Patents

Literature

213results about How to "Good sound and heat insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical foamed concrete and preparation method thereof

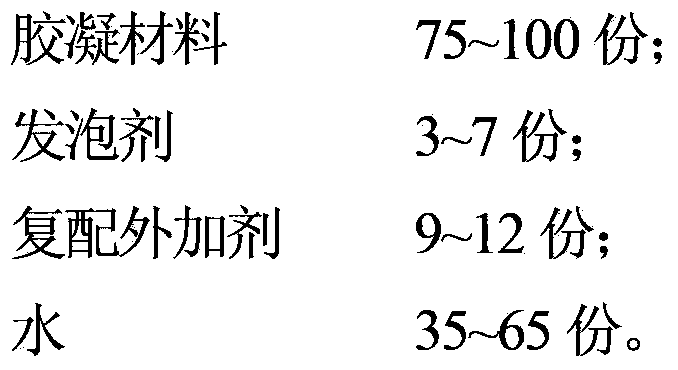

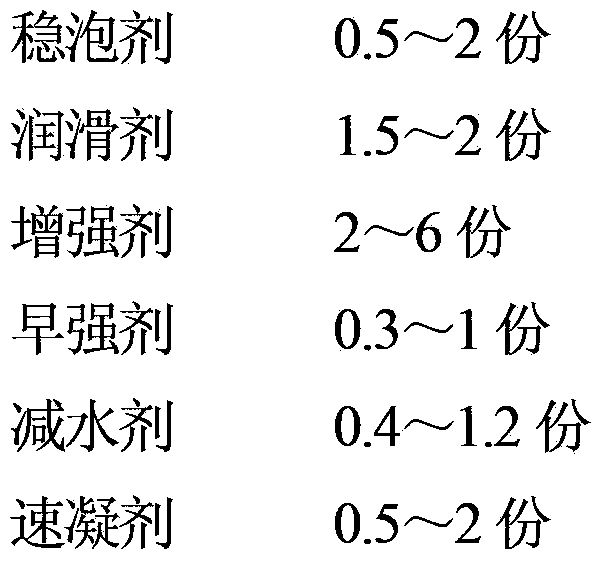

The invention discloses a chemical foamed concrete and a preparation method thereof. The concrete product is prepared by using a cementing material, a foaming agent, a compounded additive and water as raw materials through a chemical foaming principle, and the added compounded additive realizes stable foaming speed stability, uniform bubble diameter and controllability. The chemical foaming preparation method has the advantages of simplicity, low production investment cost, and convenient construction. The foamed concrete product prepared in the invention has the advantages of fireproof property, waterproof property, sound insulation, heat insulation, light weight, high compressive strength and environmental protection. The bulk density, the compressive strength and the heat conduction coefficient of the obtained product are less than 400kg / m<3>, more than 3.5MPa and less than or equal to 0.07W / (M.K) respectively. The above formula adopting alkaline ash comprising alkaline furnace ashes, alkaline slag, alkaline furnace slag and other wastes as raw materials realizes comprehensive utilization of resources, changes wastes into valuables, and accords with the demands of sustainable development of national circular economy.

Owner:LIAONING JIJIA ENERGY SAVING WALL EQUIP

Environmental-friendly lead-free PVC ceiling sheet and manufacturing method and applications thereof

The invention relates to a ceiling sheet, in particular to an environmental-friendly lead-free PVC ceiling sheet and a manufacturing method and applications thereof. The environmental-friendly lead-free PVC ceiling sheet is obtained by blending the following components according to parts by weight and then extruding to mould: 50-100 parts of PVC resin SG-5, 15-50 parts of nano calcium carbonate, 3-10 parts of calcium zinc stabilizer, 1-3 parts of rutile titanium dioxide, 1-3 parts of CPE impact modifier, 1.5-5 parts of ACR enhancer, 0.2-0.8 part of stearic acid, 0.3-1.0 part of calcium stearate, and 0.2-0.4 part of PE wax. The PVC ceiling sheet is used as a novel environmental-friendly lead-free material of which the lead content is less than or equal to 200PPM, and is applicable to non-toxic places with high environmental requirements such as hospitals, operating rooms, baby rooms, food plants, and the like. The invention also discloses the manufacturing method of the ceiling sheet and ceiling gusset plates manufactured by the sheet.

Owner:HUAJUN PLASTIC BUILDING MATERIAL

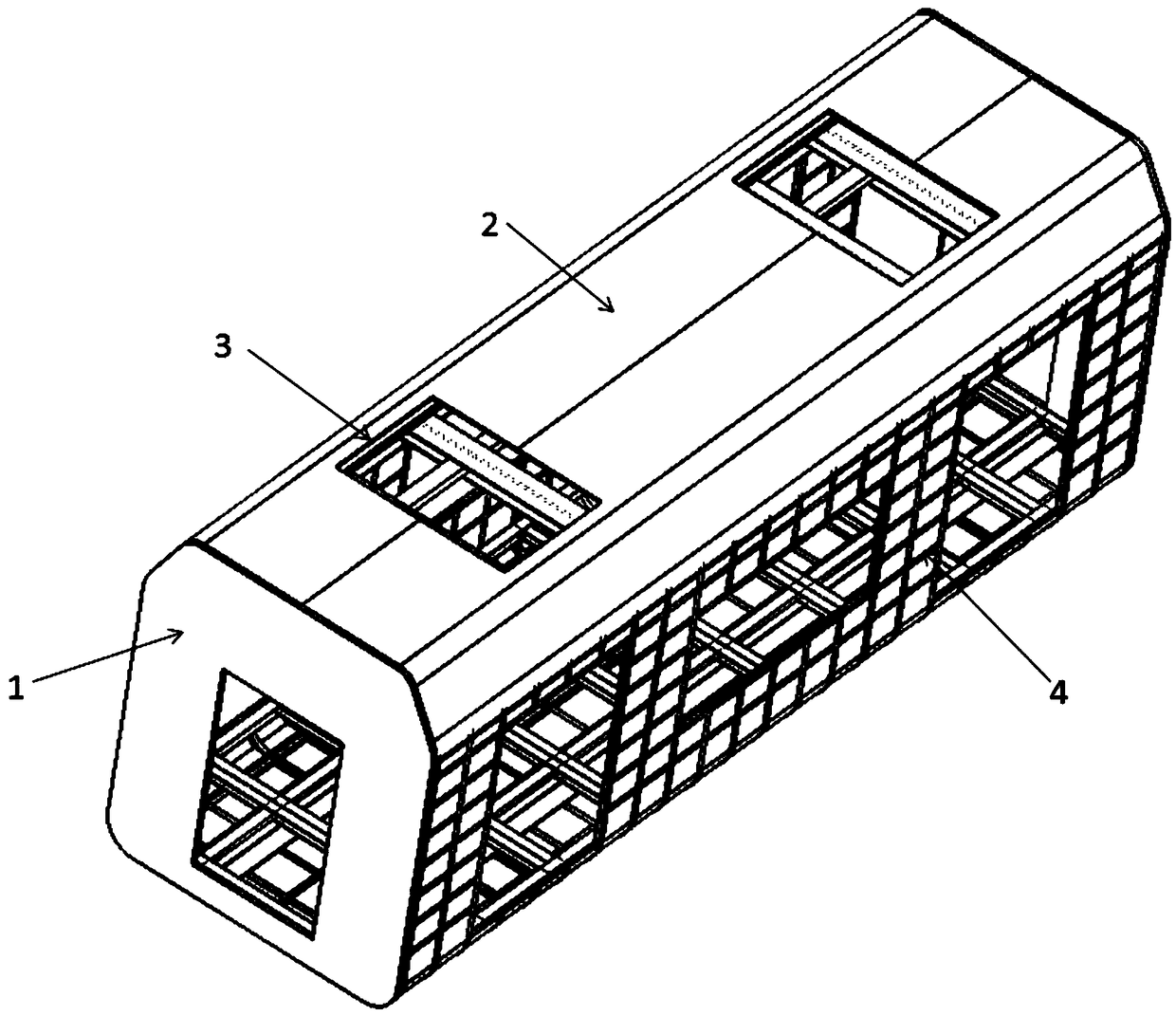

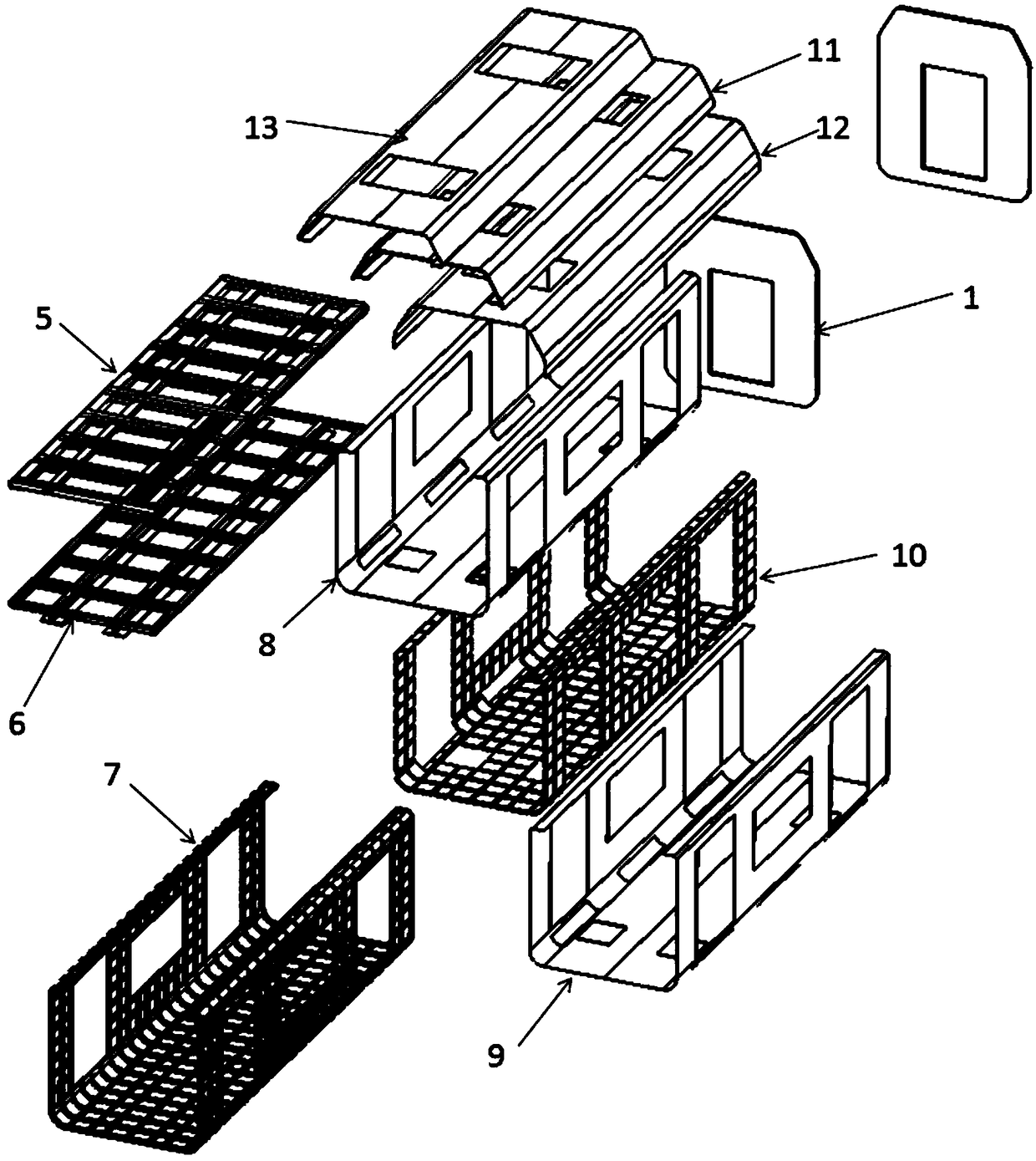

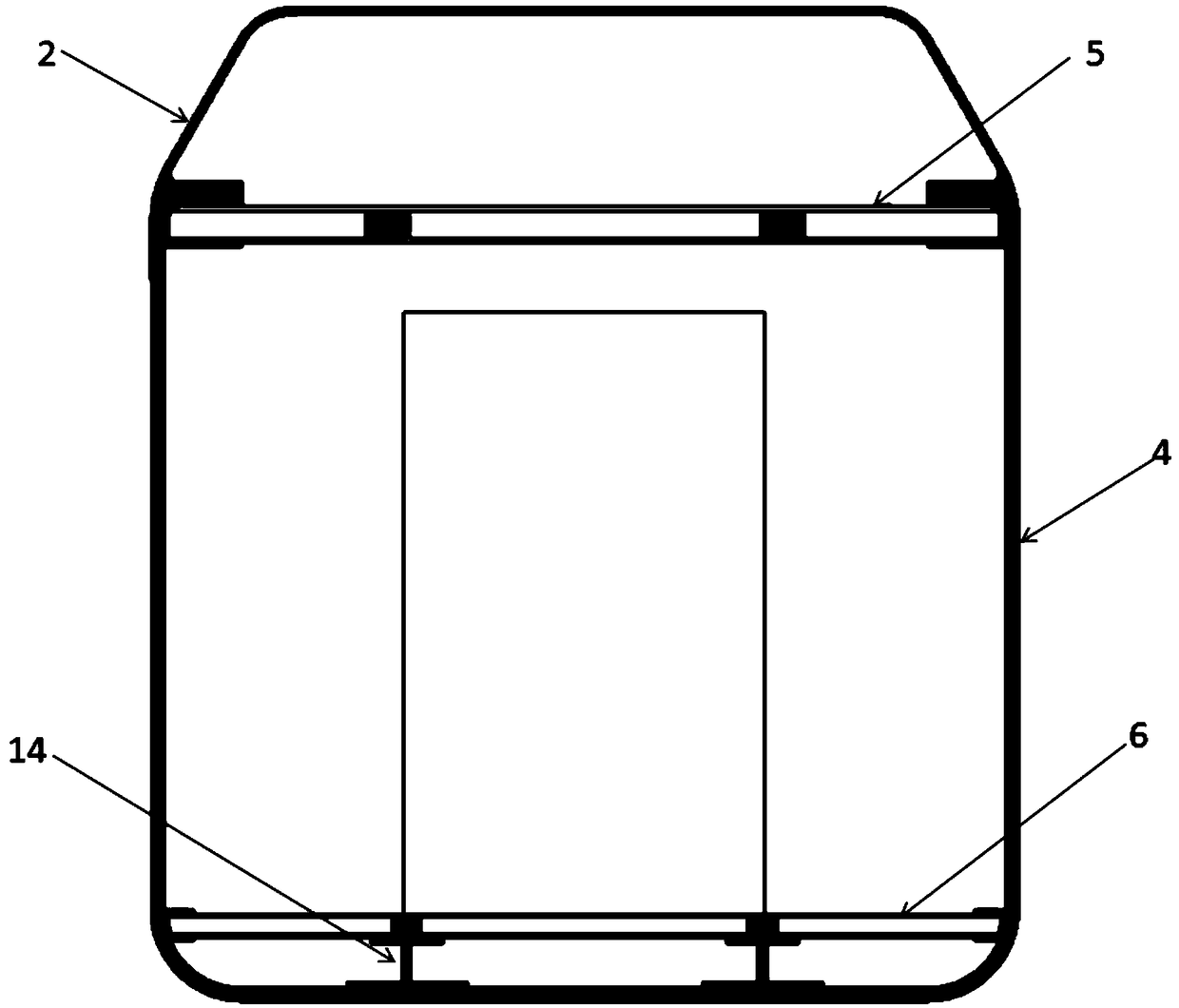

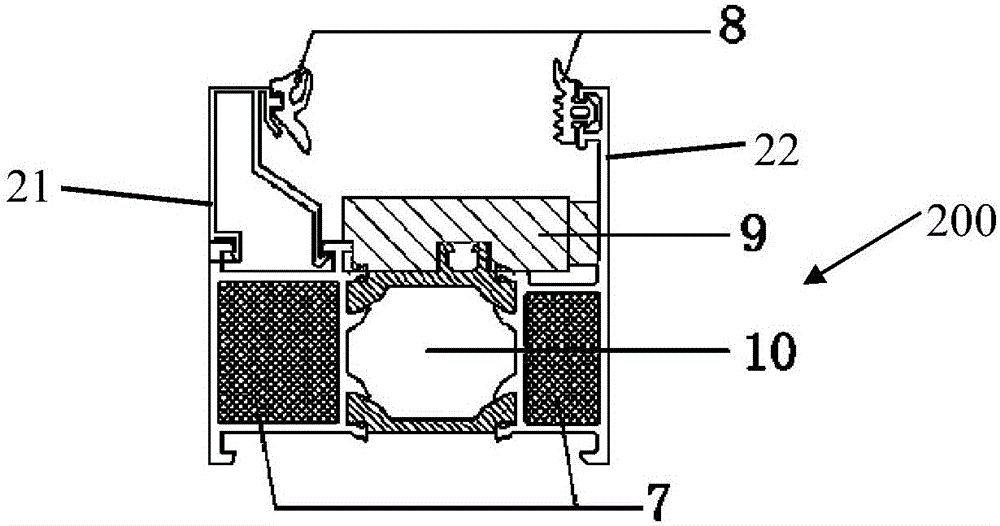

Structure and manufacturing process of low-cost carbon fiber composite material sky railway train body

ActiveCN108622123AAchieve lightweightIncrease stiffnessRailway roofsAxle-box lubricationBogieEngineering

The invention discloses a structure and a manufacturing process of a low-cost carbon fiber composite material sky railway train body, and belongs to the technical field of application of composite materials on rail vehicles. The structure comprises a train body side wall, wherein end walls are assembled and connected to the both ends of the train body side wall; a top frame and a bottom frame arecorrespondingly assembled and connected to the inner top surface and the inner bottom surface of the train body side wall, a ceiling is assembled and connected to the outer top surface of the train body side wall, and a bogie mounting hole is formed in the ceiling; the train body side wall and the end walls both comprise reinforced rib frames, inner skins and outer skins, and grids of the reinforcing rib frames are filled with sandwich foam blocks; the ceiling comprises a sandwich panel, an upper skin and a lower skin, and the top frame, the bottom frame, the reinforcing rib frame, the inner skins, the outer skins, the upper skin and the lower skin are all integrally molded from carbon fiber composite materials; and the inner portions of the reinforcing rib frames are filled with sandwichfoam, and the purpose of satisfying the function and structure of the load bearing mode of a suspension-type train body on the premise of light weight of the train body is achieved.

