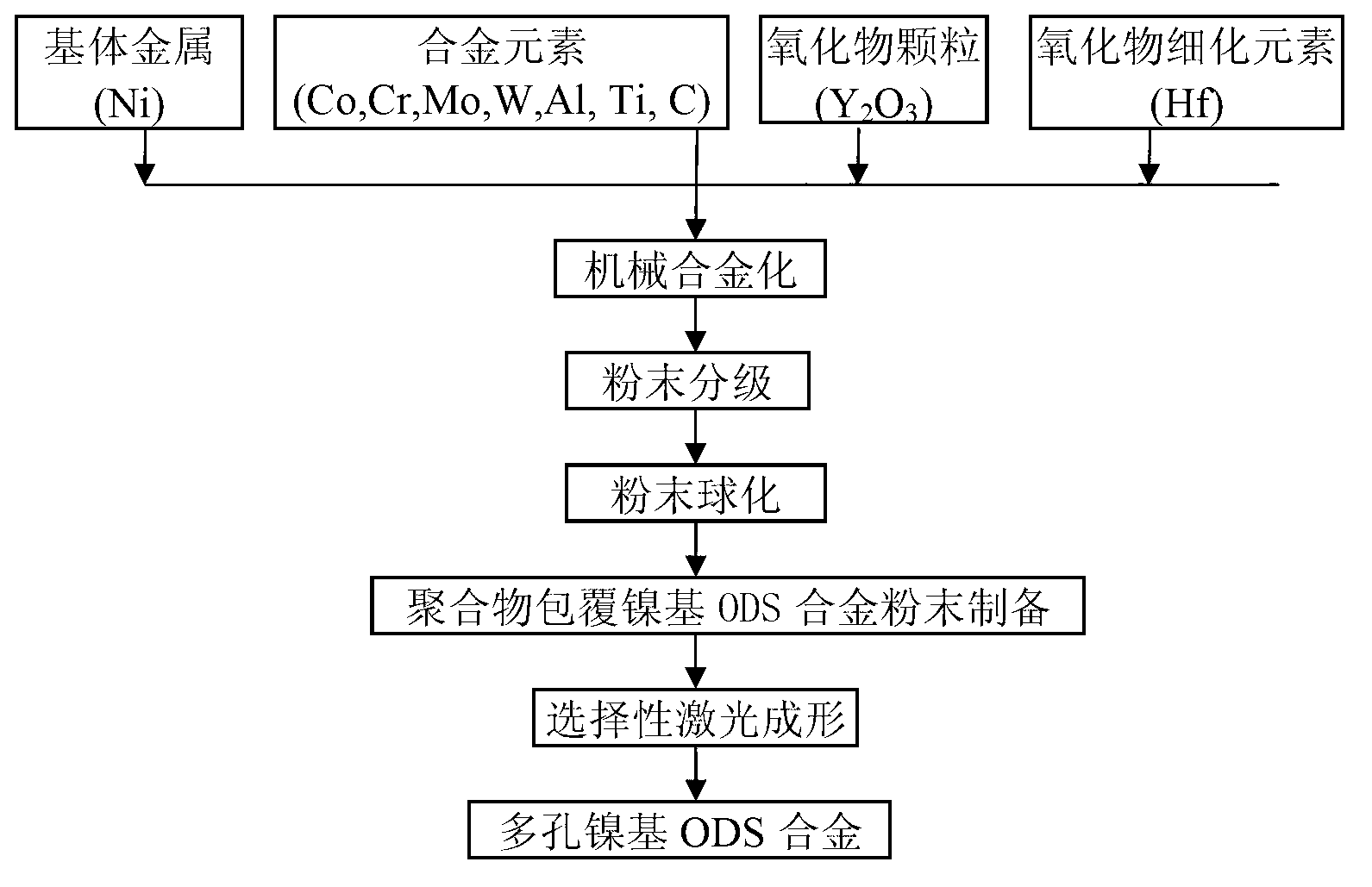

Method for near-net shaping of porous Ni-based ODS (oxide dispersion strengthening) alloy

A technology of near net forming and porous nickel, which is applied in the direction of process efficiency improvement, additive manufacturing, additive processing, etc., can solve the problems of porous nickel-based ODS alloy forming and pore structure control difficulties, and achieve strong designability, The effect of high utilization rate and high temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: the preparation of porous nickel-chromium-based ODS alloy

[0019] According to the composition of nickel-chromium-based ODS alloy [15wt.%Cr-0.3wt.%Y 2 o 3 -0.5wt.%Hf-balance Ni] Weigh nickel powder, chromium powder, Y 2 o 3 Granules and hafnium powder, and pre-mix the mixed powder evenly. The premixed powder is uniformly dispersed in the nickel matrix by high-energy ball milling in a high-purity Ar atmosphere, where the ball / material ratio is 10 / 1, the ball mill speed is 350 rpm, and the ball milling time is 24 hours. The obtained nickel matrix The particle size of ODS alloy powder is 35~74μm. Secondly, the nickel-based ODS alloy powder and the thermoplastic polymer were pre-mixed uniformly and then put into a kneader for stirring. The heating temperature was 140°C and the stirring time was 40 minutes to obtain the nickel-based ODS alloy powder uniformly coated with the polymer, and the Crushing and dispersing the aggregated polymer-coated nickel-b...

Embodiment 2

[0020] Embodiment 2: Preparation of porous nickel-aluminum-based ODS alloy

[0021] According to the composition of nickel-aluminum-based ODS alloy [20wt.%Al-1wt.%Y 2 o 3 -1wt.%Hf-balance Ni] Weigh nickel powder, aluminum powder, Y 2 o 3Granules and hafnium powder, and pre-mix the mixed powder evenly. The premixed powder is uniformly dispersed in the nickel matrix by high-energy ball milling in a high-purity Ar atmosphere, wherein the ball / material ratio is 15 / 1, the ball mill speed is 380 rpm, and the ball milling time is 36 hours. The obtained nickel matrix The particle size of ODS alloy powder is 21~62μm. Secondly, the nickel-based ODS alloy powder and the thermoplastic polymer were pre-mixed uniformly and then put into a kneader for stirring. The heating temperature was 150°C and the stirring time was 50 minutes to obtain the nickel-based ODS alloy powder uniformly coated with the polymer, and the Crushing and dispersing the aggregated polymer-coated nickel-based OD...

Embodiment 3

[0022] Example 3: Preparation of single-aperture porous nickel-based ODS alloy (MA754)

[0023] According to the composition of nickel-based ODS alloy MA754 [20wt.%Cr-0.3wt.%Al-0.5wt.%Ti-1%wt.%Fe

[0024] -0.05wt.%C-(0.3~3wt.%)-Y 2 o 3 - Balance Ni] Weigh nickel powder, chromium powder, aluminum powder, titanium powder, iron powder, carbon powder and Y 2 o 3 Granules, and pre-mix the mixed powder evenly. The premixed powder is uniformly dispersed in the nickel matrix by high-energy ball milling in a high-purity Ar atmosphere, wherein the ball / material ratio is 20 / 1, the ball mill speed is 400 rpm, and the ball milling time is 48 hours. The obtained nickel matrix The particle size of ODS alloy powder is 25~80μm. Nickel-based ODS alloy powders with different particle sizes after ball milling for different times were sieved to obtain nickel-based ODS alloy powders with a diameter of 25-28 μm. Ni-based ODS alloy powder with narrow particle size distribution at a powder fee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com