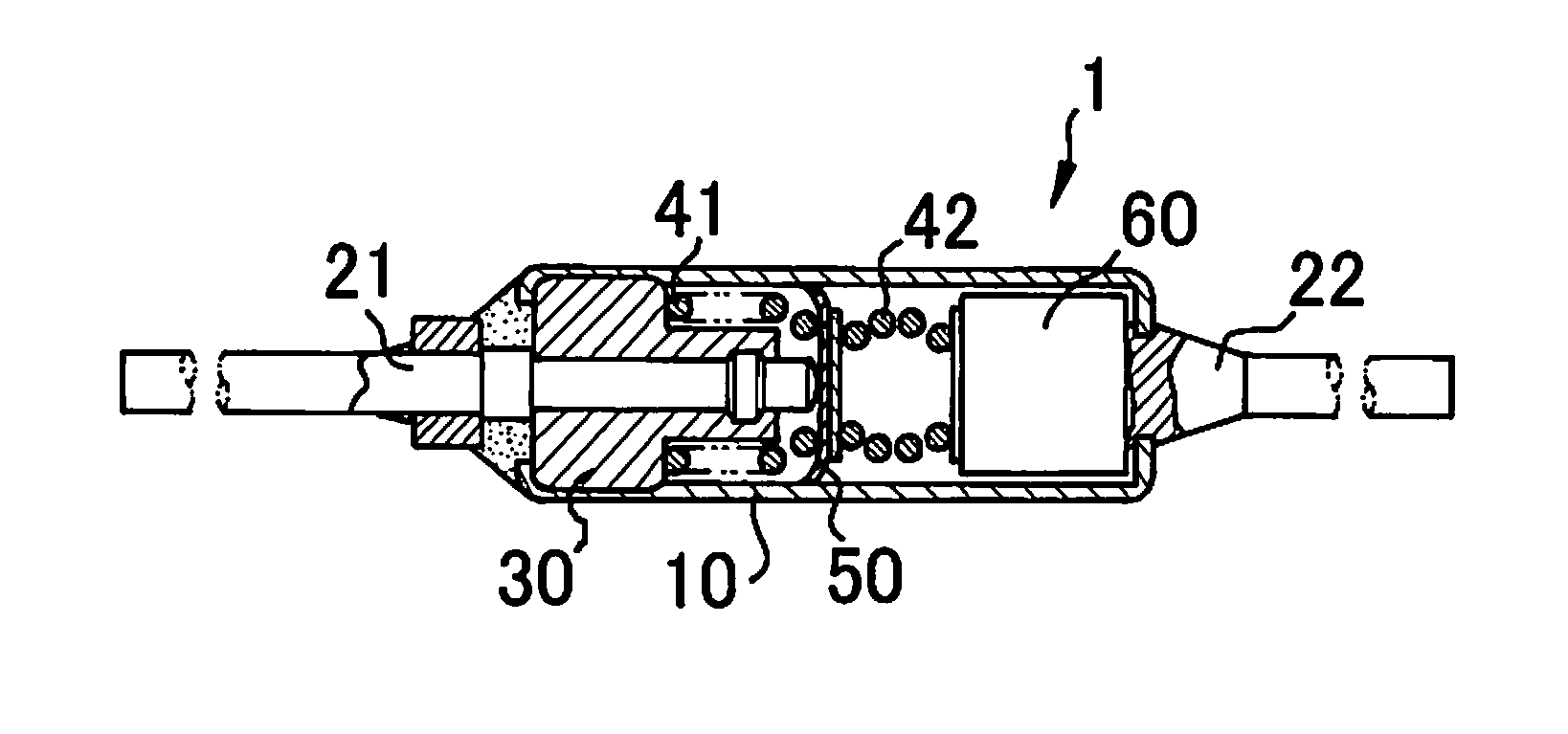

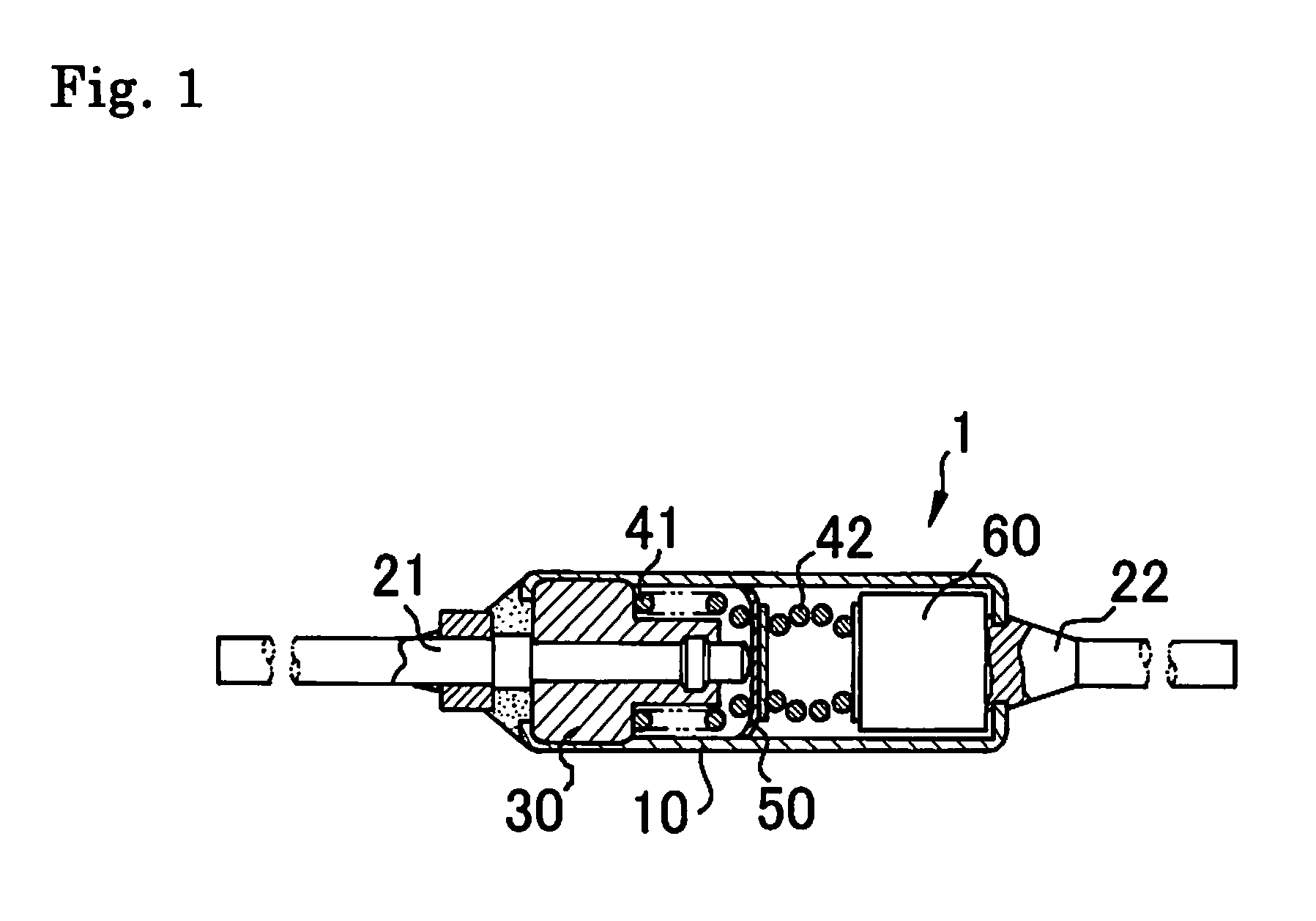

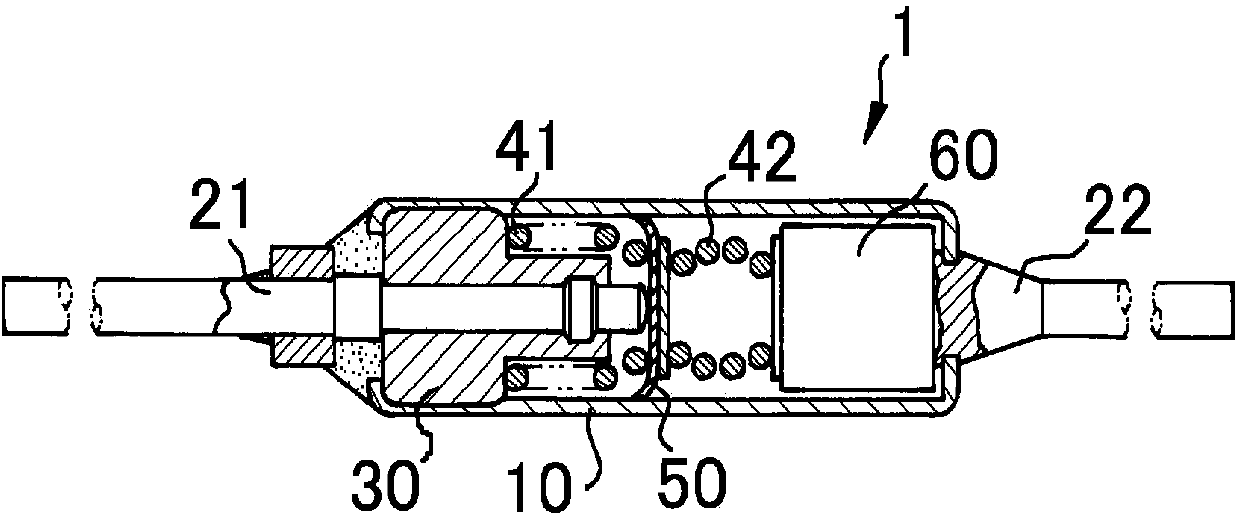

Electrode material having clad structure

InactiveUS20150015360A1Good melt adhesion resistanceProcess stabilityHeating/cooling contact switchesThermal switch detailsOxide dispersion-strengthened alloyHot melt

Provided is an electrode material constituting a movable electrode 50 of a thermal fuse 1, wherein the electrode material has a clad structure where a base layer including Cu or a Cu alloy is joined to a contact point layer made of a Ag—CuO based oxide-dispersion-strengthened alloy. The present invention is an electrode material that is suitable for a movable electrode of a thermal fuse and can solve the problem of the failure of contact with the case in association with long-term use. In this electrode material, it is preferable that a contact layer including Ag be joined to a back surface of the base layer in order to improve resistance to contact with a case 10.

