Patents

Literature

32results about How to "Will not embrittle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Highly-oil-repellenting highly-waterproof seamless polytef expansion sheet materials and preparation method thereof

ActiveCN103158310AReduce weightCorrosion resistantSynthetic resin layered productsFlat articlesLubricationChemical stability

The invention belongs to the technical field of aerospace sealing materials, and particularly discloses highly-oil-repellenting highly-waterproof seamless polytef expansion sheet materials and a preparation method thereof. The preparation method comprises the following steps: mixing materials, performing, pushing and pressing, calendaring, drying, puffing, sizing, thermocompression bonding, surface chemical processing, and the like. The highly-oil-repellenting highly-waterproof seamless polytef expansion sheet materials which are prepared and obtained by the method have good chemical stability, electrical insulating property, and self-lubrication performance, overcome the cold flow property (creepage) of pure polytef sealing materials, cannot become hard or crisp ( good elasticity) with the time, can bear the temperature range of -65 DEG C - +177 DEG C, are applicable to flat seal of various shapes, and are indispensable and important materials in frontier science and modern industries.

Owner:HUZHOU SENNUO FLUORINE MATERIAL TECH

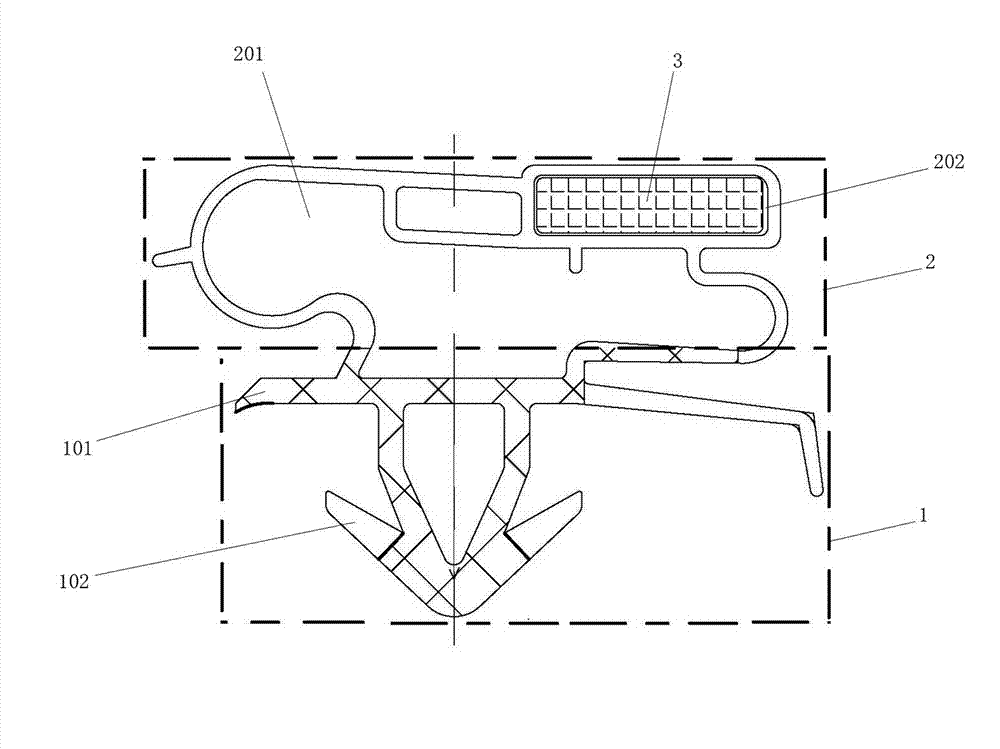

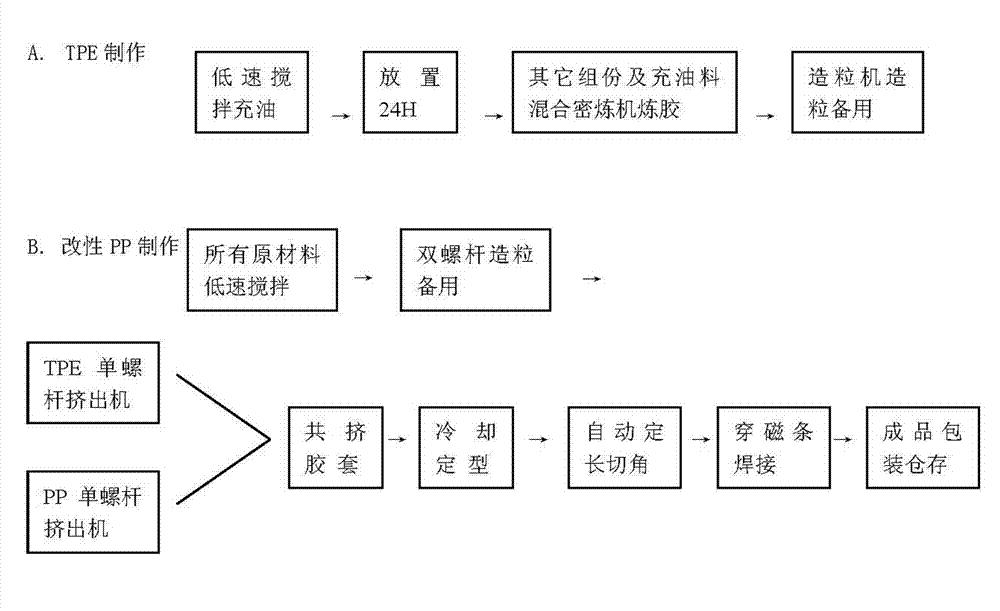

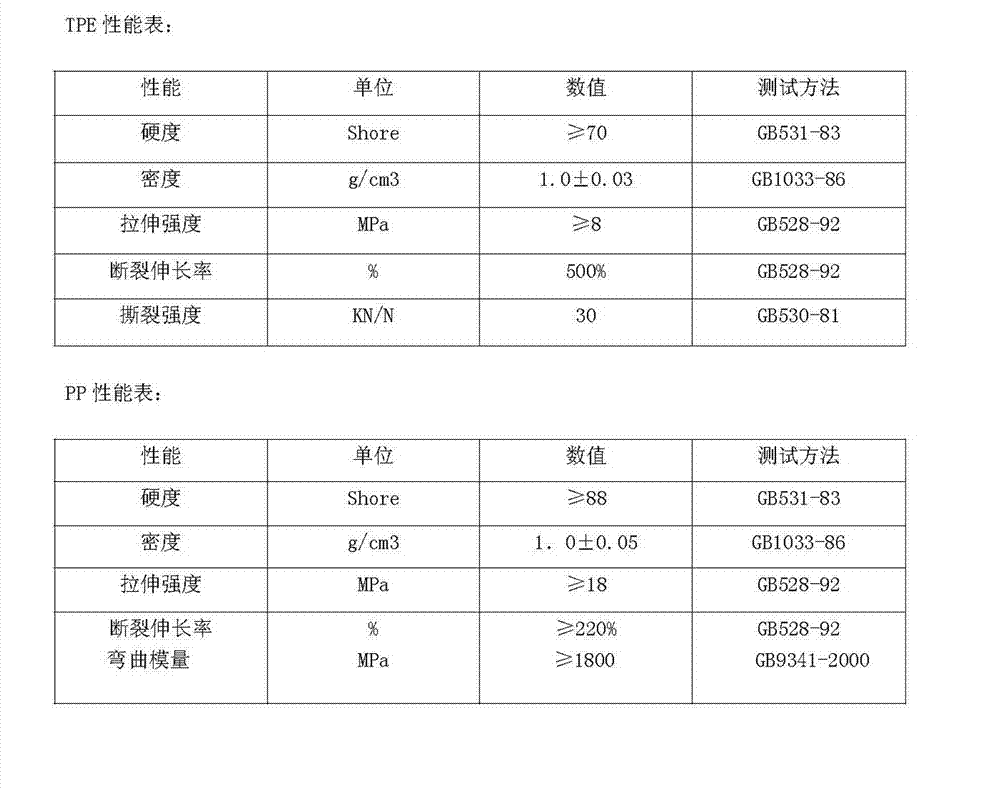

Thermoplastic elastomer (TPE) and modified PP (Polypropylene) co-extruded refrigerator magnetic door seal strip and manufacturing method thereof

InactiveCN102778101AImprove sealingImprove migration resistanceDomestic cooling apparatusLighting and heating apparatusThermoplastic elastomerEngineering

The invention relates to a thermoplastic elastomer (TPE) and modified PP (Polypropylene) co-extruded refrigerator magnetic door seal strip and a manufacturing method thereof. The TPE and modified PP co-extruded refrigerator magnetic door seal strip consists of a fixed substrate part constituted by TPE and a sealing part constituted by modified hard PP, wherein the fixed substrate part and the sealing part form the magnetic door seal strip through co-extrusion thermal fusion; the fixed substrate part consists of a substrate and an assembly plug pin; the sealing part is provided with an air bag and a magnetic strip bag; and the magnetic strip bag is provided with a magnetic strip. The TPE and modified PP co-extruded refrigerator magnetic door seal strip is a soft and hard co-extruded magnetic door seal strip consisting of the TPE material serving as a sealing strip part and a substrate hard PP material capable of fixing the door seal strip, and can be suitable for magnetic door seal strips for all refrigerators; the sealing part of the door seal strip is made of the TPE material; and thus, the requirement of environmental protection is met, and the low-temperature performance, the resilience performance and the mechanical performance are extremely superior.

Owner:GUANGDONG SHUNDE ANHE MAGNETIC PROD

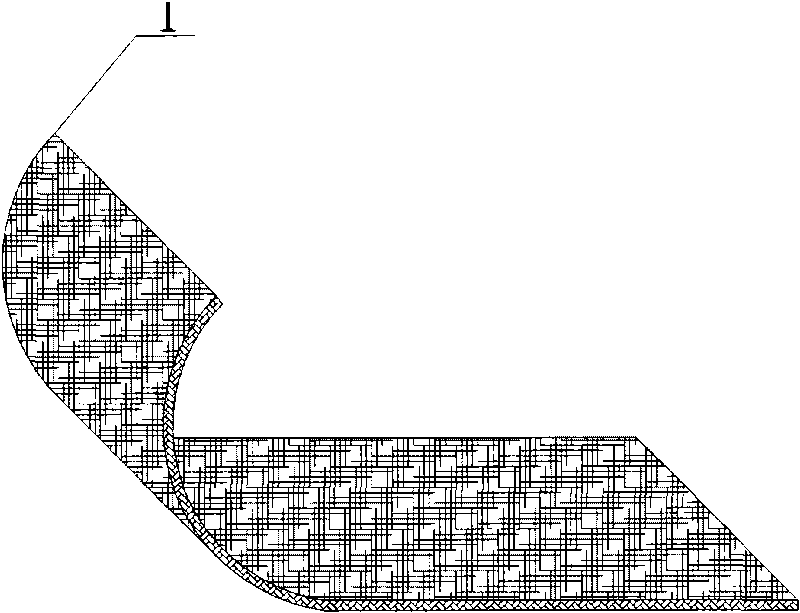

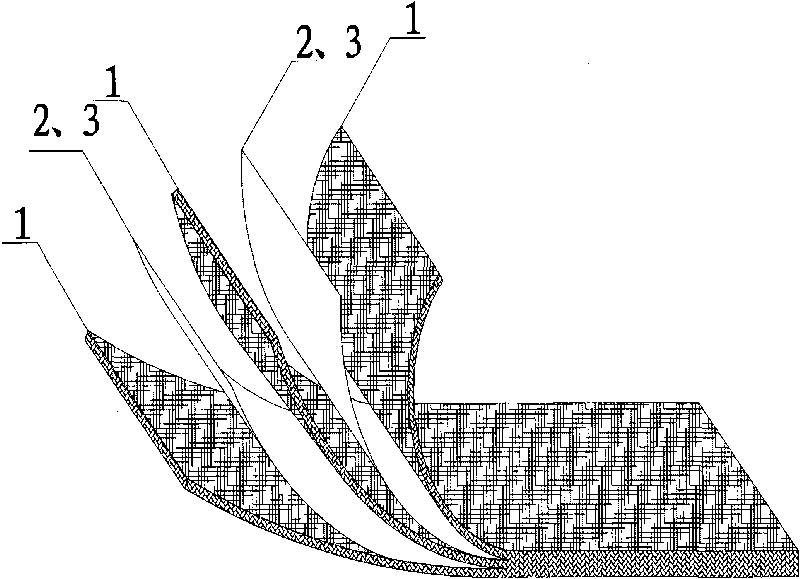

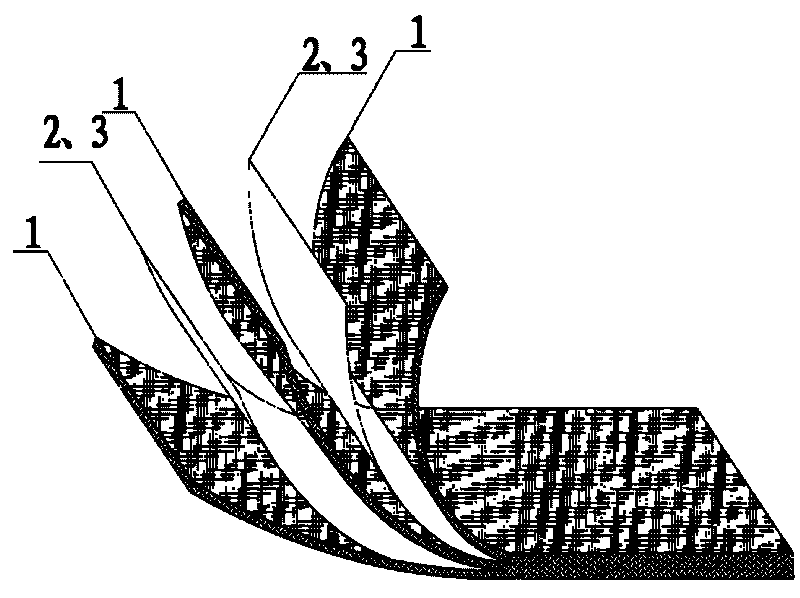

Process for preparing teflon expanded sealing plate used for space air vehicles

ActiveCN1594419AReduce weightCorrosion resistantOther chemical processesChemical stabilityFine chemical

The invention provides a process for preparing expanded polytetrafluoroethylene structure sealing plate which consists of material mixing, pre-forming, pulling, calendering, drying, bulking, and shaping. The sealing plate prepared thereby possesses fine chemical stability, electrical insulation property and self-oiliness.

Owner:SHANGHAI PLASTICS RES INST CO LTD

Normal pressure cation dyeable polyester, textile product made from the same, and process for production of the same

ActiveCN1831028AImprove qualityWill not embrittleMonocomponent polyetheresters artificial filamentMonocomponent copolyesters artificial filamentPolyesterFiber

The present invention provides one kind of normal pressure dyeable polyester and its preparation process, and the polyester may be used in producing fiber product with stable quality and high light resistance no matter water color shade is. The present invention features that the polyester has main repetition units of ethylene terephthalate, and contains metal sulfonate containing isophthalic acid component in 2.0-3.0 mol% of the acid components, polyalkylene glycol of average molecular weight 150-600 in 1.5-4.0 wt% of polyester, diglycol in 4.5-6.5 mol% of the diol components and terminal carboxyl group concentration of 20-30 equivalent / ton.

Owner:SEIREN CO LTD

Novel sound absorbing and insulating and heat insulating material and application thereof

InactiveCN101693415AGood sound and heat insulationMeet the requirements of "three defenses"Thermal insulationLayered productsEngineeringSilicon rubber

The invention discloses a novel sound absorbing and insulating and heat insulating material which can be formed by sound absorbing and insulating cotton felt and can be also compounded by the sound absorbing and insulating cotton felt and an elastic sponge body through damp compound viscose. The sound absorbing and insulating cotton felt is made of interposition aramid fiber 1313; the elastic sponge body is a silicon rubber sheet with the thickness of 0.2-0.3 mm; and the hydrophobic property of the sound absorbing and insulating and heat insulating material is 95 percent. The novel sound absorbing and insulating and heat insulating material is environment friendly and incombustible, has no pollution, long using time and good hydrophobic property, can resist high temperature and can be used as the sound absorbing and insulating and heat insulating material for aerospace vehicles and various vehicle wall plates and acoustic decoration material for halls and stadiums.

