Martensitic oxide dispersion strengthened alloy with enhanced high-temperature strength and creep property, and method of manufacturing the same

a technology of martensitic oxide and dispersions, which is applied in the field of martensitic oxide dispersionstrengthened alloys, can solve the problems of significant low strength, inability to meet design requirements, and inferior high-temperature creep properties of alloys, and achieve enhanced high-temperature strength and creep properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Manufacture of Martensitic Oxide Dispersion-Strengthened Alloy

[0047]Martensitic oxide dispersion-strengthened alloys having compositions as listed in the following Table 1 were manufactured.

TABLE 1FeCCrWMoNiTiZrY2O3Reference alloy 1Bal.0.151020.250.35Reference alloy 2Bal.0.151120.10.250.35Novel alloyBal.0.151110.10.10.20.35Units: % by weight

[0048]That is, a high-purity source powder (Fe, Cr, Mo, Ti, Zr and Ni: a grain size of 200 mesh or less and a purity of 99% or more) and Y2O3 powder (a particle size of 50 nm or less and a purity of 99.9%) were mixed at respective weight ratios, and then mechanically alloyed at 240 rpm for 48 hours under an ultra-high purity Ar atmosphere using a horizontal ball mill to manufacture an alloy powder. Thereafter, a stainless can was charged with the alloy powder and sealed, and the alloy powder was then degassed at 500° C. for 3 hours under a degree of vacuum of 10−4 torr, or less. The can charged with the manufactured alloy powder was subjected to ...

example 2

Comparison Test of Room-Temperature and High-Temperature Strength Properties

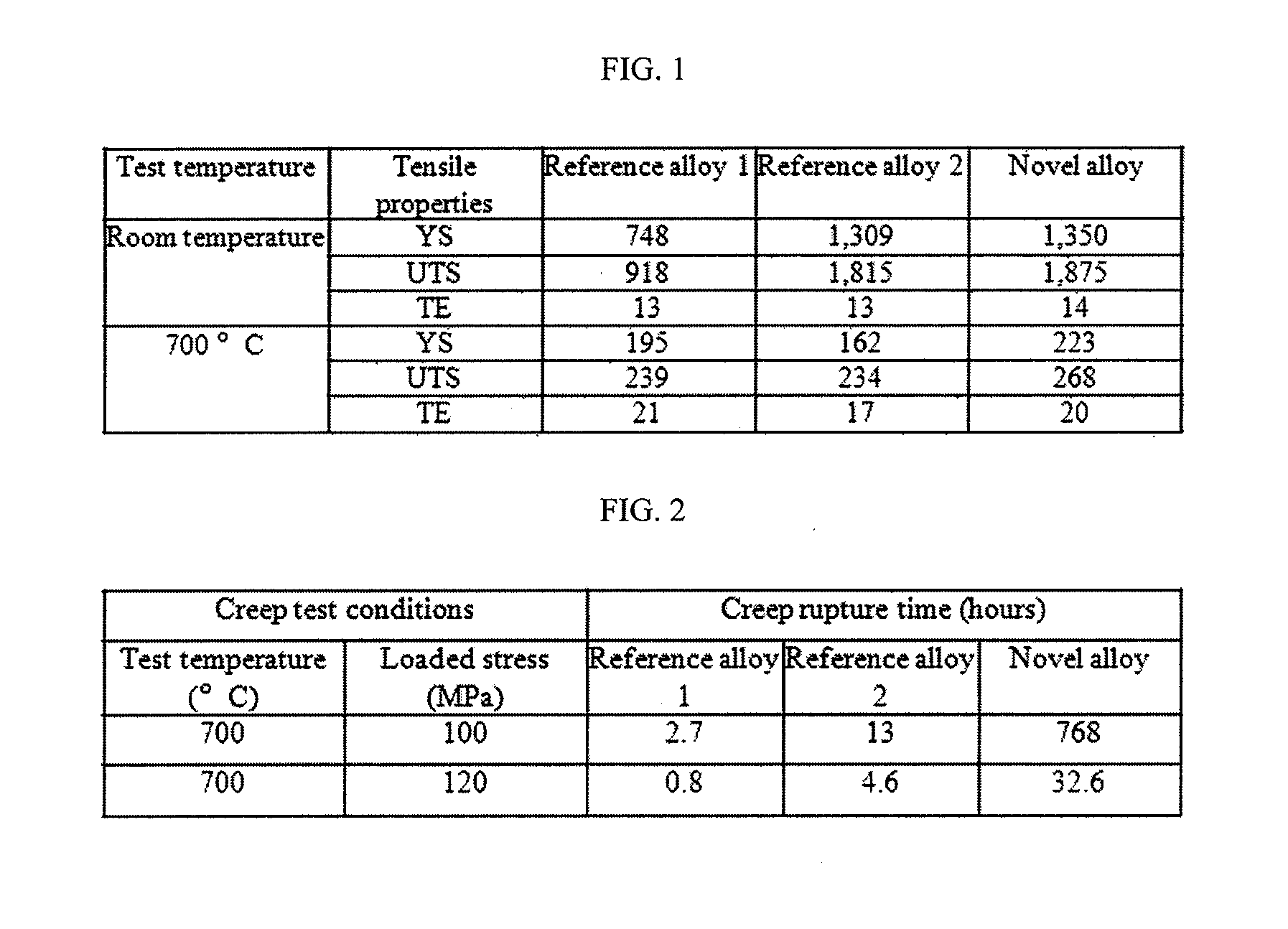

[0049]The three martensitic oxide dispersion-strengthened alloys (i.e., reference alloys 1 and 2 and the novel alloy) manufactured in Example 1 were measured for yield strength (YS), ultimate tensile strength (UTS) and total elongation (TE) at room temperature and 700° C. The results are shown in FIG. 1.

[0050]As shown in FIG. 1, it could be seen that the reference alloy 1 to which tungsten (W) and titanium (Ti) were added had yield strengths of 748 MPa and 195 MPa at room temperature and 700° C., respectively, and the reference alloy 2 to which nickel (Ni) was further added at a content of 0.1% by weight had yield strengths of 1,309 MPa and 162 MPa at room temperature and 700° C., indicating that the reference alloy 2 had enhanced tensile strength, compared with the reference alloy 1. In particular, it could be seen that the alloy (i.e., the novel alloy) according to the present invention in which tungsten ...

example 3

Comparison Test of High-Temperature Creep Property

[0052]A creep test was performed at 700° C. on the three martensitic oxide dispersion-strengthened alloys prepared in Example 1. The results are shown in FIG. 2.

[0053]As shown in FIG. 2, it could be seen that the alloy (i.e., a novel alloy) according to the present invention in which tungsten (W) was replaced with molybdenum (Mo) and to which titanium (Ti), zirconium (Zr) and nickel (Ni) were added together had a significantly increased creep rupture time under stresses of 100 and 120 MPa, compared with the reference alloys 1 and 2 containing tungsten (W) and titanium (Ti).

[0054]From these results, it could be seen that the martensitic oxide dispersion-strengthened alloy according to the present invention had a more excellent high-temperature creep property than the conventional martensitic oxide dispersion-strengthened alloy.

[0055]The martensitic oxide dispersion-strengthened alloy according to the present invention includes chromiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com