Method for preparing hard alloy through stability regulation and control

A technology of cemented carbide and cemented carbide rods, which is applied in the field of cemented carbide materials and powder metallurgy, can solve the problems of coarse particles and their internal WC grains, the difficulty of uniform distribution of Co phase, and the growth of grains, etc., to achieve The effect of uniform initial grain structure, avoiding abnormal grain growth, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

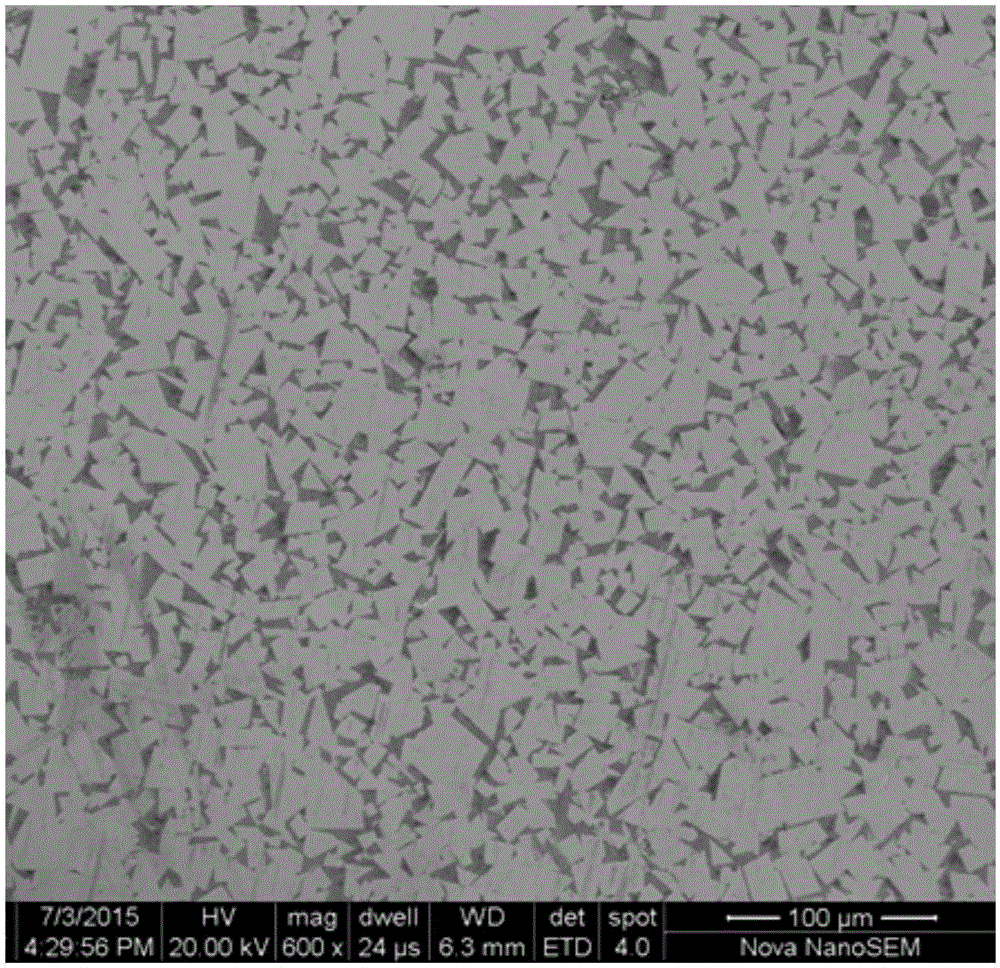

Embodiment 1

[0020] Prepare a WC-Co cemented carbide sintered body material in which the Co phase is uniformly distributed in the WC matrix, so that the Co content is 7.0wt%, the oxygen content-4 Pa, set the operating power to be 60% of the total power, and the total power is required to make the WC-Co complex phase structure at the contact end of the two cemented carbide rods reach the eutectic state during the descent of the cemented carbide rods Power, increase the power to the set power within 20 minutes, after the contact ends of the two cemented carbide round rods form a beam-like stable molten state, lower the lower cemented carbide round rod at a rate of 30mm / h, and drop simultaneously The upper hard alloy round rod, until the upper hard alloy round rod is taken out from the furnace, so that the upper hard alloy round rod becomes the hard alloy rod after zone melting treatment; the hard alloy rod after zone melting treatment The material was placed in a vacuum heat treatment furnace...