Owner:TANAKA PRECIOUS METAL IND

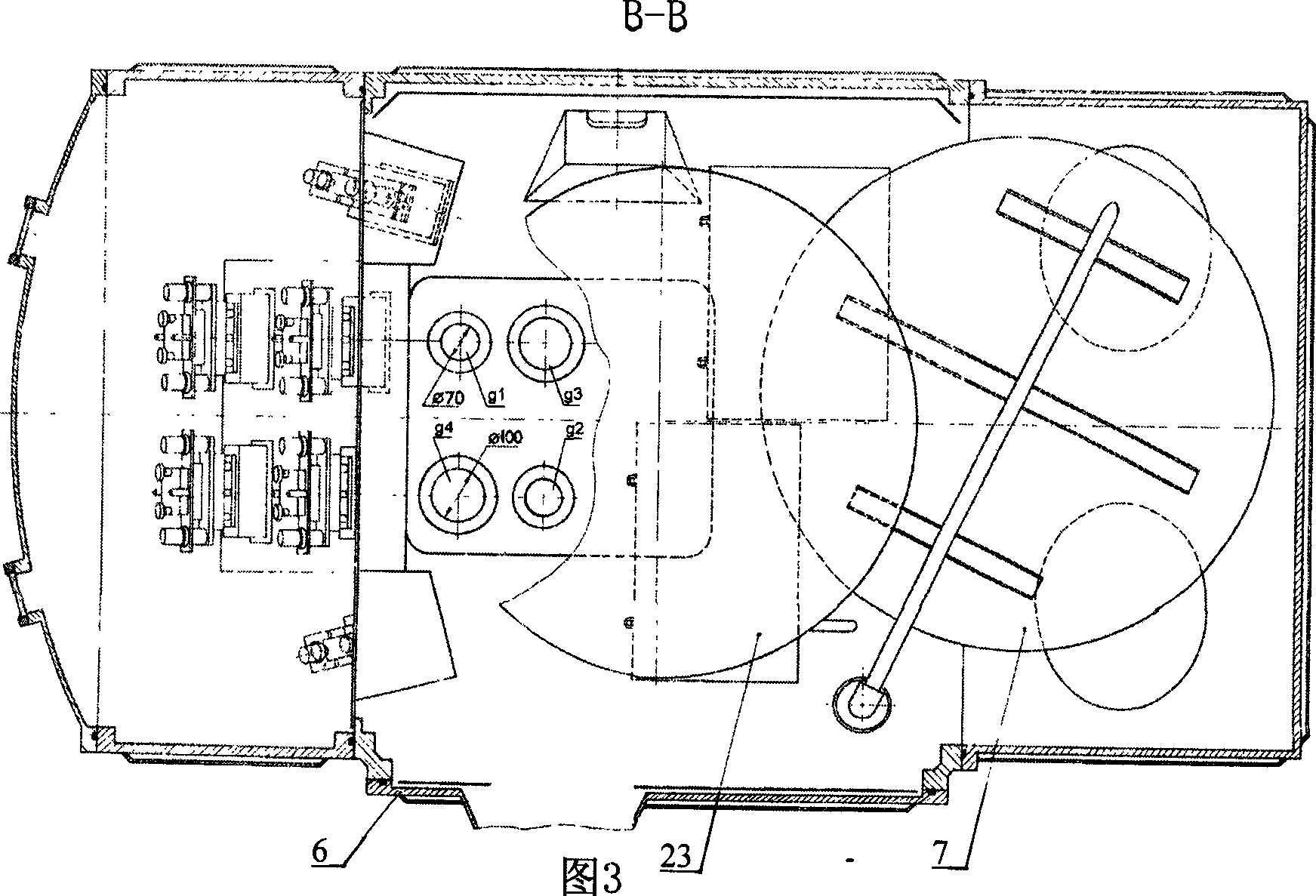

Welding method of oxide strengthened dispersion alloy shockproof screen part

The invention relates to the technical field of alloy welding, in particular to a welding method of an oxide strengthened dispersion alloy shockproof screen part. The method comprises the following steps: firstly, the welding surface of a shockproof screen part is subject to sand papering, is cleaned by chemically pure acetone, is spot-welded and positioned at two ends of a welding seam after being dried at a room temperature, and finally is welded, the welding parameter is that 0.13 to 0.24 MPa of pressure is applied to the welding surface per 0.02 seconds, the power-on welding time is 0.16 s, the welding current is 6600 to 8000 A, the welding voltage is 209 to 213 V, the flow passage ratio is 7:10, and the welding speed is 0.4 m / s. The tensile-strength of the welding surface of the oxide strengthened dispersion alloy shockproof screen welded by the welding method reaches more than 65 % of that of an MGH 956 alloy body at a temperature of 1100 DEG C, so that the design requirement of an engine is met. The welding method is simple to operate, achieves the engineered production, is popularized and applied in other military plans, civil aircrafts and combustion engines, and has wide application prospect.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

