Air-permeable interior trim composite board material for ceiling of automobile

A composite sheet and canopy technology, applied in the field of automobile interior decoration, can solve the problems of poor sound insulation and heat insulation, poor ventilation effect, poor toughness of PU board, etc., to achieve good air permeability and strength, ensure air permeability, and improve The effect of sound insulation and heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

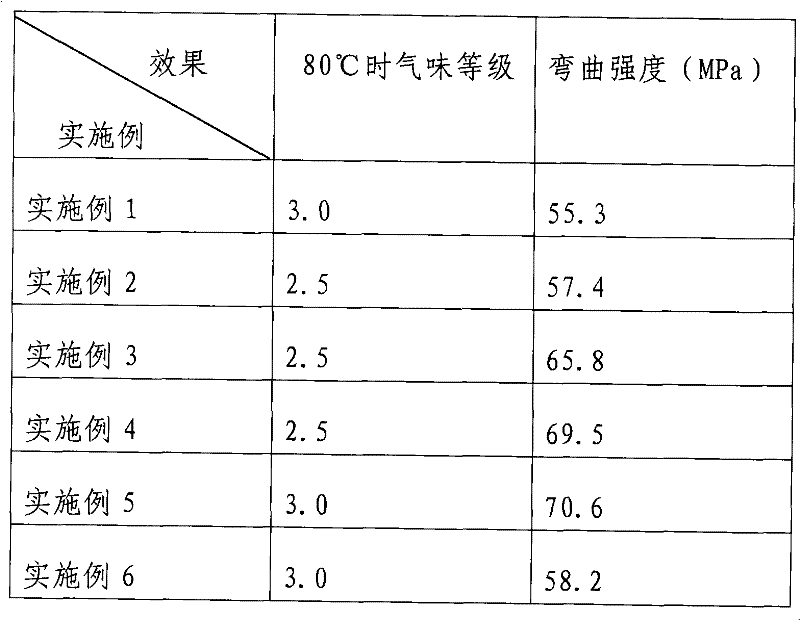

Embodiment 1

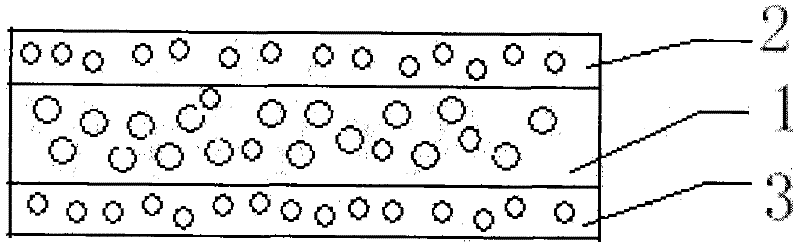

[0031] A breathable automobile headliner interior composite plate, comprising a middle foam layer 1, the upper surface and the lower surface of the middle foam layer 1 are respectively connected with the upper surface layer 2 with through holes and the lower surface layer with through holes 3 composite, the through holes are evenly distributed on the upper surface layer 2 and the lower surface layer 3 respectively, the radius of the through holes is 0.5mm, and the distance between the parallel tangents of two adjacent through holes is 2mm, In this embodiment, the material used in the middle foam layer 1 is polyurethane fiber, and the thickness of the middle foam layer 1 is 4 mm; the upper surface layer 2 and the lower surface layer 3 are respectively non-woven fabric layers, The content of the hemp fiber in each described non-woven fabric layer is 20% by weight percentage, and the gram weights of the upper surface layer 2 and the lower surface layer 3 are respectively 50g / m 2 ...

Embodiment 2

[0033] A breathable automobile headliner interior composite plate, comprising a middle foam layer 1, the upper surface and the lower surface of the middle foam layer 1 are respectively connected with the upper surface layer 2 with through holes and the lower surface layer with through holes 3 composite, the through holes are evenly distributed on the upper surface layer 2 and the lower surface layer 3 respectively, the radius of the through holes is 2 mm, and the distance between the parallel tangents of two adjacent through holes is 6 mm. In this embodiment, the material used in the middle foam layer 1 is polypropylene fiber, and the thickness of the middle foam layer 1 is 15mm; the upper surface layer 2 and the lower surface layer 3 are respectively non-woven fabric layers, The content of the hemp fiber in each said non-woven fabric layer is 90% by weight percentage, and the grammage of said upper surface layer 2 and said lower surface layer 3 is respectively 300g / m 2 .

Embodiment 3

[0035] A breathable automobile headliner interior composite plate, comprising a middle foam layer 1, the upper surface and the lower surface of the middle foam layer 1 are respectively connected with the upper surface layer 2 with through holes and the lower surface layer with through holes 3 composite, the through holes are evenly distributed on the upper surface layer 2 and the lower surface layer 3 respectively, the radius of the through holes is 1mm, and the distance between the parallel tangents of two adjacent through holes is 4mm. In this embodiment, the material used in the middle foam layer 1 is polypropylene fiber, and the thickness of the middle foam layer 1 is 6 mm; the upper surface layer 2 and the lower surface layer 3 are respectively non-woven fabric layers, The content of the hemp fiber in each described non-woven fabric layer is 60% by weight percentage, and the gram weights of the upper surface layer 2 and the lower surface layer 3 are respectively 100g / m 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com