Owner:SOUTHWEST JIAOTONG UNIV

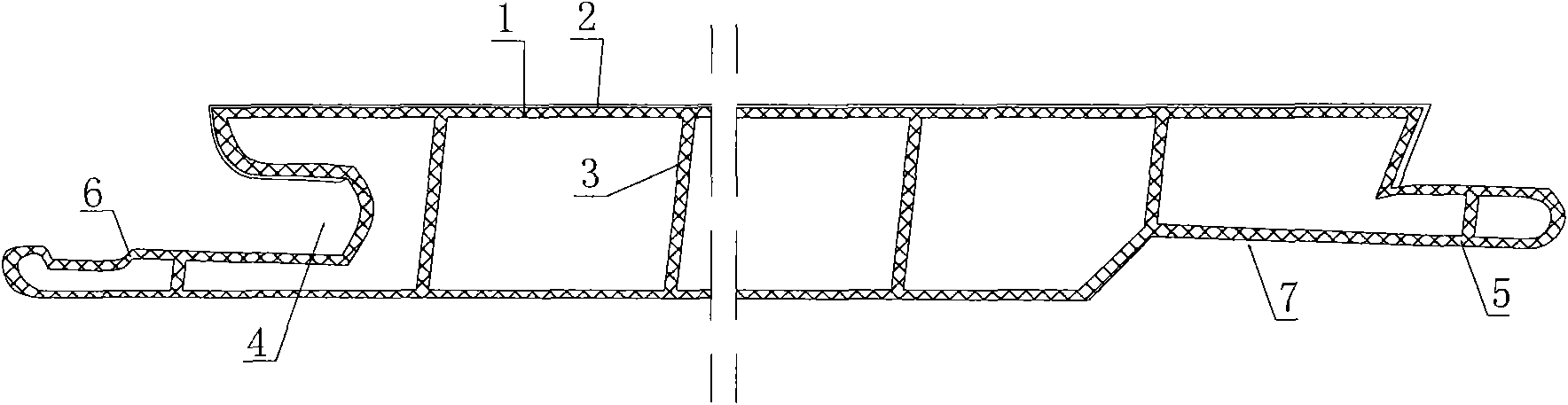

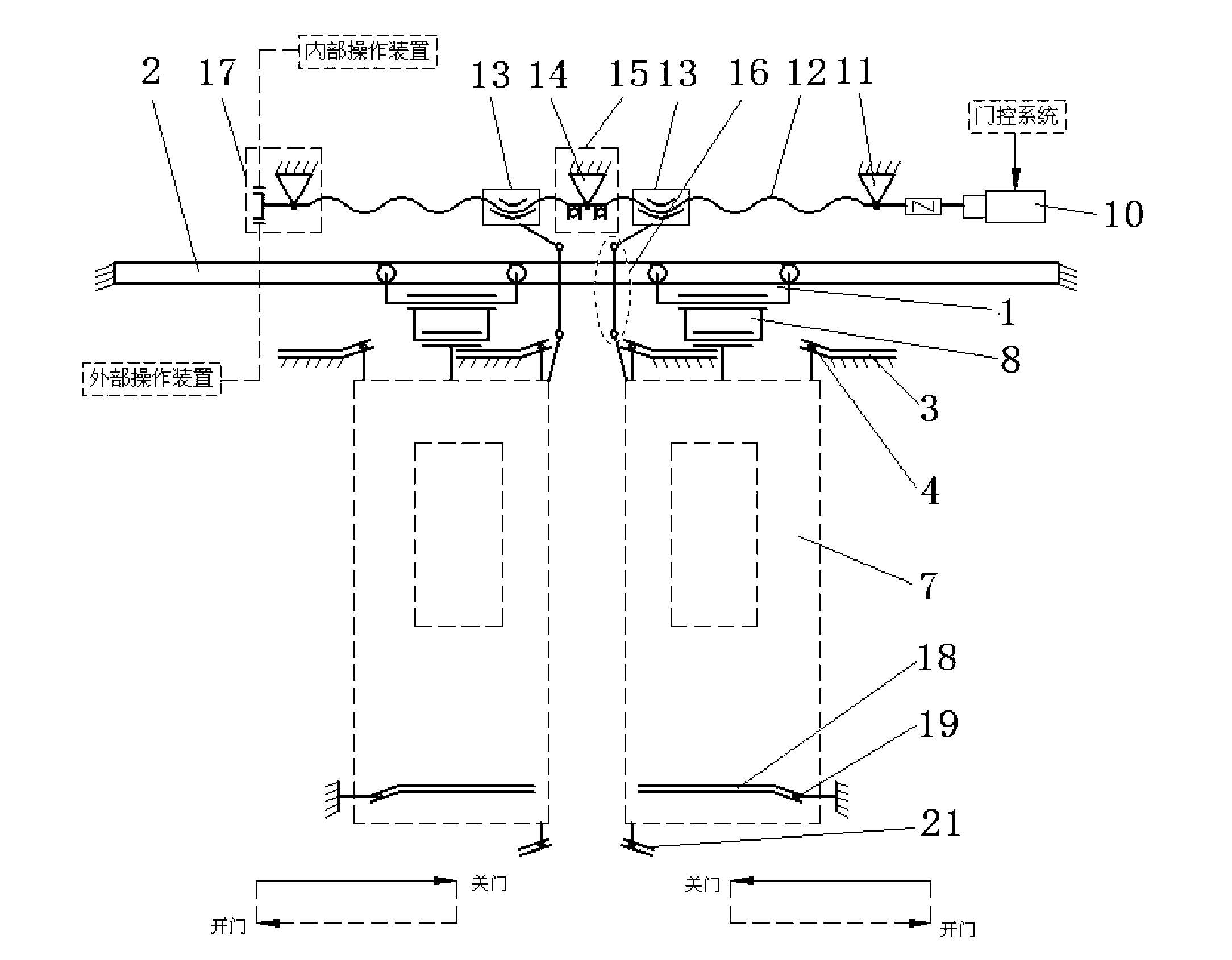

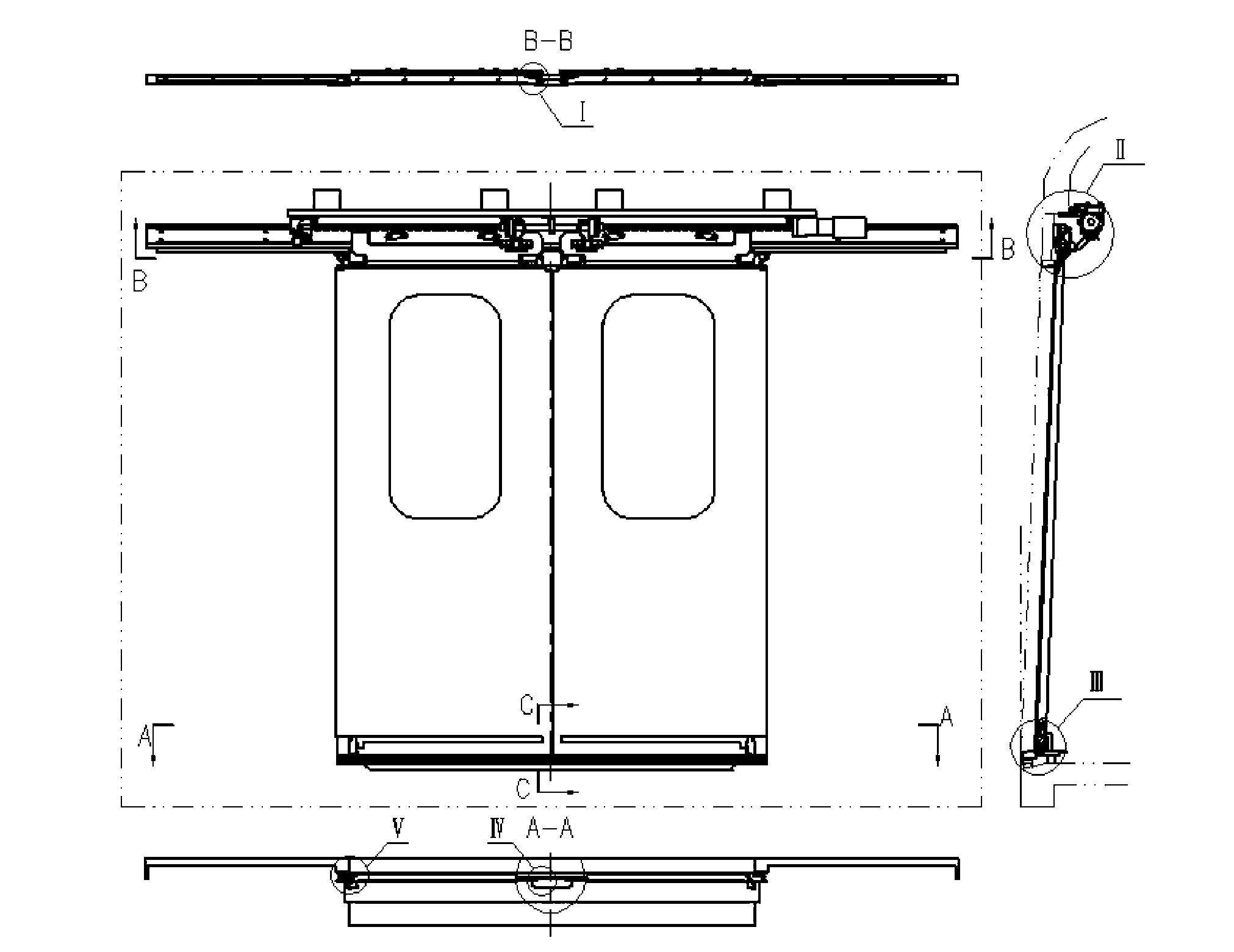

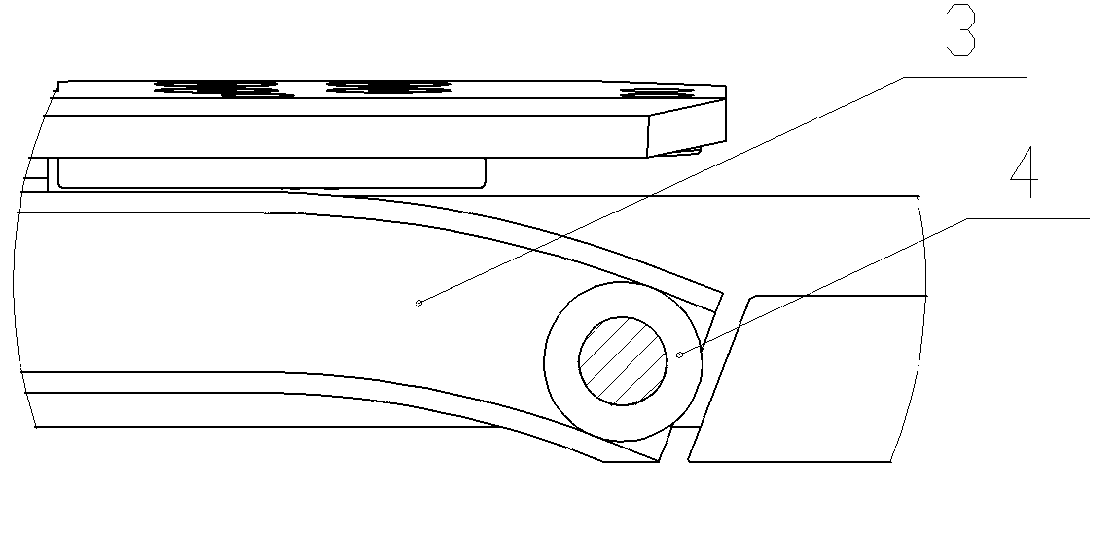

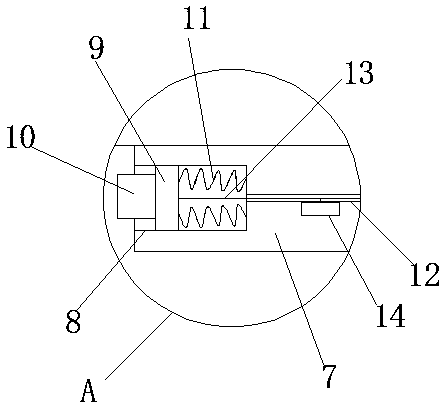

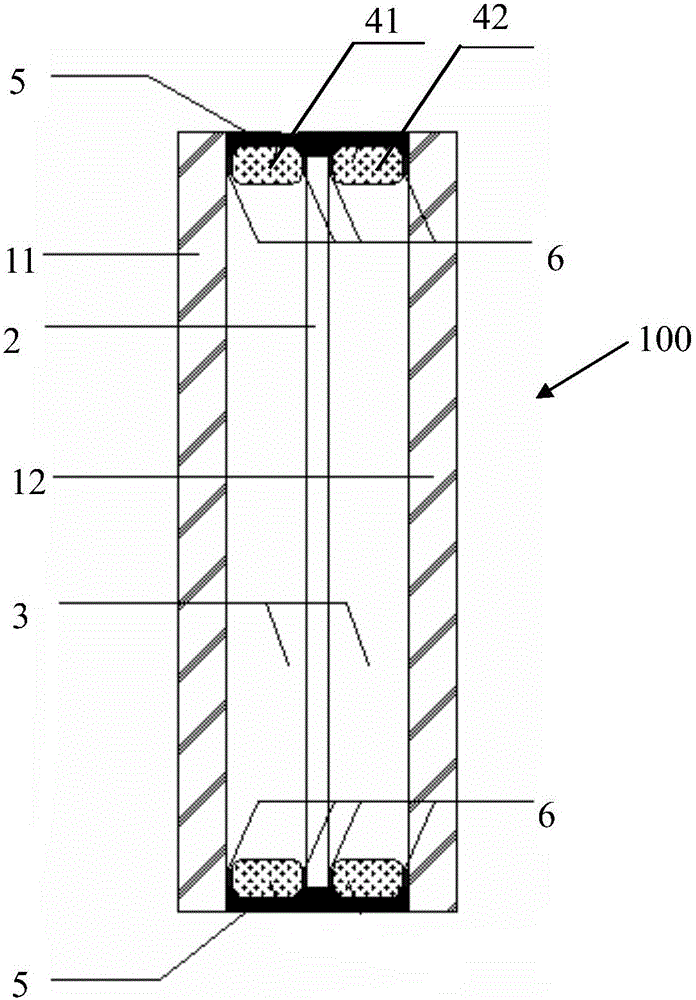

Hidden sealed door for railway vehicle

ActiveCN103233657AImprove sealingMeet comfort requirementsPower-operated mechanismDoor arrangementThermal insulationEngineering

The invention discloses a hidden sealed door for a railway vehicle. The hidden sealed door comprises a driving mechanism, a bearing mechanism, door leaves, a sealing frame and a doorsill, wherein the driving mechanism comprises a lead screw nut mechanism; the bearing mechanism comprises bearing trolleys, and two upper guide rails and two lower guide wheels which are used for performing guidance for the translation, sliding and plugging movement of the door leaves; nuts of the lead screw nut mechanism are connected with each bearing trolley through a hinge mechanism; and when opened, the doorsill is located within the wall body of the railway vehicle. According to the hidden sealing door for the railway vehicle, provided by the invention, jiggle sliding and plugging movement is additionally arranged based on the original hidden translation door; adhesive tape sealing is adopted to replace the brush sealing structure, so that the sealing effect of the railway vehicle door system is improved; meanwhile, electrically controlled door is used, and the acoustic and thermal insulation property is good, so that the comfort requirement of a passenger can be satisfied; and the structure is simple, the sliding and plugging movement can be achieved without an air supply, and the time required for shutting the door is short.

Owner:NANJING KANGNI MECHANICAL & ELECTRICAL

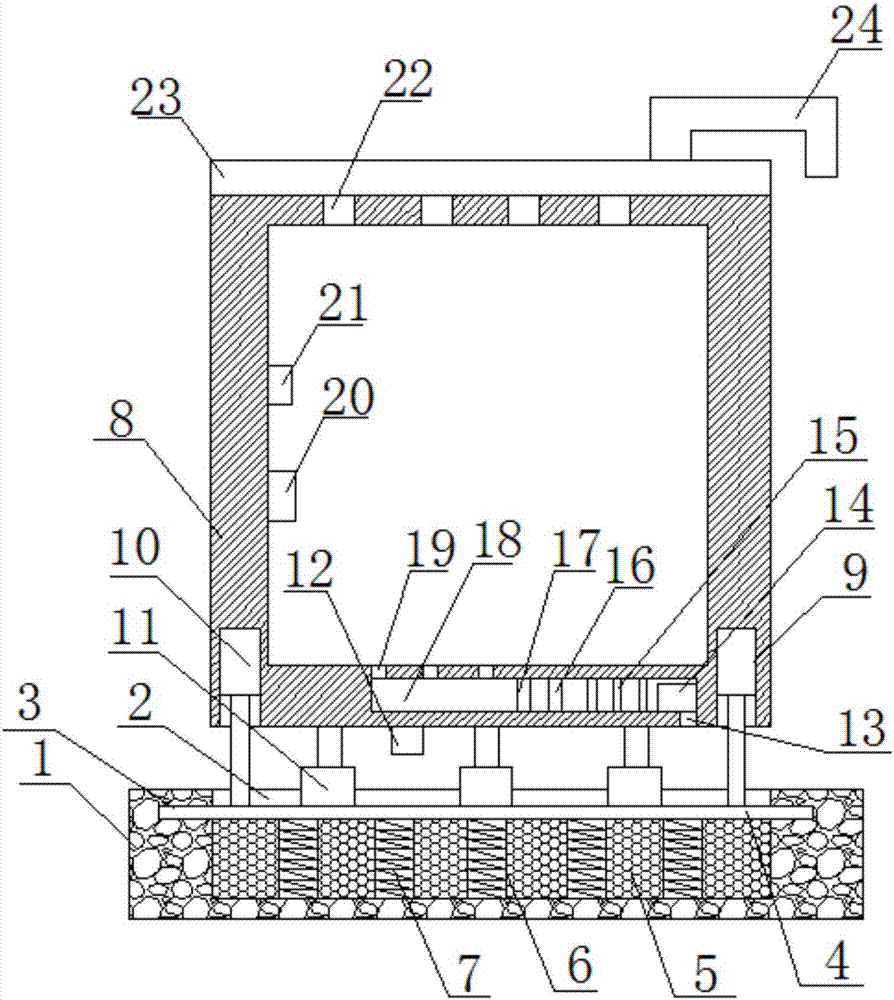

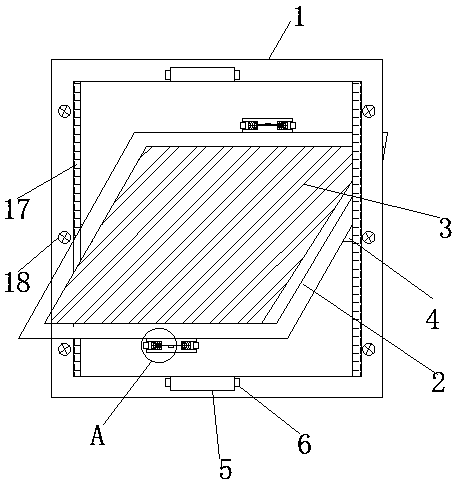

Anti-vibration box-type transformer station of sound insulation and thermal insulation type

ActiveCN106941245AKeep clean and dryReduce pollutionSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsTransformerThermal insulation

The invention discloses an anti-vibration box-type transformer station of a sound insulation and thermal insulation type, and the transformer station comprises a damping pedestal and a box body. The upper side of the damping pedestal is provided with a groove, and the upper side of an inner side of the groove is provided with a fixed groove. The groove is provided with a damping plate through the fixed groove. The lower side of the damping plate is provided with a damping pad, and the interior of the damping pad is provided with a plurality of damping cavities. The interior of each damping cavity is provided with a damping spring. Four corners of the lower side of the box body are provided with installation cavities. The interior of each installation cavity is provided with an electronic telescopic rod, and the lower end of each electronic telescopic rod is connected with the upper side of the damping plate. The lower end of the box body is provided with a water level sensor, and the interior of the box body is provided with an intelligent controller. The bottom of the box body is provided with an air incoming cavity, and the lower side of the right end of the air incoming cavity is provided with an air incoming air. The right end of the air incoming cavity is provided with a blower fan, and the left side of the upper side of the air incoming cavity is provided with a plurality of blowing ports. The upper end of the box body is provided with a plurality of air exhaust outlets. The transformer station is simple in structure, is convenient to use, is good in effects of sound insulation and thermal insulation, and is good in anti-vibration performance.

