Electrode material for thermal-fuse movable electrode

一种温度保险丝、电极材料的技术,应用在电极材料领域,能够解决温度保险丝工作不良等问题,达到实现材料成本、耐熔敷性良好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

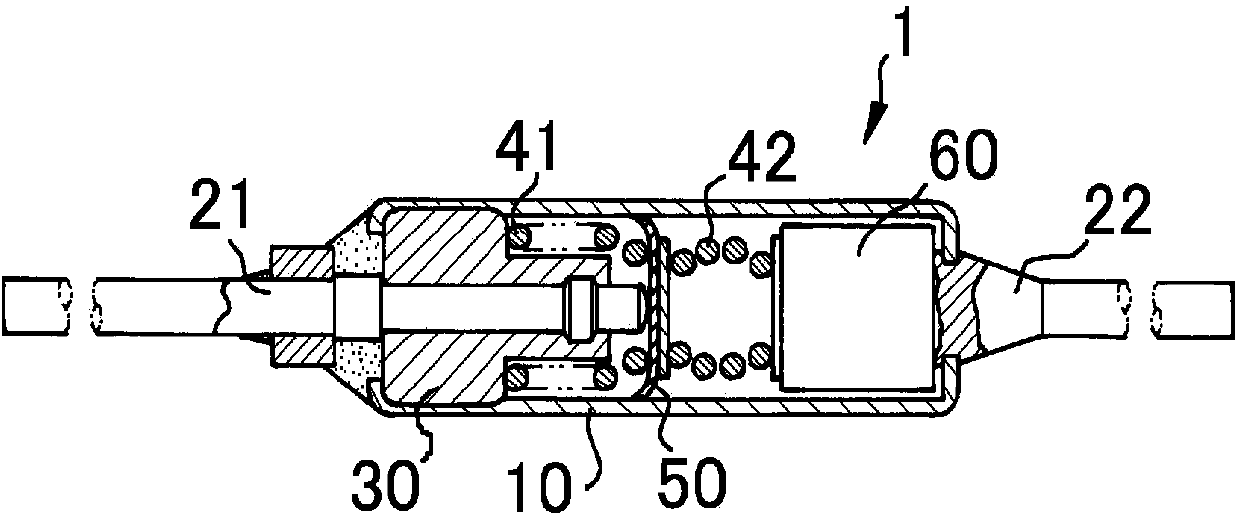

Image

Examples

Embodiment 1

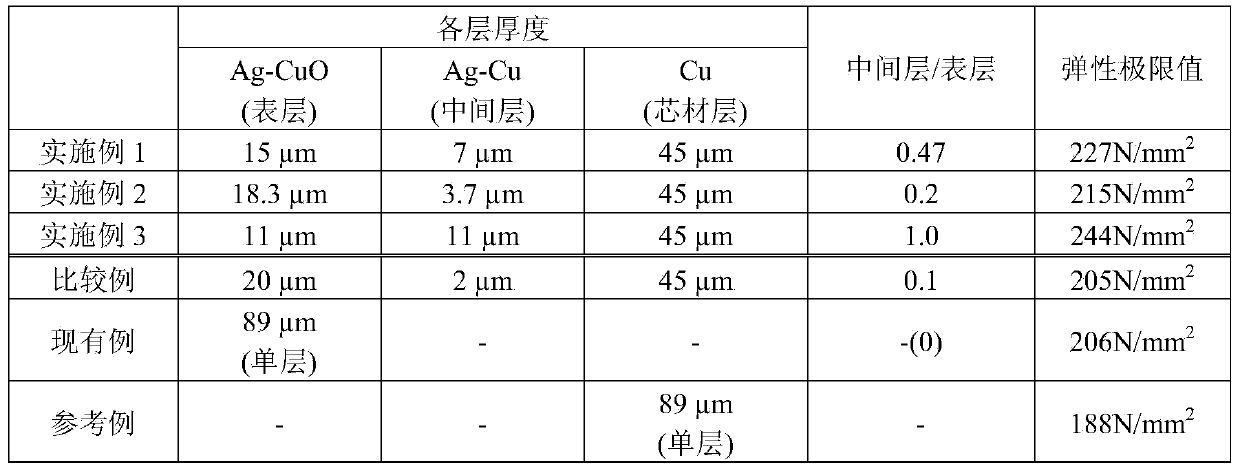

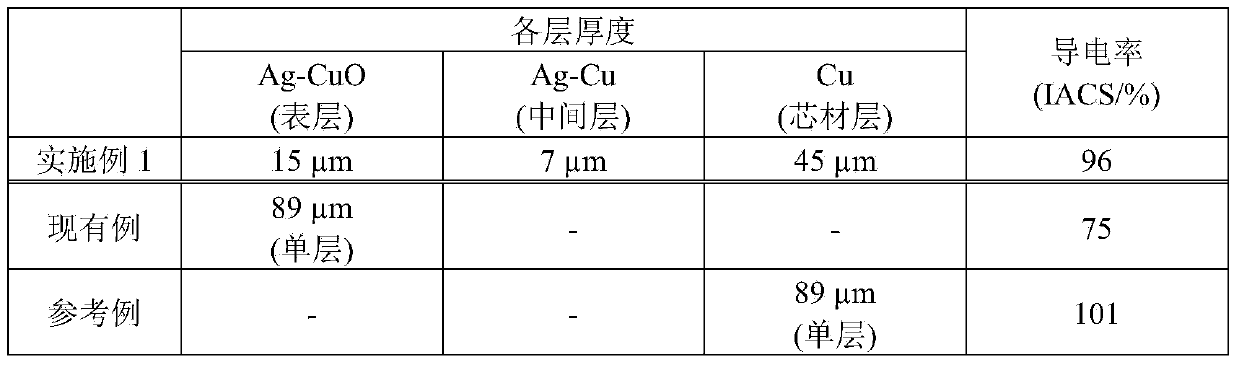

[0034] Example 1 : First, each metal was weighed so that the alloy composition would be Ag: 90.0% by mass and Cu: 10.0% by mass, and an Ag-Cu alloy was melted and cast. Thereafter, the Ag-Cu alloy ingot was rolled to a thickness of 4.15 mm and cut to manufacture an Ag-Cu alloy plate with a width of 115 mm and a length of 195 mm. In addition, an oxygen-free copper ingot was rolled to produce a Cu plate with a width of 120 mm, a length of 200 mm, and a thickness of 9 mm, and the above-mentioned Ag-Cu alloy plate was stacked on both surfaces of the Cu plate, and after cold compression bonding was performed at a pressure of 150 t, In a mixed gas of nitrogen and hydrogen, the temperature was kept at 800° C. for 60 minutes, and then thermocompression bonding was performed at a pressure of 100 tons. The crimped three-layer (Ag-Cu alloy / Cu / Ag-Cu alloy) clad material was rolled to manufacture a clad material strip.

[0035] Next, the clad strip was rolled to 450 μm to form a three-l...

Embodiment 2

