Heat-insulating self-cleaning nanometer composite multifunctional glass reflecting sunlight heat and a preparing method thereof

A nano-composite, heat-insulating nano-coating technology, which is applied in the field of self-cleaning nano-composite multifunctional glass (products) that reflects sunlight, heat insulation, and can solve problems such as poor heat insulation ability, lack of heat insulation and cooling ability, and difficult cleaning and treatment. It achieves the effects of strong thermal insulation properties, improved thermal insulation/self-cleaning performance, and reduced thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

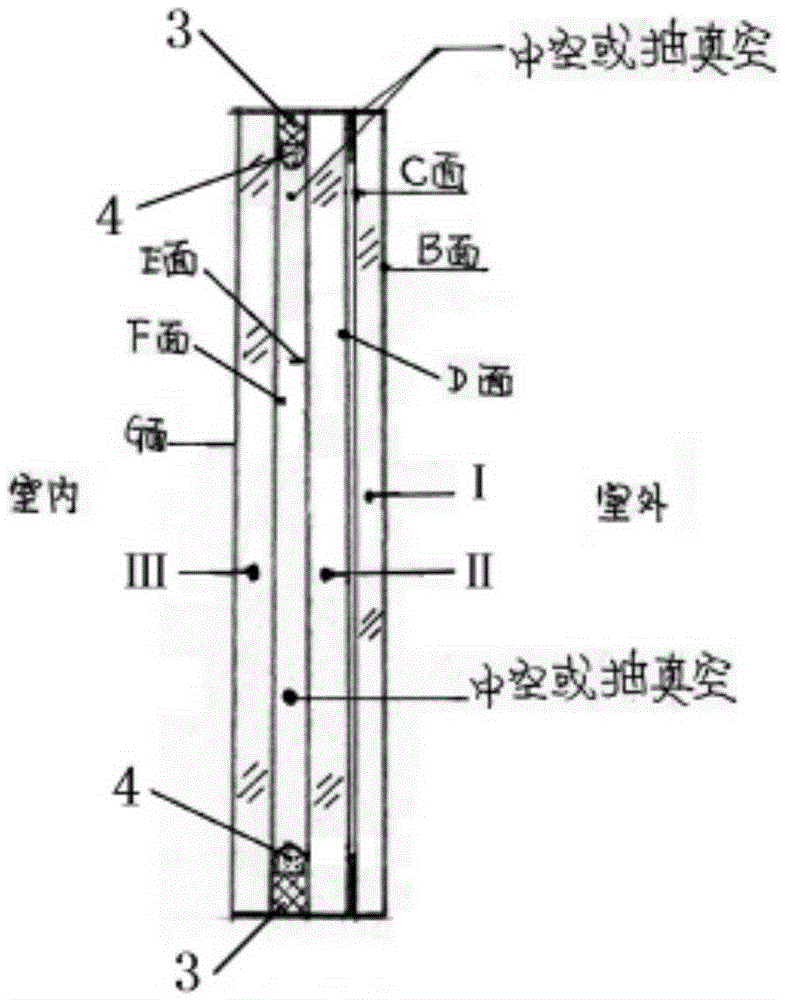

[0065] Further, the present invention also provides a method for preparing the above-mentioned heat-insulating self-cleaning nano-composite glass with a double-layer hollow structure, comprising the following steps:

[0066] (1) Select two pieces of transparent glass, preferably two pieces of transparent tempered glass, and evenly spray nanometer self-cleaning composite coating on the surface of the first piece of glass, with a coating thickness of 10 μm to 15 μm.

[0067] (2) Wipe the surface of the second piece of glass clean, keep its inner surface (the surface near the indoor side) as it is, and spray nanometer self-cleaning paint on the outer surface of the tempered glass (the surface near the outdoor side), with a thickness of 10 μm ~15 μm. Transparent tempered glass has good strength, is not easy to break, and has better stability and reliability. The surface of the transparent tempered glass sprayed with self-cleaning nano-composite paint can be the outer surface of t...