Owner:NANJING CHANGRONG ACOUSTIC INC

Production technology of full-cotton powder point hot melting adhesive interlining

InactiveCN102418252AImprove flatnessImprove smoothnessSucessive textile treatmentsMercerising of indefinite length fabricsInterliningHot melt

The invention discloses a production technology of a full-cotton powder point hot melting adhesive interlining. The production technology sequentially comprises the following steps of: A) singeing; B) primary alkali rolling; C) primary steaming; D) secondary alkali rolling; E) secondary steaming; F) acid pickling; G) mercerizing; H) back bleaching; I) cloth spreading and sewing; J) resin finishing; K) curing; L) powder point coating; and M) solidifying with rubber powder. In the production technology disclosed by the invention, multiple processes are combined, the evenness, smoothness and handfeel of the full-cotton powder point hot melting adhesive interlining are greatly improved, the product quality is enhanced, the liquid entrainment rate after padding is moderate, the whiteness can be moderate while cloth is not tendered, thus the product quality is further improved, the service life of the product is prolonged, the full-cotton powder point hot melting adhesive interlining can berapidly cleaned when being washed with water, the efficiency is improved, the alkali liquor residual volume can be lower, the product quality is improved, the handfeel of the finished product is good, the hardness degree of the finished product is moderate, and the peeling strength of the finished product is high.

Owner:江苏三泰轻工科技有限公司

Inflating bag sealed with binding base material and manufacture process for same

InactiveCN102556504ANot solubleWill not embrittlePaper/cardboard articlesFlexible container closureInternal pressureEngineering

The invention discloses an inflating bag sealed with a binding base material and a manufacture process for the same. The inflating bag is characterized by comprising an inner bag, an outer bag and the binding base material, an air valve capable of inflating is arranged on the inner bag made of a co-extruded film, the outer bag is made of polypropylene woven base fabric, polypropylene woven base fabric composite kraft paper or pure kraft paper and is provided with an exposed opening capable of leading the air valve on the inner bag to penetrate through, and the two ends of the inflating bag are sealed with the binding base material. Internal pressure of the inflating bag in use can be doubled as compared with that of an inflating bag made by means of sewing. Besides, the inflating bag adopts one-time binding technology so that binding is cured after sealing, and when a container is applied, the binding cannot be melted or embrittled at the external extreme high temperature or low temperature of the container, so that proper binding property is kept.

Owner:上海奥特玛特物流设备有限公司

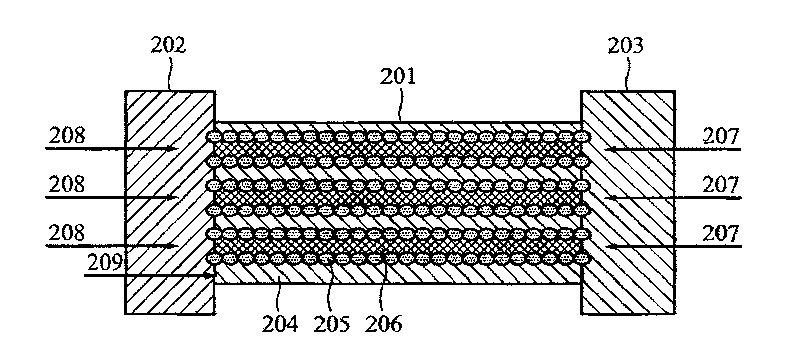

Bonding agent and membrane electrode group thereof

ActiveCN101752566AHigh tensile strengthExcellent water fixation coefficientCell electrodesBiochemical fuel cellsPolymer substratePolymer chemistry

The present invention provides a bonding agent used by a membrane electrode group. The bonding agent comprises a solvent system, a hyperbranched polymer and an organic polymer capable of conducting ions, wherein the branching degree of the hyperbranched polymer is bigger than 0.5, and the hyperbranched polymer and the organic polymer capable of conducting ions are dispersed in the solvent system.

