A kind of preparation method of high haze and high wear resistance thermoplastic polyurethane elastomer

A thermoplastic polyurethane and elastomer technology, which is applied in the field of thermoplastic polyurethane elastomers, can solve the problems of TPU processing difficulty, etc., and achieve the effects of good rigidity and permanent compression deformation, stable wear resistance, and less internal heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

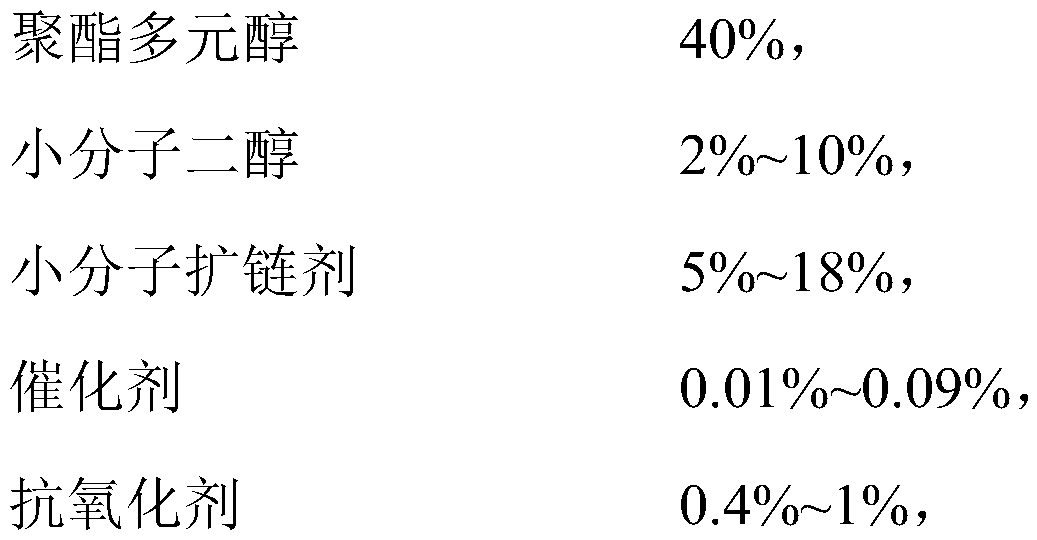

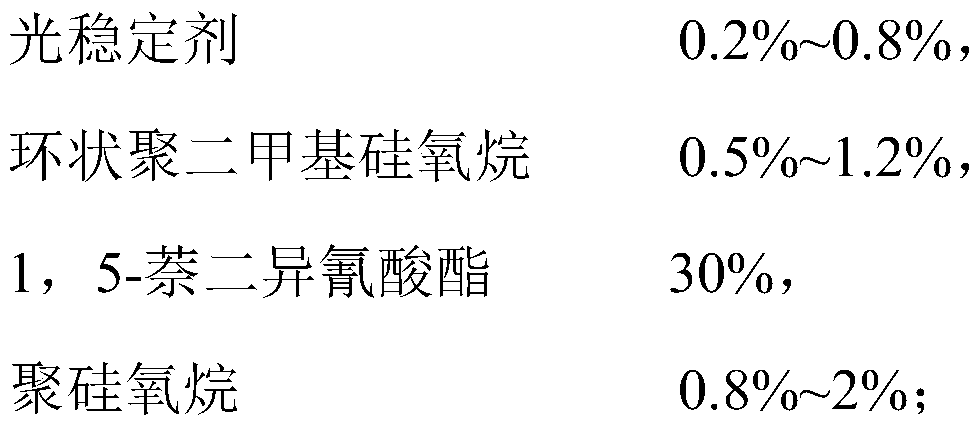

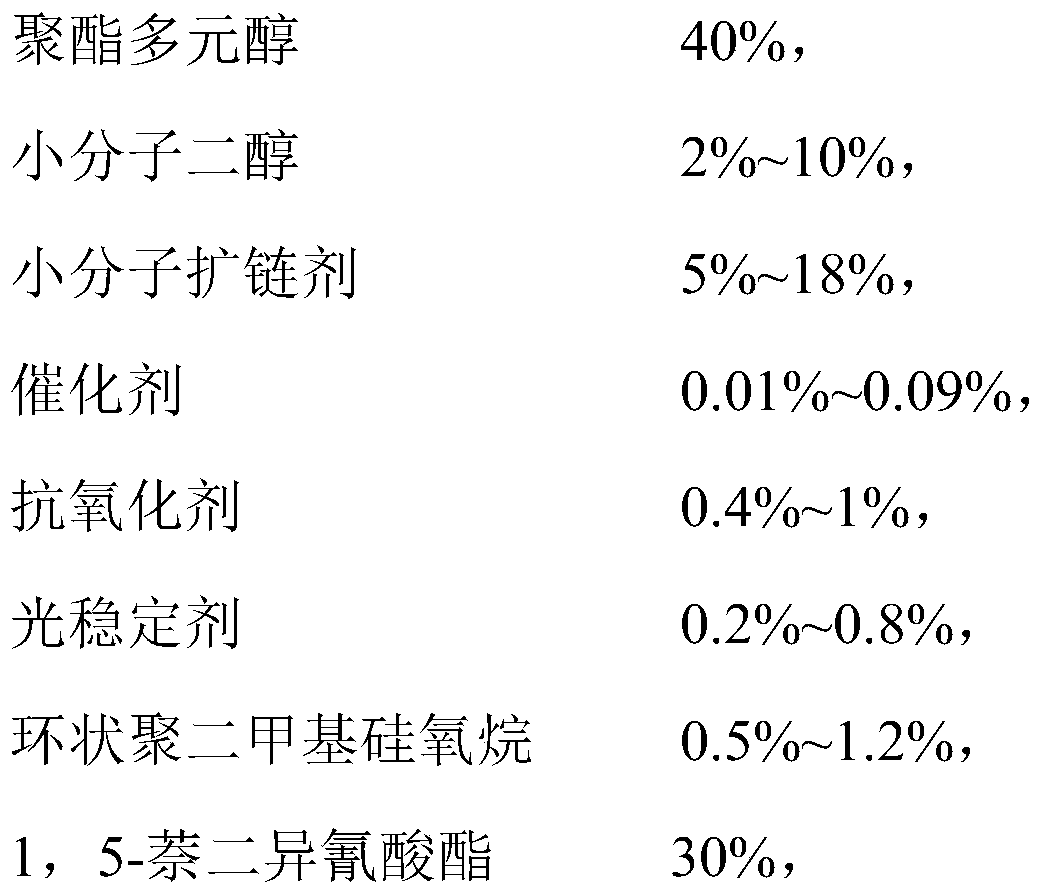

Method used

Image

Examples

Embodiment 1

[0029] 1) adding tetrakis (4-hydroxyl-3,5-tert-butylphenyl propionate) pentaerythritol ester accounting for 0.45% of the total mass of the polyurethane elastomer in the reactor, accounting for the stannous octoate of 150ppm of the total mass of the polyurethane elastomer, Polyester diol (number-average molecular weight 700-1000, condensed from adipic acid and 1,3-propanediol) accounting for 10% of the total mass of polyurethane elastomer, cyclic polydiol accounting for 1.2% of the total mass of polyurethane elastomer Methylsiloxane, 1,4-butanediol accounting for 13.4% of the total mass of polyurethane elastomer, a polyester polyol with a number average molecular weight of 3500 formed by condensation of adipic acid and 1,4-butanediol, in Dehydration, melting and mixing for 3 hours under the temperature condition of 105°C and vacuum degree of -0.09~-0.1MPa, put the water content into the measuring tank after the water content is lower than 400ppm, open the measuring tank and stir...

Embodiment 2