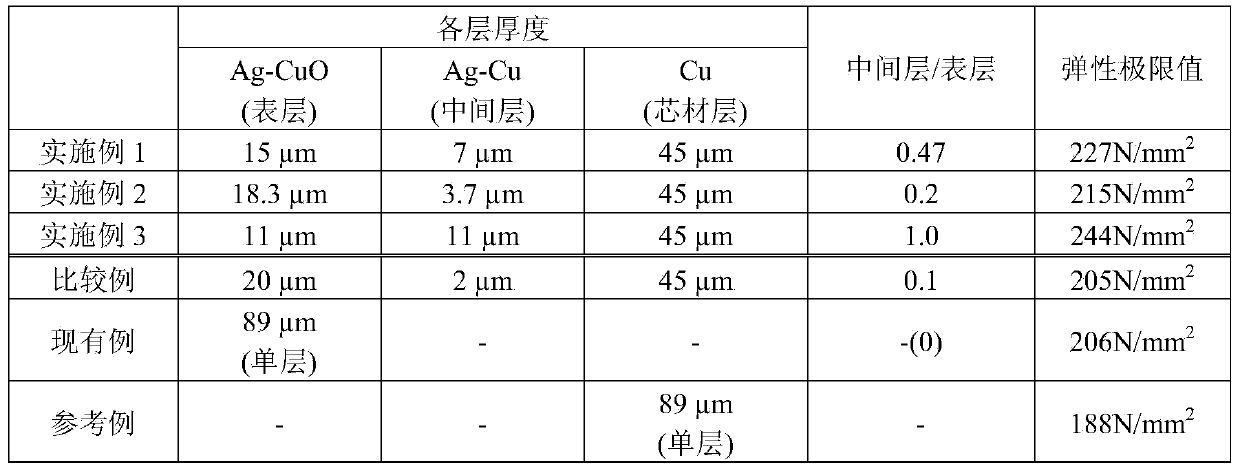

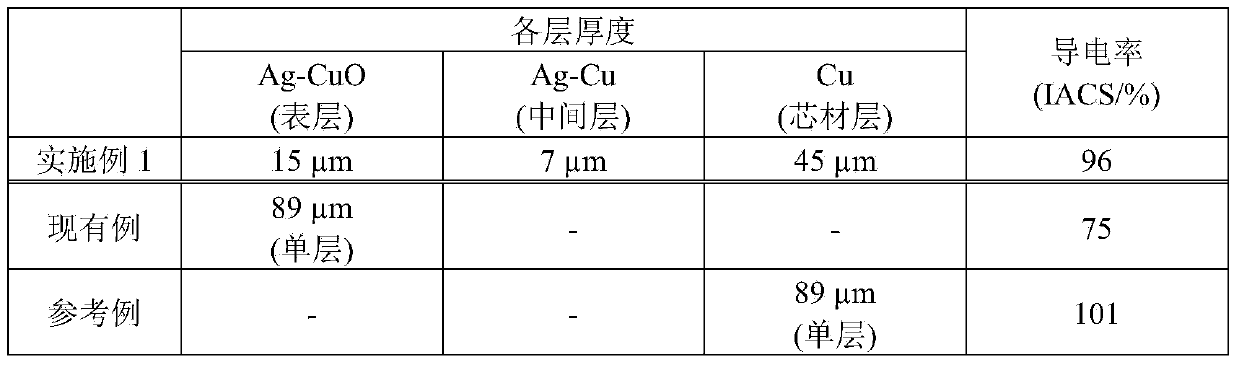

Electrode material for thermal-fuse movable electrode

ActiveCN104272419ALow costImprove welding resistanceHeating/cooling contact switchesContactsSurface layerOxide dispersion-strengthened alloy

The present invention is an electrode material for configuring a thermal-fuse movable electrode, and having a five-layer clad structure comprising a core layer, intermediate layers formed on both surfaces of the core layer, and surface layers formed on the intermediate layers, wherein: the core layer comprises Cu; the intermediate layers comprise an Ag-Cu alloy; the surface layers comprise an Ag-CuO-oxide-dispersion-strengthened alloy; and the ratio of the thickness of the intermediate layers to the thickness of the surface layers (intermediate / surface) is 0.2 to 1.0, inclusive. It is possible to produce this electrode material by sectionally performing an internal oxidation processing on a three-layer clad material obtained by cladding both surfaces of a sheet material comprising Cu with a sheet material comprising an Ag-Cu alloy.

