Bismuth brass alloy with good plasticity and corrosion resistance

A corrosion-resistant, bismuth-brass technology, applied in the fields of bismuth-brass alloy materials, brass alloy formulations and their manufacturing, can solve the problems of difficulty in recycling, inability to use old bismuth-containing materials, good corrosion resistance, etc., and achieve comprehensive performance Good, low cost, good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

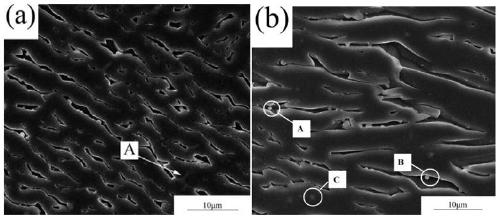

Image

Examples

Embodiment 1

[0014] A bismuth brass alloy with good plasticity and corrosion resistance, its composition and mass percentage are: Cu 58%, Bi 0.02%, Mg 0.02%, Zr 0.05%, La 0.02%, impurity element content < 0.5%, balance for Zn.

[0015] The preparation method of the above-mentioned bismuth brass alloy with good plasticity and good corrosion resistance is: according to the mass percentage of each component, use 10% (based on the weight sum of each raw material) bismuth-containing cutting brass old material, add elemental Mg, Zr , La, Cu and Zn, adjust the alloy content to the corresponding mass percentage, smelt at 1050-1100°C for 30 minutes, and use other components in the old bismuth brass used in smelting as impurities to obtain a bismuth brass alloy with good plasticity and corrosion resistance . The strength of the prepared brass alloy material exceeds 400 MPa, the hardness HB is 120, the elongation is greater than 20%, and the dezincification corrosion depth is 70 μm.

Embodiment 2

[0017] A bismuth brass alloy with good plasticity and corrosion resistance, its composition and mass percentage are: Cu 75%, Bi 2.5%, Mg 1.8%, Zr 1.5%, La 0.3%, impurity element content < 0.5%, balance for Zn.

[0018] The preparation method of the above-mentioned bismuth brass alloy with good plasticity and good corrosion resistance is: according to the mass percentage of each component, use 10% (based on the weight sum of each raw material) bismuth-containing cutting brass old material, add elemental Bi, Mg , Zr, La, Cu and Zn, adjust the alloy content to the corresponding mass percentage, smelt at 1050-1100°C for 30 minutes, and use other components in the old bismuth brass used in smelting as impurities to obtain bismuth yellow with good plasticity and corrosion resistance copper alloy. The strength of the prepared brass alloy material exceeds 400 MPa, the hardness HB is 120, the elongation is greater than 20%, and the dezincification corrosion depth is 80 μm.

Embodiment 3

[0020] A bismuth brass alloy with good plasticity and corrosion resistance, its composition and mass percentage are: Cu 58%, Bi 0.02%, Mg 0.02%, Zr 0.05%, La 0.02%, impurity element content < 0.5%, balance for Zn.

[0021] The preparation method of the above-mentioned bismuth brass alloy with good plasticity and corrosion resistance is as follows: according to the mass percentage of each component, use 50% (based on the weight sum of each raw material) bismuth-containing cutting brass old material, add elemental Bi, Mg , Zr, La, Cu and Zn, adjust the alloy content to the corresponding mass percentage, smelt at 1050-1100°C for 30 minutes, and use other components in the old bismuth brass used in smelting as impurities to obtain bismuth yellow with good plasticity and corrosion resistance copper alloy. The strength of the prepared brass alloy material exceeds 400 MPa, the hardness HB is 120, the elongation is greater than 18%, and the dezincification corrosion depth is 80 μm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com