In-situ synthesis oxide dispersion strengthening CoCrW alloy and preparation method thereof

A technology of dispersion strengthening and in-situ synthesis, which is applied in additive manufacturing, dentures, additive processing, etc., can solve the problems of waste of cutting materials, wear of jaws and teeth, and collapse of porcelain, so as to prolong service life, improve bonding ability, and avoid The effect of the crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A preparation method for in-situ synthesis of oxide dispersion strengthened CoCrW alloy, said preparation method comprising the following steps:

[0028] (1) CoCrW alloy powder is subjected to laser melting treatment in an inert gas atmosphere to obtain an in-situ synthesized oxide dispersion strengthened CoCrW alloy, the oxygen content in the inert gas atmosphere is 200-2000ppm, and the CoCrW alloy powder contains Si element , the weight content of the Si element in the CoCrW alloy powder is 0.1%-2%.

Embodiment 1

[0030] As a method for preparing an in-situ synthesized oxide dispersion-strengthened CoCrW alloy according to an embodiment of the present invention, the preparation method includes the following steps:

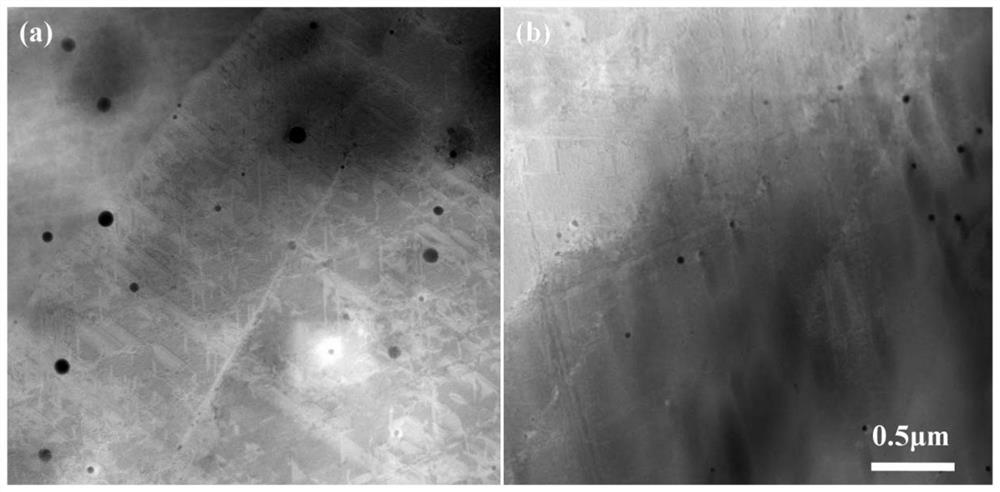

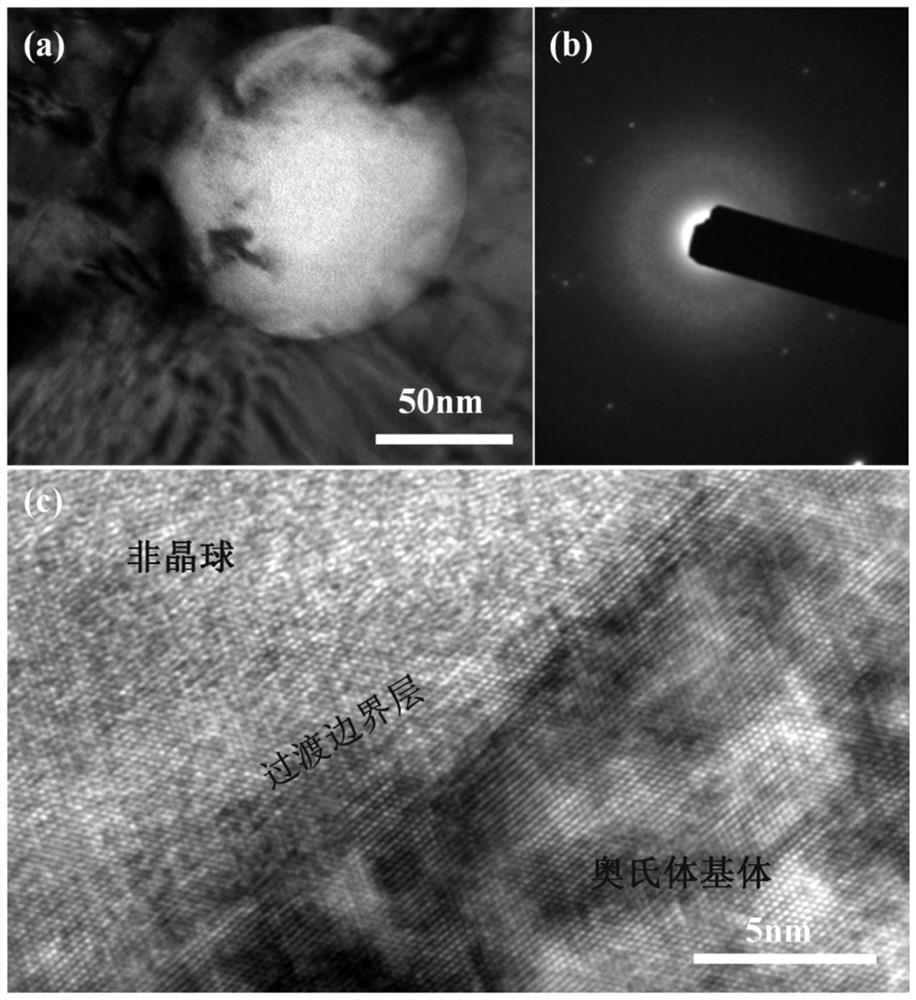

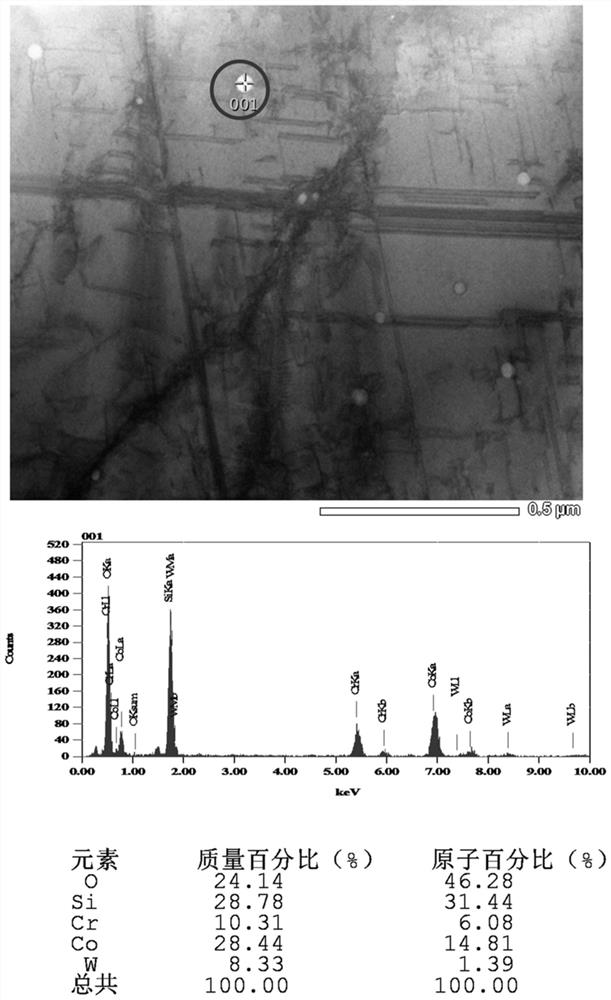