Embodiment 1

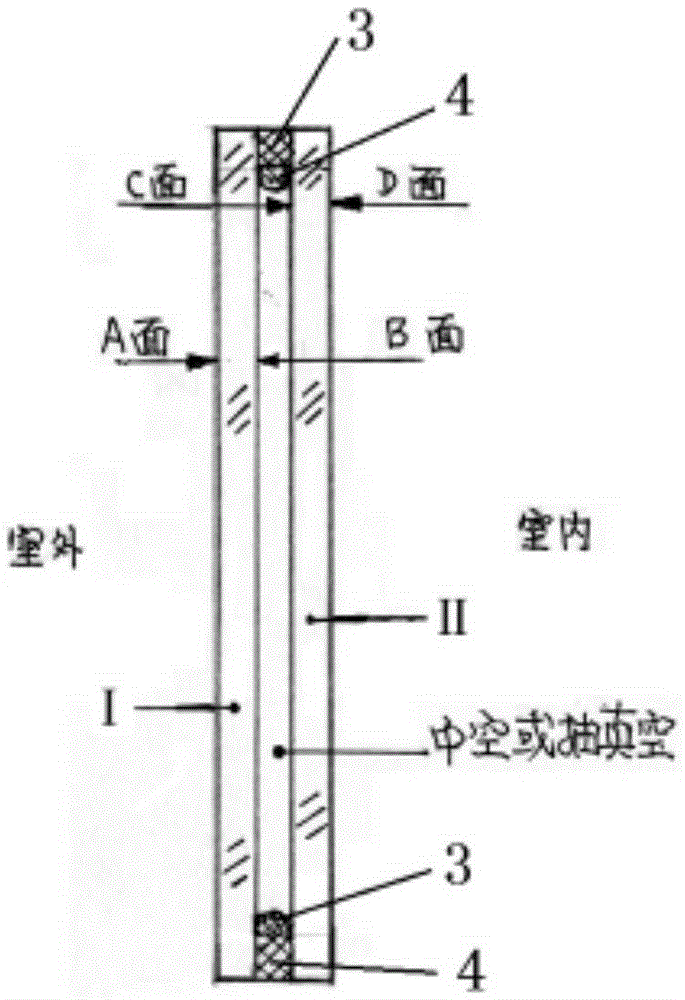

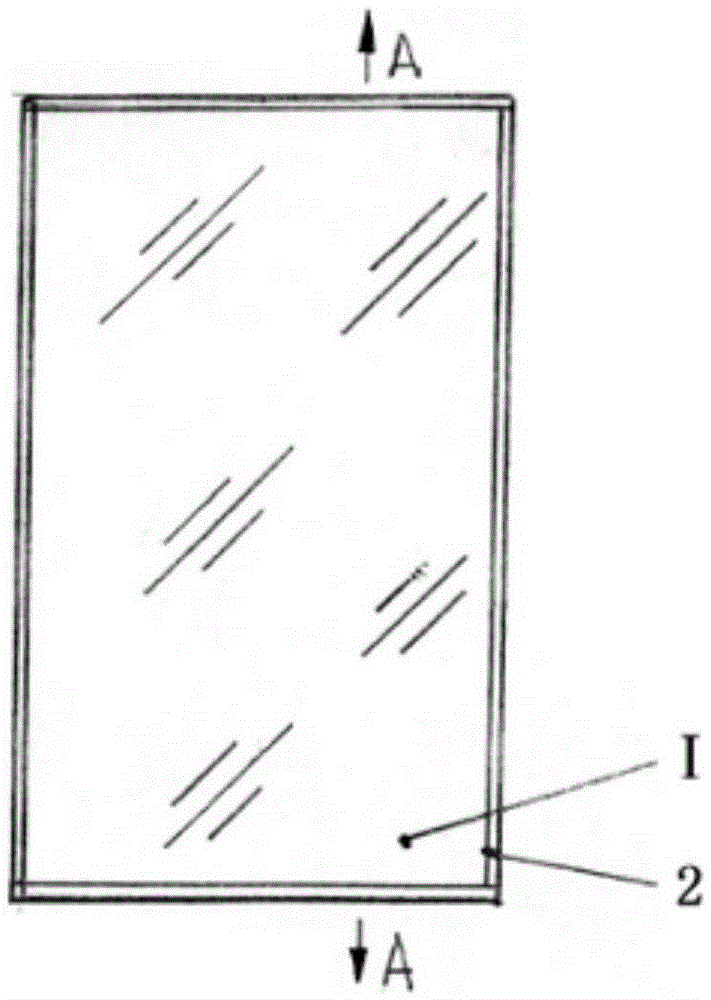

[0077] Heat-insulating self-cleaning nano-composite glass has two layers of basic glass, which are combined into two layers of insulating glass through spacers. The outer surface of the glass on the indoor side (closer to the indoor side) has a nano-coating for reflecting sunlight and heat insulation (also called a heat-insulating nano-coating or a nano-insulation layer). The composition of the nano heat insulation layer is: nano titanium dioxide (TiO 2 ) 28%, nano silicon dioxide (SiO 2) 17%, nano-antimony tin oxide (ATO) 8%, fluororesin 7%, and the rest is glue polymer material for curing. Among them, the outer surface of the glass on the outdoor side (the side close to the outdoor) has a self-cleaning nano-coating (also called a nano-self-cleaning layer). The composition of the nano self-cleaning layer contains: nano titanium dioxide (TiO 2 ) 22%, water-based fluororesin 12%, nano silicon dioxide (SiO 2 ) 13%, nano zinc oxide (ZnO) 7%, nano antimony tin oxide (ATO) 5%. ...

Embodiment 2

[0079] The heat-insulating self-cleaning nano-composite glass similar to Example 1 has only one layer of basic glass, and the glass surface on the indoor side (the side close to the indoor) has a nano-insulation layer. The composition of the nano heat insulation layer is: nano titanium dioxide (TiO 2 ) 25%, nano silicon dioxide (SiO 2 ) 18%, nano-antimony tin oxide (ATO) 9%, nano-fluorine resin 6%, and the rest is the adhesive polymer material for curing. The glass surface on the outdoor side has a nanometer self-cleaning layer. The composition of the nano self-cleaning layer contains: nano titanium dioxide (TiO 2 ) 24%, water-based fluororesin 13%, nano silicon dioxide (SiO 2 ) 11%, nano zinc oxide (ZnO) 6%, nano antimony tin oxide (ATO) 7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com