Owner:IND TECH RES INST

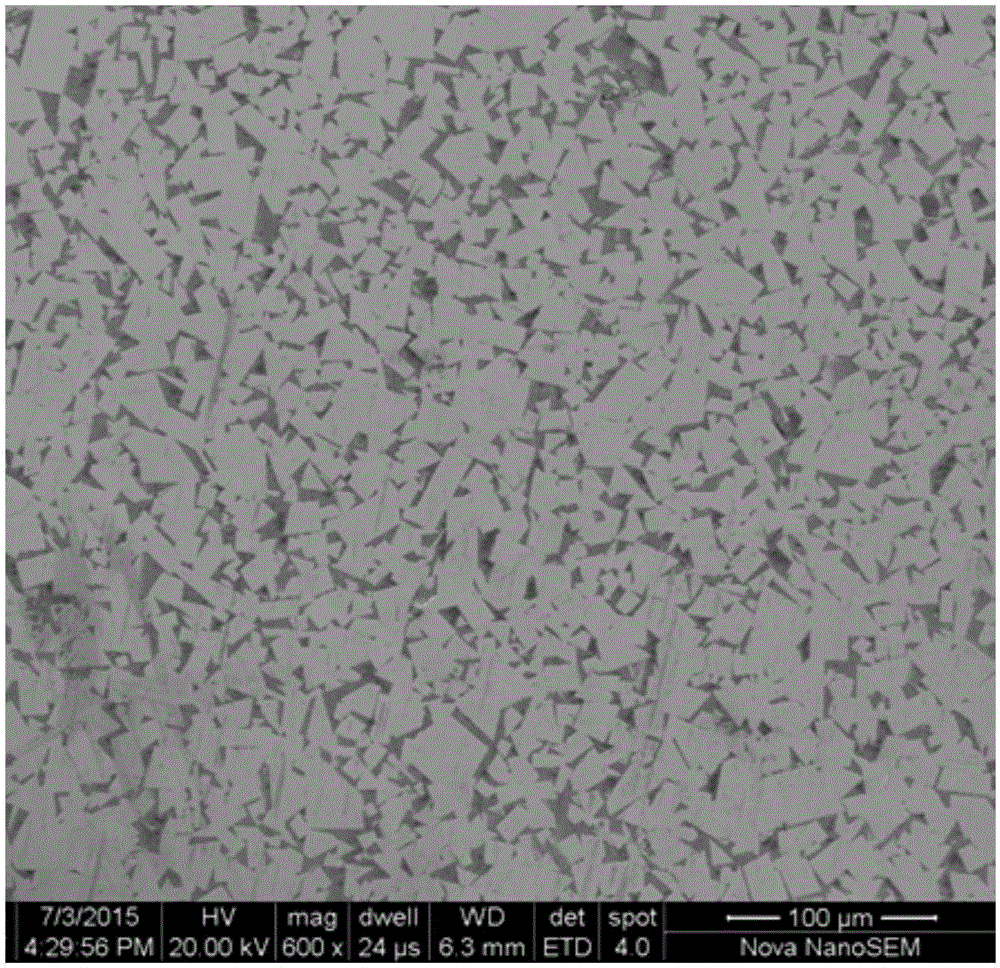

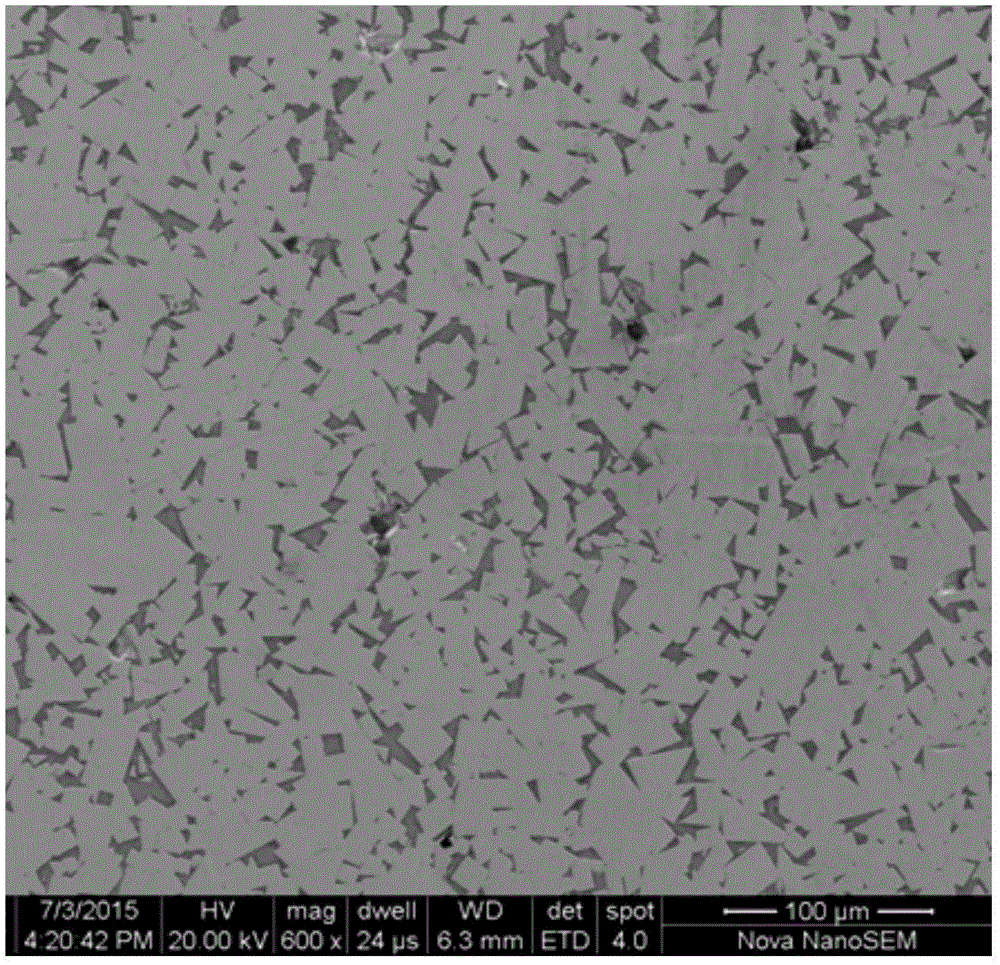

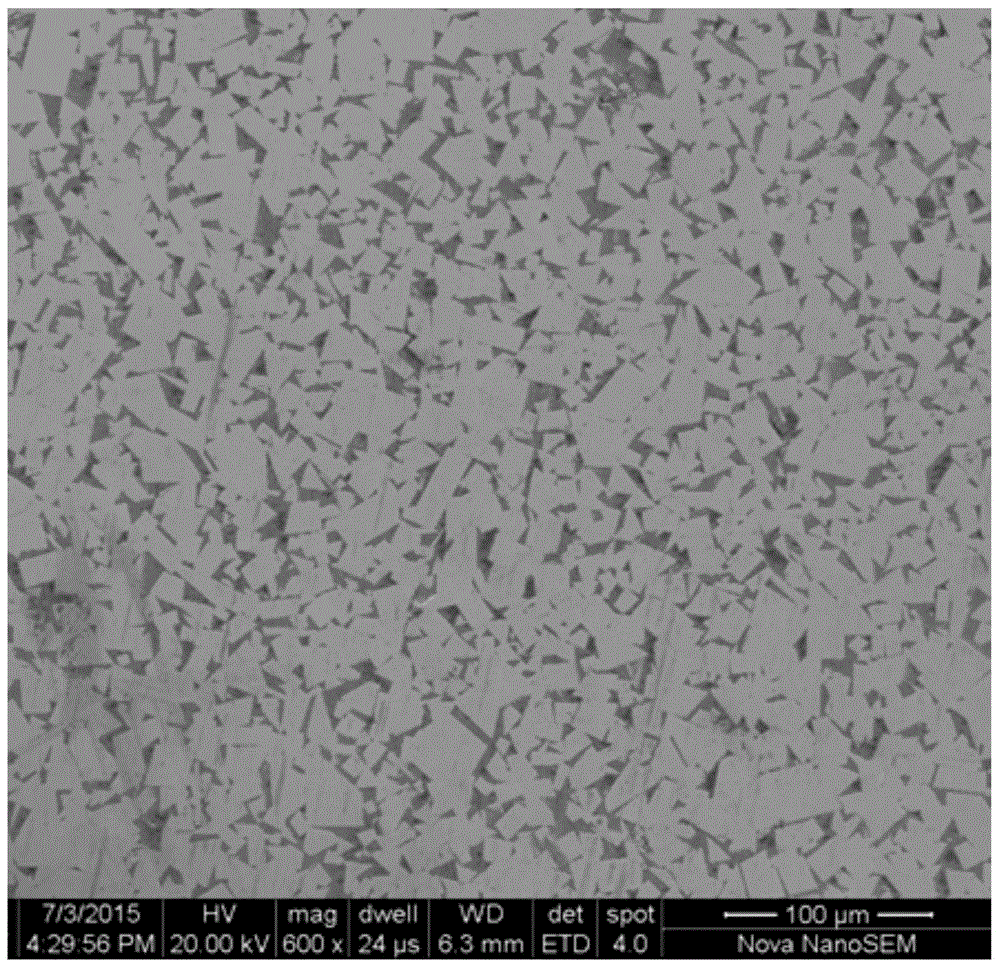

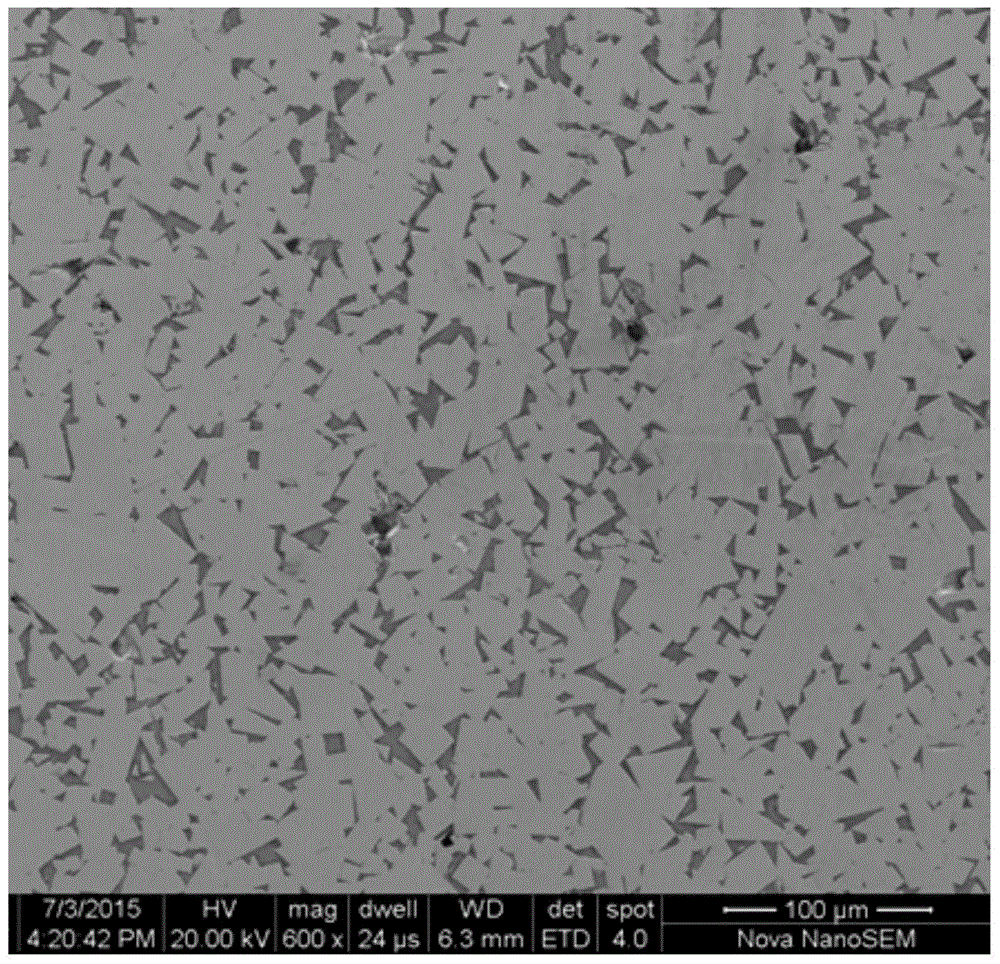

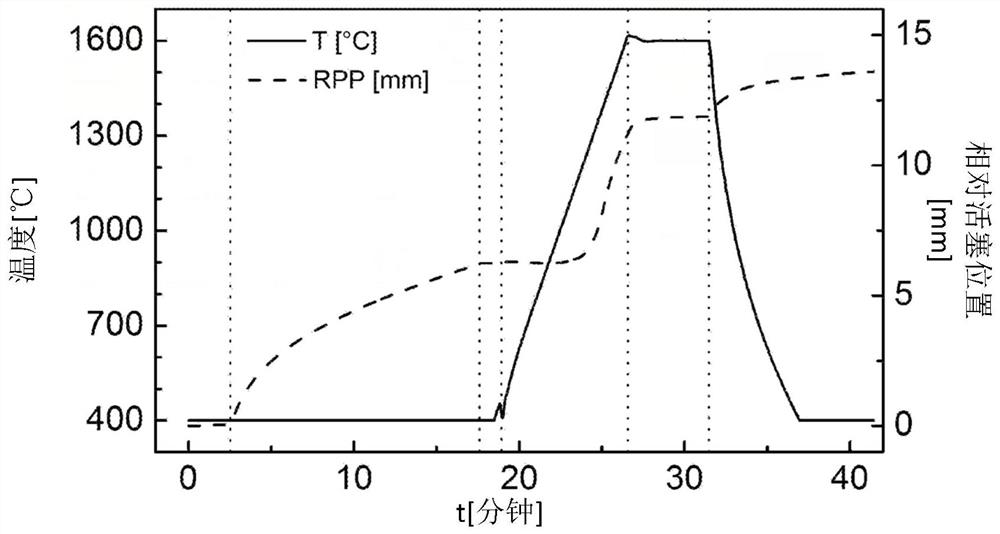

Method for preparing hard alloy through stability regulation and control

The invention provides a method for preparing hard alloy through stability regulation and control and belongs to the technical field of hard alloy material and powder metallurgy. The method includes the steps that firstly, round hard alloy bars are prepared, the two round hard alloy bars are taken and are vertical up and down, the ends of the two round hard alloy bars are adjacent, and the two round hard alloy bars are sequentially arranged in a vertical floating region of a zone melting furnace and vacuumized; the operating power is set to be 60%-95% of the total power, the power is increased to the set power within 20-30 minutes, after the contact ends of the round hard alloy bars form the beam-shaped stable molten state, the round hard alloy bar on the lower side descends, and the round hard alloy bar on the upper side descends synchronously till the round hard alloy bar on the upper side is taken out and serves as the hard alloy bar obtained after zone melting; and the hard alloy bar obtained after zone melting is arranged in a vacuum heat treatment furnace or a carbonizing oven, the carbonization atmosphere such as methane or carbon monoxide is injected, heat is preserved for 1-3 hours at the temperature ranging from 900 DEG C to 1,100 DEG C, the hard alloy bar is cooled to the room temperature along with the furnace, and then a super-coarse grain hard alloy bar is obtained. The super-coarse grain hard alloy with the excellent performance can be prepared.

Owner:BEIJING UNIV OF TECH

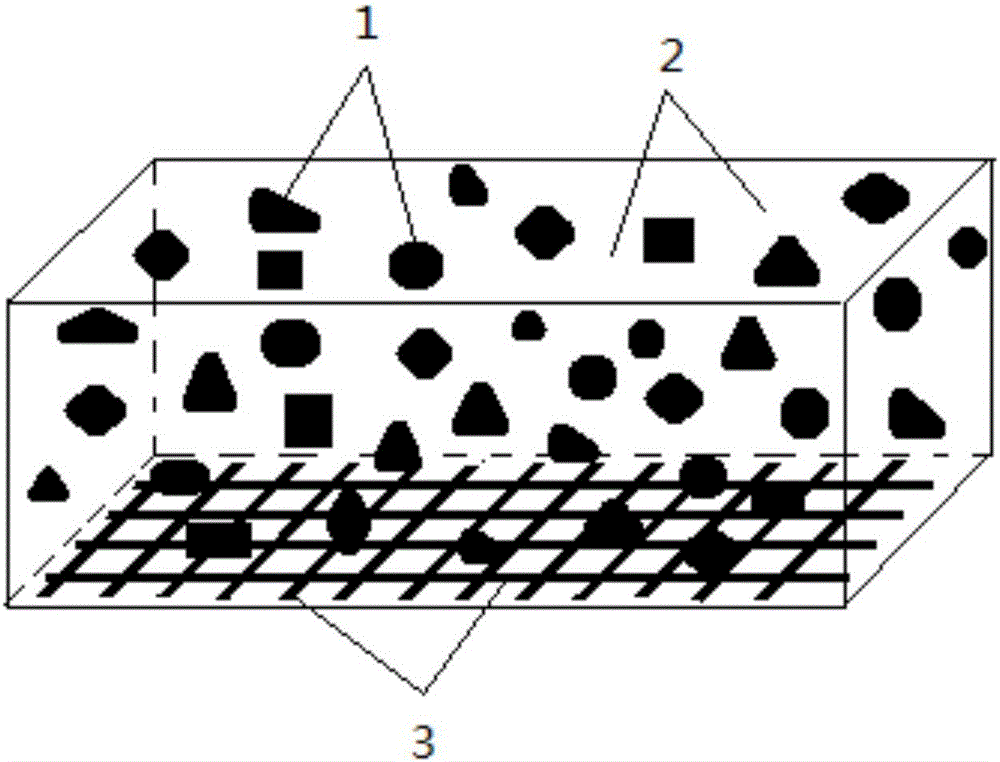

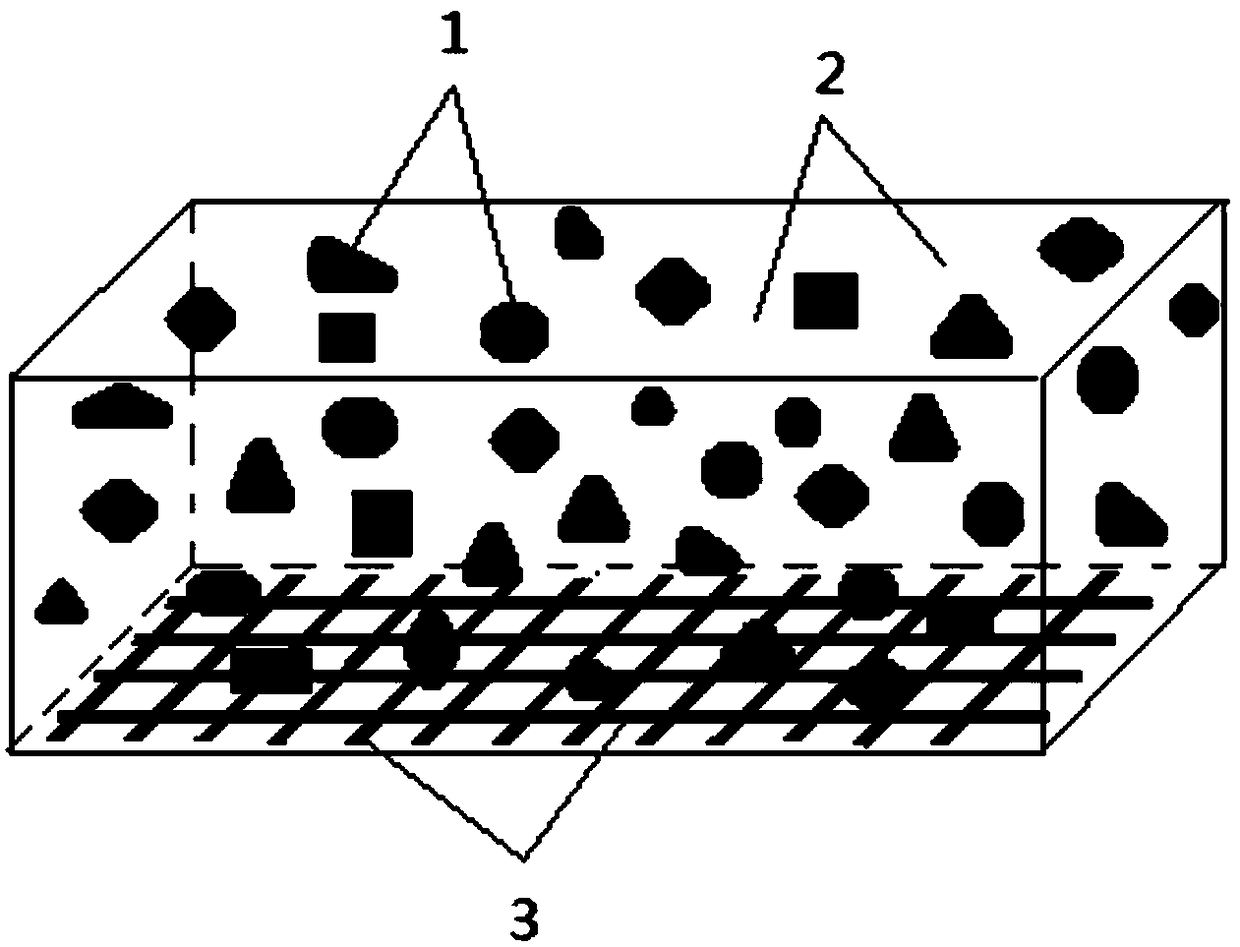

Flexible sound-insulation composite material and preparation method thereof

The invention provides a flexible sound-insulation composite material. The composite material is mainly composed of high-density particles, a viscoelastic thermoplastic material and a flexible framework which is easy to bent and can resist stretching and shearing damages. The composite material prepared by the invention has excellent properties of high strength, high density, fire resistance, no toxin and environment friendliness, corrosion resistance and good sound-insulation effect and can be widely applied to industries including highway traffic, urban rail transit, machinery equipment, house building, ships, home decoration, industrial product packaging and the like. Furthermore, the invention also provides a preparation method of the flexible sound-insulation composite material. A sheet material with low odor, low VOC (Volatile Organic Compound) content, low volatile matter content and good mechanical property indexes of the product is obtained through strictly controlling the extruding temperature and the post-period heating temperature to reduce decomposition and molecular migration of the material, and is an environment-friendly material.

Owner:秦耀东

Historic garden colored drawing repair paint

InactiveCN106497178AImprove durabilityWill not embrittleAntifouling/underwater paintsPaints with biocidesMethacrylateMixing ratio

The invention relates to historic garden colored drawing repair paint. The historic garden colored drawing repair paint comprises the following components in percentage by mass: at least 70% of basic addition materials, 3% to 5% of color particles, 5% to 7% of ferric oxide based additives and the balance of auxiliary addition materials, wherein the ferric oxide based additives consist of a mixture of red iron oxide and magnesium oxide and the mixing ratio of the red iron oxide to the magnesium oxide is 1:2 to 1:1; the basic addition materials comprise the following components in percentage by mass: 20% to 30% of acrylic ester, 10% to 15% of metacrylic acid ester, 10% to 15% of acrylic acid, 10% to 15% of methacrylic acid and the balance of a thickening agent and a filling agent. The historic garden colored drawing repair paint provided by the invention can be matched with the ageing degree of historic garden colored drawing to realize perfect repair of the historic garden colored drawing.

Owner:SUZHOU IND PARK LANDSCAPING ENG CO LTD

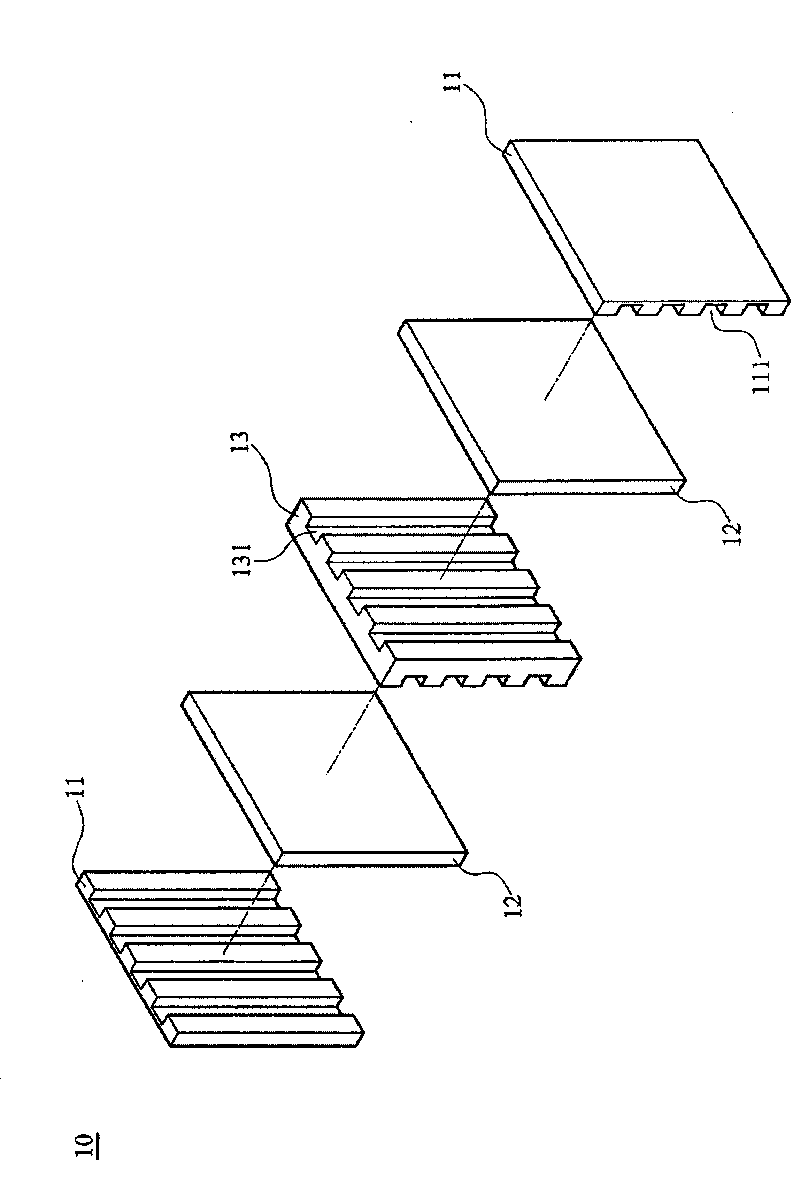

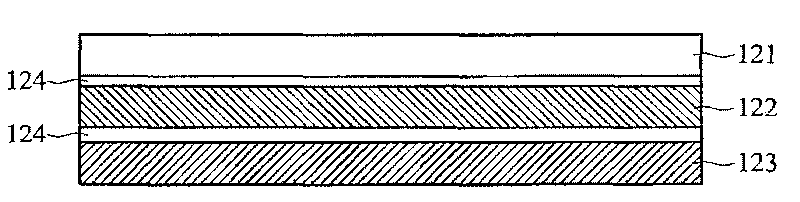

Polytetrafluoroethylene composite isolation membrane for lithium battery

InactiveCN102163703AImprove performanceLong aging lifeSynthetic resin layered productsCell component detailsIsolation membranePolypropylene

The invention discloses a polytetrafluoroethylene composite isolation membrane for a lithium battery. The polytetrafluoroethylene composite isolation membrane comprises an isolation membrane which is a polyethylene microporous membrane or a polypropylene microporous membrane or a composite membrane of the polyethylene microporous membrane and the polypropylene microporous membrane; and the polytetrafluoroethylene composite isolation membrane is characterized in that: a polytetrafluoroethylene microporous membrane is coated on an end face and two sides of the polyethylene microporous membrane, or a polytetrafluoroethylene microporous membrane is coated on an end face and two sides of the polypropylene microporous membrane, or a polytetrafluoroethylene microporous membrane is coated on an end face of the polyethylene microporous membrane of the composite membrane of the polyethylene microporous membrane and the polypropylene microporous membrane and on two sides of the composite membrane. The polytetrafluoroethylene composite isolation membrane for the lithium battery can effectively isolate positive and negative plates of the lithium battery and completely eradicate a short circuit; moreover, the lithium battery is safe and reliable and has no accident in the charging and discharging processes. The polytetrafluoroethylene composite isolation membrane for the lithium battery can be used for isolating the positive and negative plates of the lithium battery.

