Thermoplastic elastomer (TPE) and modified PP (Polypropylene) co-extruded refrigerator magnetic door seal strip and manufacturing method thereof

A technology of thermoplastic elastomers and door seals, which is applied in household refrigeration equipment, lighting and heating equipment, applications, etc., to achieve the effects of excellent hand feeling elasticity, cost reduction, and improved welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

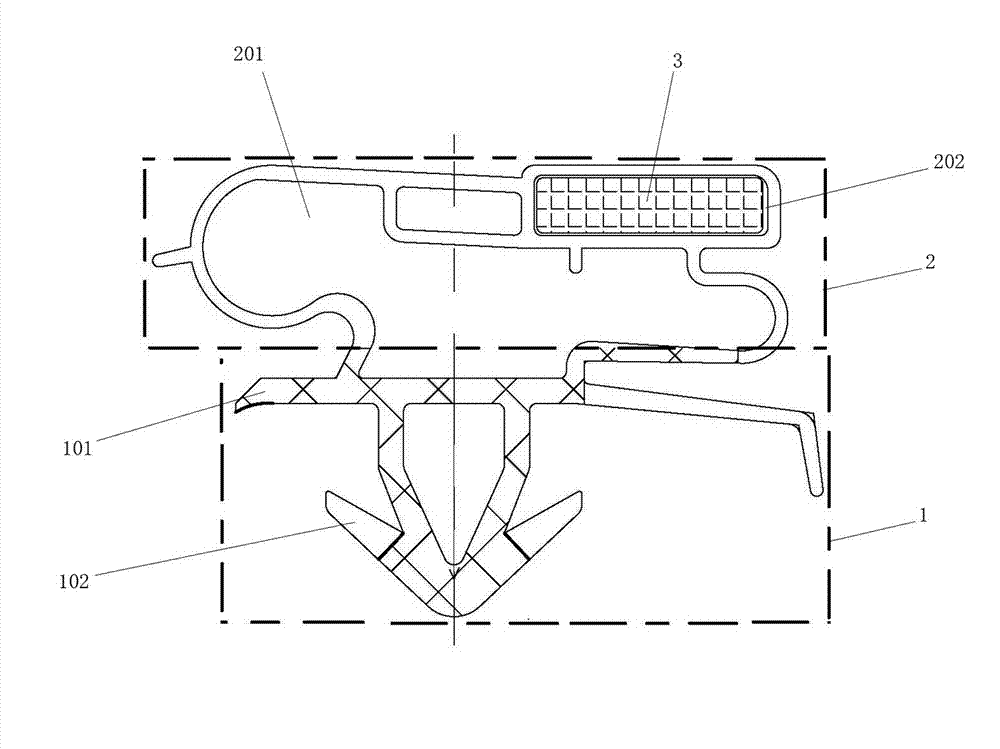

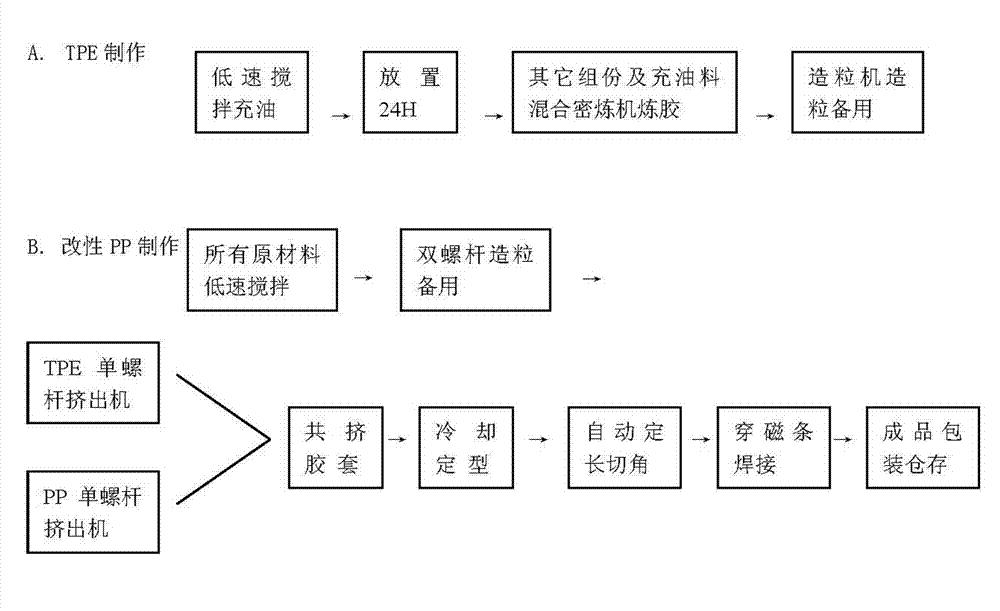

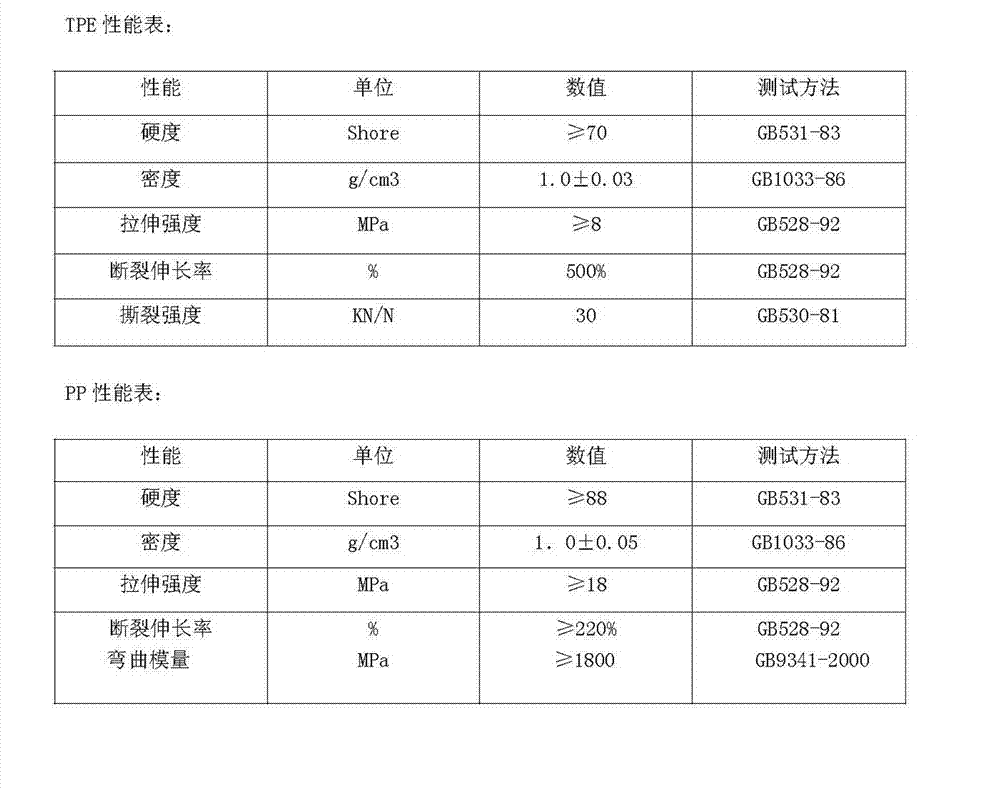

[0051] Such as Figure 1 to Figure 3As shown, a magnetic refrigerator door seal co-extruded with thermoplastic elastomer TPE and modified PP is characterized in that it includes a fixed substrate part 1 composed of thermoplastic elastomer TPE and a sealing part 2 composed of modified hard PP The fixed substrate part 1 and the sealing part 2 form a magnetic door seal through co-extrusion heat fusion. The fixed substrate part 1 is composed of a substrate 101 and an assembly pin 102. The sealing part 2 is provided with an air bag 201 and a magnetic strip bag 202. The magnetic A magnetic strip 3 is set on the strip capsule 202;

[0052] The raw materials of the fixed substrate part 1 made of thermoplastic elastomer TPE are respectively composed of the following weight ratios:

[0053] SEBS 15-25 copies;

[0054] POE 15-20 copies;

[0055] P P 15-18 copi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com