Electric resistance welding method

A technology of resistance welding and electric current, which is applied in the resistance welding field of welding copper or copper alloy and steel or steel alloy, can solve the problems of high welding cost, poor welding environment and low efficiency, and achieve the effect of meeting the sealing and strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

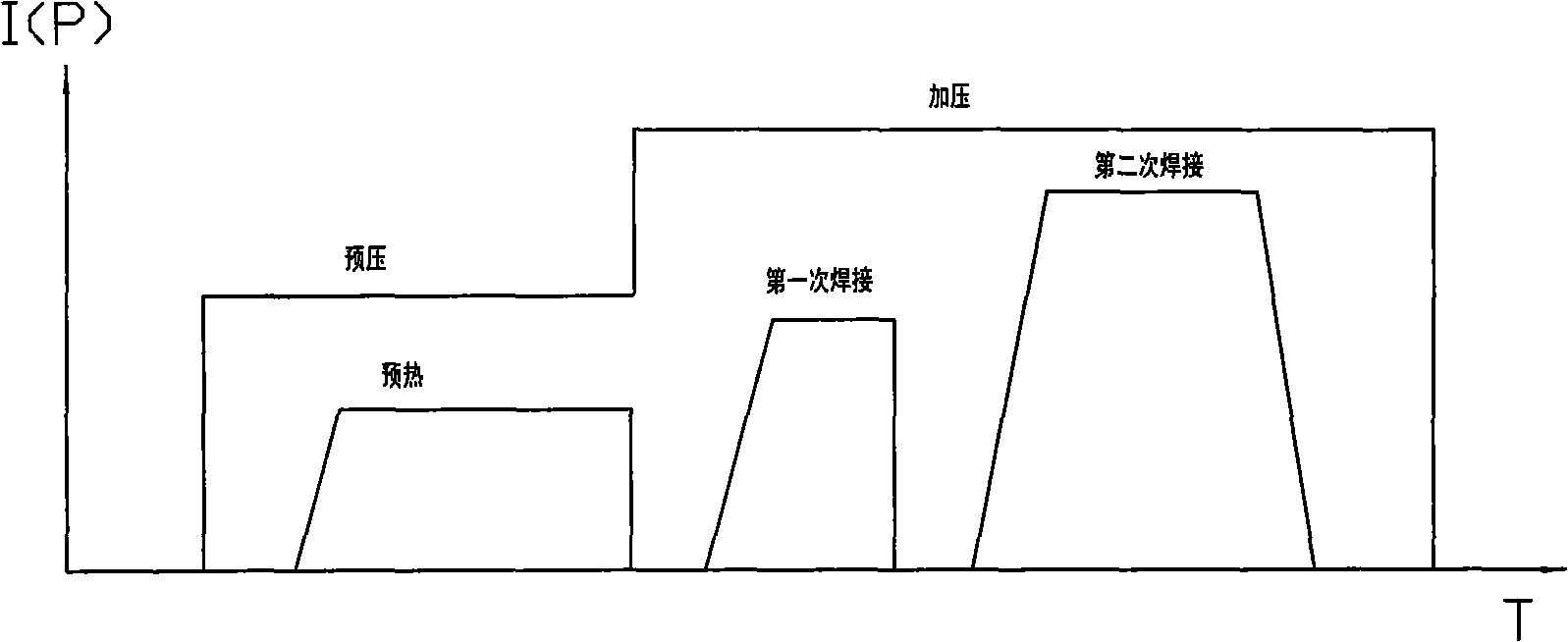

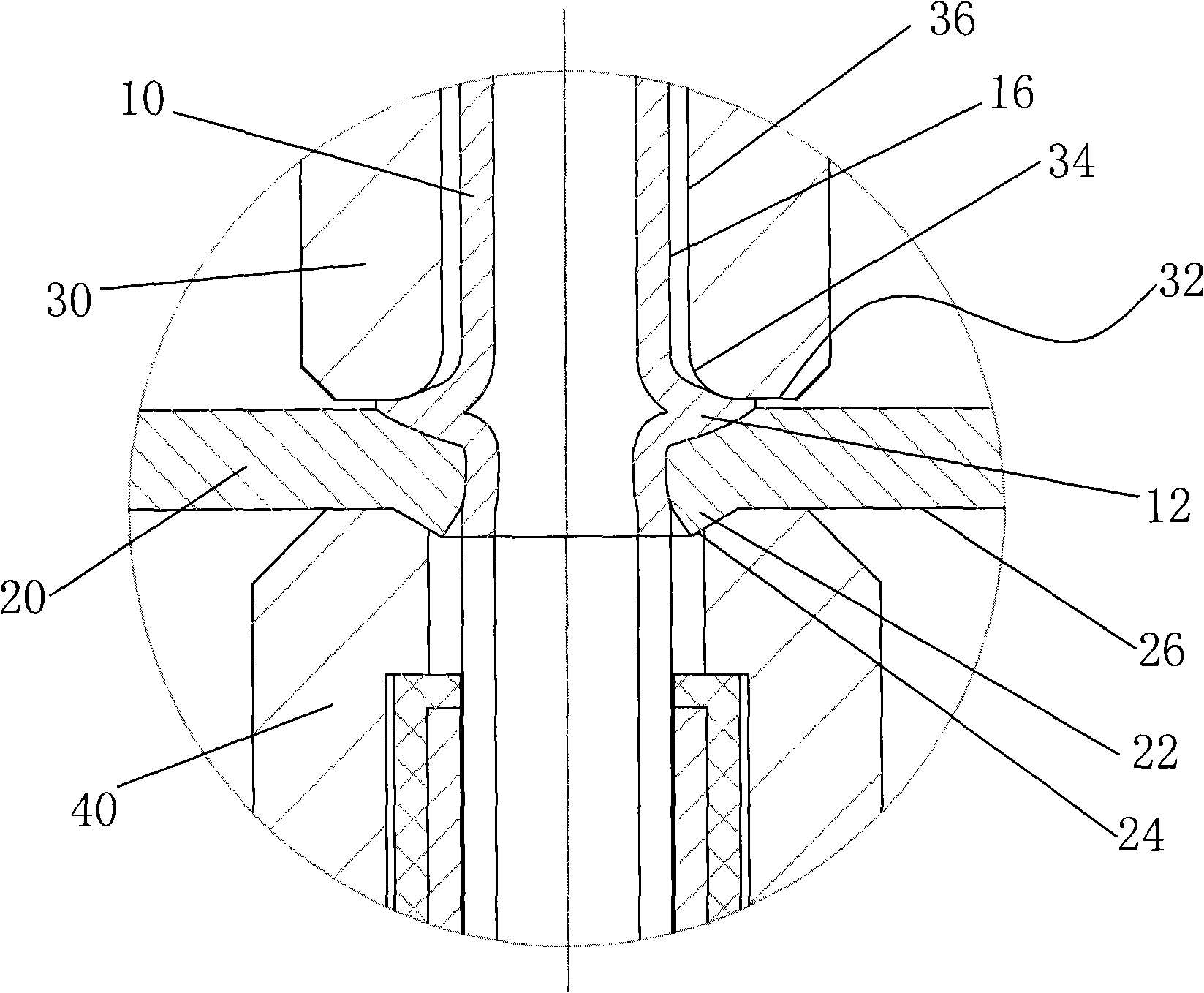

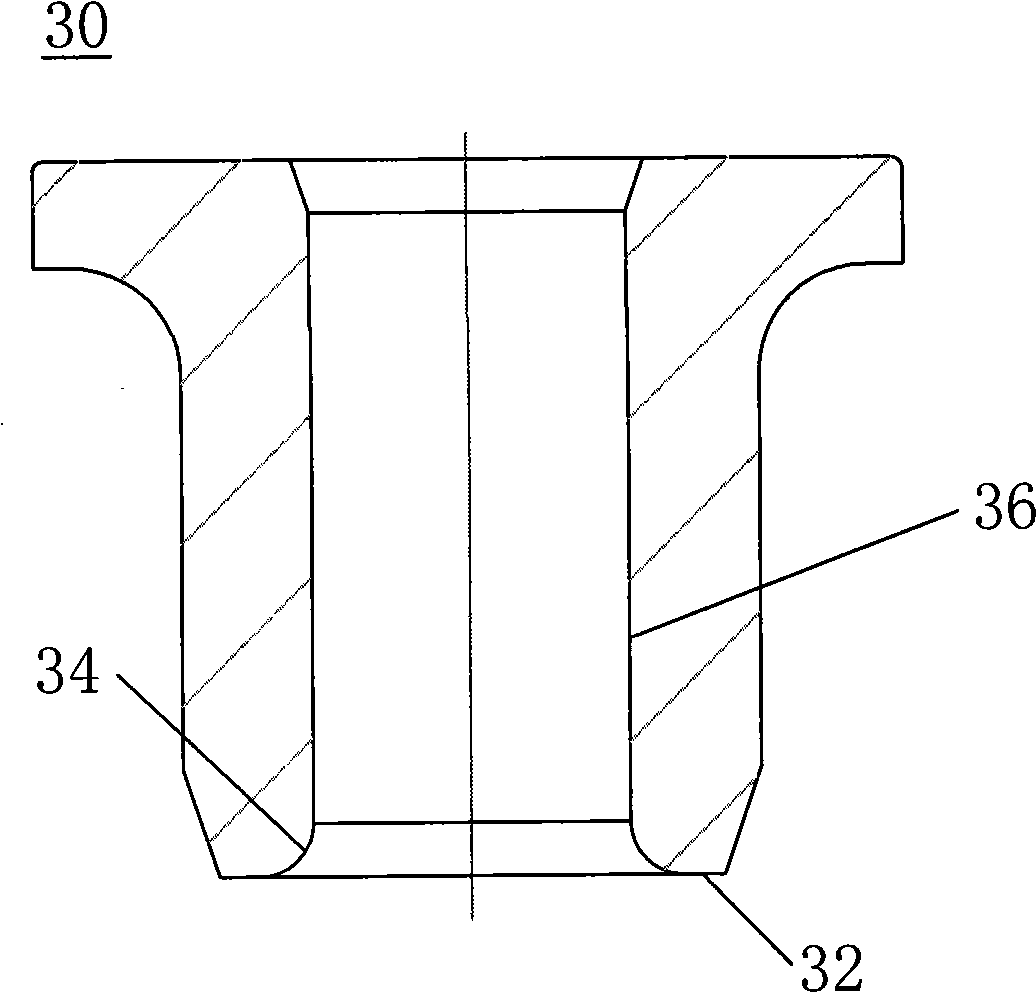

[0026] A resistance welding method of the present invention can be used for welding copper or copper alloy pipe fittings and iron or iron alloy plate parts or shells, refer to figure 1 The pressure and current waveform diagram in the welding process is shown. When welding, the upper electrode tip presses the metal pipe, and the lower electrode tip presses the metal shell or plate. The welding process includes the following steps:

[0027] (1) Installing the welding workpiece;

[0028] (2) Preset the pressure for the first time on the two welding objects through the upper electrode tip and the lower electrode tip;

[0029] (3) Maintain the preset pressure, use the first intermediate frequency pulse current for pre-welding, and stop the pre-welding after welding and pressing the two welding objects to form a good conductor for a period of time;

[0030] (4) Apply a second pressure to the two welding objects;

[0031] (5) Keep the pressure constant, increase the current at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com