Owner:SHANGHAI JINYOU FLUORINE MATERIALS

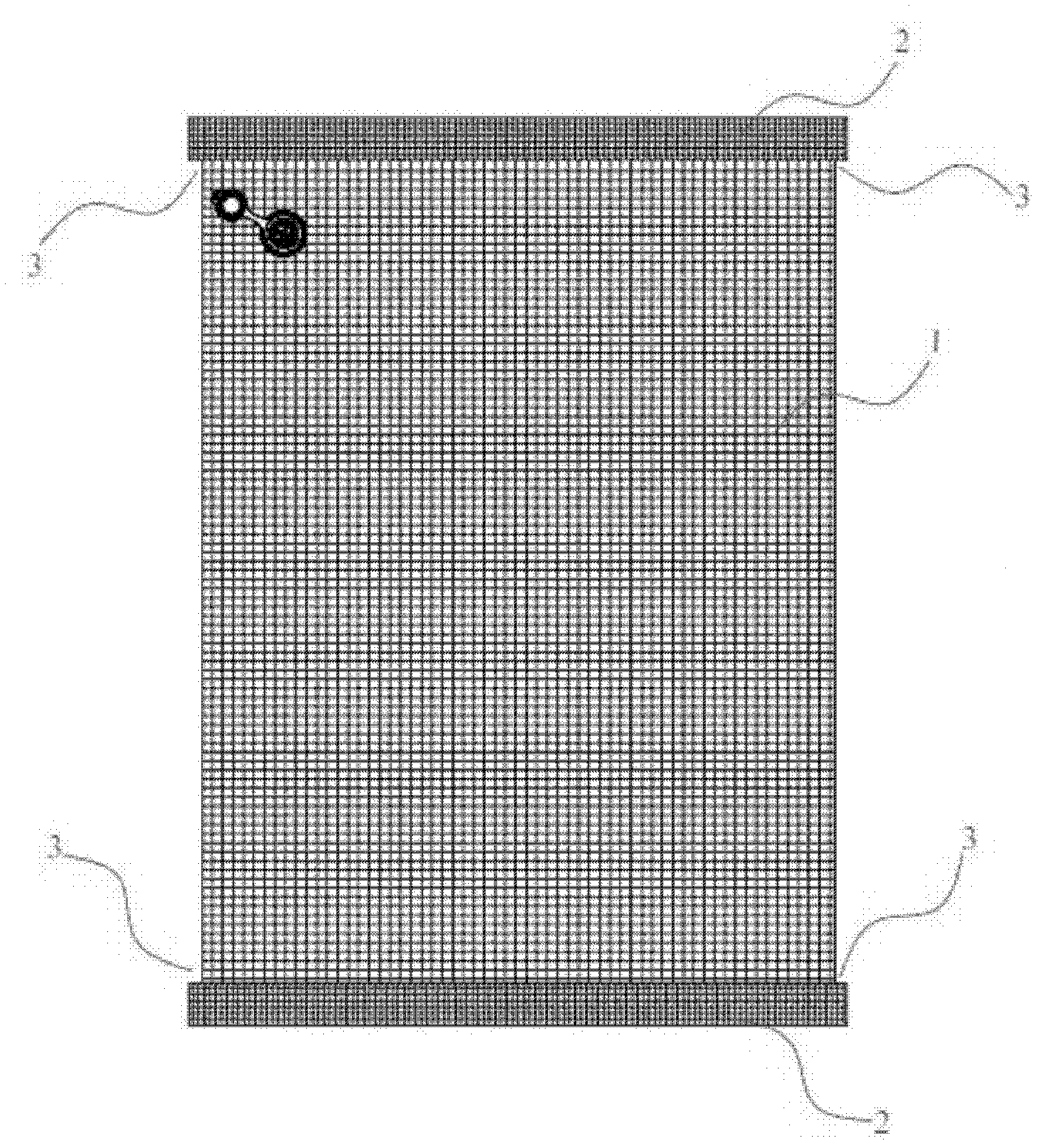

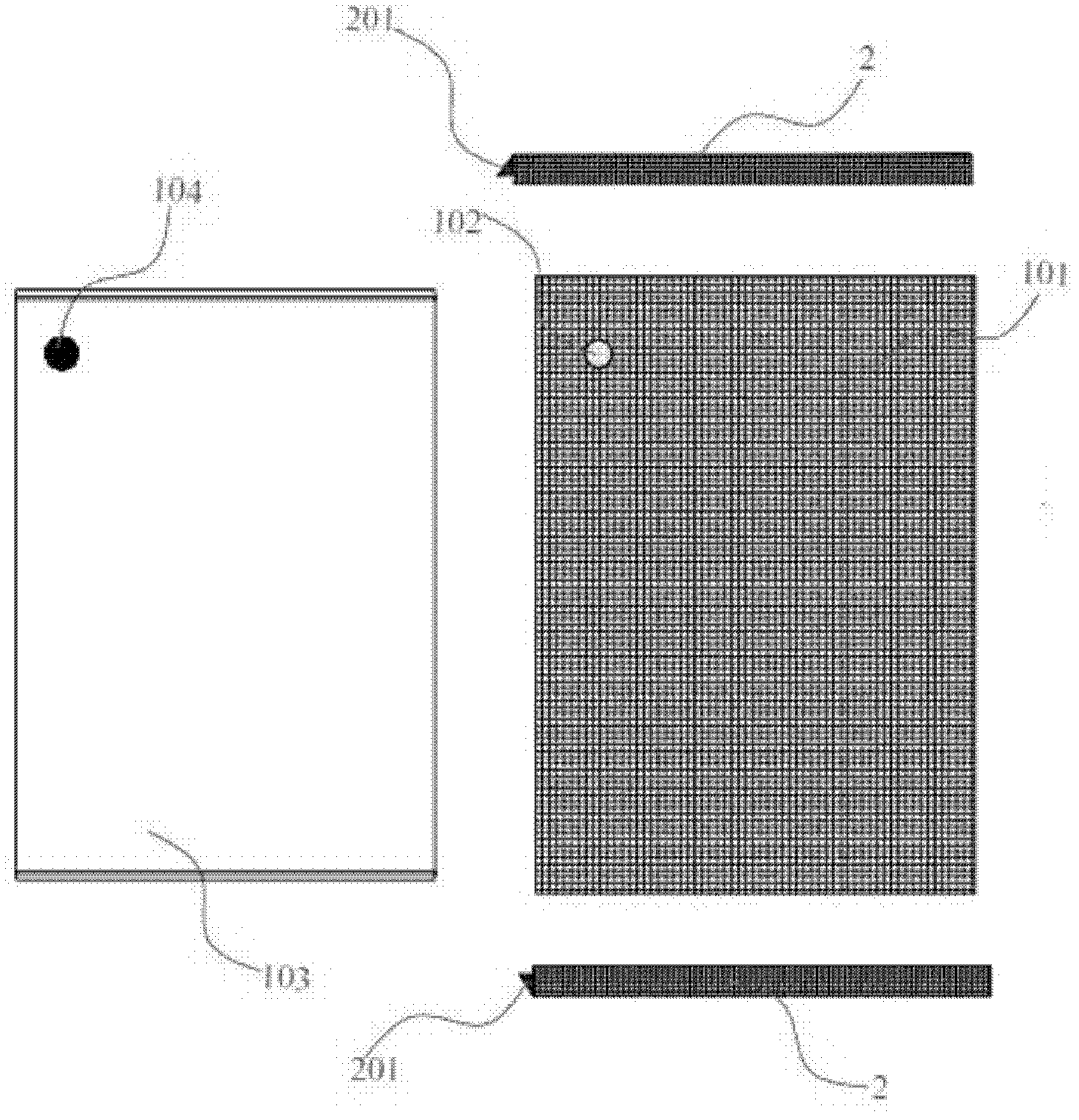

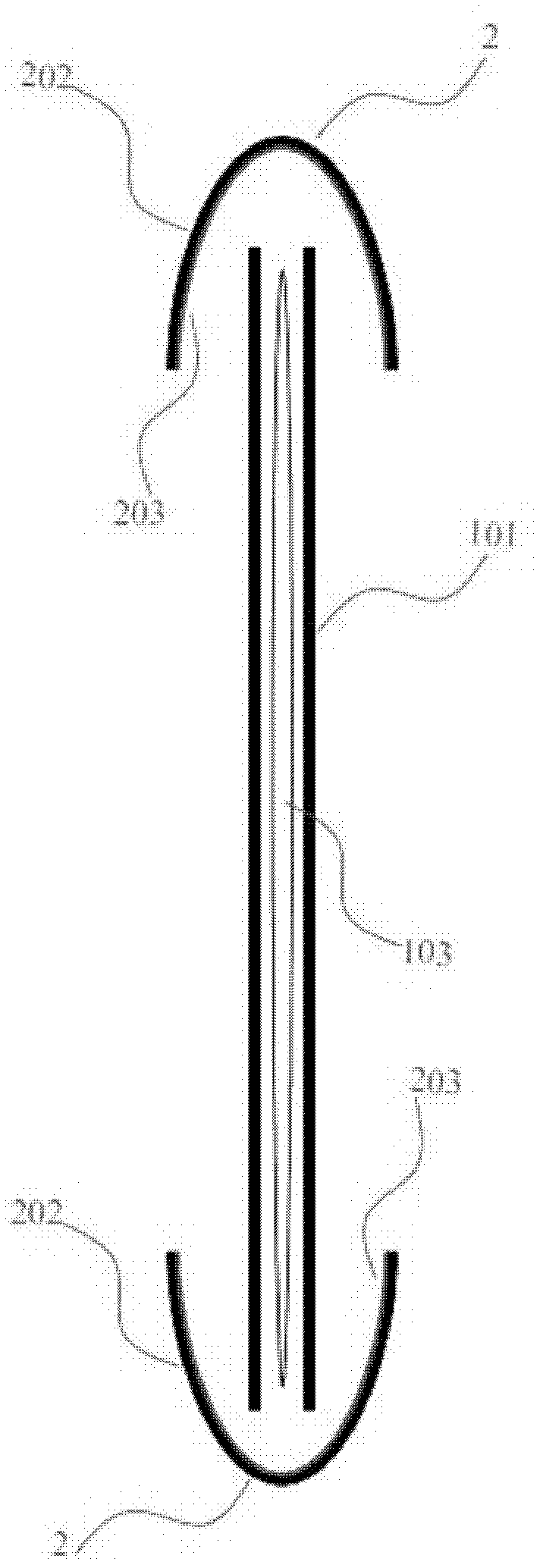

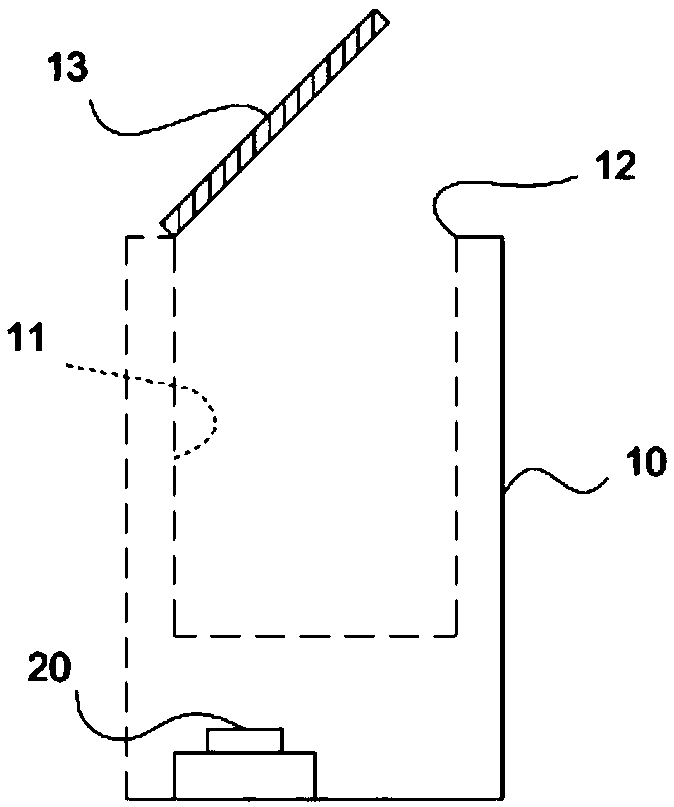

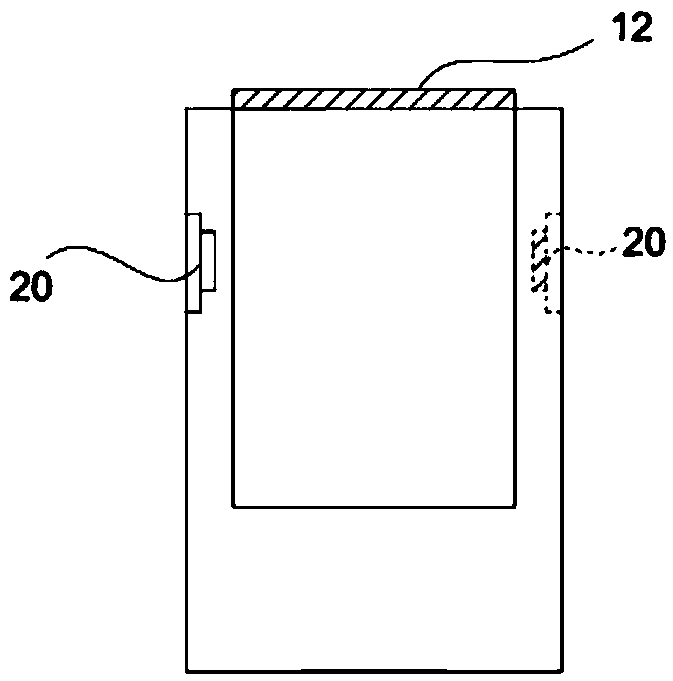

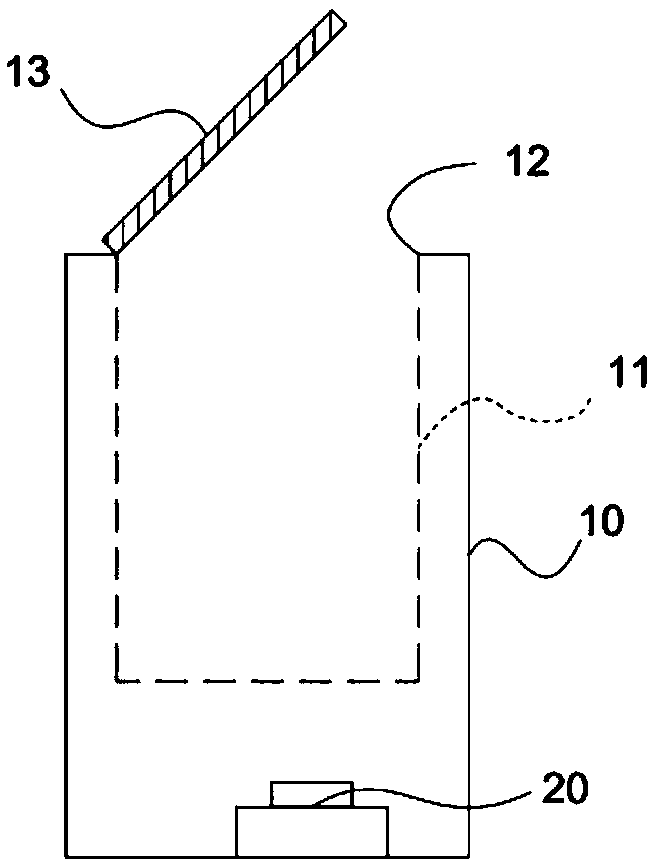

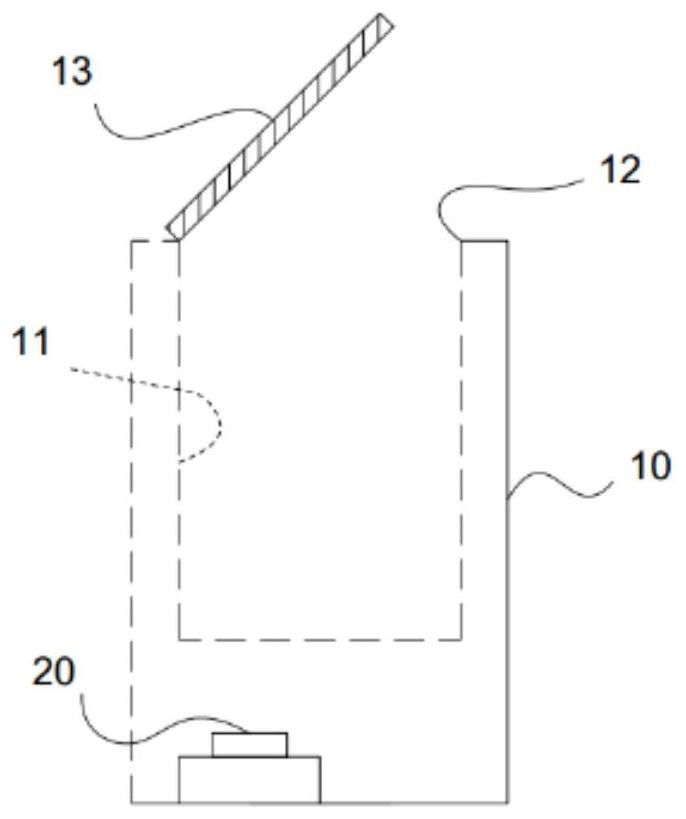

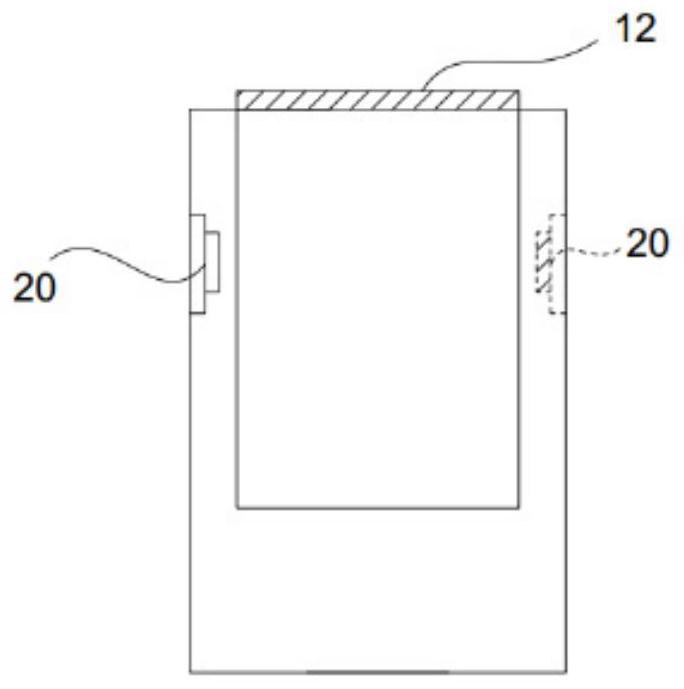