Embodiment 2

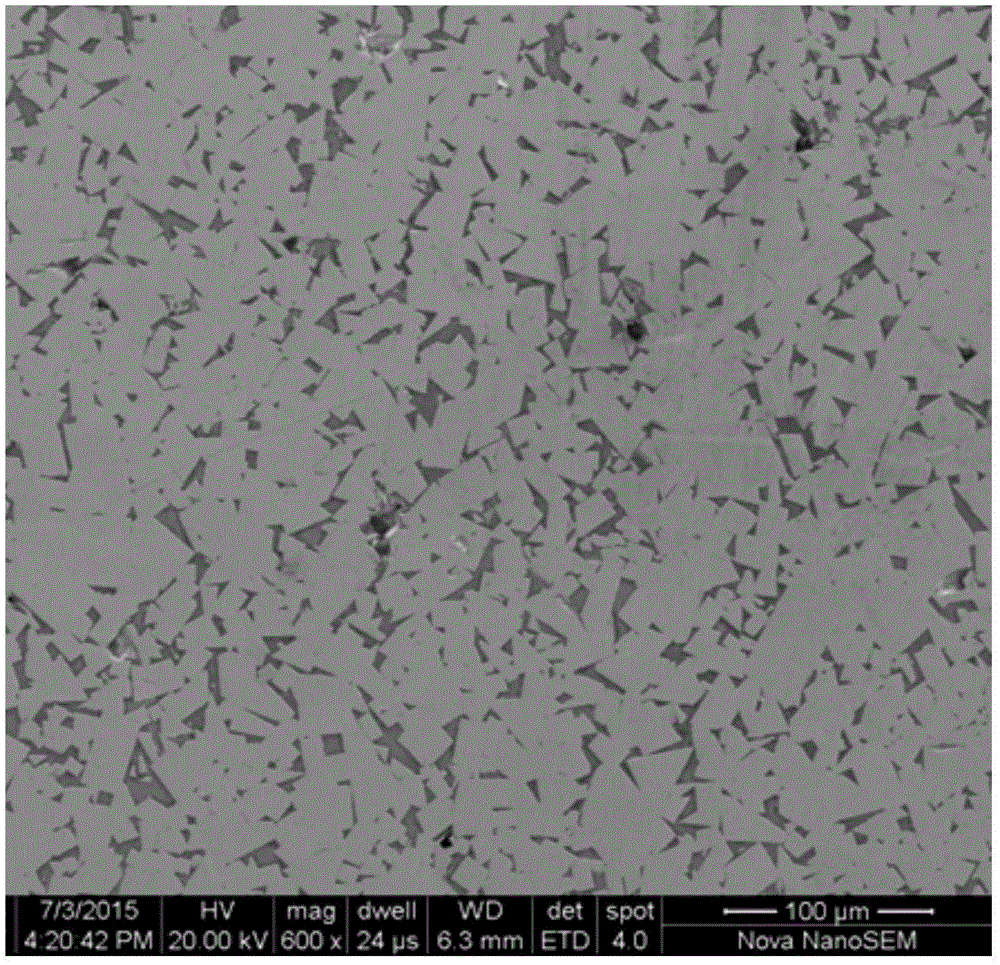

[0022] Prepare a WC-Co cemented carbide sintered body material in which the Co phase is uniformly distributed in the WC matrix, so that the Co content is 9.0wt%, the oxygen content-4 Pa, set the operating power to be 95% of the total power, and the total power is required for the WC-Co complex phase structure at the contact end of the two cemented carbide rods to reach a completely molten state during the descent of the cemented carbide rods Power, increase the power to the set power within 30 minutes, after the contact ends of the two cemented carbide round rods form a beam-like stable molten state, lower the lower cemented carbide round rod at a rate of 10mm / h, and drop simultaneously The upper hard alloy round rod, until the upper hard alloy round rod is taken out from the furnace, so that the upper hard alloy round rod becomes the hard alloy rod after zone melting treatment; the hard alloy rod after zone melting treatment The material was placed in a carbonization furnace, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com