Aramid-fiber varnished wire and production method therefor

A technology of enameled wire and aramid fiber, which is applied to electric wires. It can solve the problems of insufficient enameled wire performance and achieve long-term maintenance of electrical and mechanical properties, good hand feeling and high elongation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

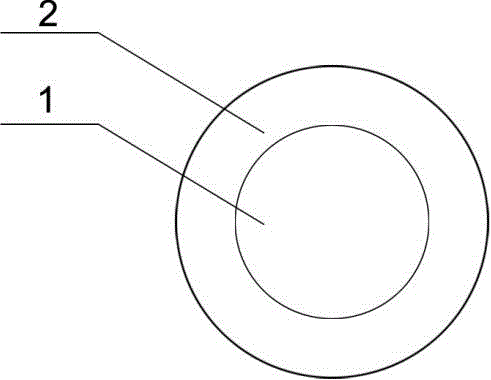

[0022] see figure 1 , the aramid enameled wire of the present invention includes a conductor 1 , and the outer surface of the conductor 1 is covered with an aramid insulating paint film 2 .

[0023] Preferably, the conductor is a single or twisted conductor.

[0024] Preferably, the conductor is a plated or unplated conductor.

[0025] Preferably, the conductor is a copper or aluminum conductor.

[0026] Preferably, the insulating paint film 2 is a meta-aramid paint film or a para-aramid paint film.

[0027] During the production of the aramid enameled wire of the present invention, 17 tinned copper wires with a diameter of 0.16 mm are twisted into a bundle of multi-strand tinned copper strands by using a precision stranding machine, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com