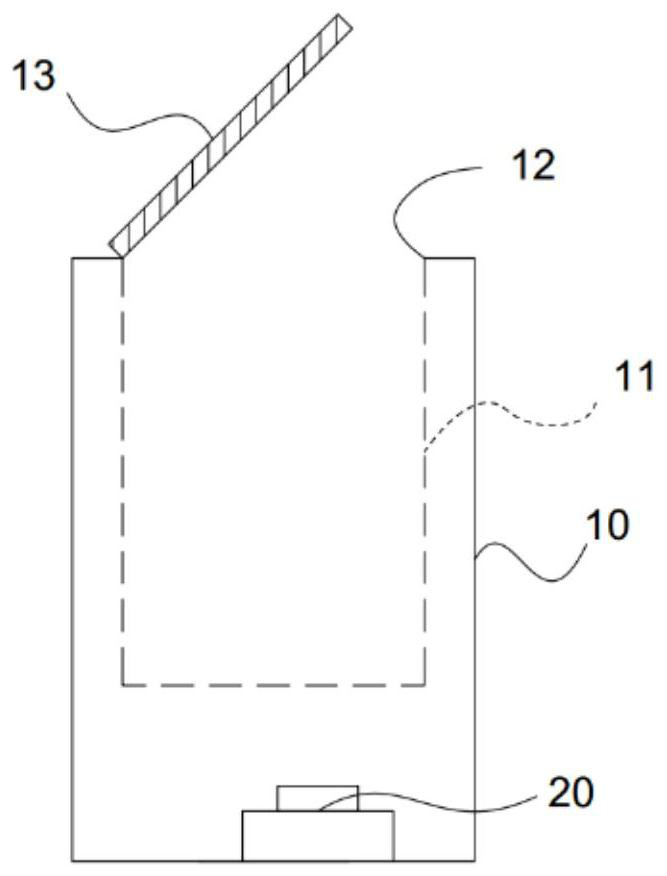

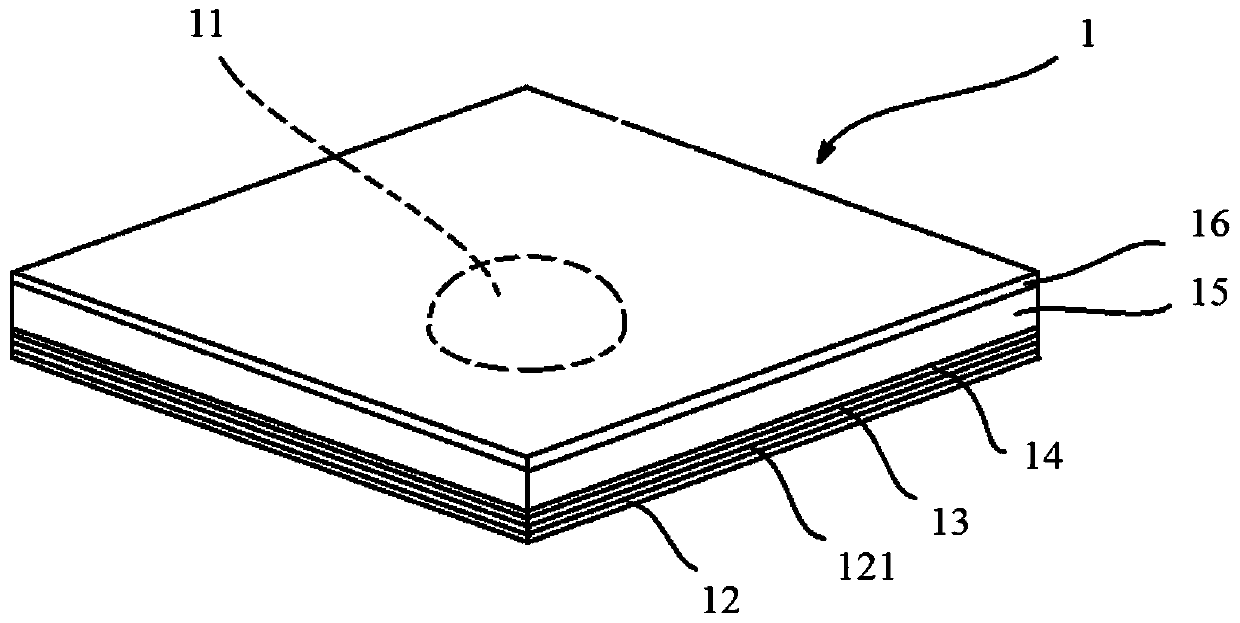

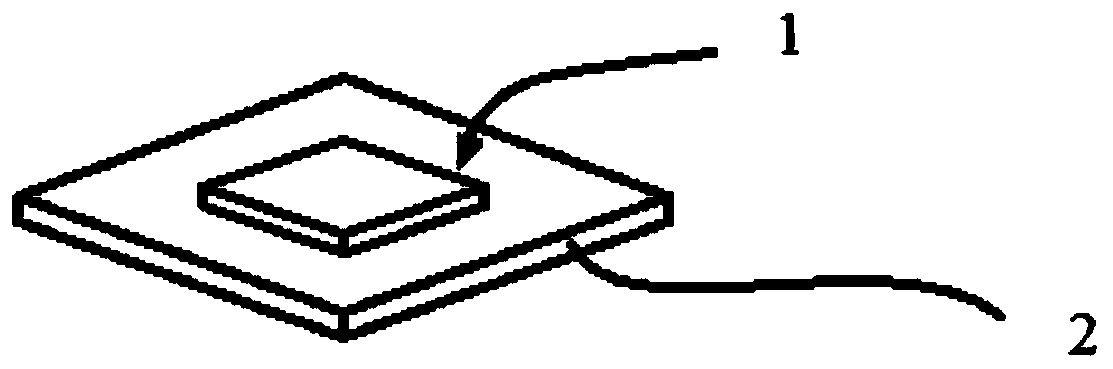

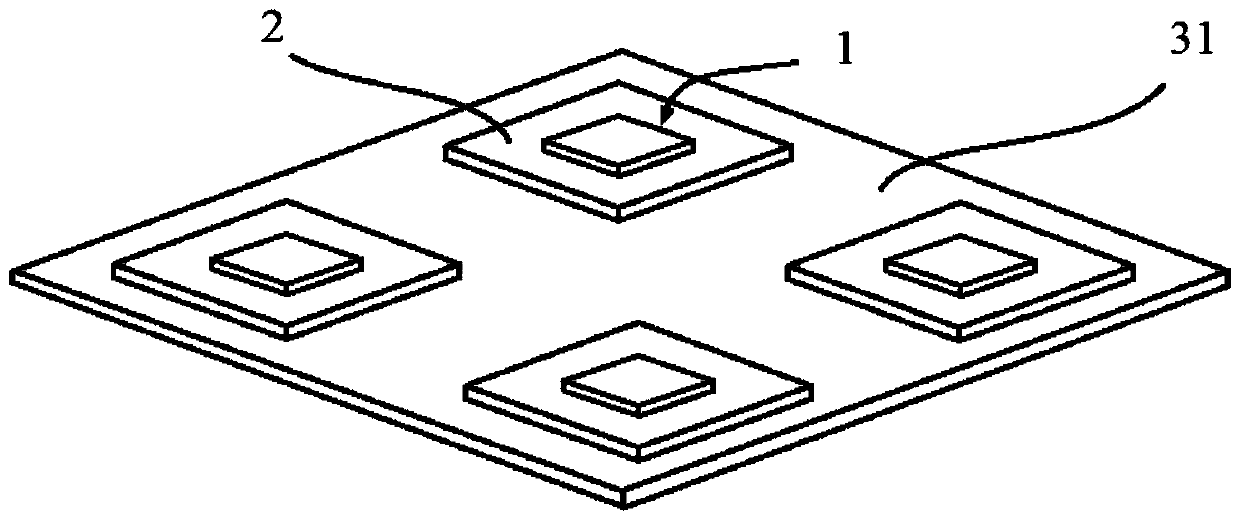

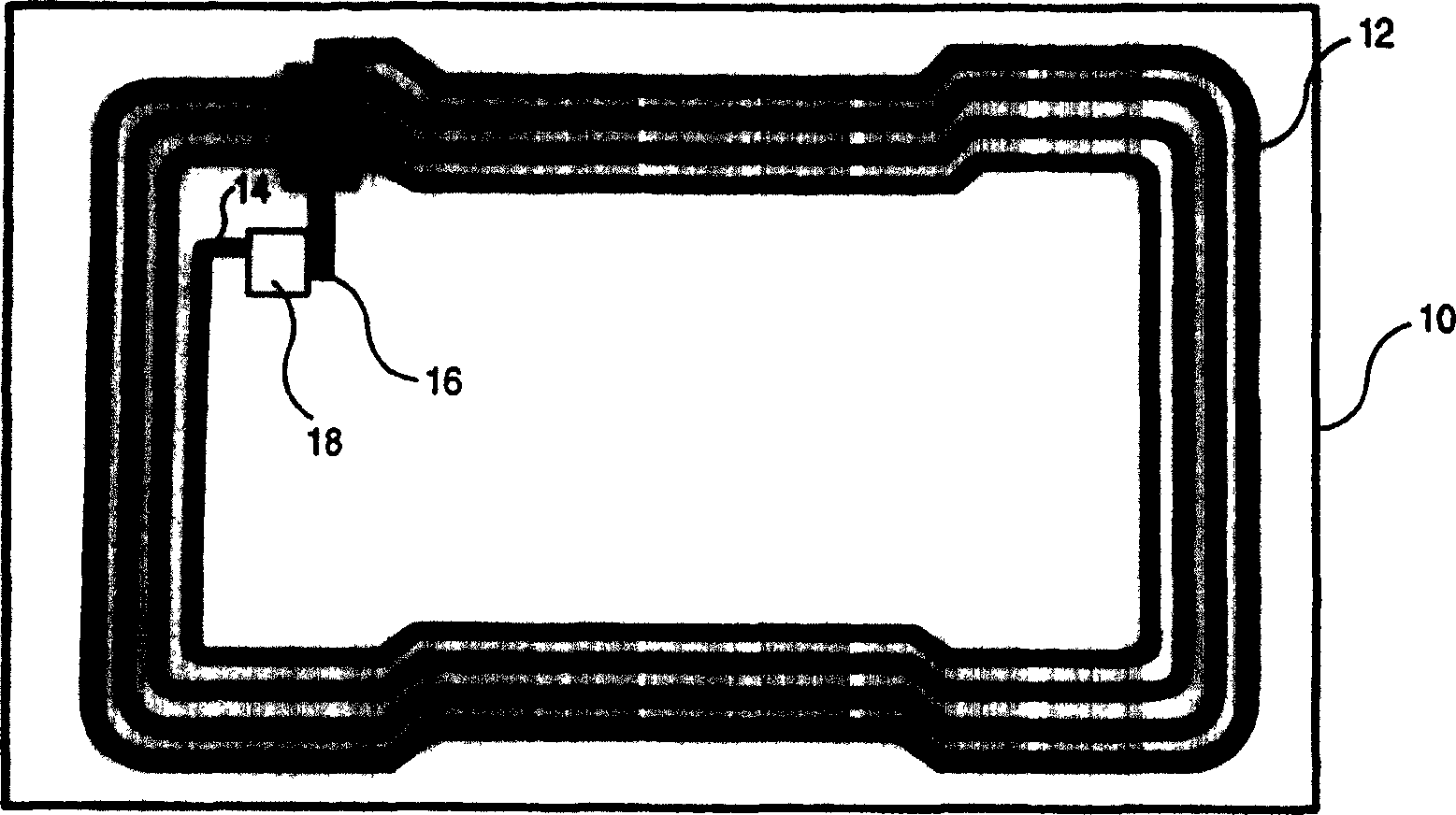

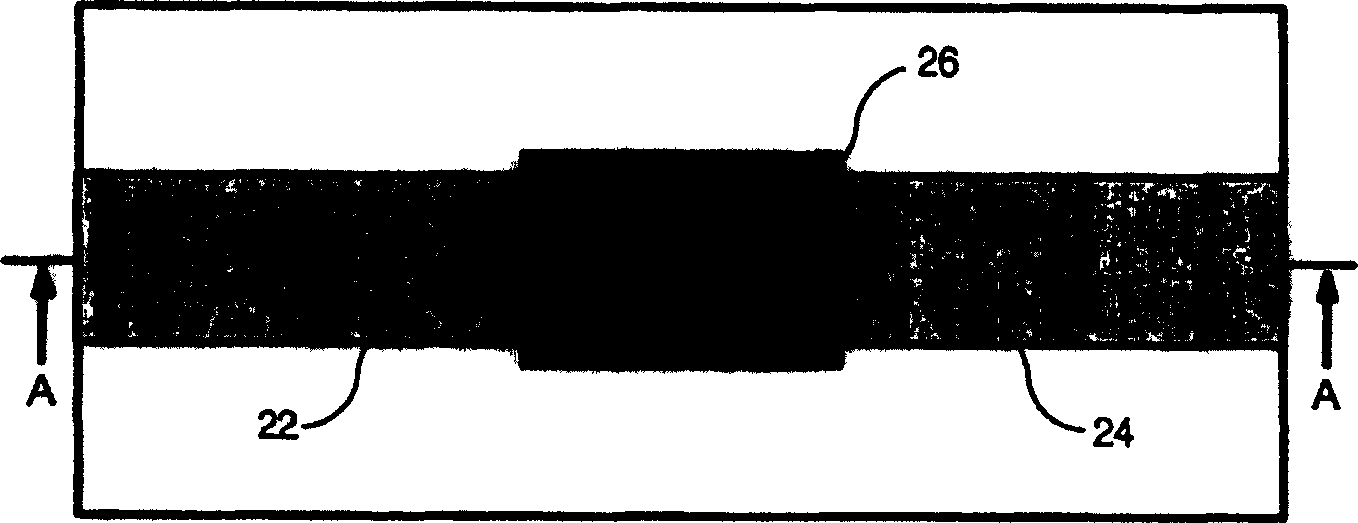

Contactless chip card with antenna support and chip support made from fibrous material

