Flame-retardant polypropylene film sealing bag used for graphene electrical heating film

A flame-retardant polypropylene and film sealing technology, which is applied in the field of electric heating film, can solve the problems of poor impact resistance, poor thermal stability, and high smoke density, and achieve structural improvement and optimization, good electrical insulation performance, and less smoke generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

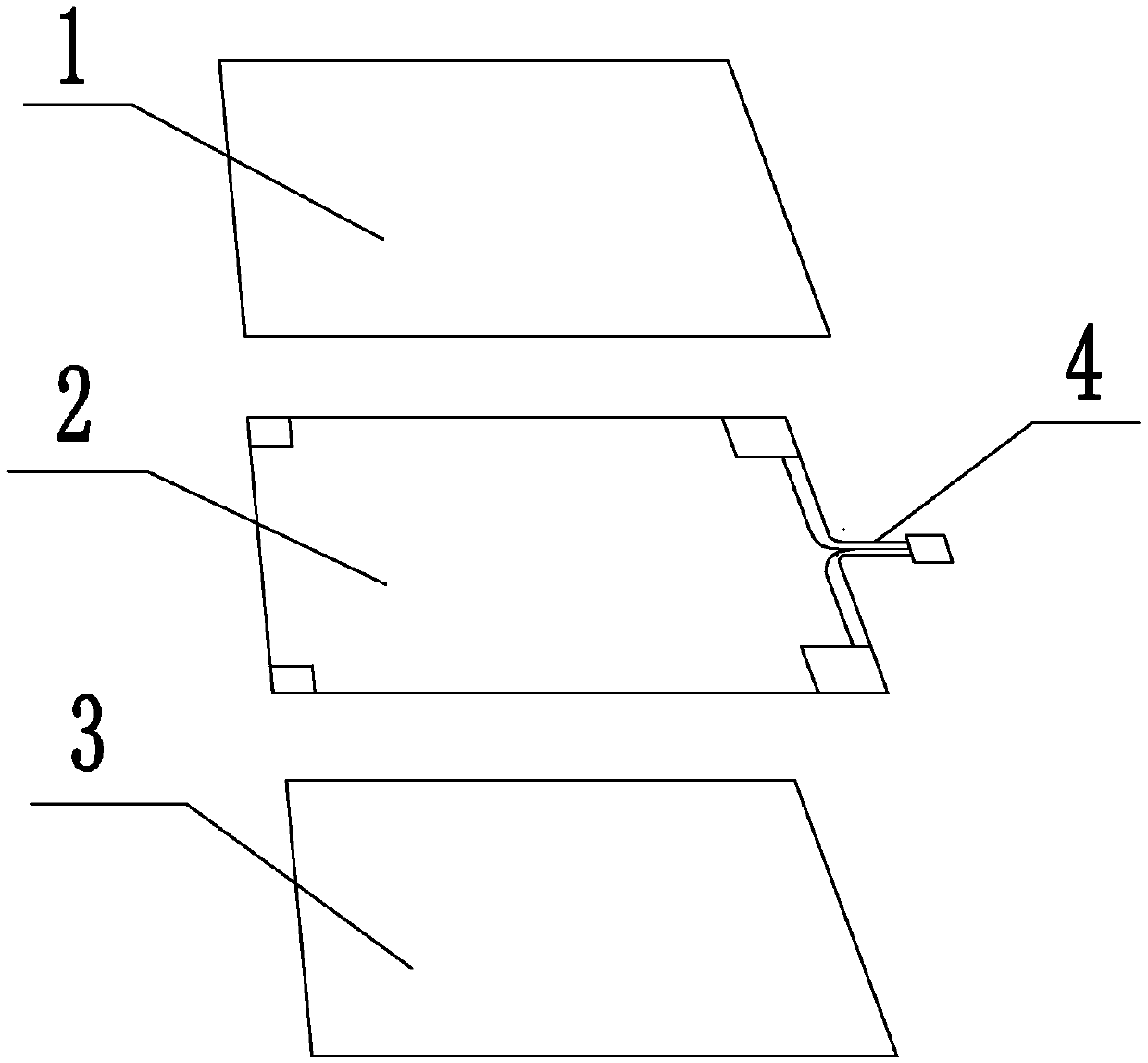

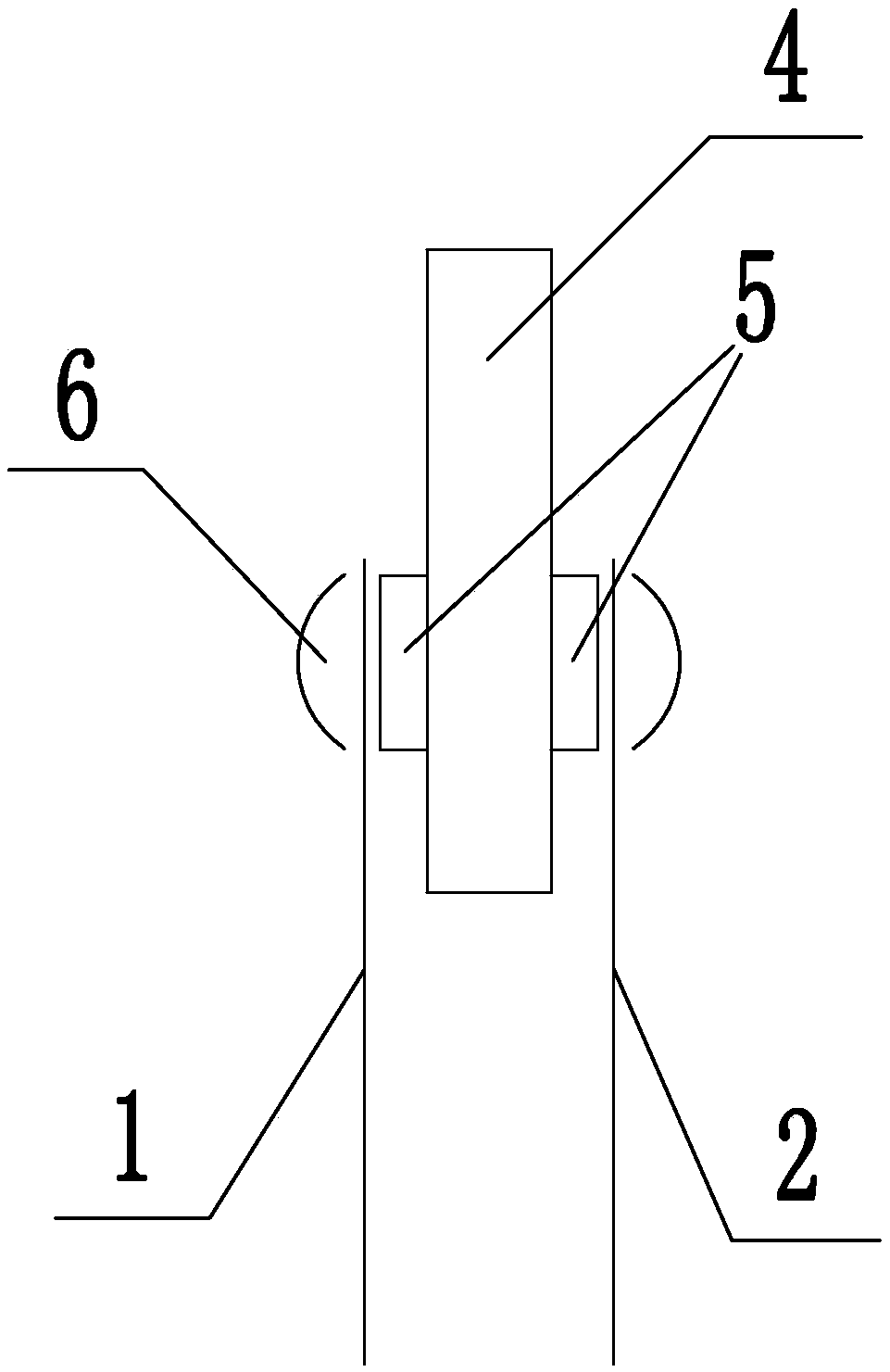

[0030] refer to Figure 1 to Figure 2 , a flame-retardant polypropylene film sealing bag for a graphene electric heating film, comprising a flame-retardant polypropylene film 1, a graphene electric heating film 2 and a flame-retardant polypropylene film 3 laminated sequentially from top to bottom, the graphene electric heating One short side of the membrane 2 is connected with a plug-in cable 4 for power supply. When sealing, a piece of special glue 5 is wrapped around the plug-in cable, and then it is initially bonded with the upper and lower layers of flame-retardant polypropylene film. The upper and lower layers of the ultrasonic plastic welding machine use a special mold. There is a groove 6 on the mold, and the groove 6 The position is aligned with the cable wrapped with glue. During the ultrasonic welding process, the special glue is melted to make the upper and lower flame-retardant polypropylene films and the plug-in cables tightly bonded together, and the flame-retard...

Embodiment 2

