Film-damping sound insulation and heat insulation glass window

A glass window and damping technology, which is applied in the installation of window glass, parallel glass structure, windows/doors, etc. Conducive to popularization, reduced material cost and manufacturing cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

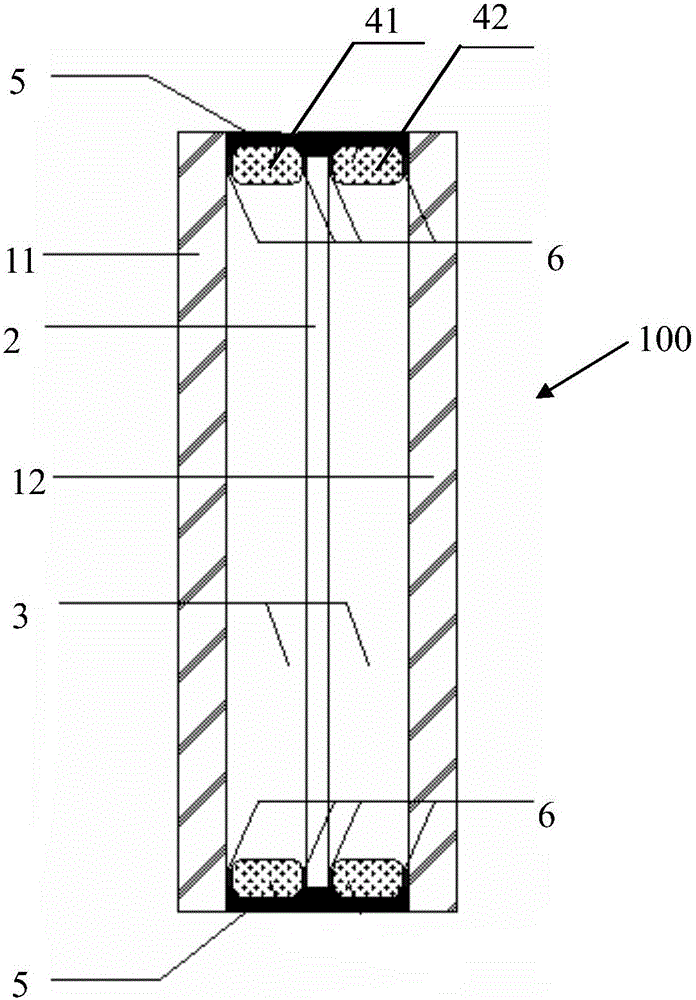

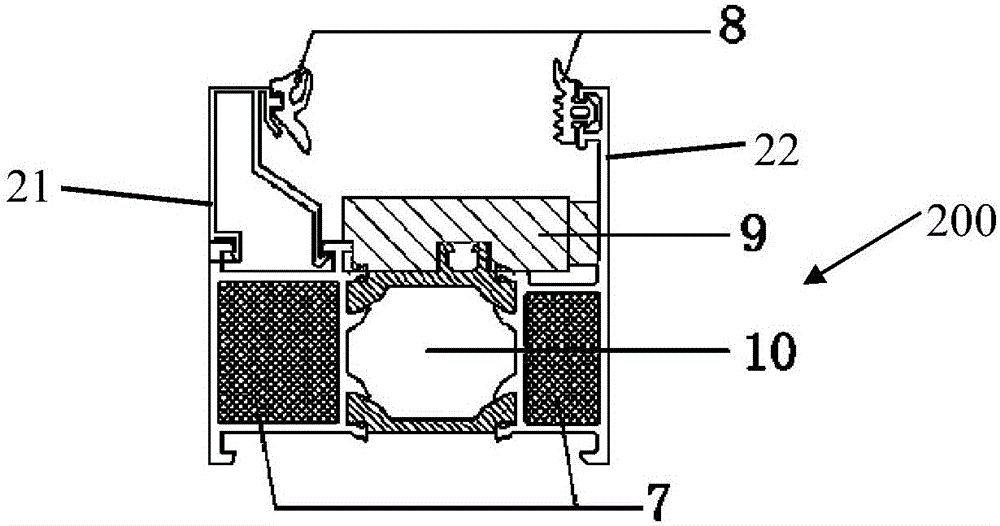

[0023] see figure 1 and figure 2 As shown, the present invention discloses a film-damping, sound-insulating and heat-insulating glass window, which includes a glass component body 100 and a frame 200 surrounding the glass component 100 and fixedly carrying the glass component 100 . The glass assembly main body 100 includes an inner tempered glass 11 , an outer tempered glass 12 , and a damping film 2 . The damping film 2 is located between the inner toughened glass 11 and the outer toughened glass 12 . Both the thickness of the inner toughened glass 11 and the outer toughened glass 12 are 5 mm. The thickness of the damping film 2 is 1 mm. A 6mm interlayer 3 is formed between the damping film 2 and the inner and outer tempered glass 11. The 6mm interlayer 3 is isolated by a 6mm aluminum frame bar, and the aluminum frame bar is filled with a molecular desiccant to ensure the drying of the gas in the cavity . Wherein the aluminum spacer includes an inner spacer 41 and an ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com