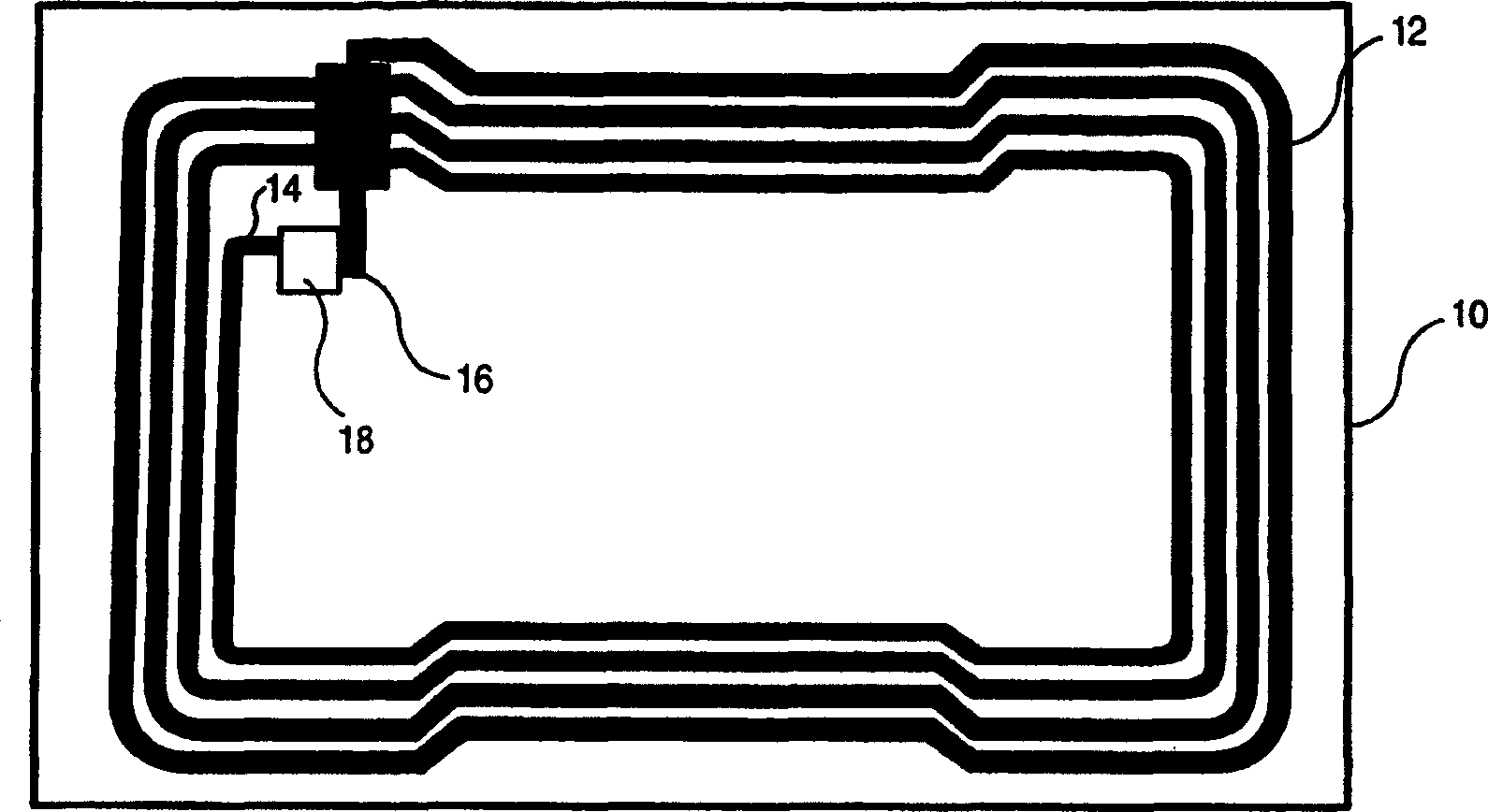

A chip support screen printed with polymerizable conductive ink is mounted on an antenna support (10) so that the chip supported by chip support is positioned in cavity (18) of the antenna support and conductive ink contacts with antenna contacts (14,16) formed on antenna support. An Independent claim is included for a method of manufacturing a smart card.

Owner:ASK CORP

A method for preparing cemented carbide with stability control

The invention provides a method for preparing hard alloy through stability regulation and control and belongs to the technical field of hard alloy material and powder metallurgy. The method includes the steps that firstly, round hard alloy bars are prepared, the two round hard alloy bars are taken and are vertical up and down, the ends of the two round hard alloy bars are adjacent, and the two round hard alloy bars are sequentially arranged in a vertical floating region of a zone melting furnace and vacuumized; the operating power is set to be 60%-95% of the total power, the power is increased to the set power within 20-30 minutes, after the contact ends of the round hard alloy bars form the beam-shaped stable molten state, the round hard alloy bar on the lower side descends, and the round hard alloy bar on the upper side descends synchronously till the round hard alloy bar on the upper side is taken out and serves as the hard alloy bar obtained after zone melting; and the hard alloy bar obtained after zone melting is arranged in a vacuum heat treatment furnace or a carbonizing oven, the carbonization atmosphere such as methane or carbon monoxide is injected, heat is preserved for 1-3 hours at the temperature ranging from 900 DEG C to 1,100 DEG C, the hard alloy bar is cooled to the room temperature along with the furnace, and then a super-coarse grain hard alloy bar is obtained. The super-coarse grain hard alloy with the excellent performance can be prepared.

Owner:BEIJING UNIV OF TECH

Ramie fiber salt elimination underground pipe used for saline-alkali soil and preparation method of ramie fiber salt elimination underground pipe

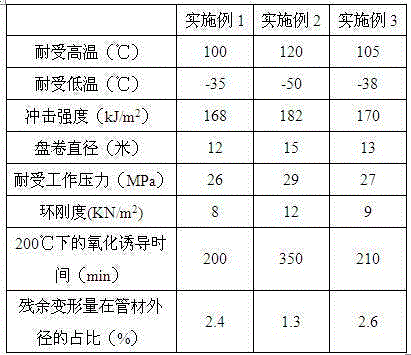

The invention provides a ramie fiber salt elimination underground pipe used for saline-alkali soil. The underground pipe comprises, by weight, 26-38 parts of ramie fiber, 45-53 parts of modified polypropylene, 4-9 parts of phenyl alkyl-sulfonate, 0.6-1.8 parts of p-toluenesulfonhydrazide, 1.4-1.9 parts of calcium stearate, 4-11 parts of devulcanized rubber powder elastomers, 1-3 parts of petroleum-based hydrocarbon oil, 6-12 parts of nanometer titanium dioxide, 7-14 parts of silicone rubber, 5-13 parts of chlorinated polypropylene resin and 1-5 parts of sulfosalicylic acid. The invention further provides a preparation method of the underground pipe. The underground pipe has the advantages that the tolerated high temperature can reach 100-120 DEG C; the coil diameter reaches 12-15 meters under the low temperature of -50DEG C to -35 DEG C; the impact strength is 168-182 kJ / m<2>; the tolerant working pressure reaches 26-29 MPa, and the ring stiffness is 8-12 KN / m<2>.

Owner:WEIFANG YOURONG IND

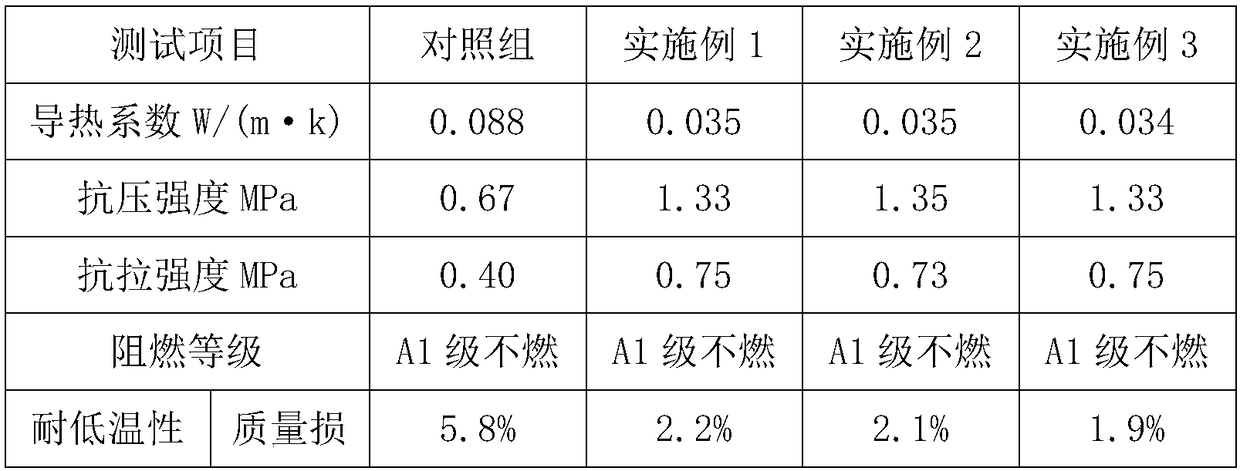

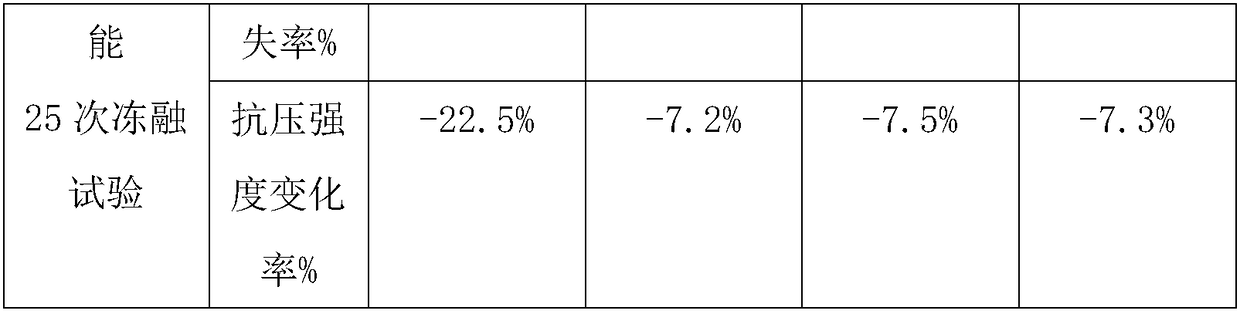

Anti-freezing anti-cracking cement foaming heat preservation board

The invention relates to the technical field of heat preservation construction materials, in particular to an anti-freezing anti-cracking cement foaming heat preservation board. The heat preservationboard is prepared from cement, coal dust, water glass, a cold-resistant flexibilizer, aluminum oxide fibers, a foaming agent, a foam stabilizer, a water reducer, an anti-freezing agent and water, wherein the cold-resistant flexibilizer is a novel material compound by various elastic materials, high-hardness fillers and the like. Cement is a mixture made by blending Portland cement with magnesium oxychloride cement according to a mass ratio of 8:1; the water reducer is a lignin water reducer or a poly-carboxyl water reducer or a melamine water reducer; the foaming agent is hydrogen peroxide; the foam stabilizer is calcium stearate; the anti-freezing agent contains propylene glycol butyl ether, glycol butyl ether acetate and diethylene glycol. The thermal conductivity of the heat preservation board is low, and the heat preservation performance is great. The cold-resistant anti-freezing performance of the materials is great, the tenacity is high, and the heat preservation board is not easily fractured at low temperature.

Owner:HEFEI LONGYANG AGRI TECH CO LTD

Aramid-fiber varnished wire and production method therefor

InactiveCN104992784AHigh breaking strengthHigh elongationInsulated cablesInsulated conductorsElectrical isolationElectrical conductor

The invention discloses an aramid-fiber varnished wire, and the varnished wire comprises a conductor. The external surface of the conductor is wrapped by an aramid fiber insulating varnish film. The invention also provides a production method for the aramid-fiber varnished wire. The aramid-fiber varnished wire is excellent in mechanical performance, flame retardation performance, electrical isolation performance, heat resistance performance and chemical corrosion resistance performance, and can be used for a field which exerts stricter requirements on the performances of wires and cables.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +4

Fluid carrier assembly with inorganically-packaged ultraviolet light emitting diode module

ActiveCN109368887AWill not embrittleWon't peel offSpecific water treatment objectivesTreatment involving filtrationUltraviolet lightsUltraviolet light emitting diodes

The invention relates to a fluid carrier assembly with an inorganically-packaged ultraviolet light emitting diode module. The fluid carrier assembly comprises a selectively-opened fluid carrier and anultraviolet light emitting diode module. The fluid carrier can be in any form and can be a cup body, a bottle body with a cap and the like. The inorganically-packaged ultraviolet light emitting diodemodule is mainly composed of a metal packaging body and a light emitting diode. Ultraviolet rays emitted by the light emitting diode are capable of achieving an effect on sterilizing a fluid in the fluid carrier, so that the aim of providing a clean fluid is achieved.

Owner:江苏奥创深紫电子科技有限公司

Graphene self-lubricating anti-drag coating

The invention discloses a graphene self-lubricating anti-drag coating which is characterized by comprising the following components: polystyrene, propylene glycol methyl ether acetate, titanium dioxide, graphene, titanium dioxide, epoxy acrylate resin, nano powder, white ceramic powder, aromatic amine resin, a defoaming agent, a flatting agent and a dispersing agent. The graphene self-lubricating anti-drag coating provided by the invention can effectively improve the relation between torque and pressure of a high-end fastener, so that the fastener can bear larger load and is not easy to loosen, and the problems of dead clamping and occlusion of the fastener, ultra-high-temperature and ultra-low-temperature lubrication, wear resistance, self-lubrication and rust and corrosion prevention are solved.

Owner:大庆市盛日石油技术开发有限公司

Preparation process of polypropylene material

InactiveCN111875877AHigh low temperature impact resistanceHigh mechanical strengthInduction heating apparatusPolymer sciencePtru catalyst

The invention belongs to the technical field of plastics, and particularly relates to a preparation process of a polypropylene material, which comprises the following steps: 1, preparing the followingraw materials in percentage by mass: 60-75% of propylene raw material, 2-6% of epoxidized soybean oil, 5-16% of powdered acrylonitrile-butadiene rubber, 0.5-1% of plasticizer DOS, 0.5-1% of plasticizer DOA, 6-9% of butadiene, 1-2% of modifier, 1-4% of stabilizer and 1-2% of a catalyst. In the preparation process of the polypropylene material, by setting blending modification, a mixture generatedby blending powdered nitrile rubber, a plasticizer DOS and a plasticizer DOA is used as a reinforcing body, so that the low-temperature impact resistance of the polypropylene material is greatly improved, and the polypropylene material can work even at the temperature of -45 DEG C and is free of being embrittled; in addition, by means of epoxidized soybean oil, the prepared polypropylene materialcan be endowed with good mechanical strength, weather resistance and electrical property, and is non-toxic.

Owner:王 兰兰

Preparation process of low-temperature-resistant anti-cracking double-layer leather

PendingCN114395646AHigh tear strengthShow cationicLeather clicking/perforating/clickingTanning treatmentPolymer chemistryEpoxy

The invention discloses a preparation process of low-temperature-resistant anti-cracking double-layer leather, and relates to the technical field of leather production. When the low-temperature-resistant anti-cracking double-layer leather is prepared, cattle hide serves as base cloth, the base cloth is sequentially tanned and re-tanned to form a first layer, then the base cloth is smashed, epoxy resin is added into the base cloth, the base cloth is rolled to form a second layer, the first layer and the second layer are coated with modified polyurethane, and the first layer and the second layer are pressed under ultraviolet light to form the low-temperature-resistant anti-cracking double-layer leather. During tanning and retanning, amino-terminated lactic-co-glycolide is used as a tanning agent, hydroxyl-terminated lactic-co-glycolide is used as a retanning agent, the tearing strength of the leather is improved, and free formaldehyde can be removed; silicon-oxygen bonds are introduced into the modified polyurethane, so that the low-temperature resistance is enhanced, and the cracking resistance of the double-layer leather is enhanced by curing and pressing under ultraviolet light.

Owner:威尔尼装饰材料(江苏)有限公司

A kind of flexible sound insulation composite material and preparation method thereof

The invention provides a flexible sound-insulation composite material. The composite material is mainly composed of high-density particles, a viscoelastic thermoplastic material and a flexible framework which is easy to bent and can resist stretching and shearing damages. The composite material prepared by the invention has excellent properties of high strength, high density, fire resistance, no toxin and environment friendliness, corrosion resistance and good sound-insulation effect and can be widely applied to industries including highway traffic, urban rail transit, machinery equipment, house building, ships, home decoration, industrial product packaging and the like. Furthermore, the invention also provides a preparation method of the flexible sound-insulation composite material. A sheet material with low odor, low VOC (Volatile Organic Compound) content, low volatile matter content and good mechanical property indexes of the product is obtained through strictly controlling the extruding temperature and the post-period heating temperature to reduce decomposition and molecular migration of the material, and is an environment-friendly material.