[0045] A flame-retardant polypropylene film sealing bag for a graphene electric heating film, the ingredients of the flame-retardant polypropylene film are: 70 parts of copolymerized polypropylene, 15 parts of high-density polyethylene, 18 parts of flame retardant, 1.6 parts of barium metaborate , 2.4 parts of manganese dioxide, 4 parts of chromium trioxide, 20 parts of polyquaternium-7, 9 parts of ceramic fiber, 0.15 parts of bis(2-ethylhexyl) phosphite, 0.25 parts of 2,6-dimethyl Oxyhydroquinone, 0.27 parts of 2,4-dimethoxy-1,3,5-triazine, 0.23 parts of 3-acetylbenzophenone.

[0046] The preparation method of described flame retardant is as follows:

[0047] (1) Preparation of silicon-containing flame retardant: Weigh an appropriate amount of 3-(1-naphthyloxy)-1,2-propylene oxide, dissolve it in dimethyl sulfoxide, pour it into a flask, and use triphenylphosphine as a catalyst , and then slowly add the dimethyl sulfoxide solution of tri(tert-butoxy)silanol into the flask, t...

Embodiment 3

[0059] A flame-retardant polypropylene film sealing bag for a graphene electric heating film, the ingredients of the flame-retardant polypropylene film are: 65 parts of copolymerized polypropylene, 12 parts of high-density polyethylene, 15 parts of flame retardant, and 1 part of barium metaborate , 2 parts of manganese dioxide, 3 parts of chromium trioxide, 15 parts of polyquaternium-7, 8 parts of ceramic fiber, 0.12 parts of bis(2-ethylhexyl) phosphite, 0.18 parts of 2,6-dimethyl Oxyhydroquinone, 0.16 parts of 2,4-dimethoxy-1,3,5-triazine, 0.14 parts of 3-acetylbenzophenone.

[0060] The preparation method of described flame retardant is as follows:

[0061] (1) Preparation of silicon-containing flame retardant: Weigh an appropriate amount of 3-(1-naphthyloxy)-1,2-propylene oxide, dissolve it in dimethyl sulfoxide, pour it into a flask, and use triphenylphosphine as a catalyst , and then slowly add the dimethyl sulfoxide solution of tri(tert-butoxy)silanol into the flask, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com