Owner:DEZHOU POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

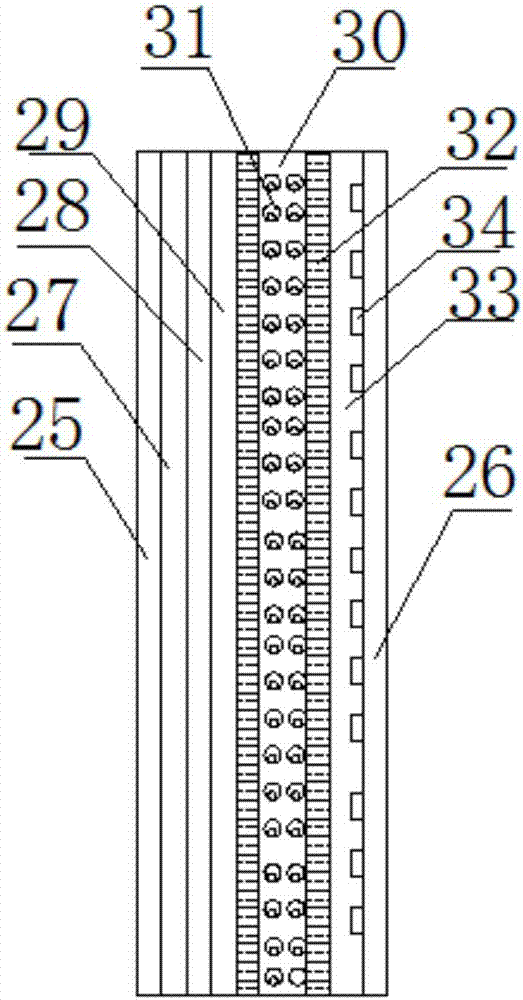

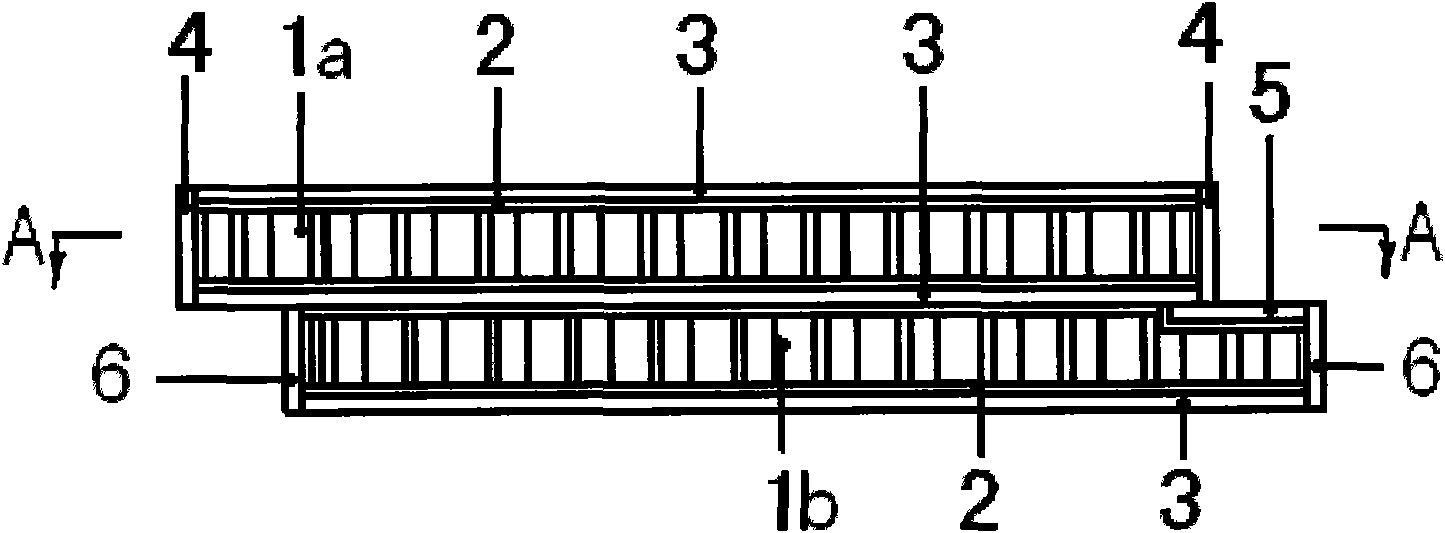

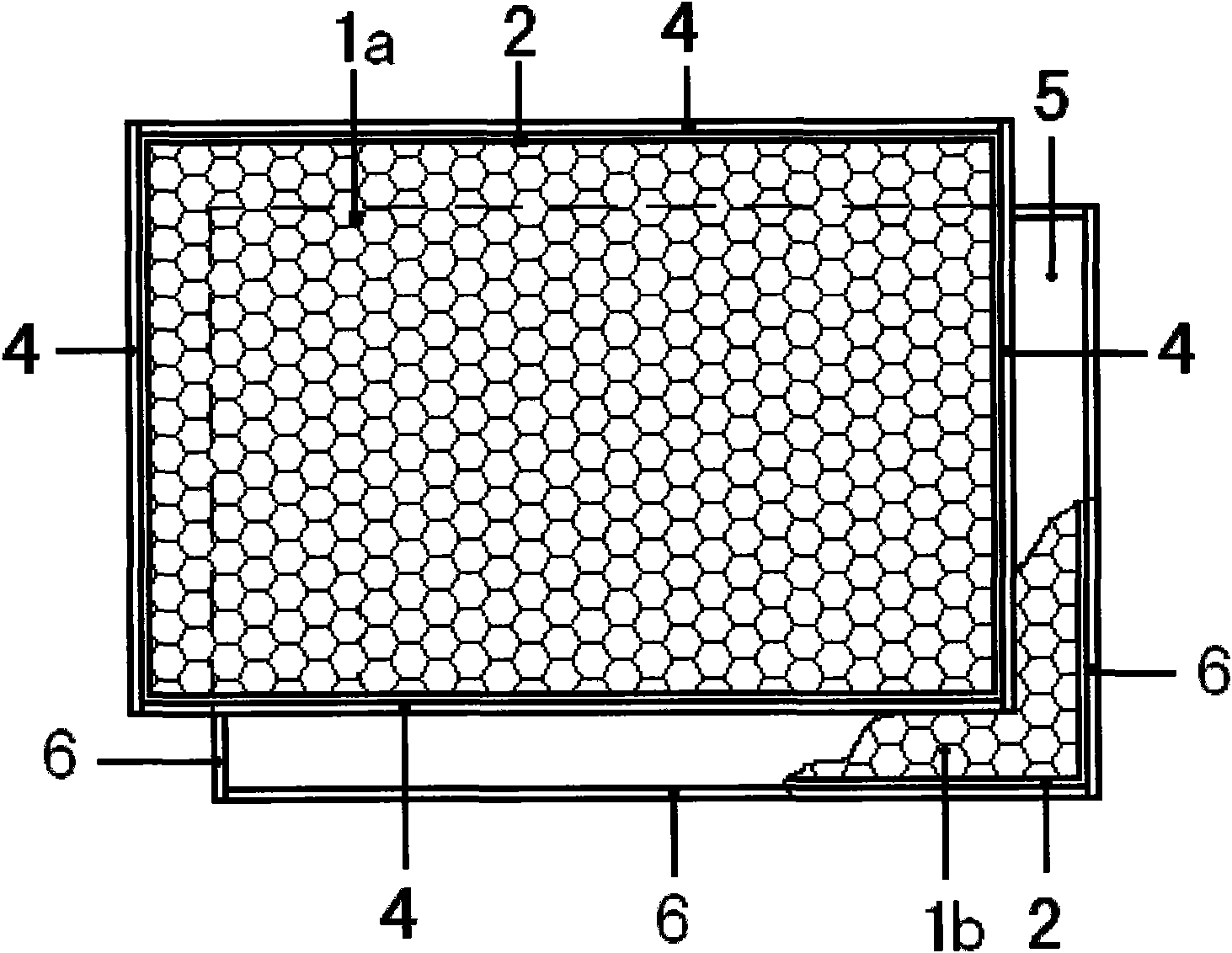

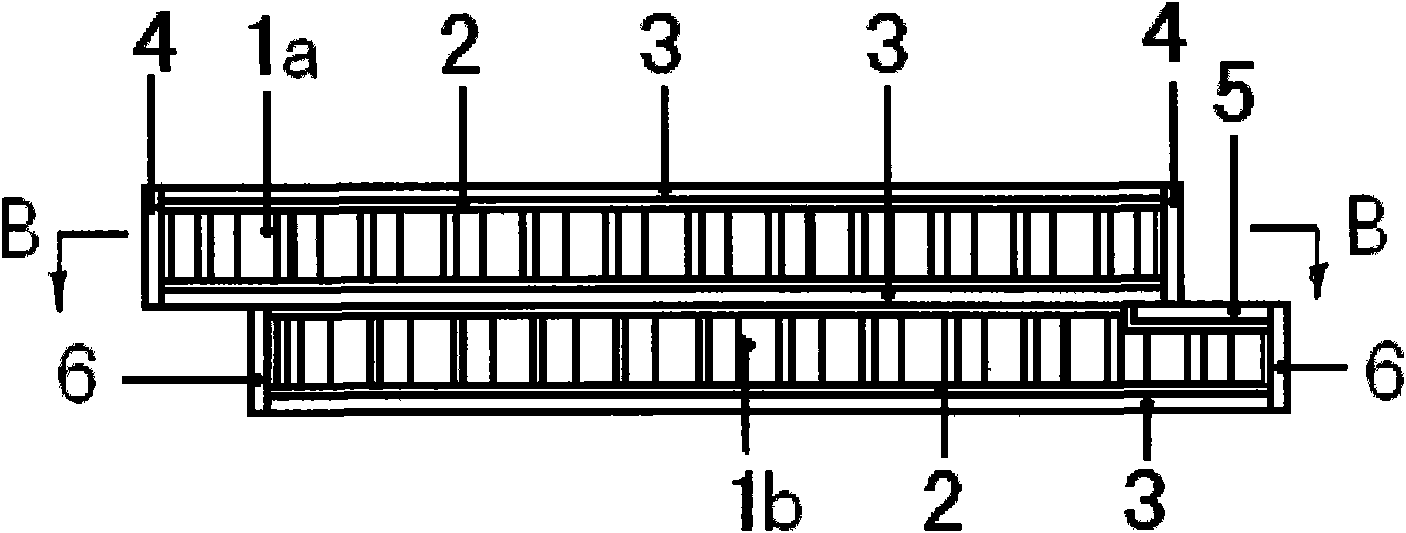

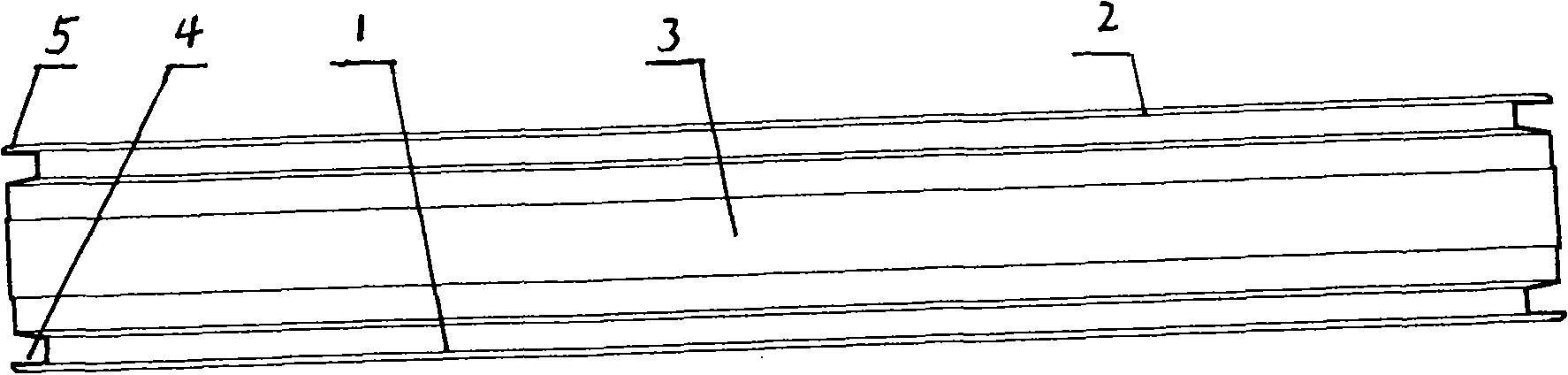

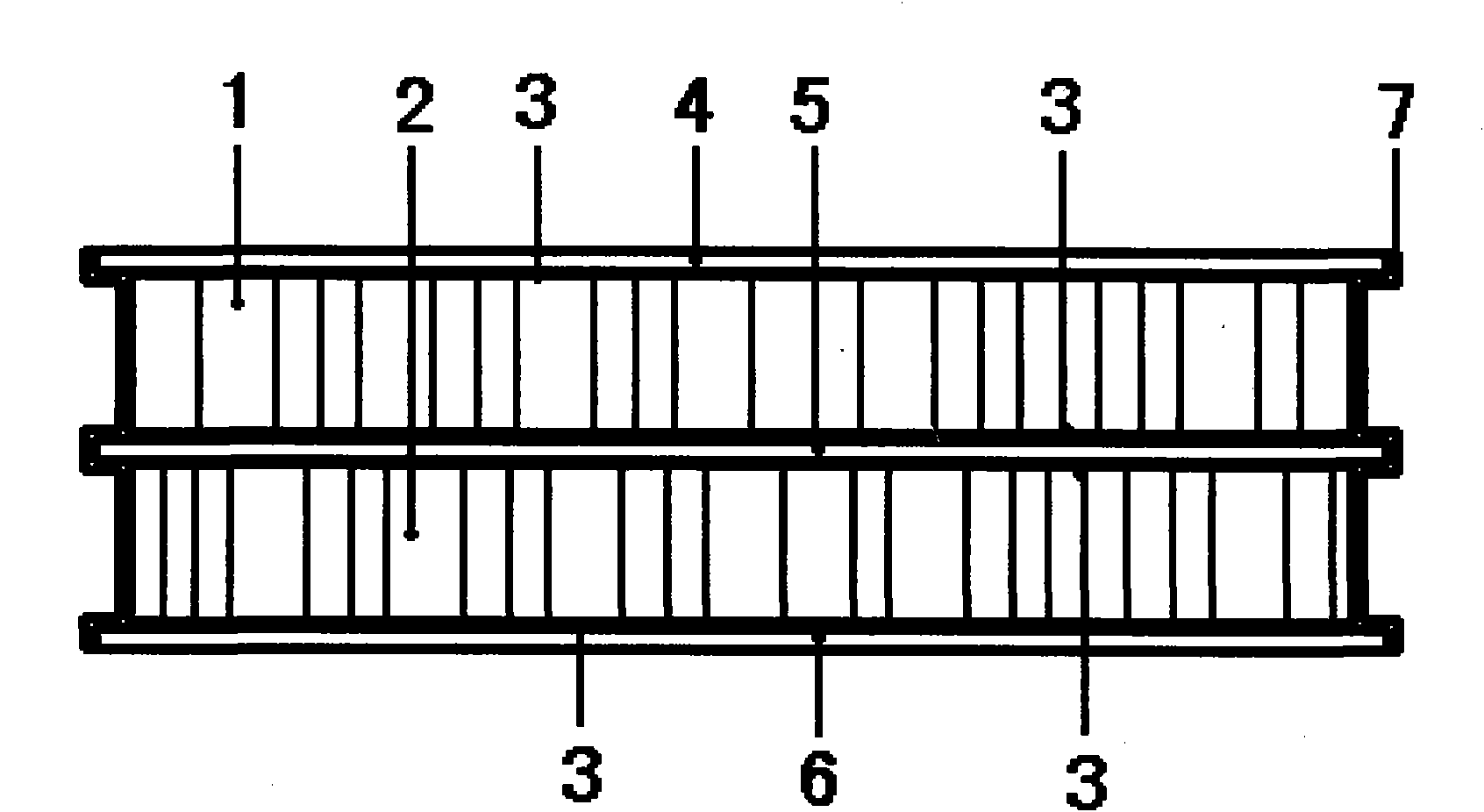

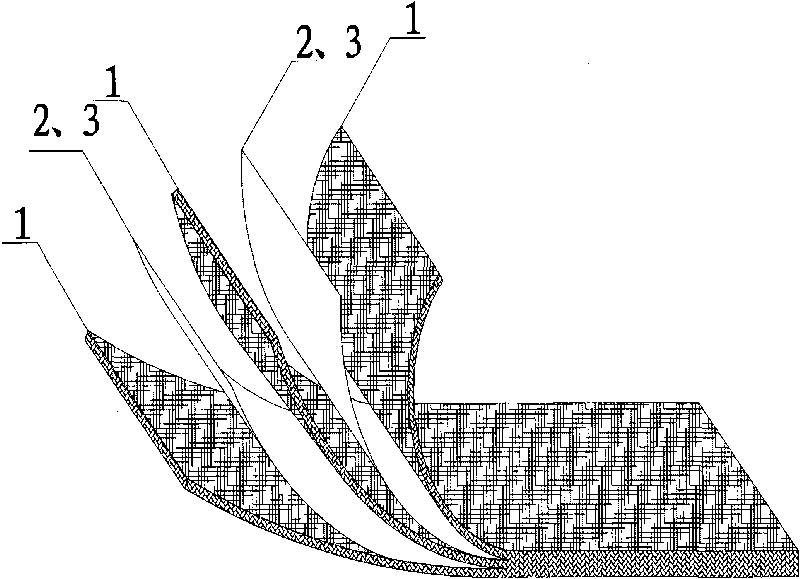

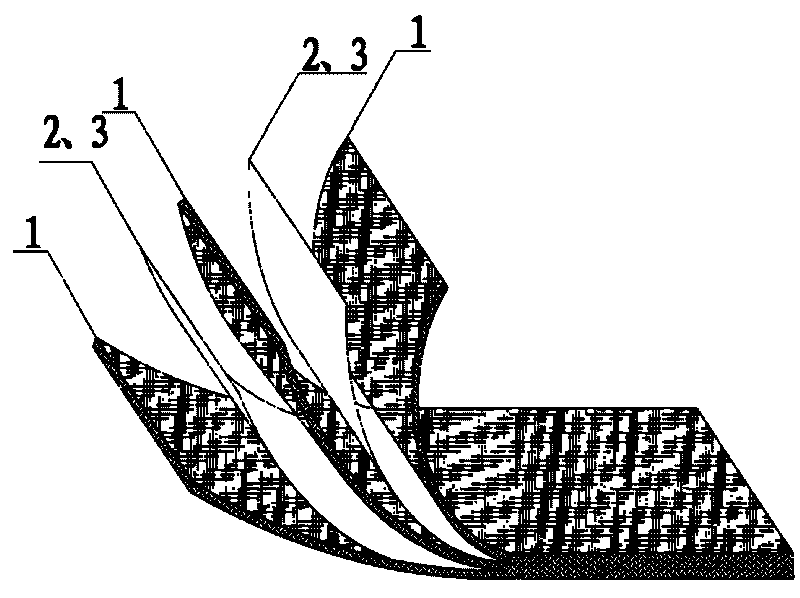

Flexible honeycomb sound-insulating and heat-insulating composite board

InactiveCN101608477AImprove insulation performanceGood flame retardantHeat proofingSound proofingCardboardHoneycomb

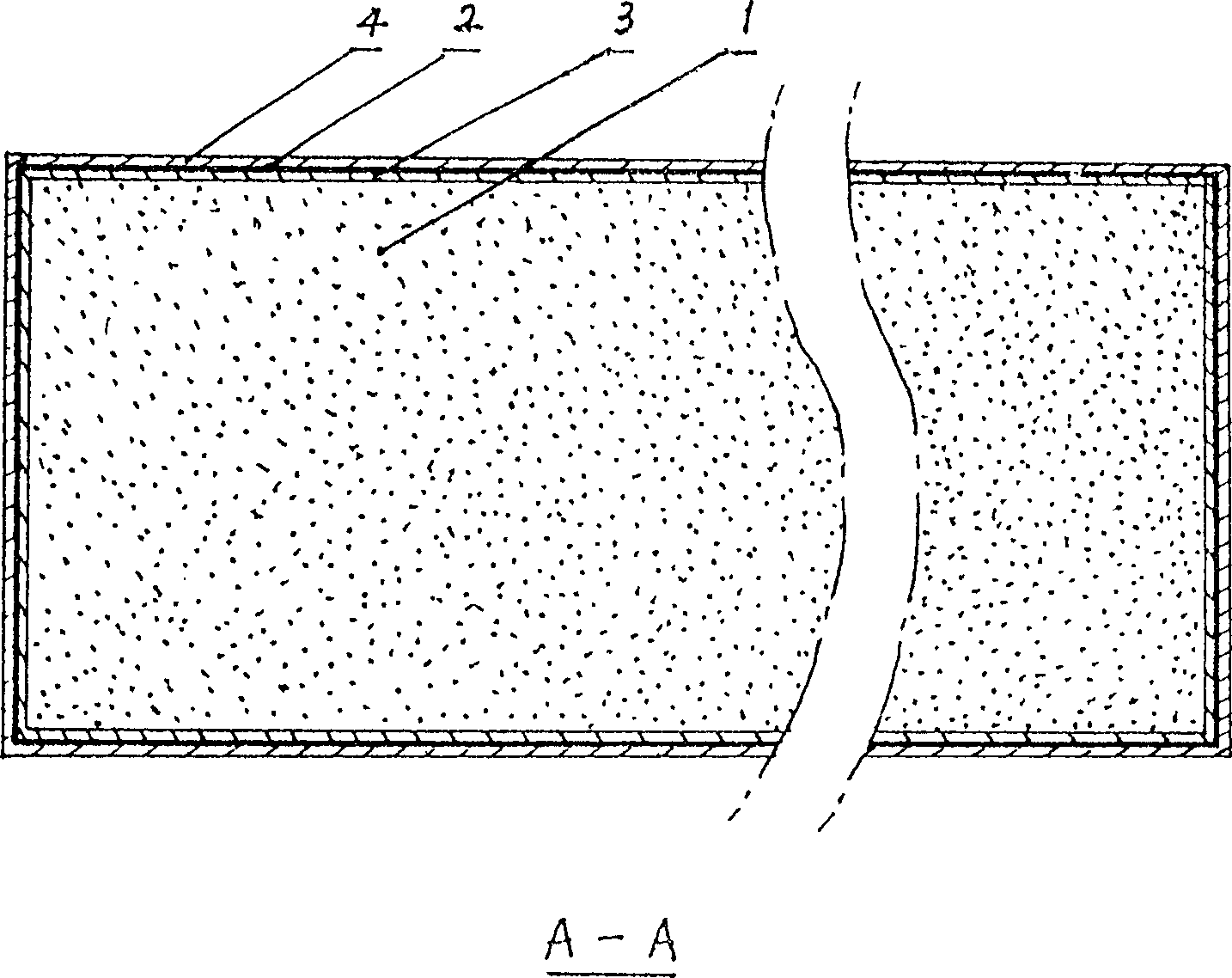

The invention relates to a flexible honeycomb sound-insulating and heat-insulating composite board having good performance in heat insulation and heat preservation, water resistance and flame resistance and belonging to the field of functional panels for building and decoration. In the invention, at least two double-layer board sound-insulating structures are formed by using the combination mode that two honeycomb cardboard filling core materials (1a, 1b) are sandwiched between an upper composite panel and a middle composite panel and between the middle composite panel and a lower composite panel respectively, wherein, the upper and the lower honeycomb cardboard filling core materials (1a, 1b) constitute hermetic air cavities between the two boards of the two double-layer board sound-insulating structures. Therefore, the honeycomb sound-insulating and heat-insulating composite board which integrates the characteristics of a single honeycomb cardboard and a single composite panel has the advantages of low density, low per-unit specific gravity, sound insulation, heat insulation, water resistance, flame resistance, high durability and the like.

