Diffusion multi-section technology-based ODS alloy component design method

A technology of alloy composition and design method, applied in the field of ODS alloy composition design, can solve problems such as low efficiency of composition design, and achieve the effects of reducing preparation cycle, improving efficiency and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

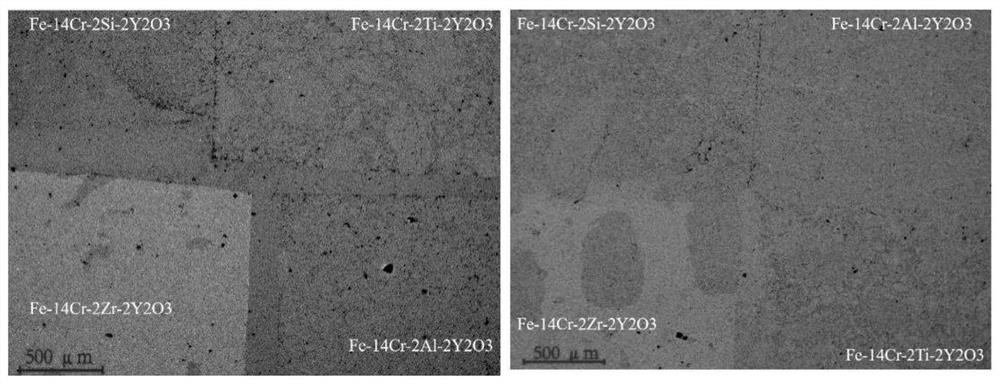

[0050] Example 1 Ti, Al, Zr, Si in Y 2 o 3 Interdiffusion in Dispersion Strengthened Steel and Effects of Ti and Al on Oxide Disperse Phase Size and Number Density in Oxide Dispersion Strengthened Steel

[0051] Step 1: Prepare Fe-Cr-Y by ball milling for more than 24 hours and spark plasma sintering 2 o 3 -X (X=Ti, Al, Zr, Si) four kinds of ODS steel body units, of which Fe-Cr-Y 2 o 3 The composition ratio of each unit is consistent, the sintering temperature is 850°C, the pressure is 50MPa, and the holding time is 10min;

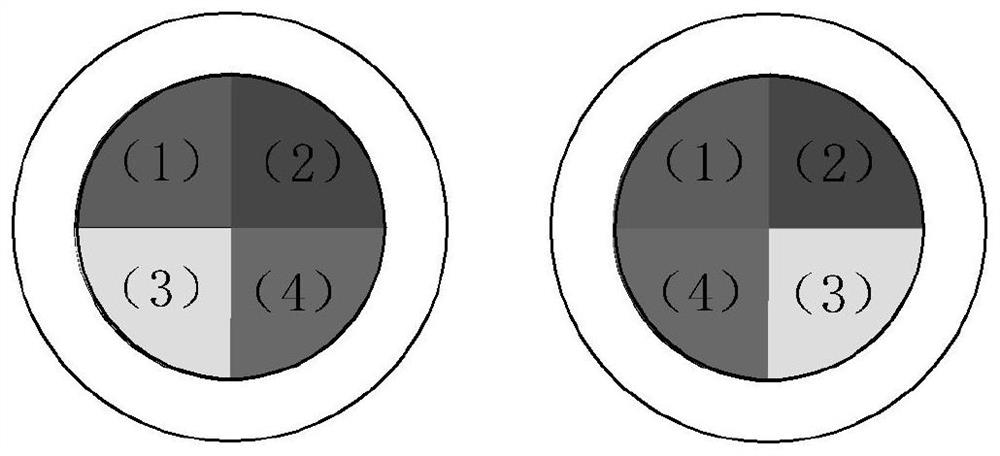

[0052] Step 2: Since the investigated elements include four types, according to figure 1 The assembly method is assembled into the bag, and the ODS steel blank body unit is wire-cut, polished, cleaned and assembled according to this assembly method;

[0053] Step 3: Use vacuum electron beam welding to seal the sheath, and then use hot isostatic pressing to ensure that the alloy units are in close contact. The welding depth of vacuum electron beam we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com