[0031] The CoCrW alloy powder with a particle size of 1-53 μm is screened, and the CoCrW alloy powder is subjected to laser melting treatment on a selective laser melting 3D printing device in an inert gas atmosphere to obtain an in-situ synthesized oxide dispersion strengthened CoCrW alloy. The oxygen content is 1800ppm, the CoCrW alloy powder contains Si element, and the weight content of Si element in the CoCrW alloy powder is 1.0%;

[0032] The laser melting treatment of the selected laser melting 3D printing equipment includes the following parameters: the printing substrate is preheated to 80°C, the laser spot size is 0.1mm during the printing process, the laser power is 200-325W, the laser scanning rate is 700-1120mm / s, the laser The scanning distance is 0.08-0.1mm, t...

Embodiment 2

[0035] As a method for preparing an in-situ synthesized oxide dispersion-strengthened CoCrW alloy according to an embodiment of the present invention, the only difference between this embodiment and Embodiment 1 is that the oxygen content in the gas atmosphere is 1500 ppm, and the CoCrW alloy powder The weight content of Si element is 1.5%.

[0036] The composition content of the in-situ synthesized oxide dispersion strengthened CoCrW alloy prepared in this example is shown in Table 1.

[0037] Table 1 Composition content (%) of oxide dispersion strengthened CoCrW alloy

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com