Owner:秦耀东

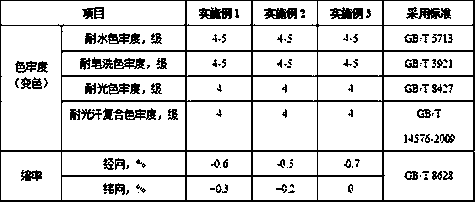

A kind of production technology of four-way stretch fabric

ActiveCN107460602BComfortable to wear without restraintGuaranteed shrinkageFabric breaking/softeningHeating/cooling textile fabricsYarnColour fastness

The invention relates to a production process of a four-way stretch fabric, which belongs to the field of textiles. The present invention comprises the following steps: weaving→pretreatment→mechanical soft finishing→grain fabric presetting→two-bath dyeing→low temperature heat setting→preshrinking, the obtained four-way stretch fabric shows nylon yarn on the front side and high wet modulus fiber on the back side yarn. In the present invention, through the cooperation of reasonable fibers and tissue structures, the adjustment of procedures and processes, and the reasonable selection of dyeing and chemical materials, the obtained four-way stretch fabric is not only comfortable and wear-resistant, but also has good color fastness and stable shrinkage. The technical problem that fabric exists in the prior art is solved.

Owner:LILANG CHINA

Preparation method of improved real silk fibers

InactiveCN112281221AImprove structural strengthAvoid breakingFilament/thread formingConjugated cellulose/protein artificial filamentsPolymer scienceSpinning

The invention discloses a preparation method of improved real silk fibers. The preparation method comprises the following steps of step 1, weighing and preparing materials, wherein formula of the improved real silk fibers comprises the following components in parts by weight of 30-44 parts of spider silk fibers, 1-10 parts of protease, 0.5-5 part of antioxidant, 2-5 parts of penetrating agent, 40-55 parts of real silk fibers, 0.3-3 part of triethylamine and 0.5-1 part of 2-bromoisobutyryl bromide. 2, preparing a spinning solution of the improved real silk fibers; 3, preparing improved real silk fibers; 4, drying; 5, observing the morphology; placing the improved silk fibers on a detection table; and placing the improved real silk fibers under a scanning electron microscope to observe the microstructure of the improved real silk fibers. The prepared real silk fiber is high in internal structural strength and has tear resistance; the silk fibers are improved, so that the silk fibers haverelatively good oxidation resistance; and the practicability is higher, and the service life of the fibers is longer.

Owner:苏州林恩时装面料有限公司

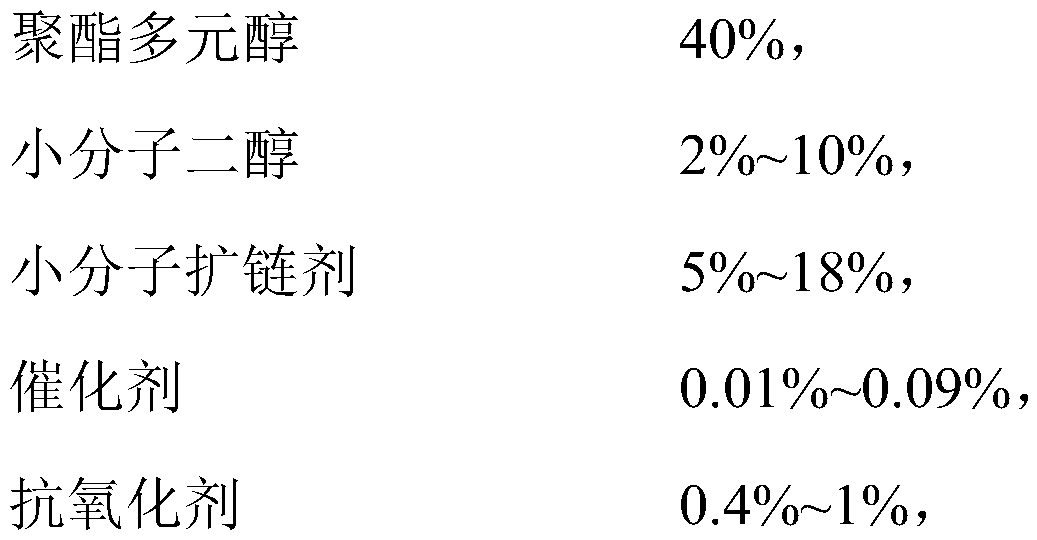

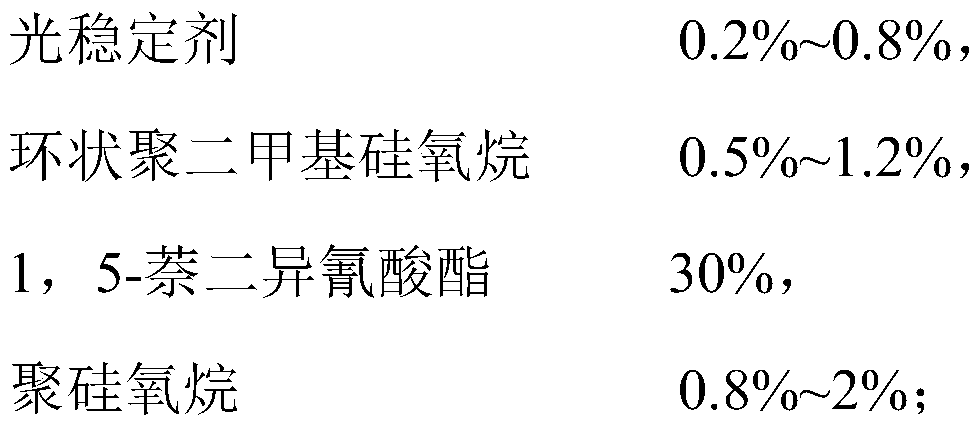

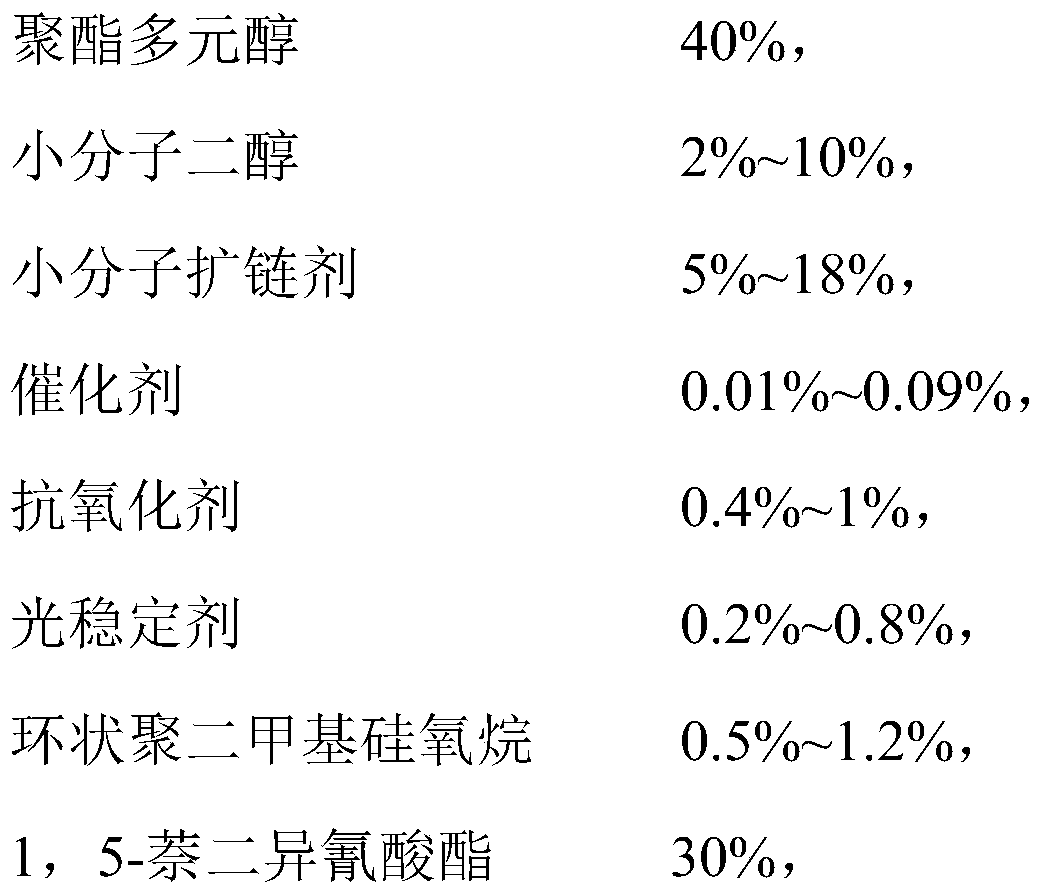

A kind of preparation method of high haze and high wear resistance thermoplastic polyurethane elastomer

The invention relates to a preparation method of a thermoplastic polyurethane elastomer with high haze and high wear resistance. The preparation method comprises the following steps: firstly, uniformly stirring and melting polyester polyol, small molecule diol, a chain extender, a catalyst, an antioxidant agent, a light stabilizer and cyclic polydimethylsiloxane according to certain mass proportions for later use; secondly, metering a product obtained in the first step and diisocyanate by a high-precision flowmeter, then carrying out rapid mixing by a gear pump and a mixing head with high rotating speed, subsequently, pouring a mixture into a double-screw extruder, carrying out sufficient melting reaction by the extruder and then obtaining the thermoplastic polyurethane elastomer with high haze and high wear resistance by an underwater granulator. The product disclosed by the invention can be used for occasions such as wire guide roller frameworks, wire guide rollers, mechanical parts, shaft seals, football soles, sports shoes supporting frames or automobile parts; in addition, the product has good comprehensive performance and good processing performance, belongs to an environment-friendly product, and can be used for replacing general plastics and partial engineering plastics.

Owner:苏州奥斯汀新材料科技有限公司

A fluid carrier assembly of an ultraviolet light-emitting diode module with inorganic packaging

ActiveCN109368887BWill not embrittleWon't peel offSpecific water treatment objectivesTreatment involving filtrationUltraviolet lightsUltraviolet light emitting diodes

A fluid carrier assembly of an ultraviolet light emitting diode module with inorganic packaging in the present invention includes a fluid carrier that can be selectively opened and an ultraviolet light emitting diode module. The fluid carrier can be any shape, such as a cup, a bottle with a lid, and the like. The inorganic package ultraviolet light emitting diode module is mainly composed of a metal package body and a light emitting diode. The ultraviolet light emitted by the light emitting diode can sterilize the fluid contained in the fluid carrier, so as to achieve the purpose of providing clean fluid.

Owner:江苏奥创深紫电子科技有限公司

Ultraviolet sterilization module for escalator handrail

PendingCN111416029AWill not embrittleWon't peel offSemiconductor devicesRadiationUltraviolet lightsAluminum substrate

The invention discloses an ultraviolet sterilization module for an escalator handrail. The ultraviolet sterilization module comprises a ceramic substrate, a titanium layer formed on the side face of the ceramic substrate, a patterned copper layer formed on the surface of the titanium layer, an ultraviolet chip fastened to one side of the patterned copper layer, an upper frame and quartz glass combined to one side of the upper frame. Furthermore, a layer of aluminum substrate (MCPCB) is fixedly arranged on one side of the ceramic substrate, and a heat dissipation structure is additionally arranged on one side of the aluminum substrate. The module also comprises a shell which can cover all the components and can be structurally arranged at one end of an escalator handrail so as to shield ultraviolet light emitted by the ultraviolet light chip and prevent the ultraviolet light from leaking. Therefore, the ultraviolet light chip can be used for continuously emitting ultraviolet light to the escalator handrail to sterilize the escalator handrail.