Owner:耿忠平

Method for preparing split joint buckled type building block composite energy-saving wall board

The invention discloses a preparation method for an assembled buckle-typed building block combination energy-saving wall plate, which is characterized in that a front panel and a rear panel are respectively inserted into panel assembly troughs which are arranged at two ends of four side plates, thus leading the front panel, the rear panel and the four side plates to be assembled together to form a whole hollow wall plate frame; subsequently, a pasty middle filling layer is injected into the hollow wall plate frame through small holes on the upper side plate by a tunnel high-pressure pouring method; after the pouring operation is completed, the solidification is carried out on a conveyor belt; subsequently, the filling layer is smoothly arranged and cured for a certain time; subsequently, the finished product is gained after the packaging is completed. The preparation method of the invention has the advantages of being directly used as screen walls, light weight, high strength, good heat preservation and sound insulation effects, good surface decoration effect, waterproofing and dust-proofing, beauty, saving decoration procedure, thus quickening the decoration progress and the construction time.

Owner:朱春生

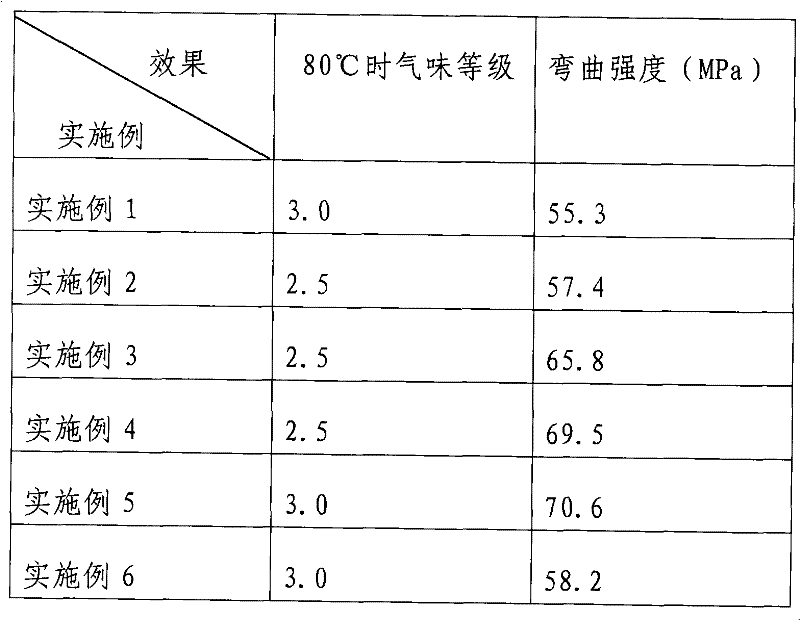

Environment-friendly PVC (Polyvinyl Chloride) foaming ceiling panel and preparation method thereof

The invention provides an environment-friendly PVC (Polyvinyl Chloride) foaming ceiling panel and a preparation method thereof. The environment-friendly PVC foaming ceiling panel comprises the following components in parts by weight: 90-110 parts of PVC resin, 5-10 parts of polylactic acid, 7-12 parts of polycaprolactone, 10-20 parts of polyester fiber, 50-70 parts of barium sulfate, 3-7 parts of plasticizer, 5-11 parts of stabilizer, 1.7-5 parts of titanium dioxide, 0.6-2 parts of PE (Poly Ethylene) wax, 2-5.5 of processing modifier, 1.4-3.2 parts of anti-impact modifier, 0.7-1.5 parts of composite foaming agent and 20-30 parts of sepiolite. The environment-friendly PVC foaming ceiling panel provided by the invention has the characteristics of environmental friendliness, good weather fastness, high fire resistance, strong scratch resistance, sound insulation, thermal insulation, dust prevention, noise absorption, insect prevention and light reflection and is very suitable for serving as an indoor ceiling.

Owner:安徽济峰节能材料有限公司

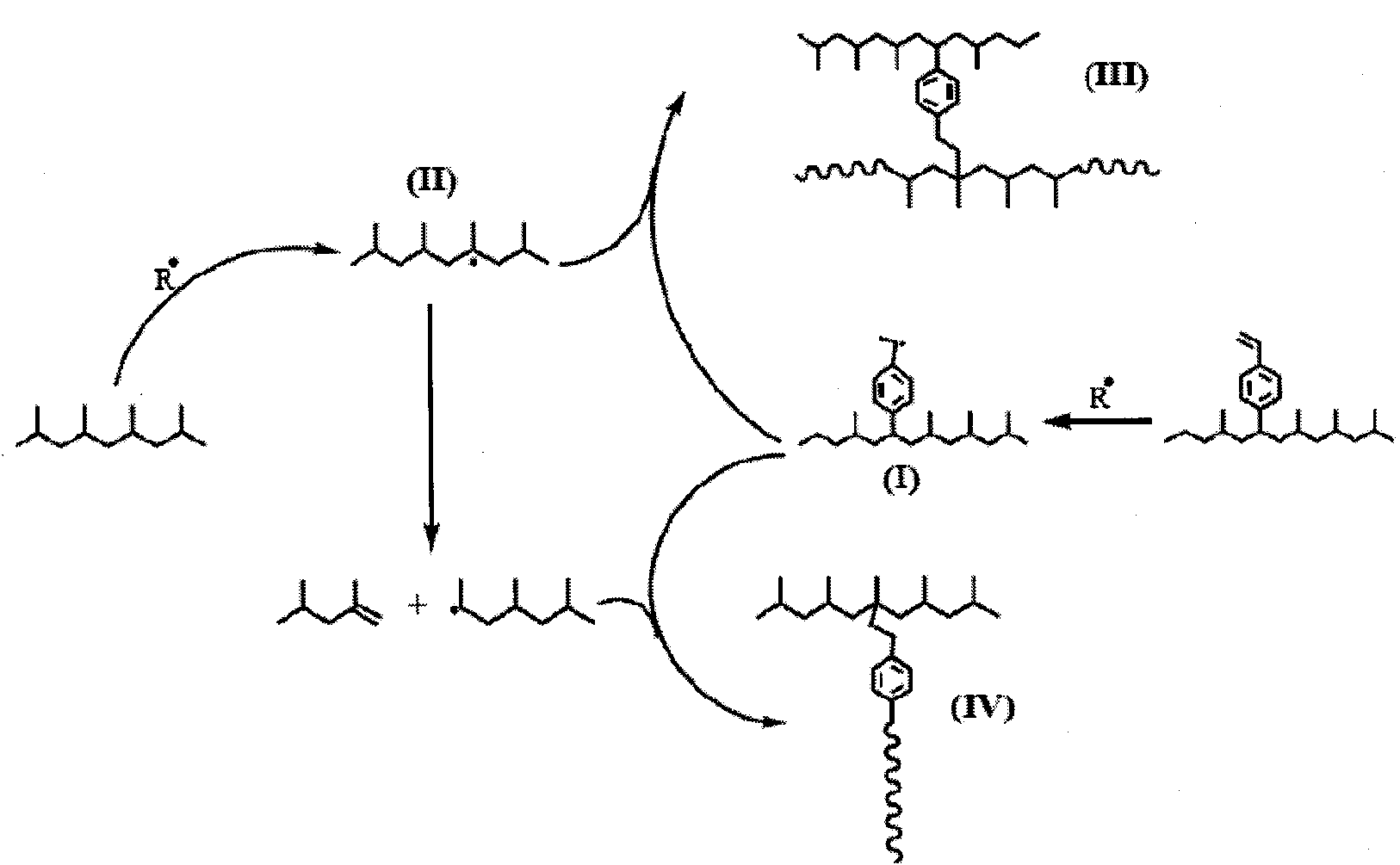

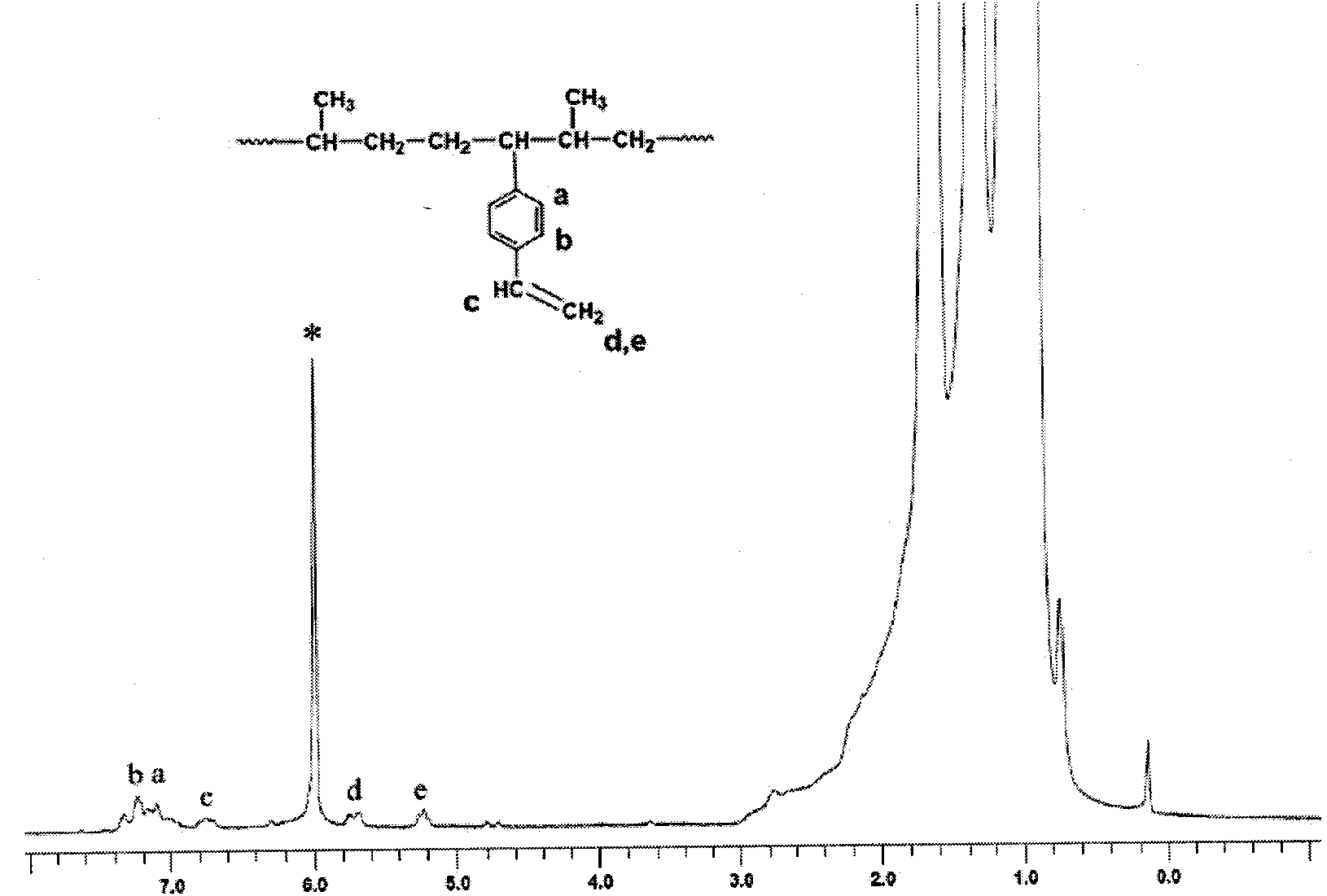

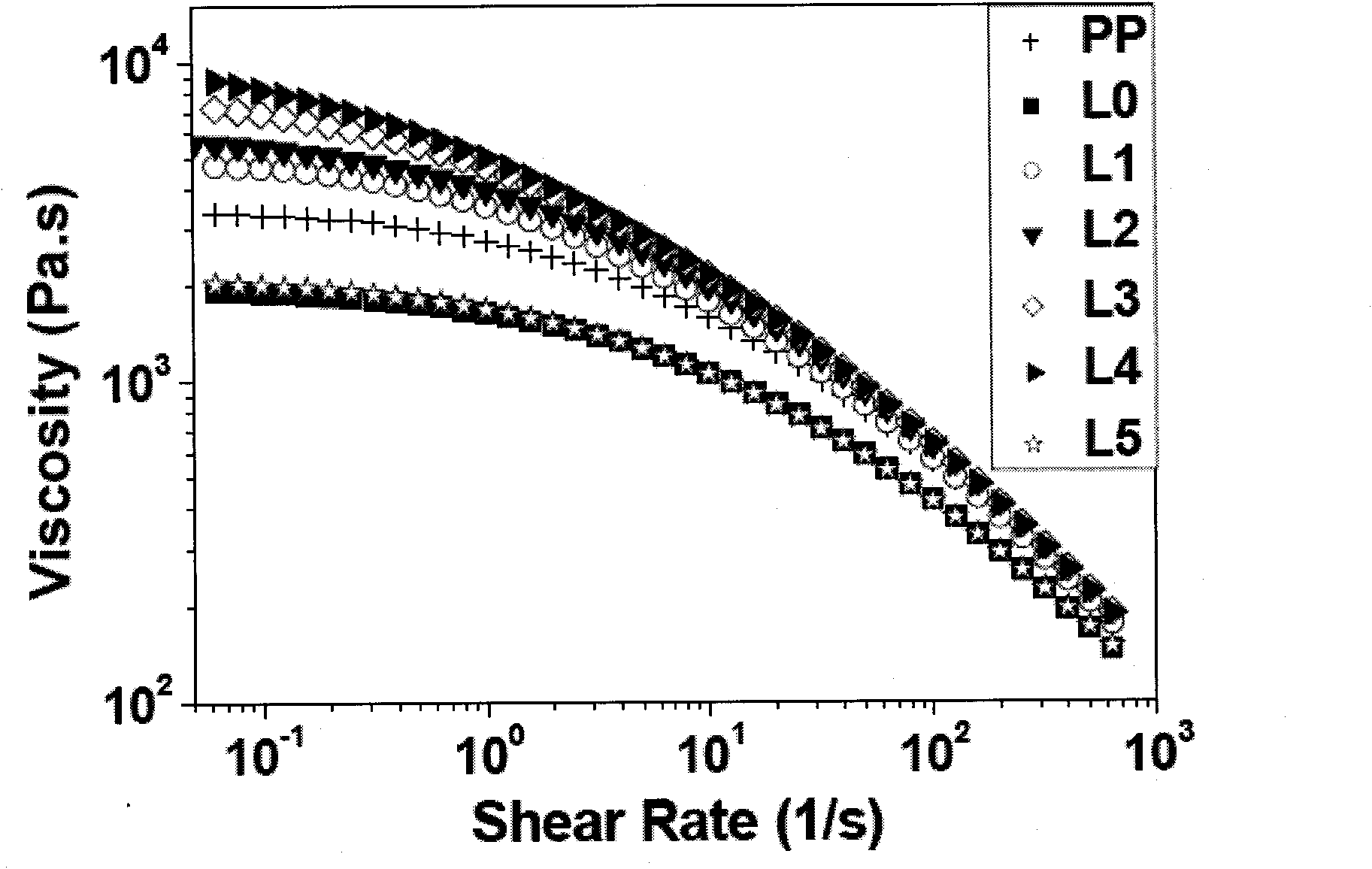

Polypropylene with high melt strength and preparation method thereof

InactiveCN101812165AImprove energy absorptionImprove high temperature resistancePolymer scienceZiegler–Natta catalyst

The invention relates to a polypropylene with high melt strength, which contains a long branched chain structure, and a preparation method thereof. In the method, Ziegler-Natta catalyst is firstly used for synthesizing a reactive polypropylene intermediate the side chain of which contains styrene groups, then the intermediate is added into a free base reaction system, the polypropylene with high melt strength, which has clear structure and adjustable branching content, is prepared by the reactivity of double bond of styrene via reactive extrusion, and the polypropylene with high melt strength, which has different performance, can be prepared by adjusting the dosage of the reactive polypropylene intermediate. The polypropylene has unique tensile property and excellent heat resistance, thereby having wide application prospects and practical value, can be widely used in the fields of extrusion foaming, thermoforming, extrusion coating, film blowing and the like, especially shows large market and application prospects in the aspect of producing foam materials, and has broad development and utilization prospects.

