Polypropylene with high melt strength and preparation method thereof

A technology of high melt strength and polypropylene, applied in the field of plastics, can solve the problems of easy generation of cross-linked structure and high price, and achieve the effects of easy degradation, strong energy absorption capacity and excellent environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

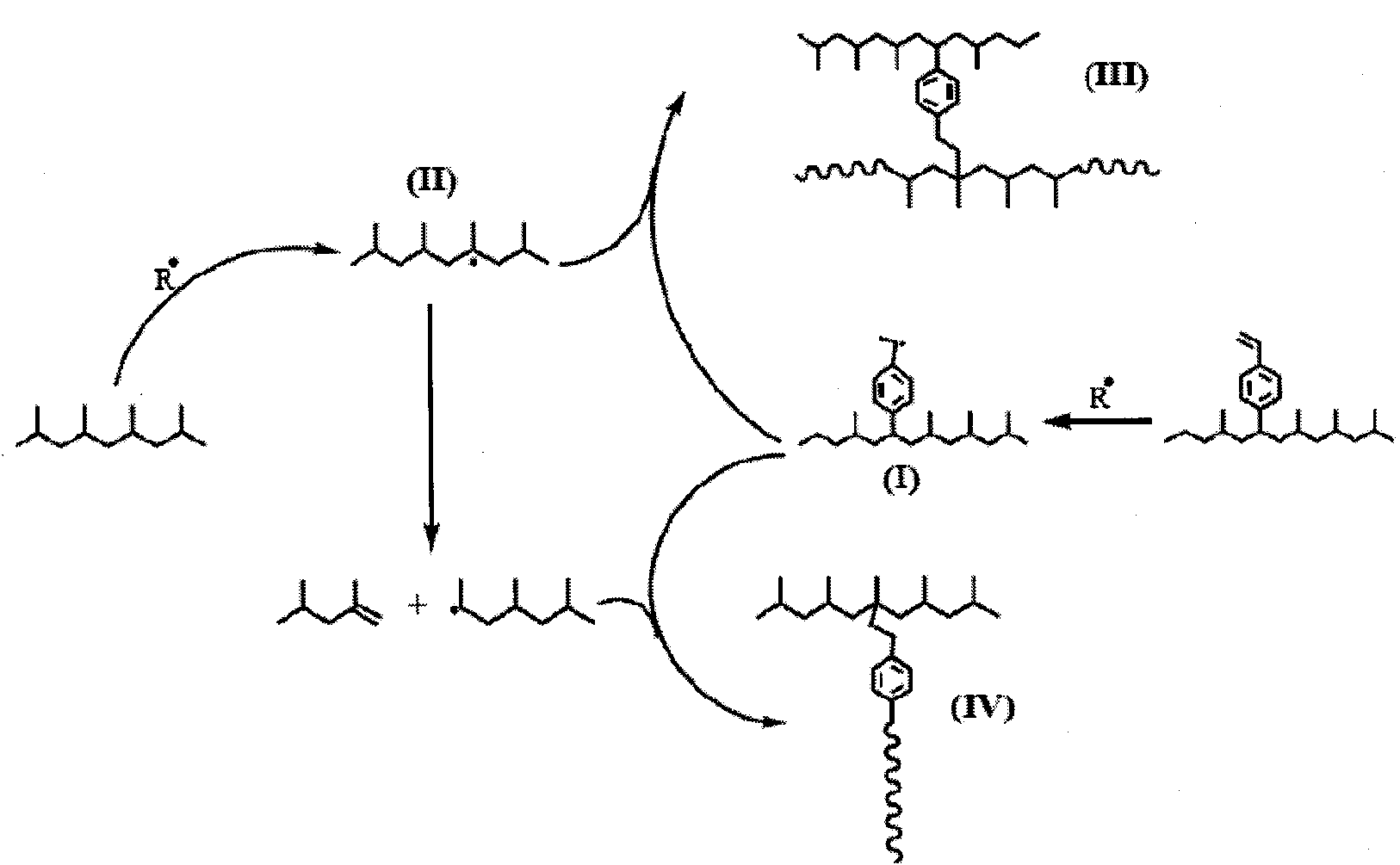

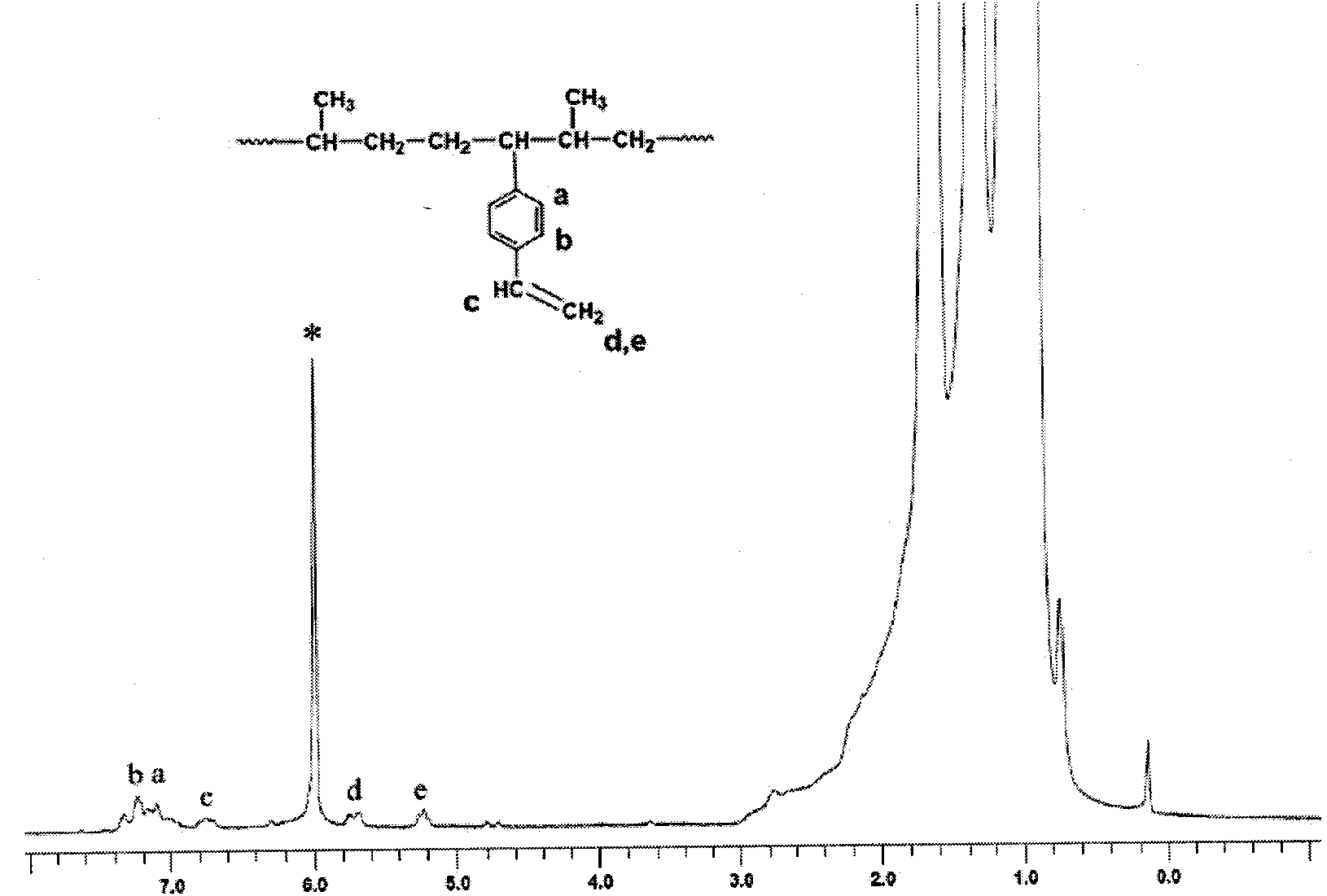

Method used

Image

Examples

Embodiment 1

[0039] Vacuumize the dry 250 ml three-necked flask, replace it with argon three times, and replace it with propylene twice. Heat the oil bath to the reaction temperature, add an appropriate amount of heptane, dimethoxydiphenylsilane, 1,4-divinylbenzene and the required amount of cocatalyst triethylaluminum, start stirring, and use a solenoid valve to control the system The pressure of propylene is maintained at 1.03×10 5 Pa, followed by the addition of the required amount of catalyst to start the polymerization of propylene. After 30 min, the propylene valve was closed, and the reaction was terminated with 10% hydrochloric acid ethanol solution. Wash with ethanol, filter, and vacuum-dry at 60°C until constant weight.