Owner:张胜翔

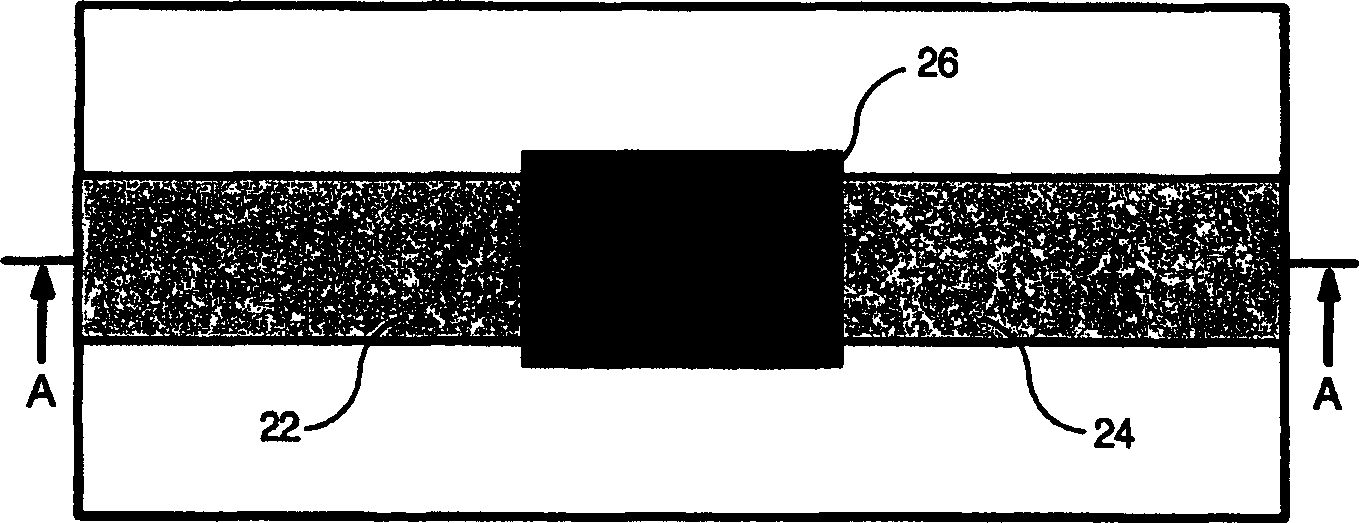

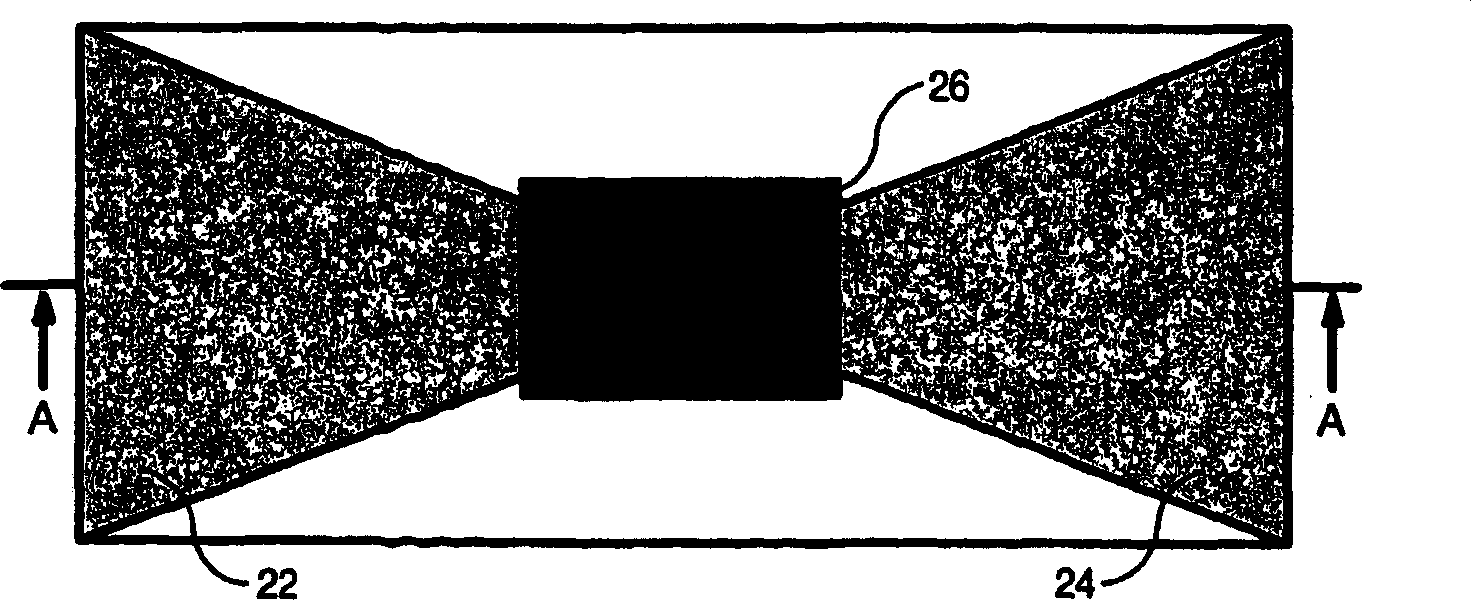

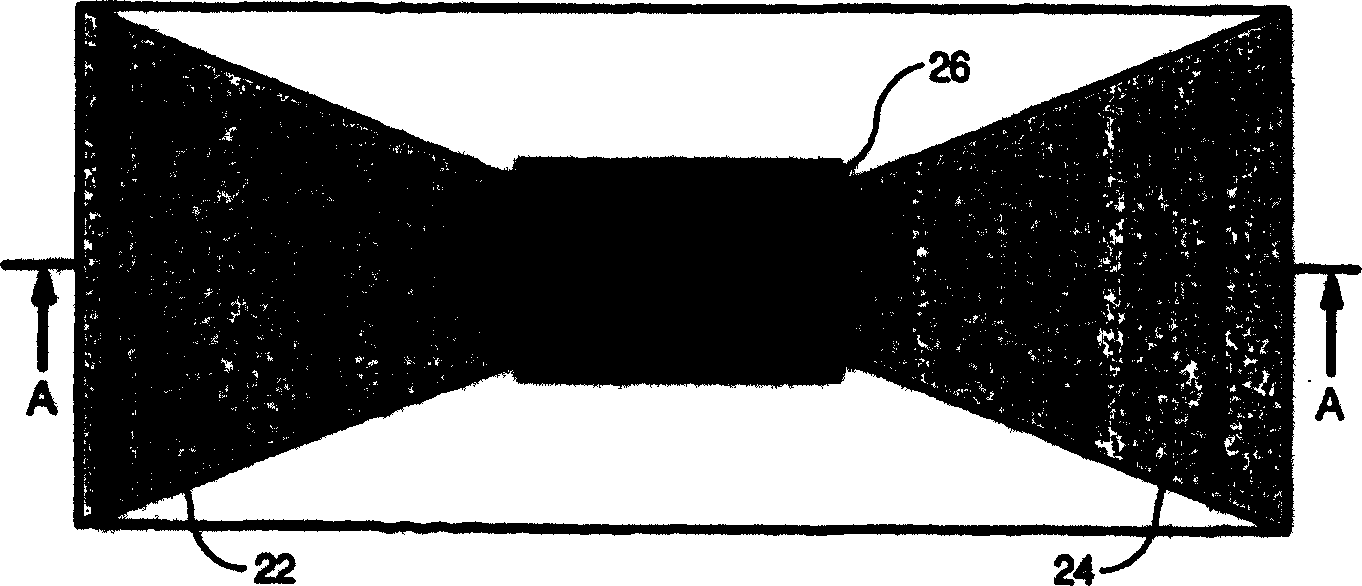

Contactless chip card with antenna support and chip support made from fibrous material

InactiveCN1284113CLow costWill not embrittleOther printing matterSolid-state devicesFiberContactless smart card

The invention relates to a contactless smart card, which includes: an antenna (12) located on an antenna base (10) made of fiber material, the antenna including turns printed on the antenna base with a silk screen and two contacts (14 , 16), a card body (32, 34) on each side of the antenna base, and a chip (26) with contacts (28, 30) connected to the antenna. The card also features a chip base (20) made of fiber material, the latter (20) having two conductive contacts (28, 30) screen printed on it and connected to the contacts (28, 30) of the chip (26). Strips (22, 24) on which the chip base (20) is positioned on the antenna base (10) such that these conductive strips (22, 24) are in contact with and connected to the contacts (14, 16) of the antenna and enable The chip (26) is located in a cavity (18) formed in the antenna base (10) for this purpose.

Owner:ASK CORP

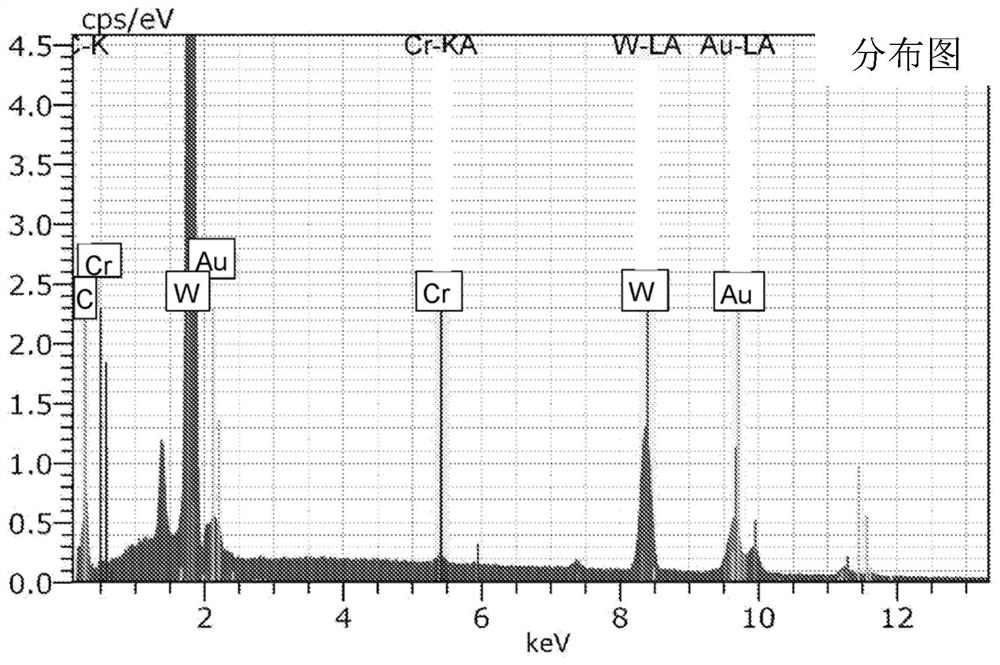

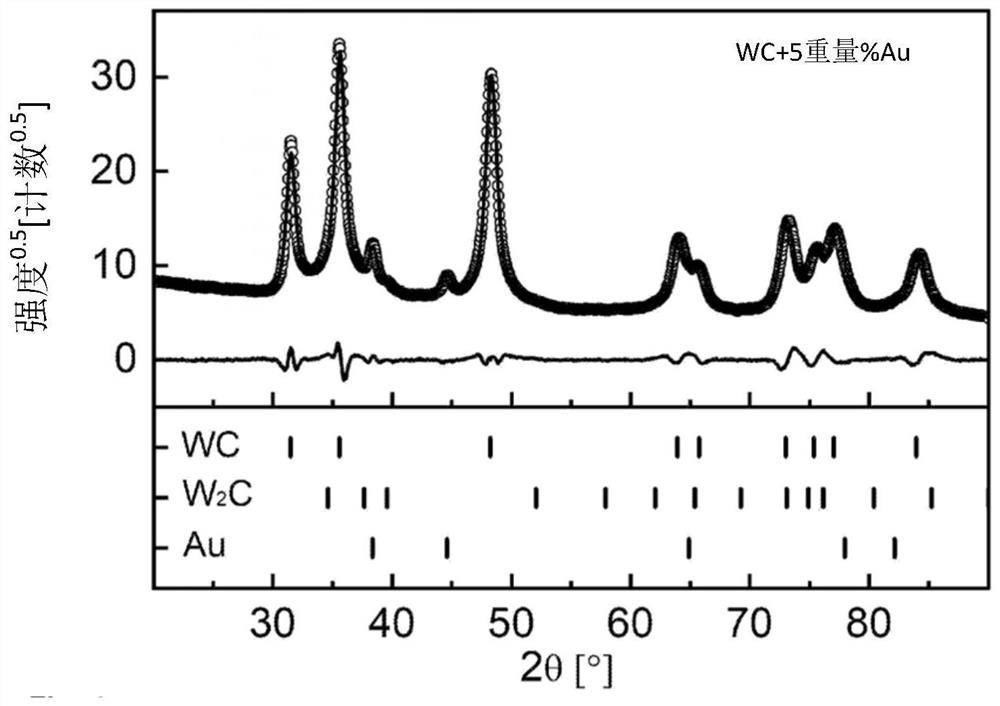

Composite materials based on tungsten carbide and having noble metal binders, and method for producing said composite materials

The invention relates to composite materials based on tungsten carbide and comprising gold, palladium and / or platinum and to a method for producing said composite materials by sintering. By means of the FAST method, hard and biocompatible WC / (Au, Pd, Pt) composite materials can be produced, inter alia for use as coatings on tools and prostheses and as solid bodies in, for example, blood pumps.

Owner:UNIVERSITY OF ROSTOCK +1

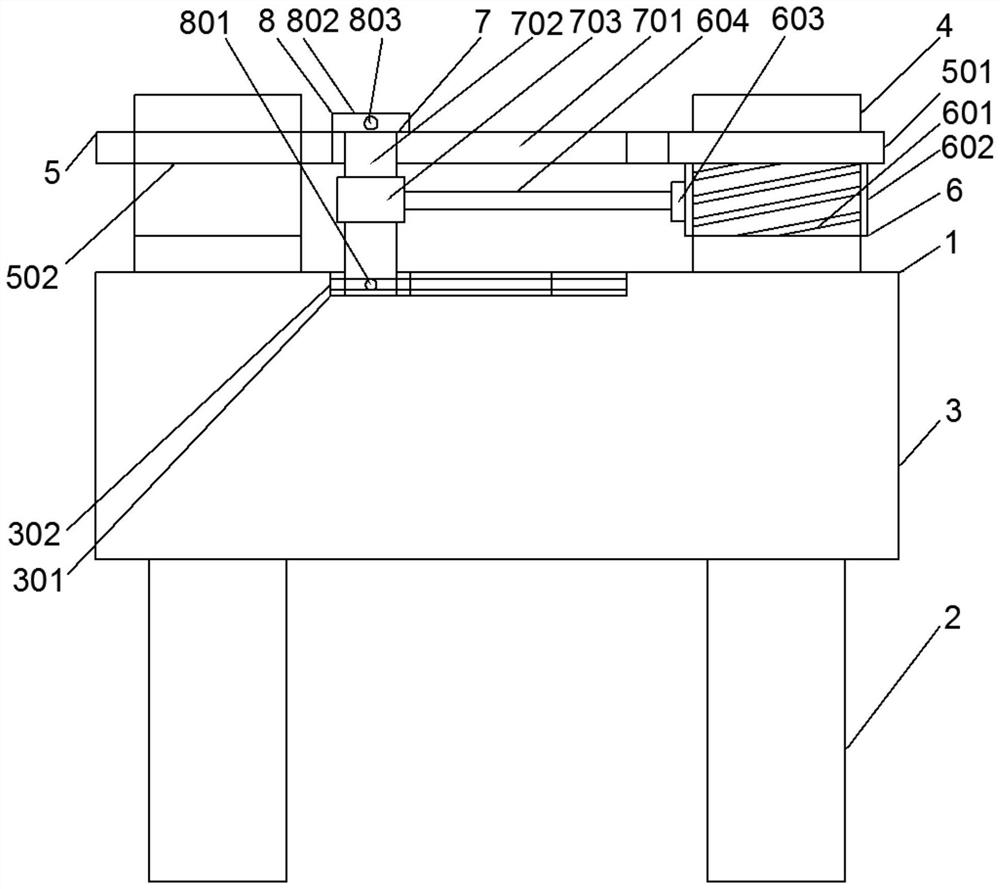

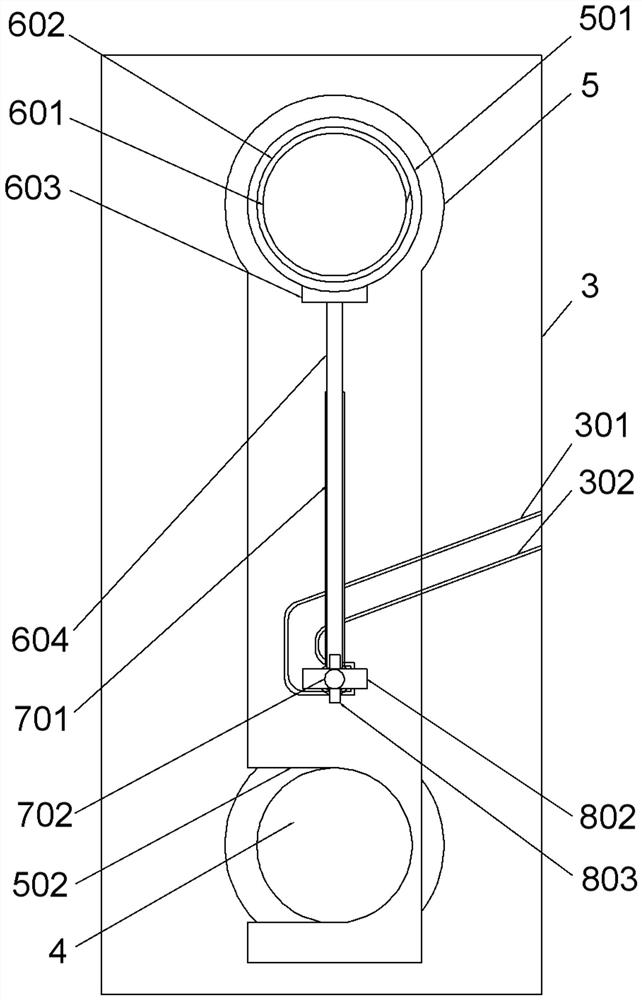

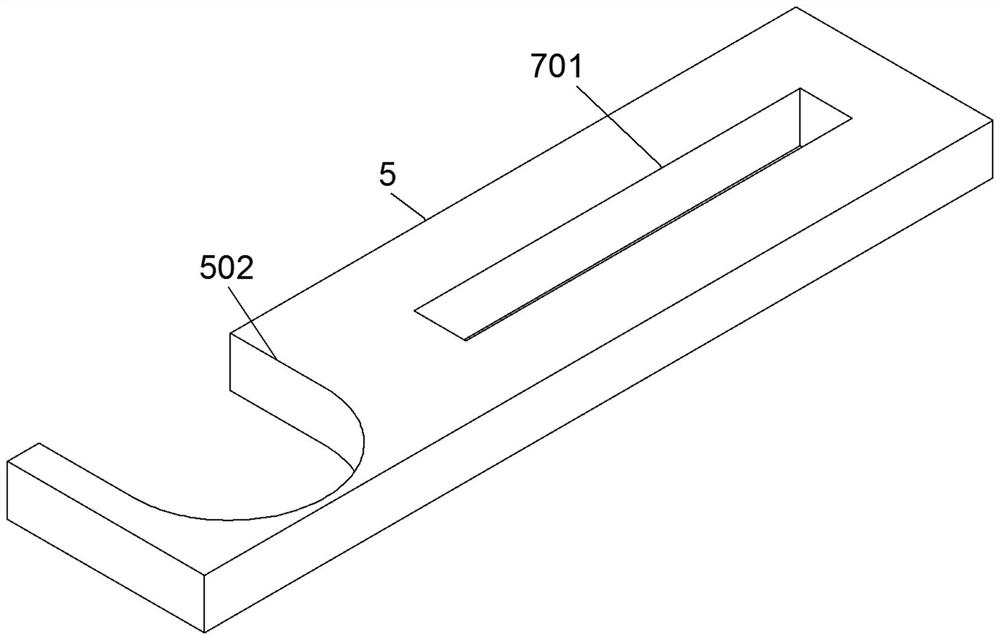

Relay protection-based pressing plate device

PendingCN114038716ANo embrittlement accidentsPrevent accidentsProtective switch terminals/connectionsProtective switch operating/release mechanismsRotary valvePower equipment

The invention relates to the technical field of power equipment, and discloses a relay protection-based pressing plate device, which comprises a device main body, a connecting valve, a platform, a joint, a knife switch, a resetting device, a positioning device and a retreating device. According to the relay protection-based pressing plate device, the rotary valve is rotated to enable the sliding column to drive the clamping block, the pointer observes that the clamping block is separated from the positioning groove, the rotary valve is lifted to drive the sliding column to be separated from the inflection point of the sliding rail, the locking state of the torsional spring is relieved, the torsional spring loses a positioning object and starts to reset, and the knife switch is driven to be disconnected, and thebeneficial effect that direct contact with the knife switch is not needed when disconnecting contact is achieved. The bottoms of the sliding columns make contact with the sliding rails, the clamping blocks are inserted into the positioning grooves when the sliding columns enter, the clamping blocks are positioned through the positioning grooves, the sliding columns connected with the tail ends of the clamping blocks are synchronously positioned, the sliding columns continuously move on the inner sides of the sliding rails, and after the knife switch makes contact with the connector at the other end, the sliding column is clamped into the corner of the L-shaped sliding rail to form locking, so that the beneficial effect of no looseness after the knife switch is closed is achieved.

Owner:国网新疆电力有限公司超高压分公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com