Electro-thermal push bar for electronic thermostat of engine

A technology of thermostat and engine, which is applied in the direction of engine components, machine/engine, engine cooling, etc. It can solve the problems that affect the service life of the engine, the high operating temperature of the engine, and the short service life, so as to reduce the production cost and difficulty, Extended service life, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

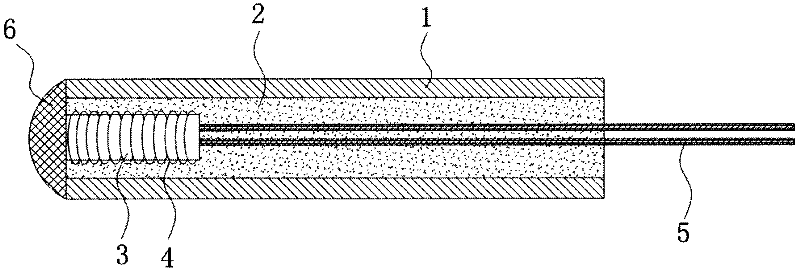

[0011] Example 1: Such as figure 1 As shown, an electric push rod for an electronic thermostat of an engine includes a push rod body 1. Preferably, the push rod body 1 is a hollow stainless steel tube. In this embodiment, the material of the push rod body 1 is 316 titanium, which is what we call titanium steel, and its chemical formula is 1Cr18Ni12Mo2Ti. The electric push rod made of 316 titanium has good heat transfer, which ensures the electric push The heat transfer efficiency of the rod; at the same time, the electric push rod made of 316 titanium can ensure a good surface finish, avoiding the sticking of the push rod when it is pushed by the hose; 316 titanium also has good high temperature resistance, which helps Extend the service life of the push rod of the electronic thermoelectric heater.

[0012] A heating element is provided inside the push rod body 1. Before inserting the heating element into the push rod body 1, one end of the push rod body 1 is welded and sealed b...

Embodiment 2

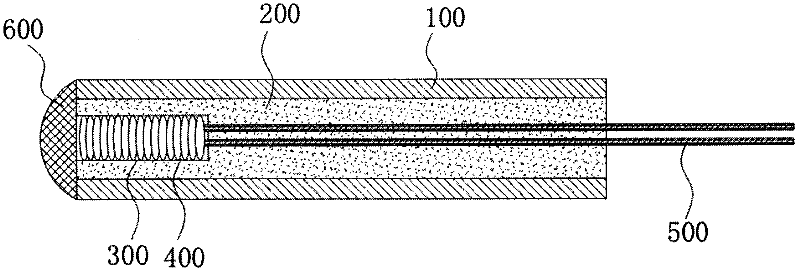

[0017] Example 2: Such as figure 2 As shown, an electric push rod for an engine electronic thermostat includes a push rod body 100, which is a hollow stainless steel tube, and one end of the stainless steel tube is sealed by a stainless steel seal 600. A heating element is arranged inside the push rod body 100, and the heating element is inserted into the push rod body 100 through the open end of the stainless steel tube. In this embodiment, the heating element includes a magnesium oxide tube 400, an electric heating wire 300, and a high temperature wire 500. During installation, the two ends of the heating wire 300 are first connected to the high temperature wire 500, and then the heating wire is inserted into the magnesium oxide tube 400, and finally the magnesium oxide tube 400 is inserted into the push rod body 100.

[0018] Of course, in order to ensure the positioning and heat transfer efficiency of the heating element inside the push rod body 100, the inside of the push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com