Owner:宋建学

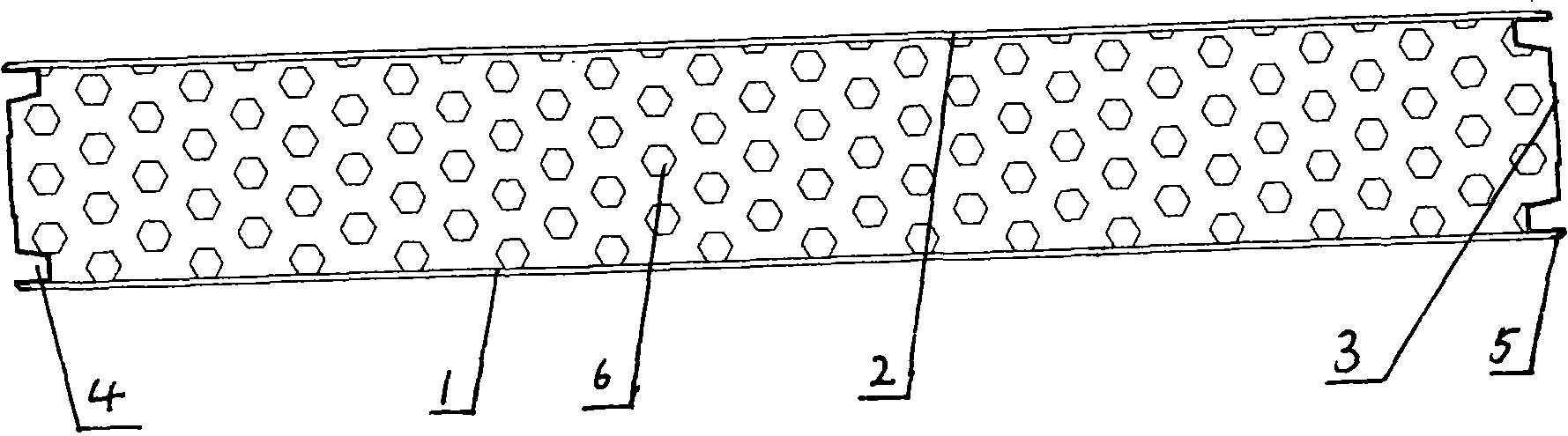

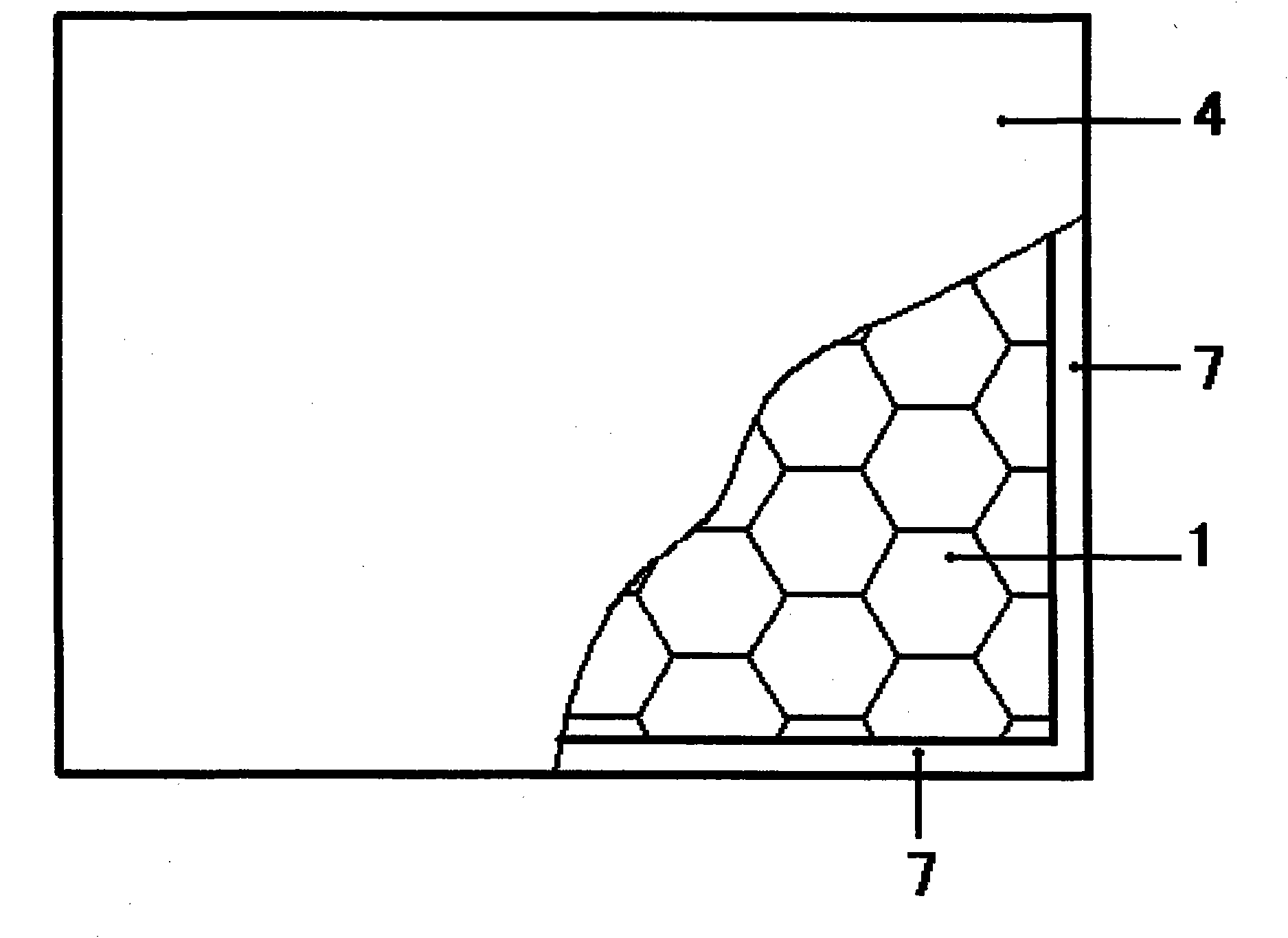

Low-carbon environment-friendly cellular light composite wallboard

InactiveCN102155054AGood sound and heat insulation performance and pressure bearing capacityIncreased load carrying capacity and durabilityCovering/liningsHeat proofingCarbon dioxideEngineering

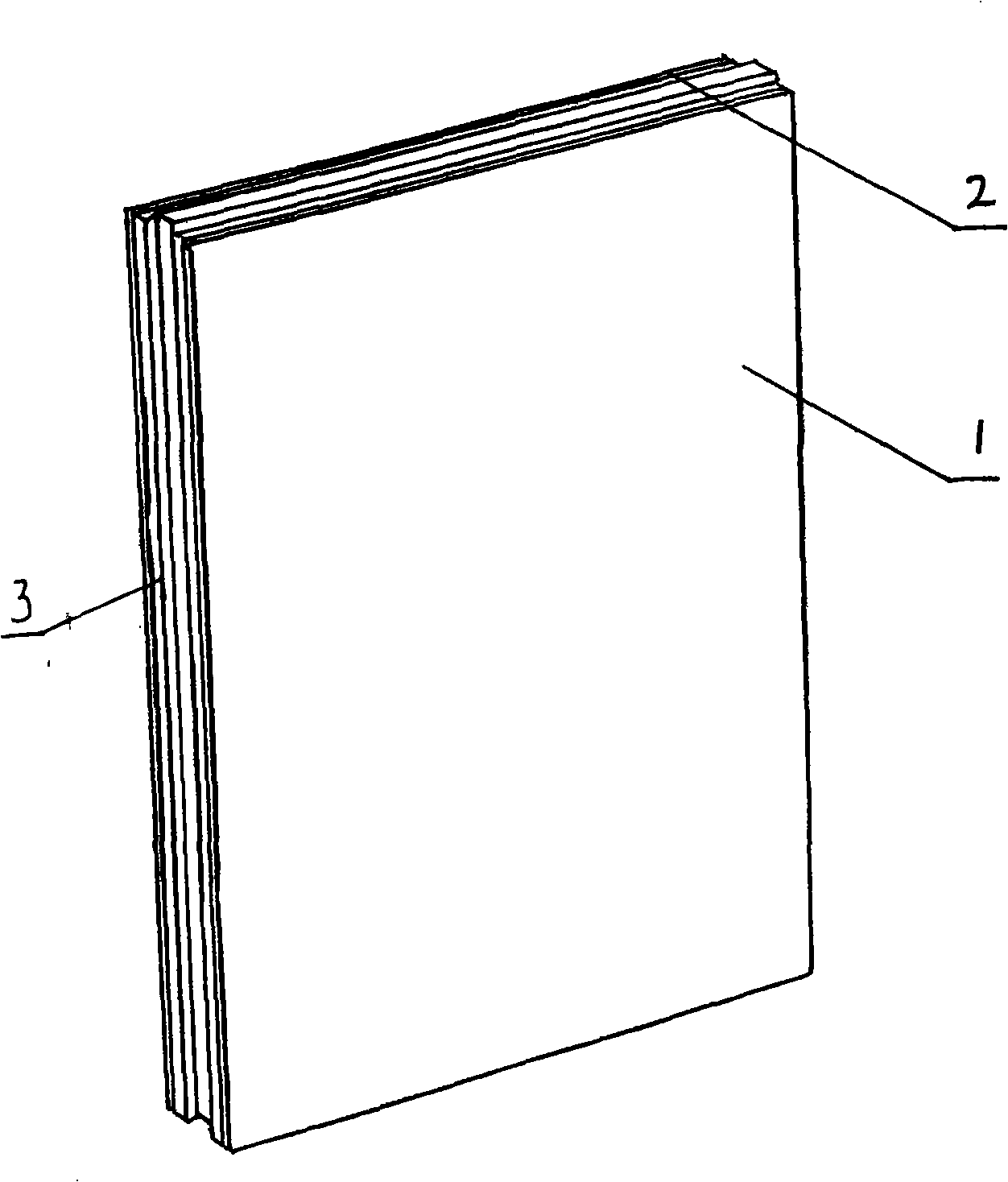

The invention discloses a low-carbon environment-friendly cellular light composite wallboard, comprising cellular paperboard inner core material, a waterproof heat-resisting adhesive layer, environment-friendly panels and a reinforced edge banding connecting and fastening strip. A cellular paperboard with a stable hexagon structure is used as the inner core material and has good sound insulation, heat-shielding performance and loading capacity. The waterproof heat-resisting adhesive layer firmly adheres an upper environment-friendly panel, a middle environment-friendly panel and a lower environment-friendly panel of the cellular paperboard inner core material together so as to form two double-board sound insulation structures, and the double-board sound insulation structures are also reliable heat insulation structures. The environment-friendly panels have the functions of sound insulation, heat insulation, antiflaming and appearance keeping and protecting and can improve the bearing capacity and durability of the cellular light composite wallboard. The reinforced edge banding connecting and fastening strip can exert sealing, moistureproof and supporting protective effects on the four sides of a single composite wallboard and also can exert connection function in wall surface combination and assembly during the installation of the composite wallboards. The prepared cellular light composite wallboard has low density and light weight and has the advantages of good sound insulating, heat insulating, waterproof, antiflamming performances and good durability. By applying the environment-friendly cellular light composite wallboard, the running time of a heating and ventilating equipment system can be reduced, thus consumption of energy source and discharge of carbon dioxide gas can be reduced, and a low-carbon environment-friendly pleasant environment is created.

Owner:YUNNAN JUHE CONSTR GROUP

Sound-insulation and thermal-insulation laminated glass and preparation method thereof

InactiveCN107384286AEffective scatteringAvoid directly passing throughNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEmulsionHeat conducting

The invention relates to the technical field of glass, in particular to sound-insulation and thermal-insulation laminated glass and a preparation method thereof. The sound-insulation and thermal-insulation laminated glass comprises a film clamped between a first glass sheet and a second glass sheet, wherein one side, close to the film, of the first glass sheet and / or the second glass sheet is coated with a sound-insulation and thermal-insulation glue layer which is 15-20 mu m thick; the sound-insulation and thermal-insulation glue layer is prepared from substances in parts by weight as follows: 80-100 parts of a waterborne polyurethane emulsion, 0.01-0.2 parts of a leveling agent, 0.01-0.2 parts of a defoaming agent, 5-15 parts of glass beads, 1-9 parts of titanium dioxide, 1.5-5 parts of coated particles and 180-200 parts of water; titanium dioxide contained in the glue layer can scatter the passing light rays effectively, so that the light rays are prevented from transmitting through the laminated glass directly, and good thermal insulation effect of the laminated glass is guaranteed; meanwhile, each glass bead is of a hollow structure and has lower heat conducting coefficient and good chemical stability, and the glass beads contained in the sound-insulation and thermal-insulation glue layer have good thermal insulation performance.

Owner:安徽艺云玻璃有限公司

Anti-radiation heat insulation plate and preparation method thereof

ActiveCN108658488AMeet application requirementsHigh strengthCoatingsWater-setting substance layered productRed mudSlag

The invention provides concrete anti-radiation coarse aggregate, an anti-radiation heat insulation plate comprising the aggregate and a preparation method of the anti-radiation heat insulation plate.The method comprises the steps of preparing the concrete anti-radiation coarse aggregate from serpentine acid-leaching slag, red mud and barite powder, and then preparing the anti-radiation heat insulation plate in a four-layer structure. The heat insulation plate has performance such as heat insulation, sound insulation, flame retardance and light weight.

Owner:上海万骊家居有限公司

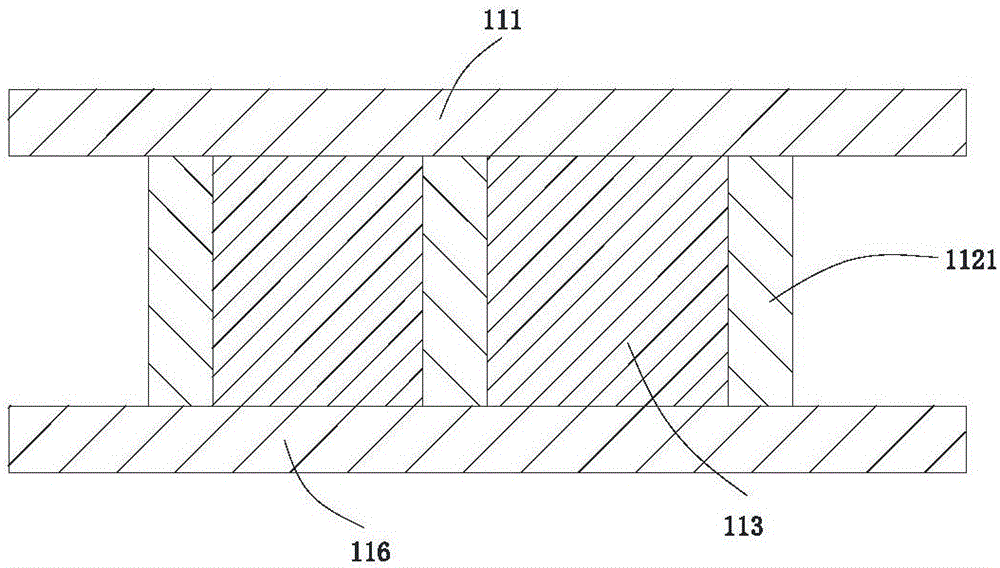

Honeycomb core board

ActiveCN103112202AHigh strength to weight ratioImprove fastnessLaminationLamination apparatusHoneycombPrism

The invention relates to a honeycomb core board used for replacing blockboards and the like, mainly aiming to solve the problems that present blockboards and the like have low strength and low weight ratios. The honeycomb core board comprises upper and lower panel layers and a honeycomb core layer and is characterized in that the upper and lower panel layers and the honeycomb core layer are prepared with polypropylene short fibers and jute fibers as raw materials; a preparation method of the honeycomb core board comprises the following steps of: preparing coiled materials or sheets from the polypropylene short fibers and the jute fibers in a weight ratio of 30-70%:70-30% by adopting an air laying method and preparing the upper and lower panel layers from the panels pressed at 180-200 DEG C; and putting the coiled materials or the sheets into a honeycomb core shaped die to be pressed at 180-200 DEG C to prepare the honeycomb core layer, adhering the upper and lower panel layers to the upper and lower surfaces of the honeycomb core layer and pressing the three layers to prepare the honeycomb core board; cylinders or prisms are arranged on a lower plate of the honeycomb core shaped die and under an upper plate; and the upper and lower panel layers can be also prepared from polymer boards, plywood or nonwovens and the like. The honeycomb core board has the advantages of high strength and high weight ratio.

Owner:辽宁艺朦织旺地毯有限公司

Gangue porous sintered brick and manufacturing method thereof

InactiveCN106336240AReduce weightGood sound and heat insulationCeramic materials productionCeramicwareThermal insulationIndustrial waste

The invention discloses a gangue porous sintered brick, which is composed of the following raw materials (by weight): 30-45 parts of gangue, 30-45 parts of fly ash and 20-35 parts of shale. The invention also discloses a manufacturing method of the gangue porous sintered brick, comprising the following steps: processing raw materials, stirring and mixing, compressing for moulding, drying and sintering. By the adoption of the technical scheme and by substituting shale for clay, cultivated farmland is avoided from being destroyed. By adding gangue, industrial waste residue can be fully utilized. The gangue can be spontaneously combusted during the sintering process. Then, vertical pores are formed. Therefore, weight per unit volume is reduced, and it is ensured that the brick has better sound insulation and thermal insulation effects. Dew formation will not occur to interior walls in winter. The brick is spontaneously combusted so as to reduce consumption of fuels, and good performance of the sintered brick is guaranteed.

