Light extinction type waterborne polyurethane emulsion and preparation method thereof

A water-based polyurethane, matte technology, applied in the field of polyurethane, can solve the problems of poor wear resistance, poor gloss, acetone residue, etc., and achieve the effects of simple process, improved hardness and tensile properties, and accelerated polymerization or cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

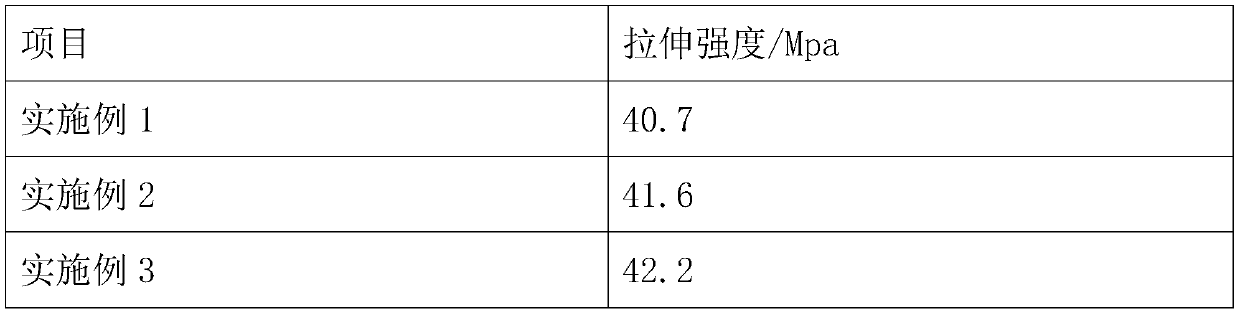

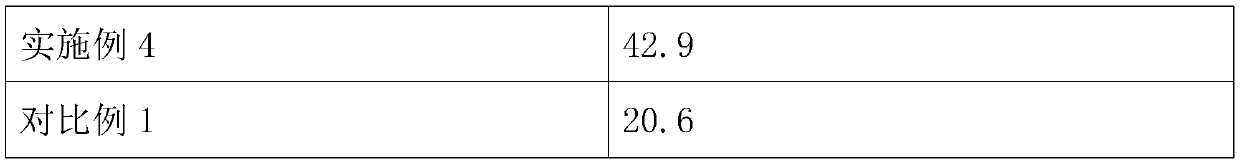

Examples

Embodiment 1

[0030] The matting type water-based polyurethane emulsion of the present embodiment is made up of the following components: a total of 10 parts of polyester diol and polycarbonate diol, 8 parts of castor oil, 30 parts of toluene diisocyanate, dimethylol 5 parts of propionic acid, 3 parts of trimethylolpropane, 4 parts of ethylenediamine, 6 parts of triethylamine, 100 parts of deionized water, 14 parts of nitrogen methylpyrrolidone, 10 parts of trimethylolpropane, ethyl acrylate and A total of 13 parts of 2-methyl methacrylate and 10 parts of dehydroabietic acid.

[0031] The preparation method of the matting type aqueous polyurethane emulsion of the present embodiment comprises the following steps:

[0032] 1) Put the polyol and castor oil into the reaction vessel according to the weight ratio, stir evenly and heat to 100°C for dehydration for 1.0h; then add dehydroabietic acid to the system, and slowly heat up to 155°C under nitrogen atmosphere and normal pressure , stir, an...

Embodiment 2

[0044] The matting type water-based polyurethane emulsion of the present embodiment is made up of the following components: 13 parts of polyester diols, 9 parts of castor oil, 20 parts of isophorone diisocyanate, 6 parts of dimethylol propionic acid , 2 parts of trimethylolpropane, 4 parts of ethylenediamine, 6 parts of triethylamine, 150 parts of deionized water, 14 parts of nitrogen methyl pyrrolidone, 7 parts of trimethylol propane, 12 parts of methyl acrylate, dehydrogenation 9 parts of abietic acid.

[0045]1) Put polyol and castor oil into the reaction vessel according to the weight ratio, stir evenly and heat to 105°C for dehydration for 0.8h; then add dehydroabietic acid to the system, and slowly heat up to 158°C under nitrogen atmosphere and normal pressure , stir, and heat up to 220°C;

[0046] 2) Cool the mixture to 55°C, and add isocyanate according to the weight ratio, heat up to 70-90, 70°C, keep warm for 1.5 hours and fully react, then add trimethylolpropane to...

Embodiment 3

[0057] The matting water-based polyurethane emulsion of the present embodiment is composed of the following components: 20 parts of polycarbonate diol, 10 parts of castor oil, 35 parts of hexamethylene diisocyanate, and 7 parts of dimethylol propionic acid , 1 part of trimethylolpropane, 5 parts of ethylenediamine, 7 parts of triethylamine, 170 parts of deionized water, 10 parts of nitrogen methylpyrrolidone, 9 parts of trimethylolpropane, 2-ethyl methacrylate, A total of 15 parts of ethyl acrylate and 2-methyl methacrylate, and 11 parts of dehydroabietic acid.

[0058] 1) Put the polyol and castor oil into the reaction vessel according to the weight ratio, stir evenly and heat to 110°C for 1.5h dehydration; then add dehydroabietic acid to the system, and slowly heat up to 160°C under nitrogen atmosphere and normal pressure , stir, and heat up to 220°C;

[0059] 2) Cool the mixture to 50°C, add isocyanate according to the weight ratio, heat it up to 75°C and keep it warm for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com