[0036] Example 2 : In Example 1, when the inside of the three-layer cladding material (Ag-Cu alloy / Cu / Ag-Cu alloy) was oxidized, the heat treatment time was set to 10 hours. Thus, the thickness of the Ag-CuO alloy layer was set to 91 μm, and the thickness of the Ag-Cu alloy layer was set to 19 μm. Thereafter, calendering was performed in the same manner as in Example 1 to manufacture a five-layer clad material tape. The clad material tape produced was Ag-CuO (18.3 μm) / Ag-Cu (3.7 μm) / Cu (45 μm) / Ag-Cu (3.7 μm) / Ag-CuO (18.3 μm) with a total thickness of 89 μm. The obtained clad material tape was cut and processed to form an electrode material for evaluation.

Embodiment 3

[0037] Example 3 : In Example 1, when the inside of the three-layer cladding material (Ag-Cu alloy / Cu / Ag-Cu alloy) was oxidized, the heat treatment time was set to 3 hours. Thus, the thickness of the Ag-CuO alloy layer was 55 μm, and the thickness of the Ag-Cu alloy layer was 55 μm. Thereafter, calendering was performed in the same manner as in Example 1 to manufacture a five-layer clad material tape. The clad material tape produced was Ag-CuO (11 μm) / Ag-Cu (11 μm) / Cu (45 μm) / Ag-Cu (11 μm) / Ag-CuO (11 μm) with a total thickness of 89 μm. The obtained clad material tape was cut and processed to form an electrode material for evaluation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com