[0035] 1) Add tetrakis(4-hydroxyl-3,5-tert-butylphenyl propionate) pentaerythritol ester accounting for 0.45% of the total mass of polyurethane elastomer to the reactor, account for stannous octoate of 150ppm of the total mass of polyurethane elastomer, and account for 0.45% of the total mass of polyurethane elastomer. 10% polyester diol (number average molecular weight 700-1000, condensed from adipic acid and 1,3-propanediol) with 10% of the total mass of the elastomer, cyclic polydimethyl alcohol with 0.8% of the total mass of the polyurethane elastomer Siloxane, 1,4-butanediol accounting for 7.5% of the total mass of polyurethane elastomer, a polyester polyol with a number average molecular weight of 3500 formed by condensation of adipic acid and 1,4-butanediol, at 105°C Under the temperature conditions of -0.09~-0.1MPa vacuum, dehydration, melting and mixing for 3 hours, after the water content is lower than 400ppm, put it into the metering tank, open the metering tank and ...

Embodiment 3

[0041] 1) Add tetrakis(4-hydroxyl-3,5-tert-butylphenyl propionate) pentaerythritol ester accounting for 0.45% of the total mass of polyurethane elastomer to the reactor, account for stannous octoate of 150ppm of the total mass of polyurethane elastomer, and account for 0.45% of the total mass of polyurethane elastomer. 10% of the total mass of the elastomer is polyester diol (the number average molecular weight is 700-1000, formed by condensation of adipic acid and 1,3-propanediol), and 1.8% of the total mass of the polyurethane elastomer is cyclic polydimethyl Siloxane, 1,4-butanediol accounting for 18% of the total mass of polyurethane elastomer, a polyester polyol with a number average molecular weight of 3500 formed by condensation of adipic acid and 1,4-butanediol, at 105°C Under the temperature conditions of -0.09~-0.1MPa vacuum, dehydration, melting and mixing for 3 hours, after the water content is lower than 400ppm, put it into the metering tank, open the metering tank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com