Photovoltaic battery component packaged by heat-shrinkable material and preparation method thereof

A photovoltaic cell and heat shrinkable film technology, applied in photovoltaic power generation, electrical components, chemical instruments and methods, etc., can solve the problems of difficulty in grasping the thickness of glue, waste, and high cost, and can meet the temperature range, long service life, Good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

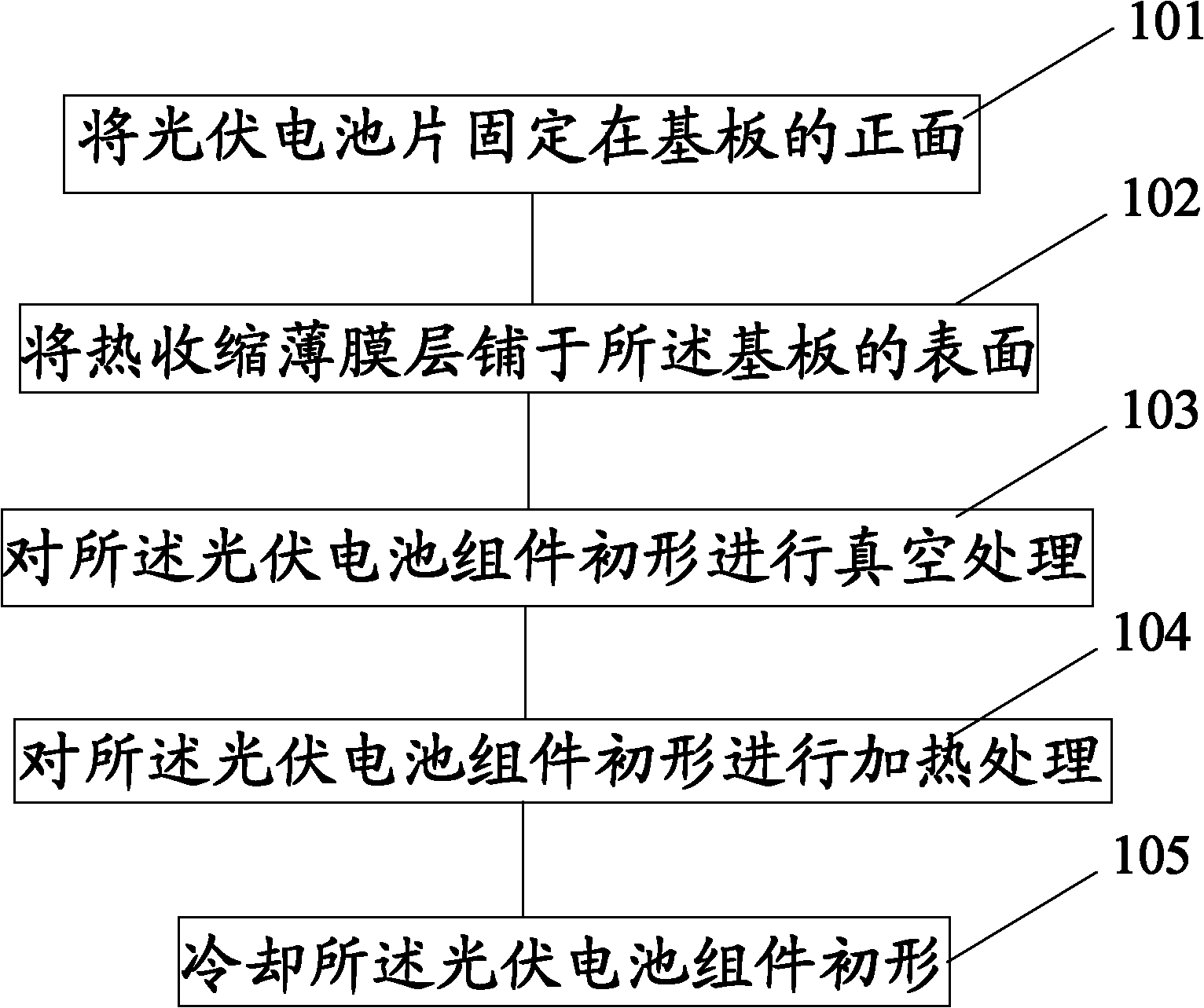

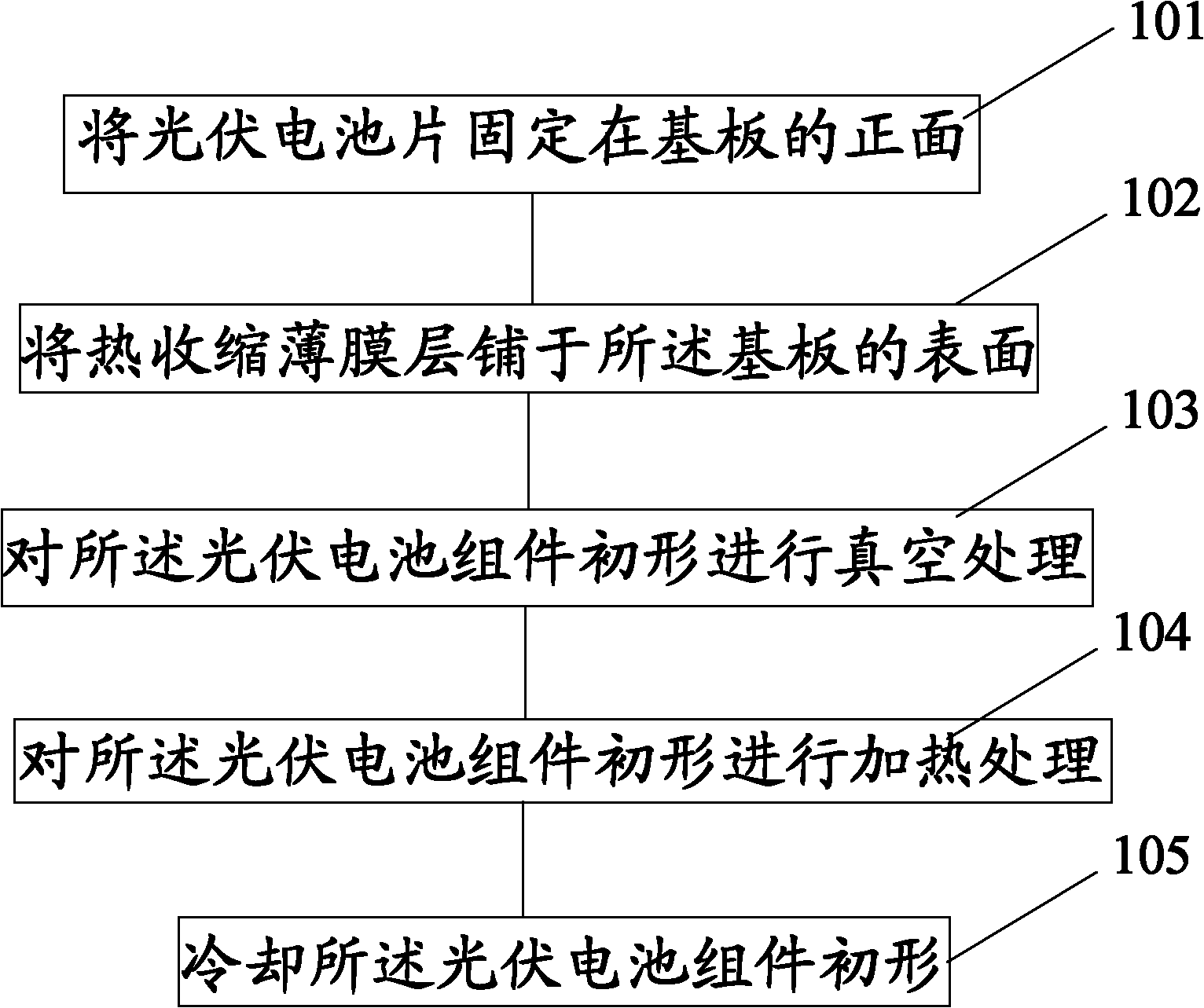

[0030] like figure 1 As shown, the method for preparing a photovoltaic cell module provided by the present invention includes the following steps.

[0031] Step 101, fixing the photovoltaic cells on the front surface of the substrate. First, classify and test the photovoltaic cells according to their performance parameters, find the required photovoltaic cells, weld each single photovoltaic cell on the front side and back side to form a string-welded photovoltaic cell, and fix the photovoltaic cell on the The front side of the cleaned substrate, in a specific solution, the photovoltaic cells can be fixed on the front of the substrate by bonding, forming an adhesive layer between the photovoltaic cells and the substrate, in a more specific solution, the photovoltaic cells can be Bonded to the substrate with double-sided tape.

[0032] Step 102, laying a heat-shrinkable film layer on the surface of the substrate to form a preliminary shape of the photovoltaic cell module. Spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com