Enamel imitating ceramic product and preparation method thereof

A technology of ceramic products and enamel, which is applied in the field of enamel-like ceramic products and its preparation, can solve the problems of metal tires being easy to rust, affecting human health, and easy to drop porcelain, so as to improve the service life and make the process non-toxic and pollution-free , the effect of high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

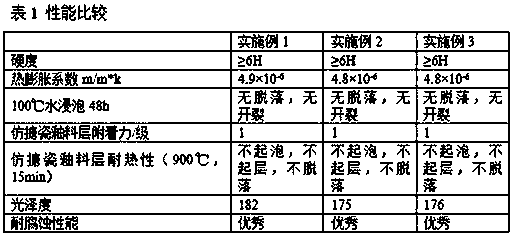

Embodiment 1

[0023] Embodiment 1: a kind of imitation enamel ceramic product, described imitation enamel ceramic product is made up of ceramic substrate and the imitation enamel glaze layer covered on ceramic substrate surface, and described imitation enamel glaze layer contains following weight part raw material: 35 parts of epoxy resin, 14 parts of oyster shell powder, 10 parts of talcum powder, 10 parts of silicon dioxide, 12 parts of yellow gardenia juice, 4 parts of wax emulsion, 5 parts of glass fiber, 3 parts of pigment and 0.3 part of defoamer.

[0024] In Example 1, the ceramic matrix contains the following raw materials in parts by weight: 50 parts of diatomite, 20 parts of carbon fiber, 7 parts of alumina, 15 parts of glass powder, 8 parts of pyrophyllite, 8 parts of shell powder, and 8 parts of lignin fiber 15 parts, 15 parts of talcum powder and 3 parts of sodium carboxymethyl starch.

[0025] The preparation method of the enamel-like ceramic product comprises the steps of:

...

Embodiment 2

[0031] Embodiment 2: a kind of imitation enamel ceramic product, described imitation enamel ceramic product is made up of ceramic substrate and the imitation enamel glaze layer that covers ceramic substrate surface, and described imitation enamel glaze layer contains following weight part raw material: 30 parts of epoxy resin, 12 parts of oyster shell powder, 7 parts of talcum powder, 5 parts of silicon dioxide, 10 parts of yellow gardenia juice, 3 parts of wax emulsion, 3 parts of glass fiber, 2 parts of pigment and 0.2 part of defoamer.

[0032] In Example 2, the ceramic matrix contains the following raw materials in parts by weight: 45 parts of diatomite, 10 parts of carbon fiber, 5 parts of alumina, 10 parts of glass powder, 5 parts of pyrophyllite, 5 parts of shell powder, 5 parts of lignin fiber 10 parts, 10 parts of talcum powder and 2 parts of sodium carboxymethyl starch.

[0033] The preparation method of the enamel-like ceramic product comprises the steps of:

[003...

Embodiment 3

[0039] Embodiment 3: a kind of imitation enamel ceramic product, described imitation enamel ceramic product is made up of ceramic matrix and the imitation enamel glaze layer that covers ceramic matrix surface, and described imitation enamel glaze layer contains following weight part raw material: 40 parts of epoxy resin, 16 parts of oyster shell powder, 14 parts of talcum powder, 15 parts of silicon dioxide, 15 parts of yellow gardenia juice, 5 parts of wax emulsion, 6 parts of glass fiber, 5 parts of pigment and 0.5 part of defoamer.

[0040] In Example 3, the ceramic matrix contains the following raw materials in parts by weight: 55 parts of diatomite, 25 parts of carbon fiber, 10 parts of alumina, 20 parts of glass powder, 10 parts of pyrophyllite, 10 parts of shell powder, and 10 parts of lignin fiber. 20 parts, 20 parts of talcum powder and 5 parts of sodium carboxymethyl starch.

[0041] The preparation method of the enamel-like ceramic product comprises the steps of:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com