Owner:岳佐星

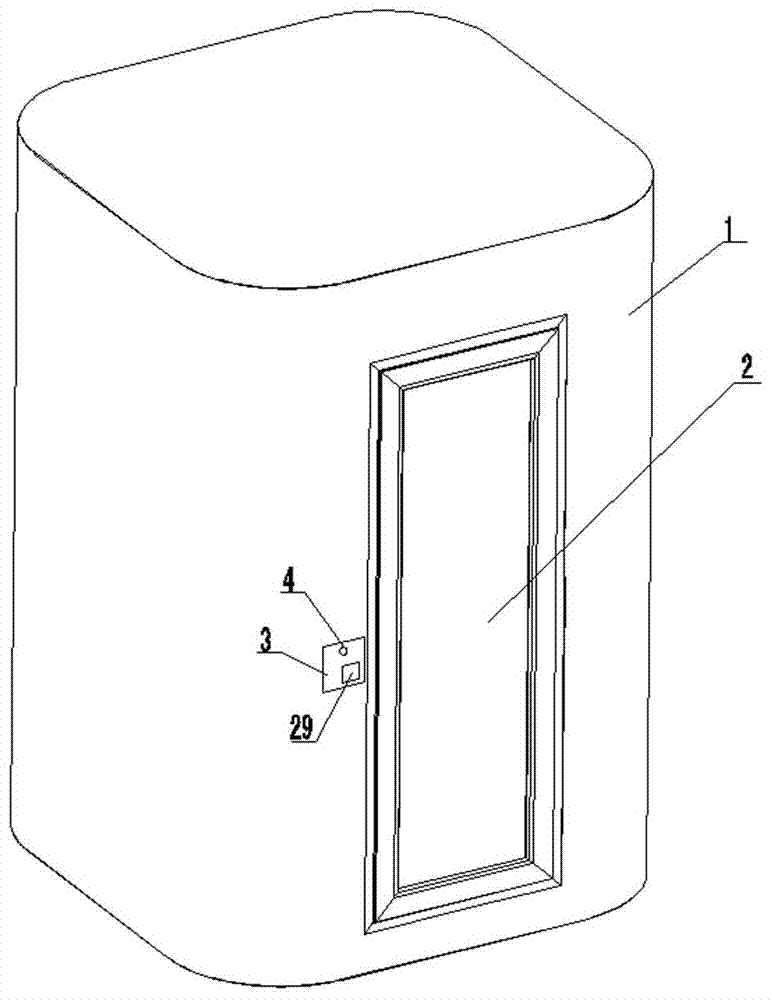

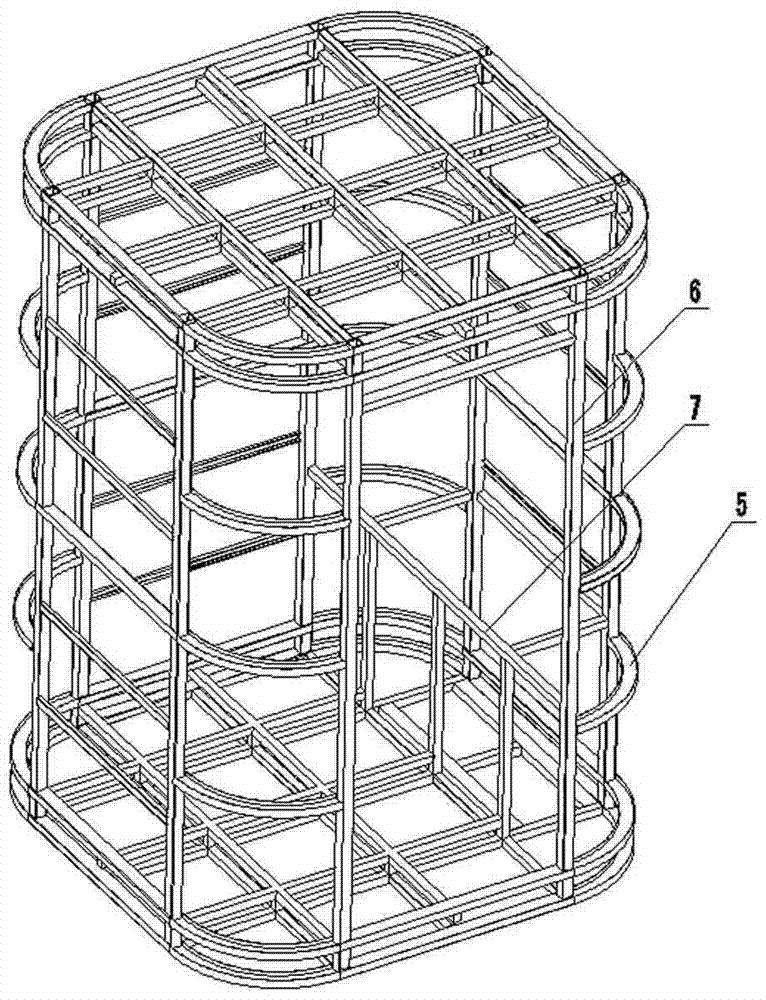

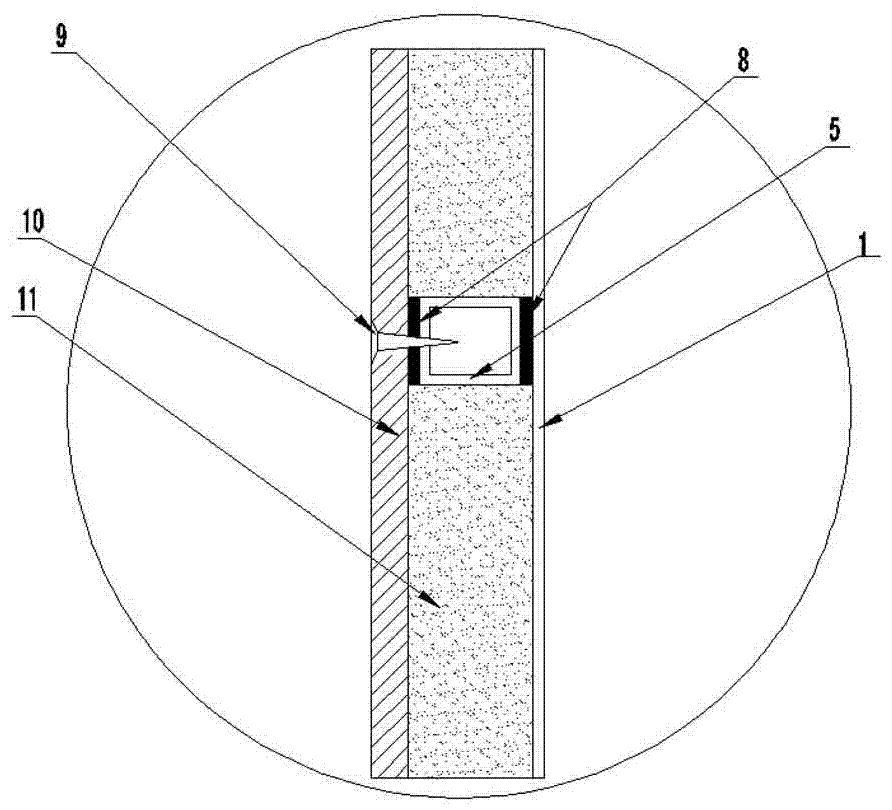

Integrated intelligent mini-house system

PendingCN106988561AImprove space utilizationGood sound and heat insulationLighting and heating apparatusFireproof doorsAdhesiveSteel bar

The invention discloses an integrated intelligent mini-house system which comprises a house frame system, a ventilation system and an intelligent entrance guard system. The house frame system comprises an outer skin, an interior plate and a square pipe skeleton which is a house skeleton formed by welding steel bar square pipes. The outer skin is bonded to the outer surface of the square pipe skeleton through a flexible adhesive, and the interior plate is bonded to the inner surface of the square pipe skeleton through a flexible adhesive. The space between the outer skin and the interior plate is filled with a soundproof layer. The soundproof layer and the outer skin as well as the soundproof layer and the interior plate are bonded together. The square pipe skeleton is internally provided with a seat skeleton formed by welding steel bar square pipes. The lower side of the seat skeleton is provided with a ventilation system. The front face of the square pipe skeleton is provided with a door frame used for mounting a heat insulation broken bridge door which is provided with the intelligent entrance guard system. The integrated intelligent mini-house system has the characteristics of being closed, light in weight, high in space utilization rate and good in sound and heat insulation performance, the fragmentized time of people is fully utilized, and the house system meets the demands of leisure, entertainment and health.

Owner:山东金贝壳智能科技有限公司

Light cement and bamboo composite and manufacturing method thereof

The invention discloses a light cement and bamboo composite and a manufacturing method thereof. The manufacturing method comprises the following steps of: firstly, mixing and uniformly stirring cement, bamboo and water; then, respectively adding a thickening agent, a foaming agent and a coagulant aid into cement slurry and uniformly stirring, wherein the thickening agent, the foaming agent and the coagulant aid are uniformly mixed with water; and finally, filling a die, foaming, forming, carrying out steam curing and carrying out static culture to obtain the light cement and bamboo composite. Compared with a common cement-bonded board, the light cement and bamboo composite manufactured by the invention is low in density smaller than 0.7g / cm<3>, excellent in physical and mechanical properties, particularly good in impermeability and sound and heat insulation property and capable of adjusting the indoor environment and also has a biomass characteristic; and compared with a synthetic material such as a shaving board taking urea-formaldehyde resin, phenolic resin and the like as an adhesive, the light cement and bamboo composite is free of harmful gas release, environmentally-friendly, fireproof, flame retardant, rich in raw material source, low in raw material cost, simple in production process and capable of realizing improved production on the basis of the design of the traditional aerated concrete production line.

Owner:FUJIAN AGRI & FORESTRY UNIV

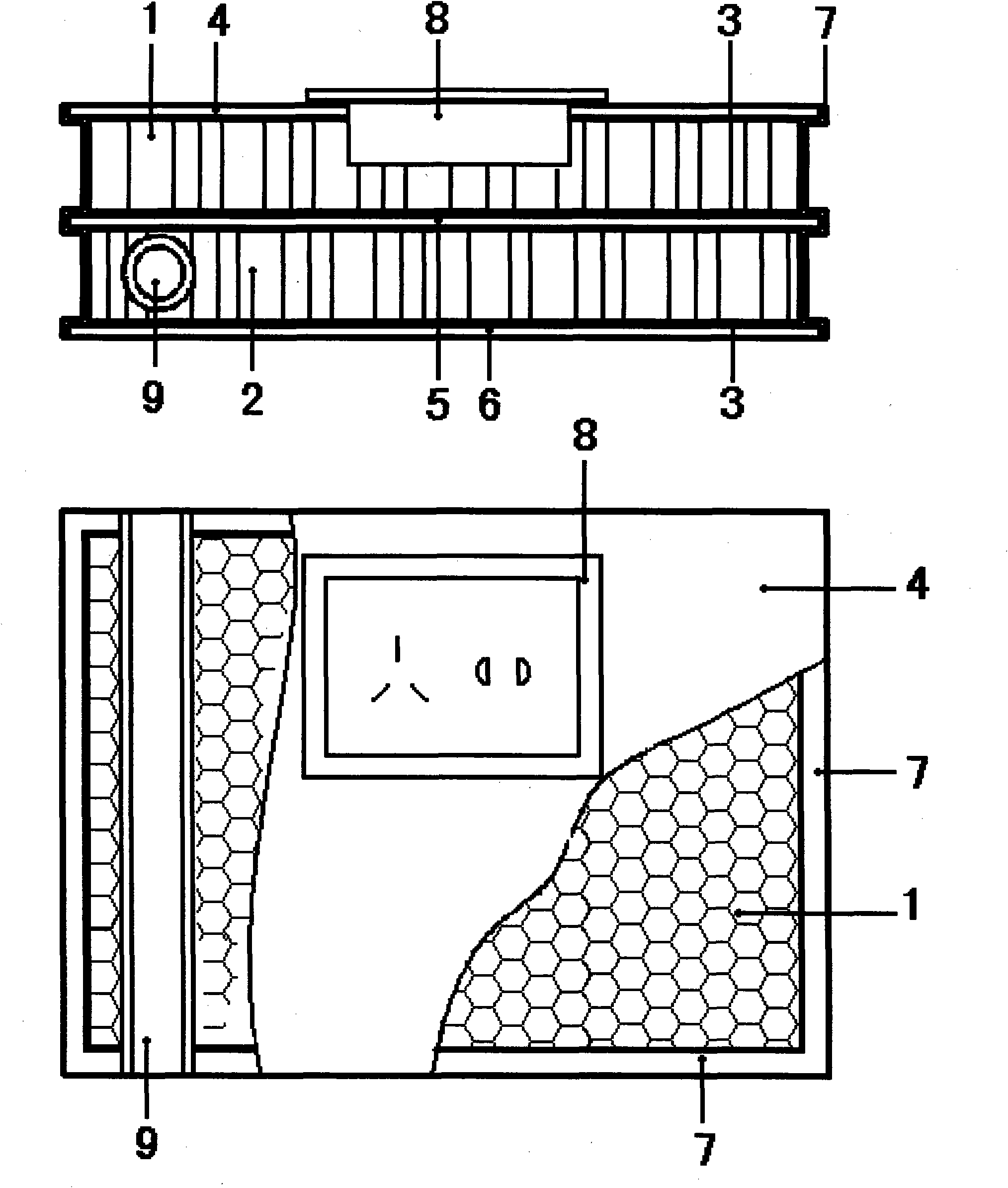

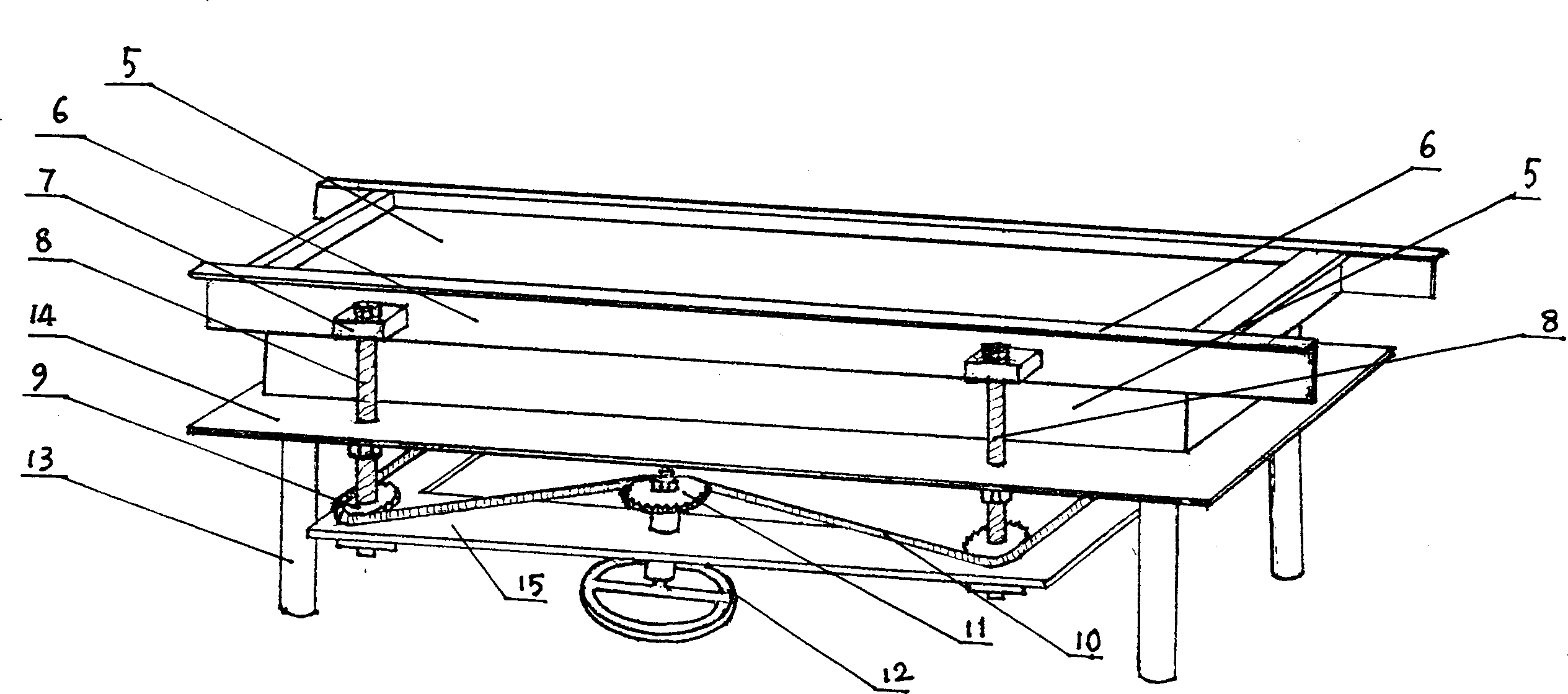

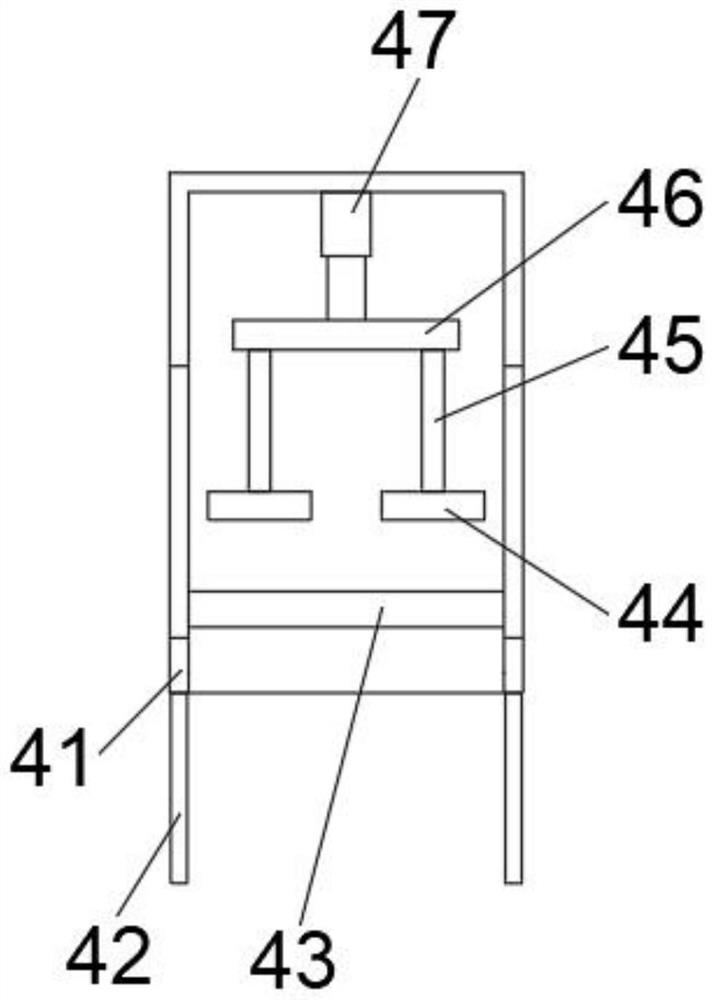

Special equipment for producing light prefabricated plate for building

InactiveCN1425542ASimple structureStrong enoughConstruction materialCeramic shaping apparatusGlass fiberEngineering

The special equipment for producing light perfabricated building plate includes a support, a transmission mechansm, a smooth plain stage in the same size and the prefabricated plate and a frame around the plain stage in the height not lower than the thickness of the prefabricated plate, with the plain stage being movable relatively to the frame by means of the transmission mechanism. The special equipment is suitable for producing light perfabricated building plate with central foamed plastic layer, glass fiber cloth layer around the foamed plastic layer and adhesive material layers between the foamed plastic layer and the glass fiber cloth layer and on the surface of the glass fiber cloth layer.

Owner:肖志永

Energy-saving brick prepared on basis of building waste and preparation method thereof

InactiveCN108264333AImprove stabilityImprove compactnessCeramic materials productionClaywaresFiberTO-18

The invention discloses an energy-saving brick prepared on the basis of building waste. The energy-saving brick is prepared from the following raw materials in parts by weight: 32 to 36 parts of modified building waste, 24 to 28 parts of modified flay ash, 14 to 18 parts of coal gangue, 12 to 14 parts of lithium bentonite, 8 to 12 parts of cotton fiber, 6 to 10 parts of wood fiber, 8 to 12 parts of glass beads, 8 to 12 parts of crushed crude pearlite, 4 to 6 parts of water reducers, 3 to 5 parts of anti-foaming agents, 3 to 5 parts of cement and 1 to 3 parts of filling materials. The inventionaims at providing the energy-saving brick prepared on the basis of building waste. The energy-saving brick has the advantages that the building waste is sufficiently utilized; meanwhile, the properties such as the intensity, the sound isolation and heat isolation performance and the like of the brick can be improved; high use value and good application prospects are realized.