Owner:TANAKA PRECIOUS METAL IND

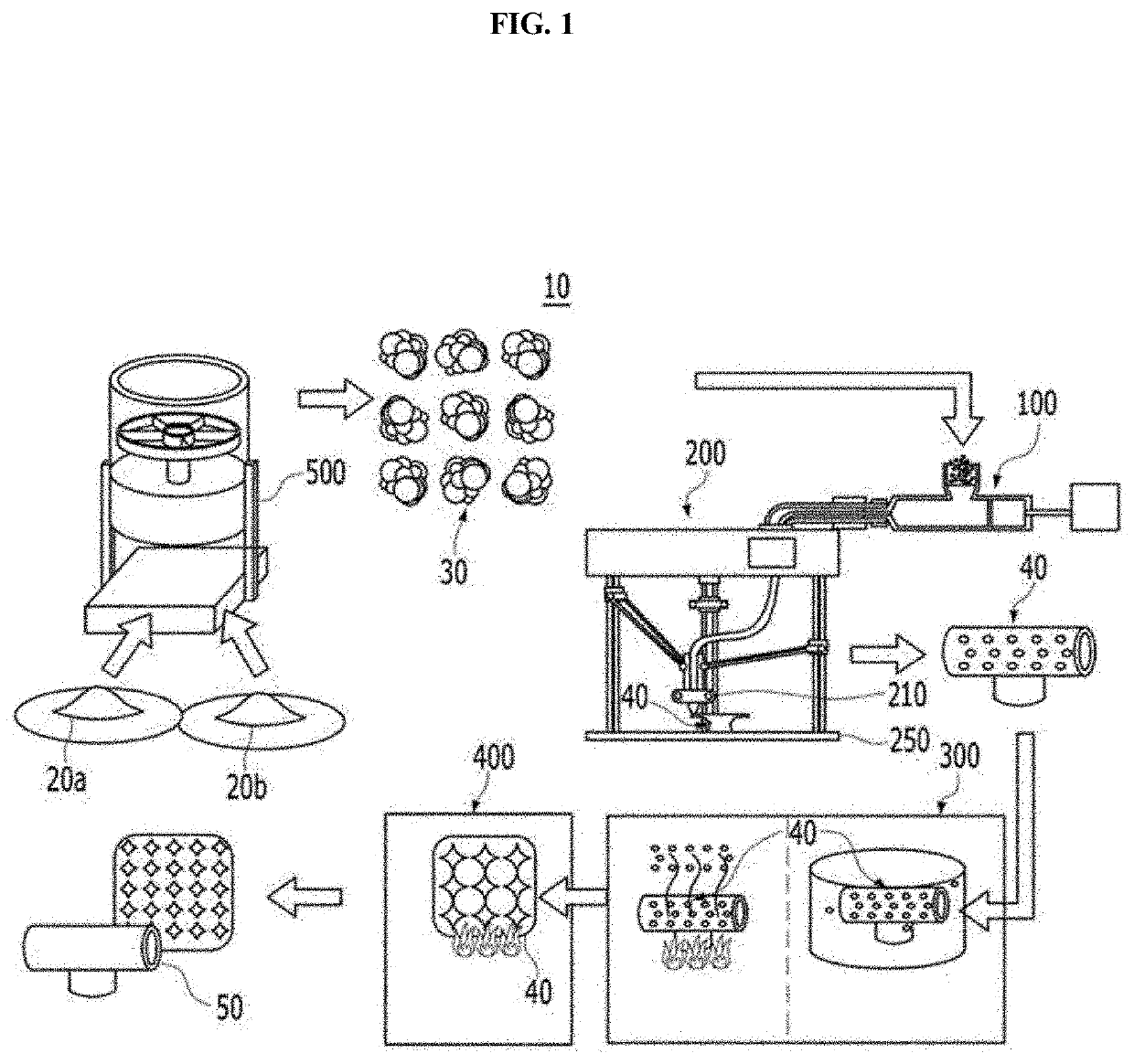

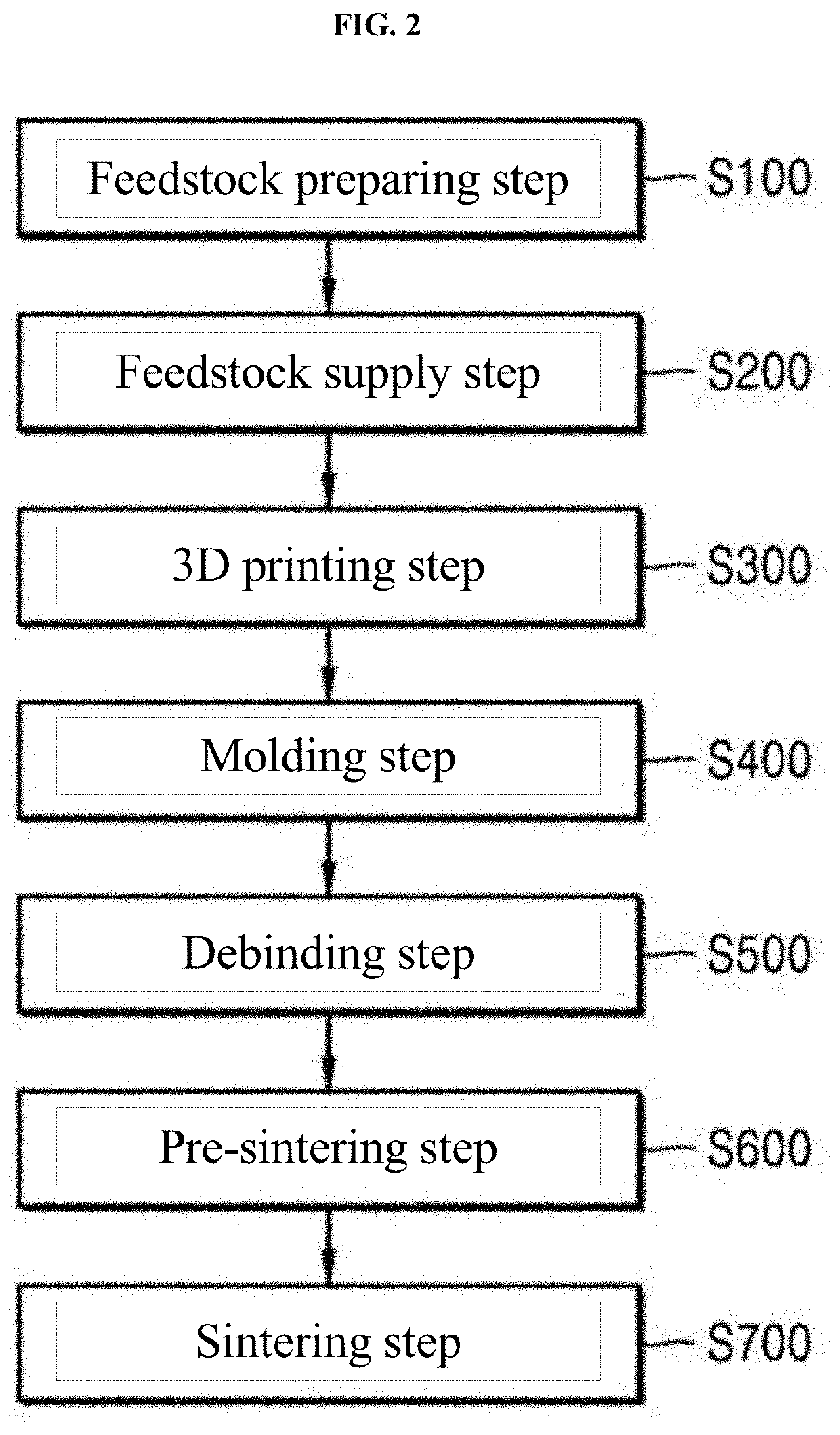

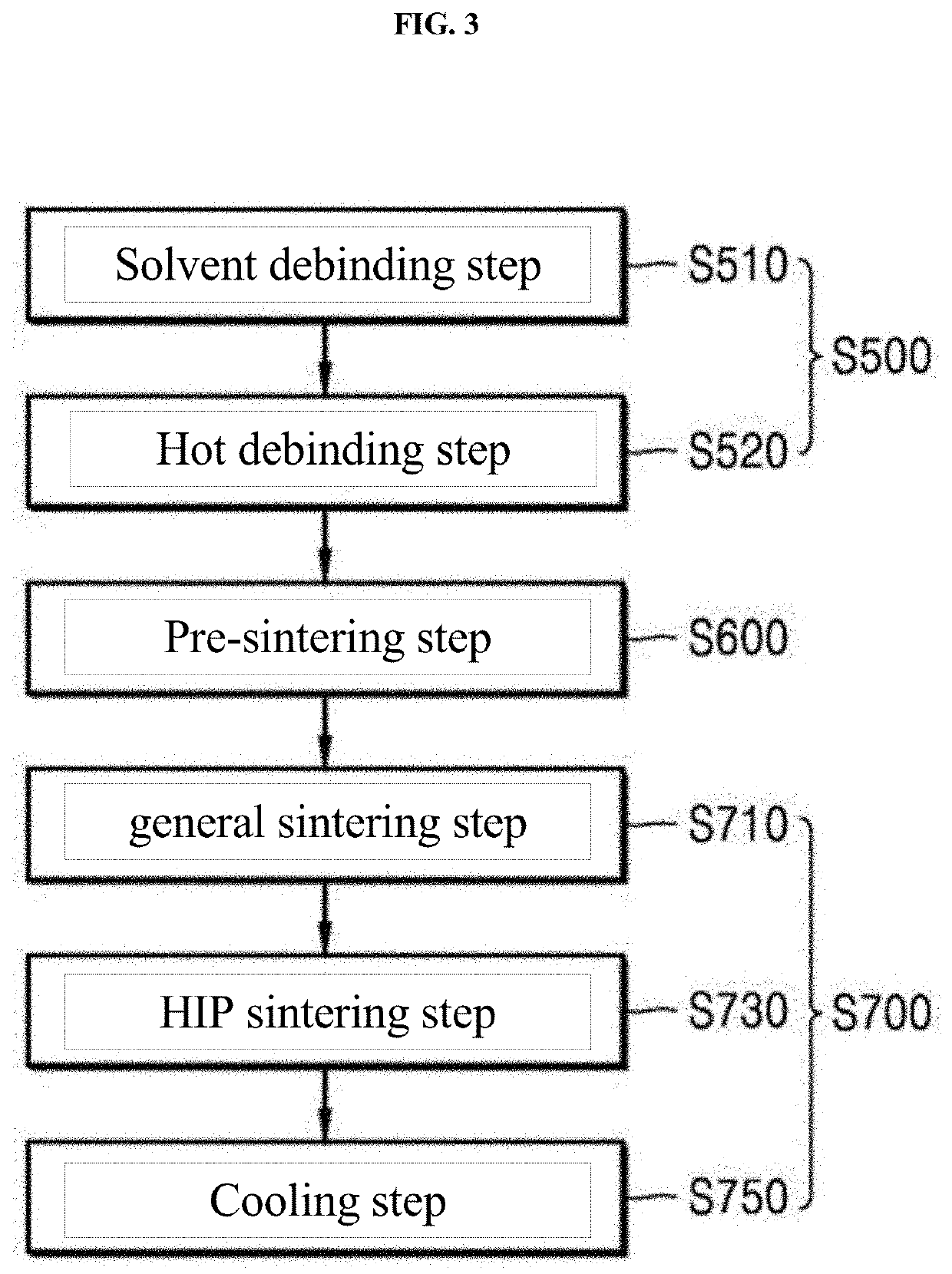

Method for manufacturing oxide dispersion strengthened alloy using organic/inorganic mixed composition as raw material

PendingUS20210260655A1Improve mechanical propertiesImprove accuracyAdditive manufacturing apparatusTransportation and packagingOxide dispersion-strengthened alloyPolymer

According to an aspect of the present invention, a method for producing an oxide-dispersed strengthened alloy using organic-inorganic kneaded composition is provided. The method, comprises: a feedstock preparing step of preparing the organic-inorganic kneaded composition prepared by kneading, pulverizing and granulating ODS mixed powders and a polymer binder; a molding step of forming a semi-finished product having a predetermined shape using the organic-inorganic kneaded composition; a