[0040] Raw material components: component (A) is 100 parts of homopolypropylene, produced by Daqing Petrochemical Company, the brand is T30S; component (B) is 5 parts of reactive polypropylene intermediate PP-co-DVB obtained by the above reaction; Component (...

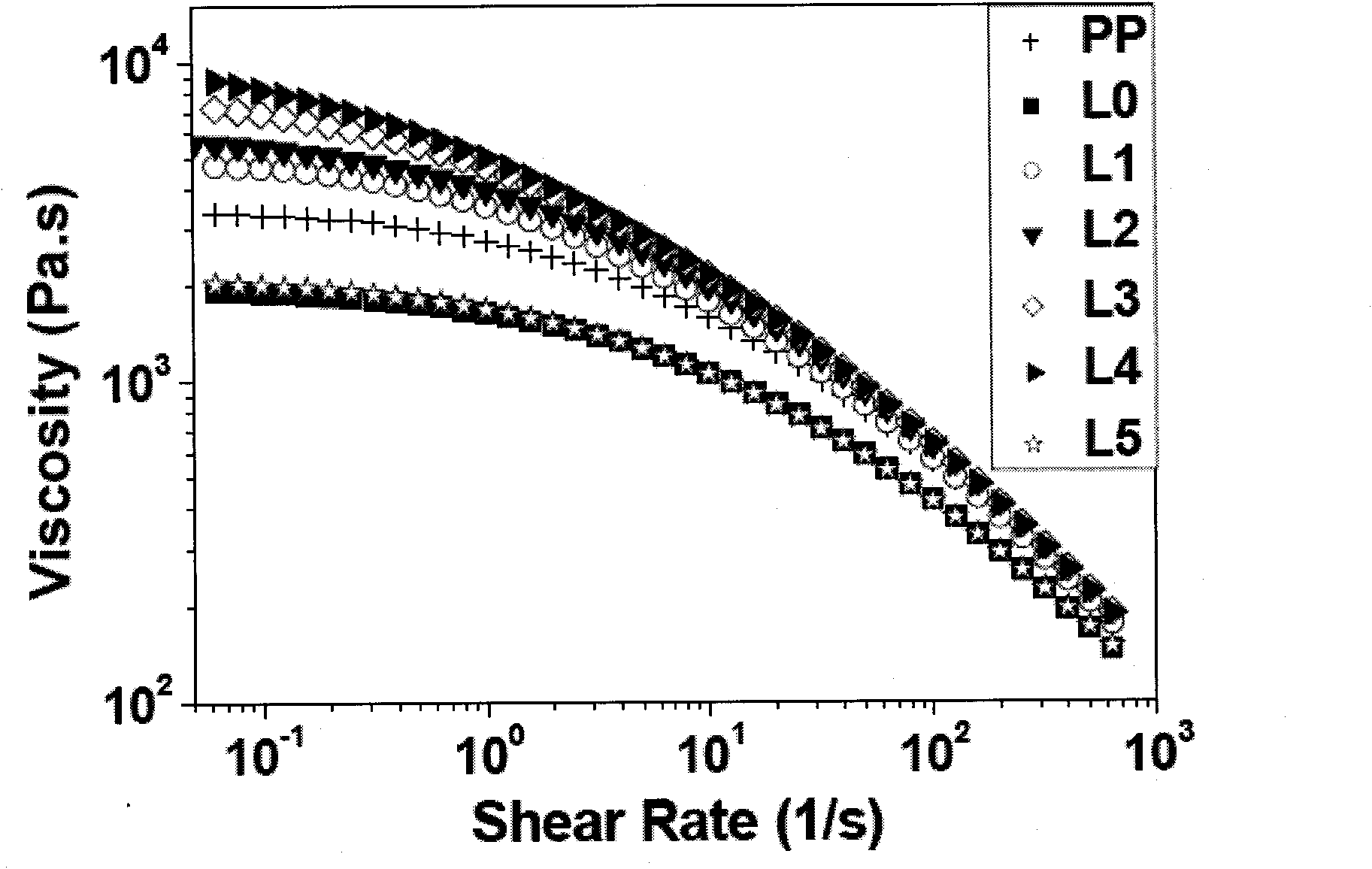

Embodiment 2

[0045] Except that the number of parts of component B was changed to 10 parts, other composition and preparation process were the same as in Example 1, and the obtained product was marked as L2.

Embodiment 3

[0048] Except that the number of parts of component B was changed to 15 parts, other composition and preparation process were the same as in Example 1, and the obtained product was marked as L3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com