Owner:HEFEI YAKELI NEW BUILDING MATERIAL CO LTD

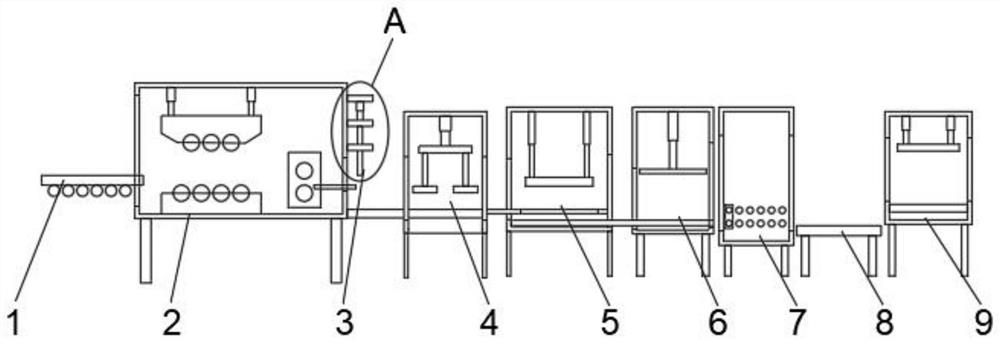

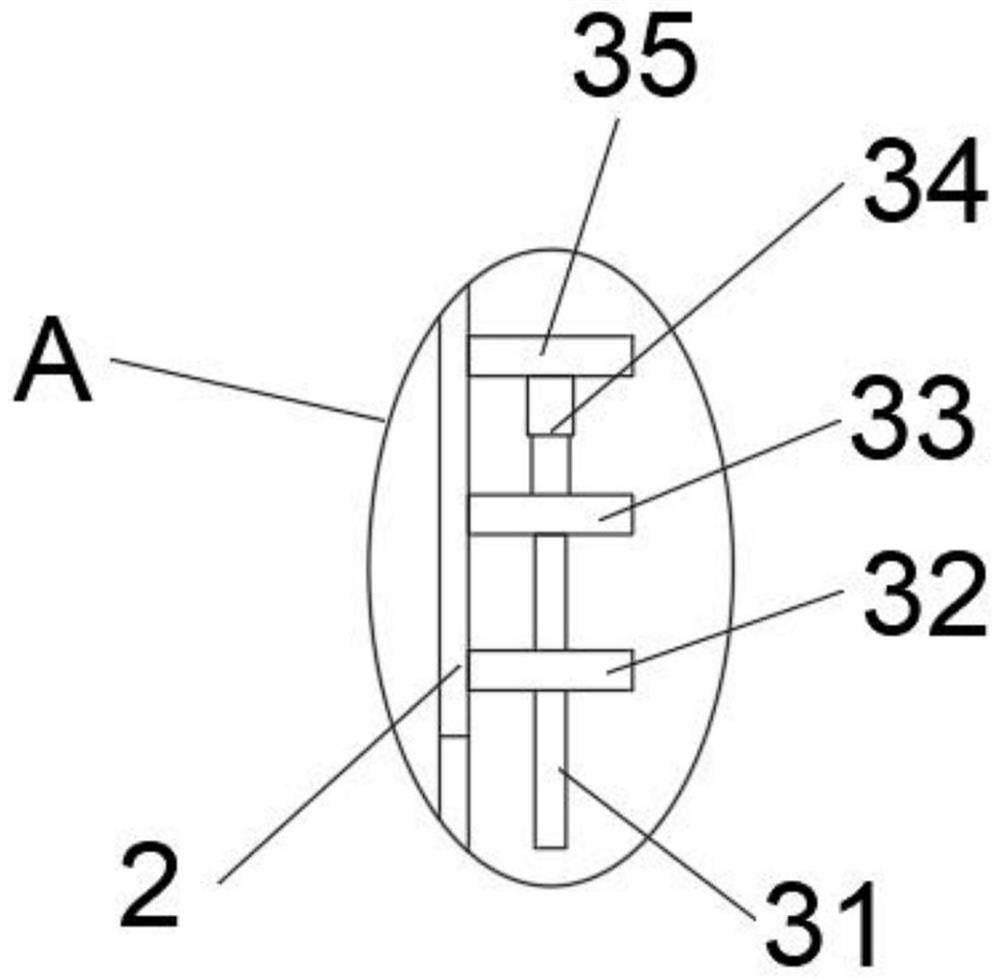

Combined glue composite aluminum honeycomb plate production equipment and process

PendingCN112171187AEfficient and simple production processReduce weightLiquid surface applicatorsLamination ancillary operationsAluminum honeycombAdhesive glue

The invention discloses combined glue composite aluminum honeycomb plate production equipment and process, and relates to the technical field of aluminum honeycomb plate production. The combined gluecomposite aluminum honeycomb plate production equipment specifically comprises a feeding machine and a decoiler, wherein a cutting device is arranged at a discharging port of the decoiler; the lower portion of the discharging port of the decoiler is connected with a feeding port of an angle shearing machine; a discharging port of the angle shearing machine is connected with a feeding port of a bending machine; a discharging port of the bending machine is fixedly connected with a feeding port of a grinding machine; a discharging port of the grinding machine is connected with a feeding port of agluing machine; a discharging port of the gluing machine is connected with a workbench used for the laying of the composite aluminum honeycomb plate; and a hot press is arranged on the side face of the workbench. According to the aluminum honeycomb plate produced by the production equipment and process, high-strength alloy aluminum plates are used as a panel and a bottom plate, a hexagonal aluminum foil honeycomb core is adhered in the middle by using an aviation adhesive, hot-pressing compounding is carried out, and a decorative and anti-corrosion coating is applied to the surface of the aluminum plate, so that the defects of low brittleness, low tear resistance and low impact resistance of a honeycomb plate bonding layer produced by the conventional process are overcome.

Owner:湖北航飞蜂窝复合材料有限公司

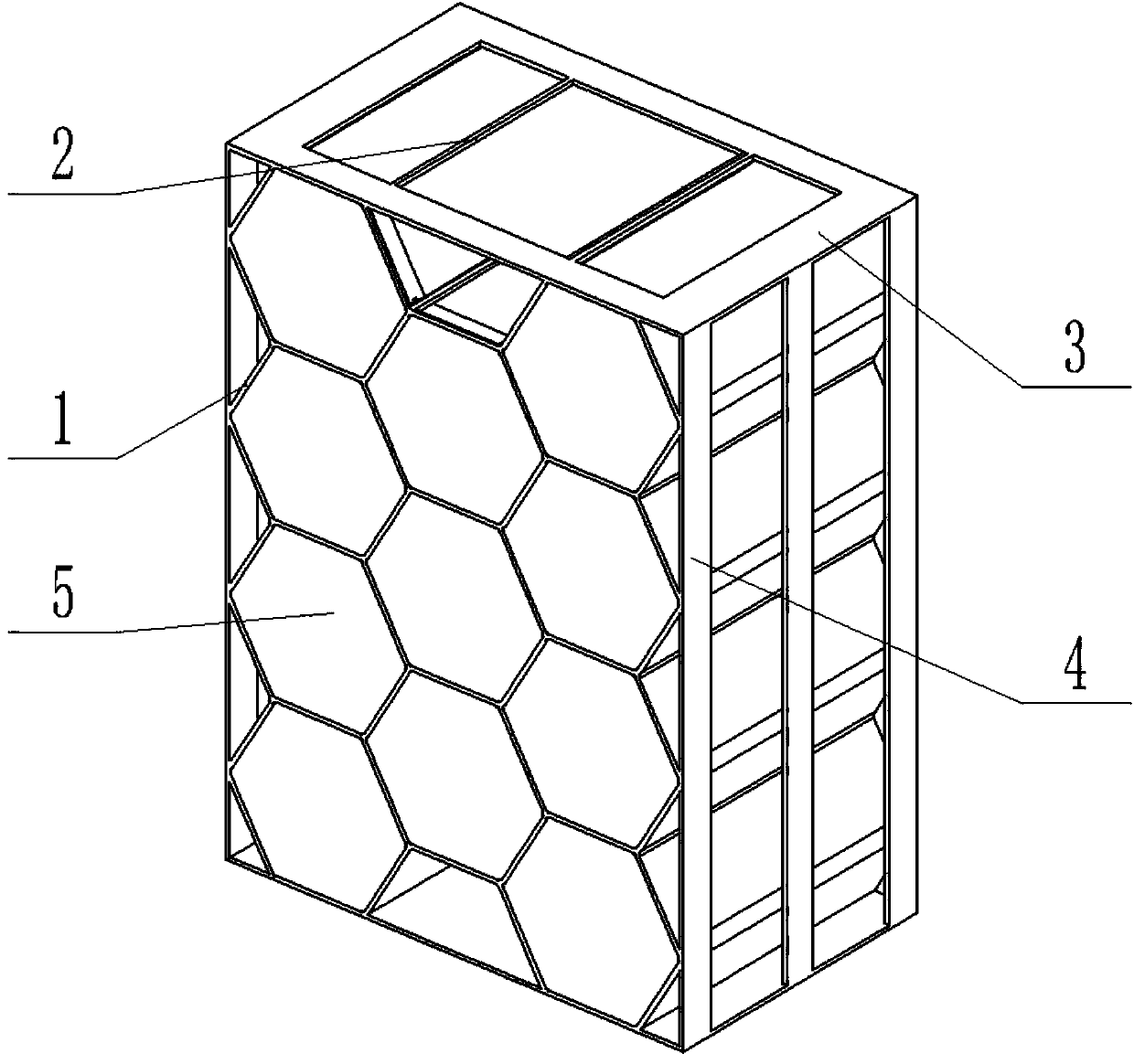

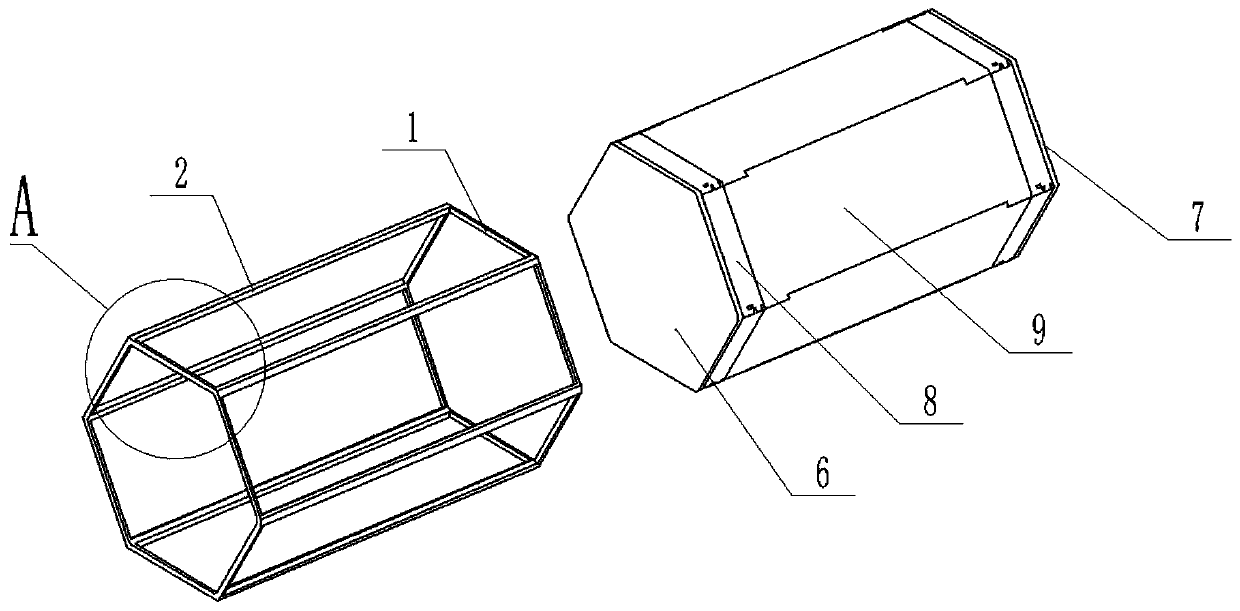

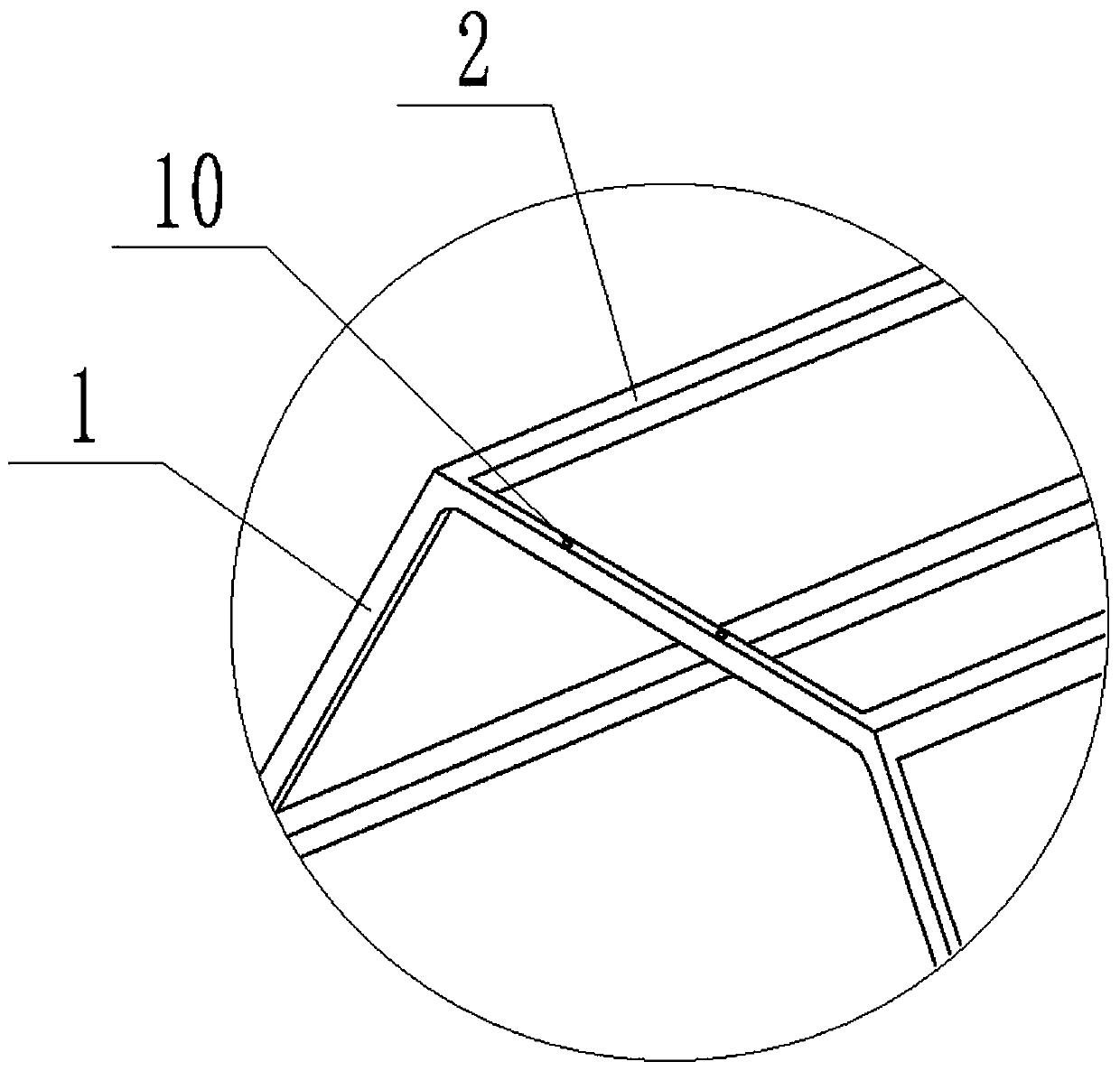

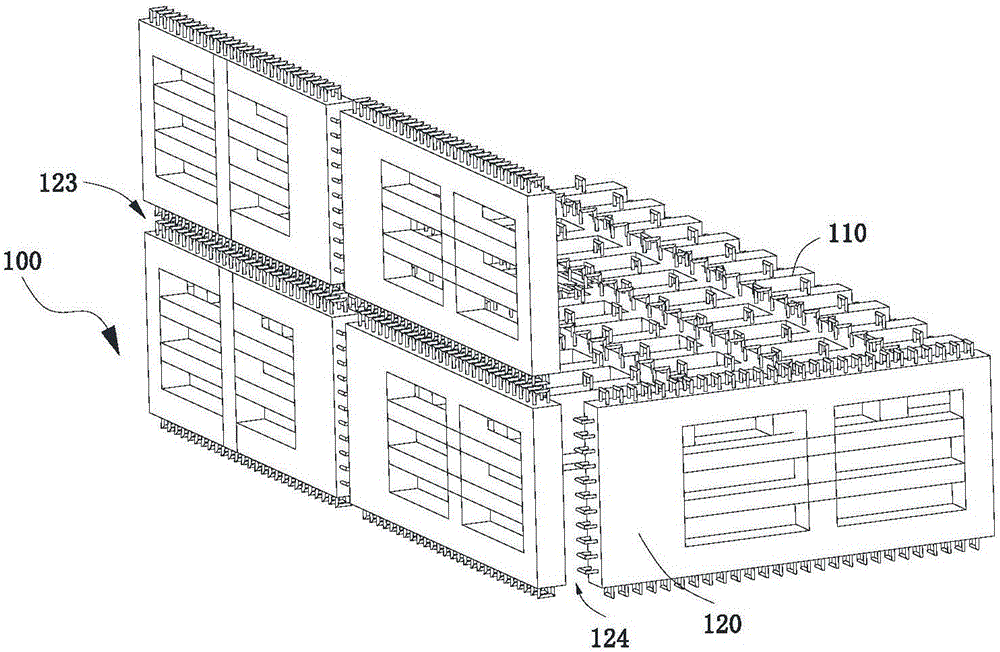

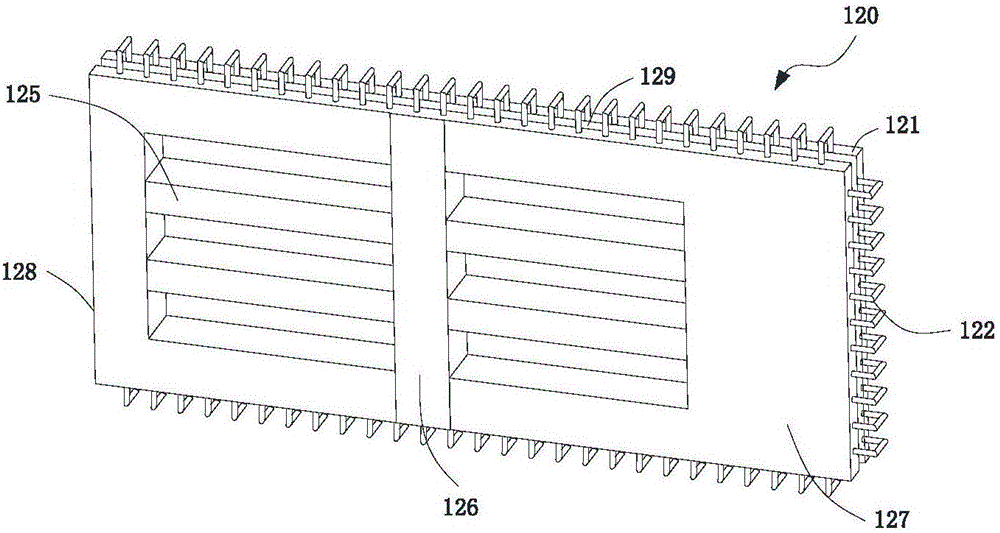

Modular honeycomb building capable of being assembled quickly

ActiveCN111255271AShort construction periodImprove efficiencySpecial buildingHeat proofingHoneycombEngineering

The invention relates to the technical field of building structures and particularly discloses a modular honeycomb building capable of being assembled quickly. The modular honeycomb building compriseshoneycomb space units, wherein each honeycomb space unit comprises two skeletons, lateral panels, a front panel and a rear panel; each framework comprises folding rods; a first bump and a second bumpare arranged at one end of each folding rod; a rotating shaft is fixedly arranged on each first bump and penetrates through the corresponding second bump; a first pin hole is formed in each first bump; a second pin hole is formed in each second bump; an inserting pin is arranged in each first pin hole; a first hollow column and a second hollow column are arranged at the other end of each foldingrod and rotationally arranged on the corresponding rotating shaft; third pin holes are formed in each first hollow column and the corresponding second hollow column; when each inserting pin is inserted into the corresponding first pin hole, second pin hole and third pin holes, an angle of 120 degrees is formed between two corresponding folding rods; the adjacent lateral panels are rotationally connected; the front panel and the rear panel are fixed on the two skeletons; and a plurality of regular hexagonal column body mounting cavities are formed in a honeycomb framework unit. The modular honeycomb building is intended to solve problems in the prior art as well as achieve the effects of high construction speed and reutilization.

Owner:CHONGQING UNIV

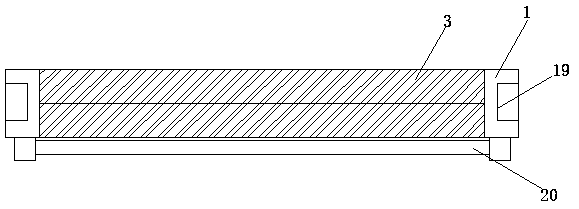

Mid-set aluminum alloy sun-shading integral double-layer window

InactiveCN110173192AEasy to cleanGood sound and heat insulationFireproof doorsNoise insulation doors/windowsThermal insulationSlide plate

The invention discloses a mid-set aluminum alloy sun-shading integral double-layer window which comprises a framework, wherein a window frame is disposed inside the framework; glass disposed symmetrically is fixed on inner side walls of the window frame; roller shutters are fixed on the lateral wall of one side of the window frame; spindles are fixed on side walls of both sides of the window frame; the other ends of the spindles are in rotatable connection to the inner side walls of the frame; first grooves are formed in inner walls of the top end and the bottom end of the framework; fixed grooves disposed symmetrically are formed in side walls of two sides of the first grooves; fixed plats are fixed on side walls of the top end and the bottom end of the window frame; second grooves disposed symmetrically are formed in side walls of both sides of the fixed plates; first through holes are disposed between the second grooves; fixed mechanisms are disposed inside the second grooves; and each fixed mechanism comprises a slide plate which is in slide connection between the side walls of two sides of each second groove. The mid-set aluminum alloy sun-shading integral double-layer windowdisclosed by the invention has the beneficial effects that effects of sound insulation and thermal insulation are good; the double-layer window can be rotated, so the outer-layer glass can be cleanedeasily; and convenience is enhanced.