debinding step of removing the polymeric binder from the semi-finished product molded in the molding step; and a sintering step of extracting a final product having a predetermined shape by sintering and cooling the semi-finished product in which the polymeric binder has been removed in the debinding step.

Owner:LEE SANGKYU

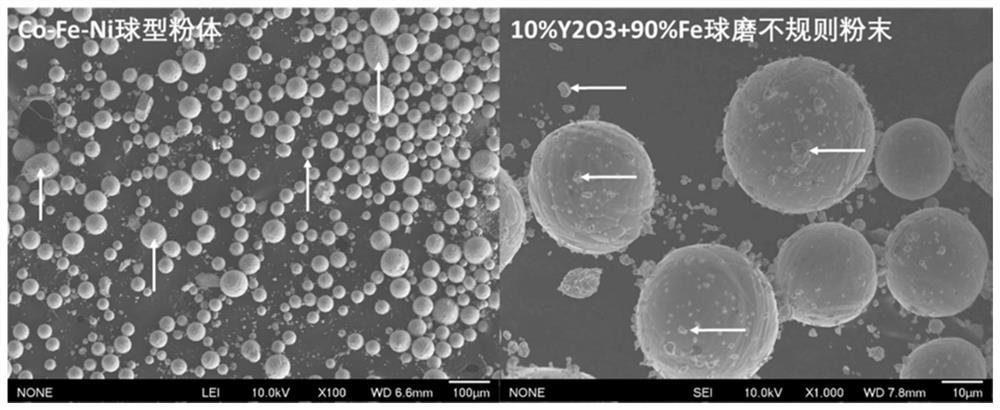

Oxide dispersion strengthened alloy and preparation method and application thereof

ActiveCN114535606AHigh strengthGood strength and toughness ratioAdditive manufacturing apparatusIncreasing energy efficiencyOxide dispersion-strengthened alloyAdditive layer manufacturing

The invention relates to an oxide dispersion strengthened alloy and a preparation method and application thereof, and the preparation method comprises the following steps: mixing main body material powder and additive material powder, printing and forming by adopting a powder laying additive manufacturing mode, and then carrying out heat treatment to obtain the oxide dispersion strengthened alloy, the main body material powder is alloy material powder containing Cr and / or Ni, and the additive material powder is iron-based mechanical ball-milled powder containing Y2O3 and / or TiO2; the oxide dispersion strengthened alloy is used in the field of molds. Compared with the prior art, the defects of preparation of oxide dispersion strengthened alloy through powder metallurgy are overcome, the comprehensive mechanical property of current additive manufacturing alloy is also improved, compared with additive manufacturing forming of existing die steel, additional steps do not need to be added in the whole preparation process, set main body material printing parameters do not need to be changed, the preparation method is simple, and the cost is low. And the die quality is improved, and the method is suitable for industrial production.