Owner:江苏科宇装饰工程有限公司

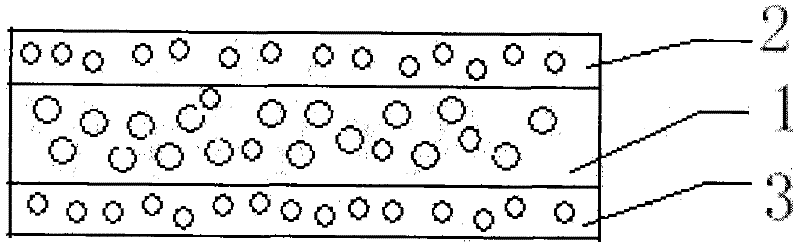

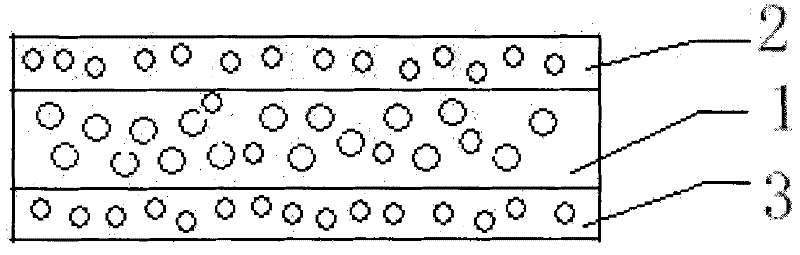

Air-permeable interior trim composite board material for ceiling of automobile

InactiveCN102501519AImprove breathabilityGood heat insulationSynthetic resin layered productsSuperstructure subunitsSurface layerEngineering

The invention relates to the field of interior trim of an automobile, in particular to air-permeable interior trim composite board material for the ceiling of an automobile. The composite board material comprises an intermediate foam layer, and the upper surface and the lower surface of the intermediate foam layer are laminated with an upper surface layer and a lower surface layer both having a via-hole, respectively. With such configuration, the composite board material has better sound insulation and heat insulation effects compared with intermediate foam layer-containing board material in the prior art.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

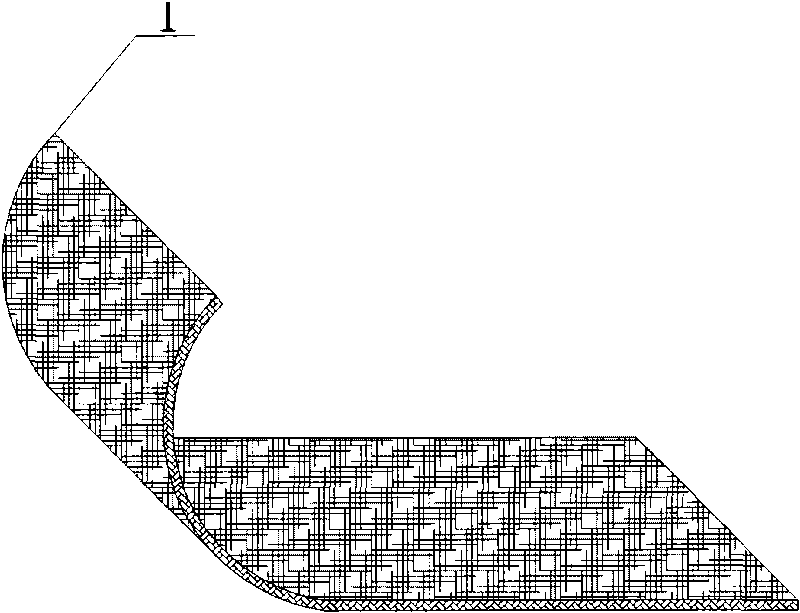

Method for preparing lightweight high-strength composite material by utilization of paper-based honeycomb panel and wood plastic composite material

InactiveCN102431219AHigh strengthGood sound and heat insulationSynthetic resin layered productsLaminationHoneycombWater resistance

A method for preparing a lightweight high-strength composite material by the utilization of a paper-based honeycomb panel and a wood plastic composite material relates to a preparation method of a lightweight high-strength composite material. Present wood plastic composite materials are not convenient to use and are prepared at high cost, and present paper-based honeycomb panels have low strengthand are easy to absorb water and deform. The invention solves the above problems of present wood plastic composite materials and present paper-based honeycomb panels. The method provided by the invention comprises the following steps of: firstly, dipping a paper-based honeycomb panel into a container filled with phenol-formaldehyde resin adhesive, taking out and splaying out the paper-based honeycomb panel, heating and sanding to obtain a paper core plate; secondly, matting one surface of a wood plastic thin plate; thirdly, coating a layer of isocyanate adhesive or epoxy resin adhesive with aroller on upper and lower surfaces of the paper core plate and the matted surface of the wood plastic thin plate; and finally, using two wood plastic thin plates to respectively cover the upper and lower surfaces of the paper core plates, allowing the matted surface to contact with the paper core plate to obtain a combined slab, and bonding to finish. The lightweight high-strength composite material obtained in the invention is low carbon and environmentally friendly during the production and application processes, is convenient to use, and has characteristics of high water proofness, non-deformable performance, light weight, high strength and low cost.

Owner:NORTHEAST FORESTRY UNIVERSITY

Novel prefabricated house and construction method thereof

ActiveCN106436894ASimple structureEasy to processConstruction materialArchitectural engineeringFloor plate

The invention belongs to the field of building construction and provides a novel prefabricated house and a construction method thereof. The novel prefabricated house comprises a plurality of house units, each house unit comprises an overlapped dense-rib mould box floor plate and a plurality of latticed frame shear wall bodies, and the overlapped dense-rib mould box floor plate of each house unit is mounted at tops of the latticed frame shear wall bodies. Each overlapped dense-rib mould box floor plate comprises an upper plate, a lower plate and in-plate rib beams, wherein the upper plate and the lower plate are in opposite arrangement, the in-plate rib beams are positioned between the upper plate and the lower plate and fixedly connected with the upper plate and the lower plate, and the lower plate is fixedly connected with the latticed frame shear wall bodies. The construction method is used for construction of the novel prefabricated house. By standard design and industrial production of multiple parts of the house, standardization, unification and diversification of key parts are realized while quality of prefabricated components is improved, and diversified requirements of different types of houses can be met.

Owner:CHINA AEROSPACE CONSTR GROUP

Heat-insulating self-cleaning nanometer composite multifunctional glass reflecting sunlight heat and a preparing method thereof

Heat-insulating self-cleaning nanometer composite glass reflecting sunlight heat is disclosed. The composite glass includes one or more base glass layers. The surface of at least one base glass layer is provided with a sunlight-heat-reflecting heat-insulating nanometer coating. The surface of at least one base glass layer has a self-cleaning nanometer coating. The sunlight-heat-reflecting heat-insulating nanometer coating comprises 25-30% of nanometer titanium dioxide (TiO2), 15-18% of nanometer silica (SiO2), 5-10% of nanometer antimony tin oxide (ATO) and 5-10% of fluororesin. The self-cleaning nanometer coating comprises 20-25% of nanometer titanium dioxide (TiO2), 10-15% of waterborne fluororesin, 10-15% of nanometer silica (SiO2), 5-8% of nanometer zinc oxide (ZnO) and 5-8% of nanometer antimony tin oxide (ATO). The composite glass has excellent performance, high transmission of light in the visible light zone, and excellent reflection barrier properties for infrared light and ultraviolet, and can achieve effects of heat insulation in summer and heat preservation in winter.

Owner:邓才松

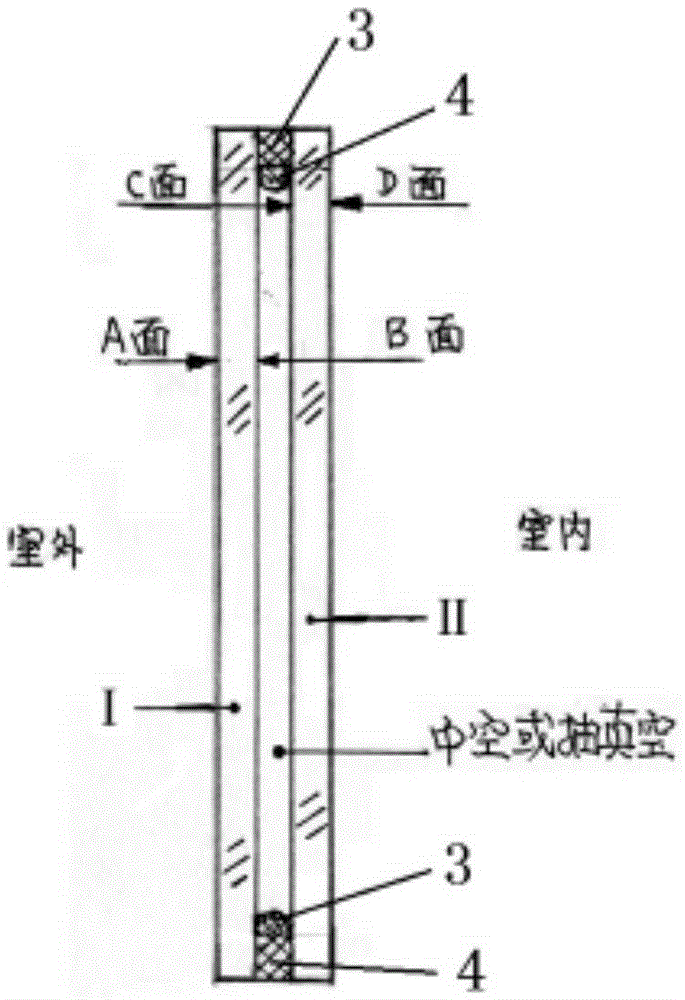

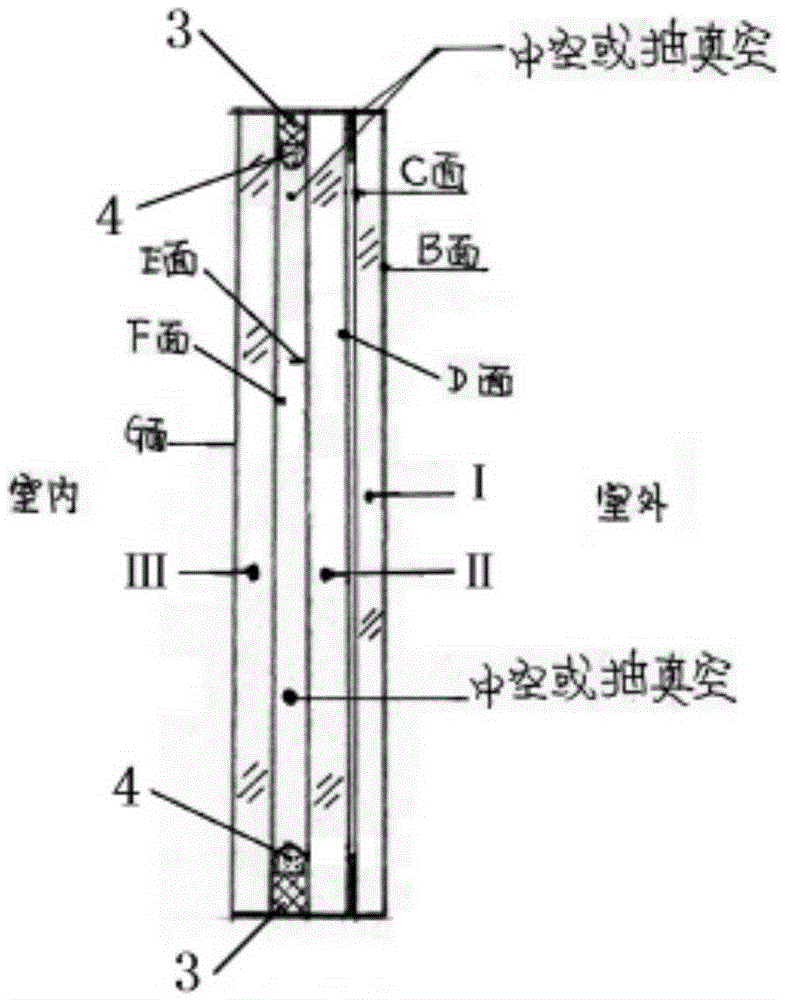

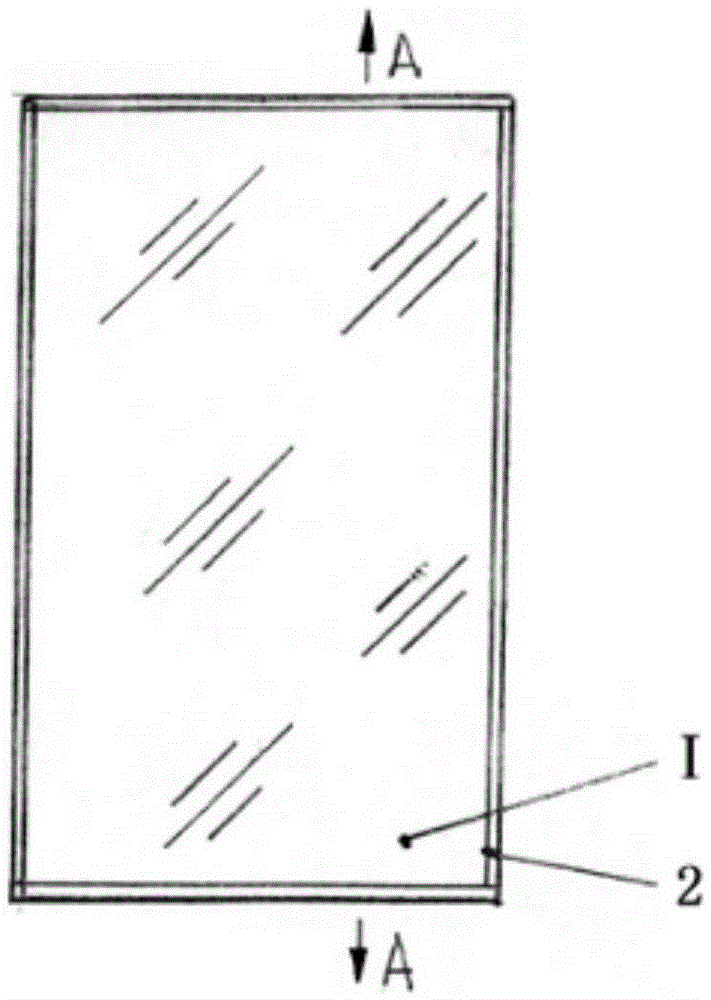

Film-damping sound insulation and heat insulation glass window

InactiveCN105863455ALow costReduce manufacturing costSealing arrangementsUnits with parallel planesAdhesiveEngineering

The invention discloses a thin-film damping sound-insulation and heat-insulation glass window, which comprises a glass assembly main body and a frame; the glass assembly main body includes inner toughened glass, outer toughened glass, and a damping film; the damping film is located between the inner toughened glass and the outer toughened glass The sound and heat insulation effect is achieved through good sealing; while the frame is hollow and filled with damping and sound-insulating filling glue. Especially obvious. The glass window of the present invention has the advantages of good sound insulation and heat insulation effect, simple structure, and reduced material cost and manufacturing cost. Meanwhile, the thickness of the overall structure can also be made thinner, which is favorable for popularization and use.

Owner:王文举

Novel sound absorbing and insulating and heat insulating material and application thereof

InactiveCN101693415AGood sound and heat insulationMeet the requirements of "three defenses"Thermal insulationLayered productsEngineeringSilicon rubber

The invention discloses a novel sound absorbing and insulating and heat insulating material which can be formed by sound absorbing and insulating cotton felt and can be also compounded by the sound absorbing and insulating cotton felt and an elastic sponge body through damp compound viscose. The sound absorbing and insulating cotton felt is made of interposition aramid fiber 1313; the elastic sponge body is a silicon rubber sheet with the thickness of 0.2-0.3 mm; and the hydrophobic property of the sound absorbing and insulating and heat insulating material is 95 percent. The novel sound absorbing and insulating and heat insulating material is environment friendly and incombustible, has no pollution, long using time and good hydrophobic property, can resist high temperature and can be used as the sound absorbing and insulating and heat insulating material for aerospace vehicles and various vehicle wall plates and acoustic decoration material for halls and stadiums.

Owner:NANJING CHANGRONG ACOUSTIC INC

Honeycomb core board

ActiveCN103112203AHigh strength to weight ratioImprove fastnessGlass/slag layered productsGlass fiberHoneycomb

The invention relates to a honeycomb core board used for replacing blockboards and the like, mainly aiming to solve the problems that the present blockboards and the like have low strength and low weight ratios. The honeycomb core board comprises upper and lower panel layers and a honeycomb core layer and is characterized in that the upper and lower panel layers and the honeycomb core layer are prepared with glass fibers and jute fibers as raw materials; a preparation method of the honeycomb core board comprises the following steps of: preparing coiled materials or sheets from the glass fibers and the jute fibers in a weight ratio of 30-70%:70-30% by adopting an air laying method and preparing the upper and lower panel layers from the panels pressed at 180-200 DEG C; and putting the coiled materials or the sheets into a honeycomb core shaped die to be pressed at 180-200 DEG C to prepare the honeycomb core layer, adhering the upper and lower panel layers to the upper and lower surfaces of the honeycomb core layer and pressing the three layers to prepare the honeycomb core board; cylinders or prisms are arranged on a lower plate of the honeycomb core shaped die and under an upper plate; and the upper and lower panel layers can be also prepared from polymer boards, plywood or nonwovens and the like. The honeycomb core board has the advantages of high strength and high weight ratio.

Owner:辽宁艺朦织旺地毯有限公司

Non-woven fabric applied to automobile interior parts

InactiveCN102425036AImprove breathabilityEasy compoundLayered productsSevering textilesNonwoven fabricCivil engineering

The invention relates to a non-woven fabric, in particular to the non-woven fabric applied to automobile interior parts. According to the non-woven fabric for the automobile interior parts, through holes which are uniformly distributed are molded on the non-woven fabric; and the radiuses of the through holes are between 0.5 and 2mm, and the distances between the circle tangent sides of any two adjacent through holes are between 2 and 6mm. The through holes are molded on the non-woven fabric and have an effect of accommodating sound and heat. Thus, the non-woven fabric with the molded through holes has better sound insulation effects and heat insulation effects and higher air permeability.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

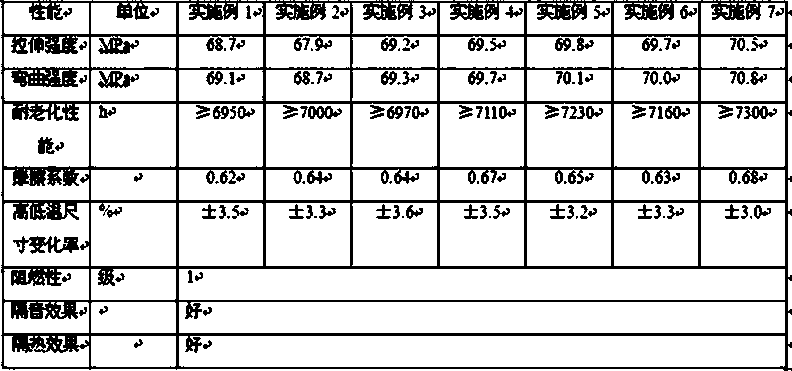

Straw-fiber-reinforced polyester tile and manufacturing method thereof

InactiveCN102951870AEfficient use ofGood sound and heat insulationSolid waste managementFiberEcological environment

The invention discloses a straw-fiber-reinforced polyester tile and a manufacturing method thereof. The manufacturing method comprises the following steps: evenly stirring and mixing straw fiber, metaphenylene polyester resin, mica powder, wollastonite powder and other raw materials according to a certain formula, and carrying out hot compacting. The straw-fiber-reinforced polyester tile has the characteristics of sound insulation, heat insulation and long service life in the colored steel tile and synthetic resin tile which are commonly used at present, can effectively utilize the straw resources, is beneficial to protecting the ecological environment, and lowers the production cost and use cost.

Owner:北京传树建材科技集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com