Owner:SHANGHAI JIAO TONG UNIV

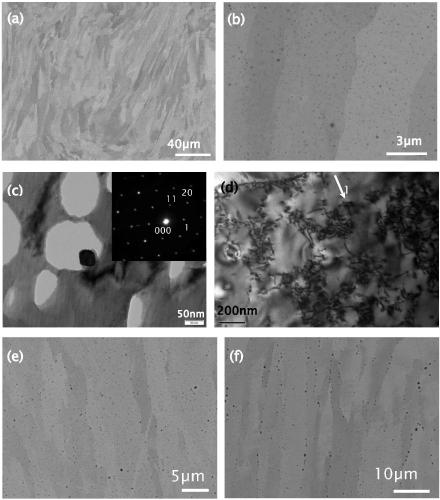

Martensitic oxide dispersion strengthened alloy with enhanced high-temperature strength and creep property, and method of manufacturing the same

InactiveUS20140294653A1Improve high temperature strengthImproved creep propertiesOxide dispersion-strengthened alloyTitanium

The present application discloses a martensitic oxide dispersion-strengthened alloy having enhanced high-temperature strength and creep properties. The alloy includes chromium (Cr) of 8 to 12% by weight, yttria (Y2O3) of 0.1 to 0.5% by weight, carbon (C) of 0.02 to 0.2% by weight, molybdenum (Mo) of 0.2 to 2% by weight, titanium (Ti) of 0.01 to 0.3% by weight, zirconium (Zr) of 0.01 to 0.2% by weight, nickel (Ni) of 0.05 to 0.2% by weight and the balance of iron (Fe). The application also discloses a method of making the alloy.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD

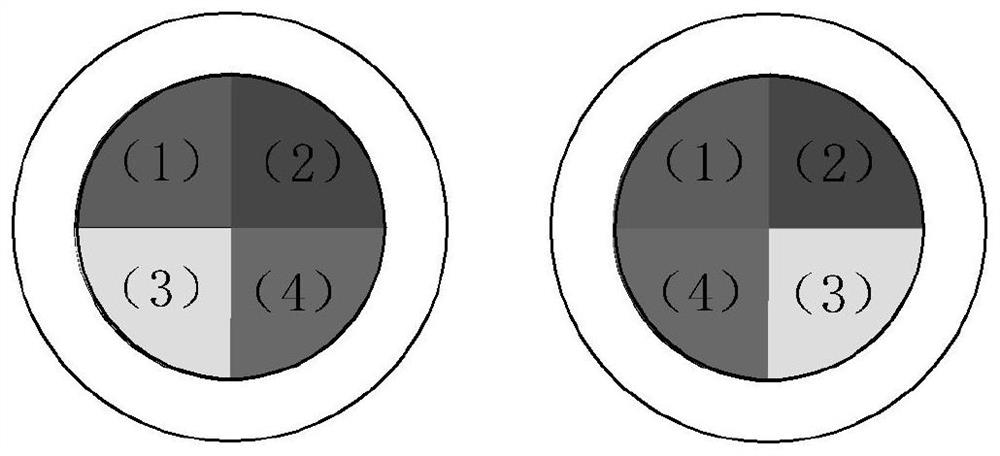

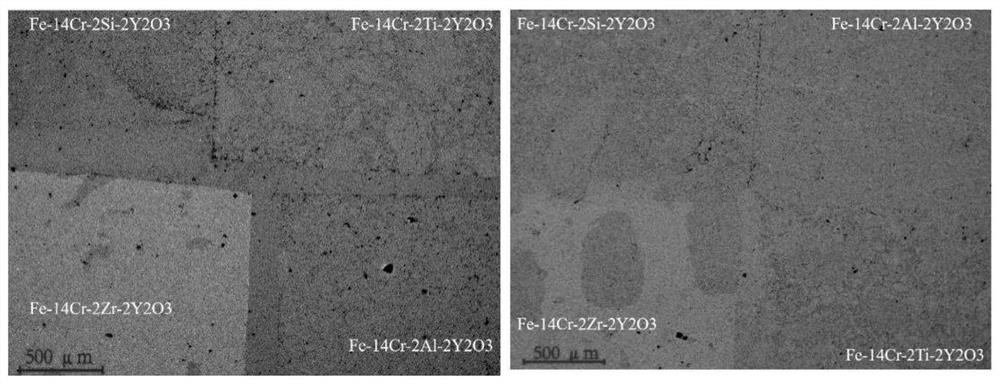

Diffusion multi-section technology-based ODS alloy component design method

PendingCN114505479AShort manufacturing cycleImprove efficiencyNuclear energy generationOxide dispersion-strengthened alloyHot isostatic pressing

The invention belongs to the field of oxide dispersion strengthened alloys, and adopts a diffusion multi-section technology to guide the ODS alloy component design. The method comprises the steps of ODS alloy blank unit component design and preparation, blank polishing, diffusion multi-section design and assembly, vacuum packaging, hot isostatic pressing machining forming and long-time diffusion annealing at the high temperature, and ODS alloys with different components meeting different working conditions can be obtained at a time. The method is easy to implement, efficient, rapid and capable of obtaining the ODS alloy with multiple different components at the same time, the research and development speed can be shortened, the research and development cost can be reduced, and the method has important significance on component design and development of the ODS alloy.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com