Environmental-friendly lead-free PVC ceiling sheet and manufacturing method and applications thereof

A technology of ceiling and PVC resin, which is applied in the direction of building construction, construction, covering/lining, etc., to achieve the effect of easy splicing, good sound insulation and heat insulation, and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

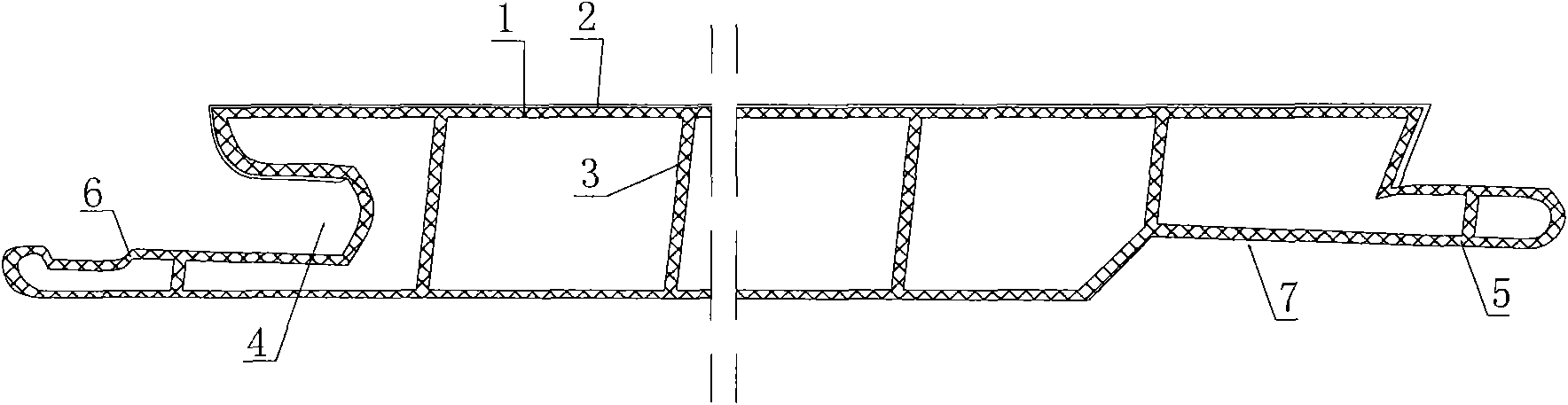

Image

Examples

Embodiment 1

[0042] The raw material components of environmentally friendly lead-free PVC ceiling panels are as follows:

[0043] 70 parts of PVC resin SG-5, 20 parts of nanometer calcium carbonate;

[0044] 4 parts of calcium zinc stabilizer 1.5 parts of rutile titanium dioxide;

[0045] CPE impact modifier 1.5 parts ACR enhancer 2 parts;

[0046] 0.3 part of stearic acid 0.4 part of calcium stearate;

[0047] 0.3 parts of PE wax.

[0048] The production method of above-mentioned environment-friendly lead-free PVC ceiling plate, this method comprises the following steps:

[0049] ① Nano-calcium carbonate, calcium-zinc stabilizer, rutile titanium dioxide, CPE impact modifier, ACR enhancer, stearic acid, calcium stearate and PE wax are put into a hot pot for pre-mixing;

[0050]②When the temperature is 75°C, put in PVC resin SG-5 for blending, when the temperature is 118°C, put the material into the cold pot, and cool to the temperature of 45°C;

[0051] ③Unload the material until extr...

Embodiment 2

[0057] The raw material components of environmentally friendly lead-free PVC ceiling panels are as follows:

[0058] 90 parts of PVC resin SG-5, 35 parts of nanometer calcium carbonate;

[0059] Calcium zinc stabilizer 7.5 parts rutile titanium dioxide 2.5 parts;

[0060] CPE impact modifier 2.8 parts ACR enhancer 1.5 parts;

[0061] 0.4 part of stearic acid 0.45 part of calcium stearate;

[0062] 0.32 parts of PE wax.

[0063] The manufacturing method of the above-mentioned environmentally friendly lead-free PVC ceiling board is as described in Example 1.

Embodiment 3

[0065] The raw material components of environmentally friendly lead-free PVC ceiling panels are as follows:

[0066] 50 parts of PVC resin SG-5, 15 parts of nanometer calcium carbonate;

[0067] 4.5 parts of calcium zinc stabilizer 1.5 parts of rutile titanium dioxide;

[0068] CPE impact modifier 1.8 parts ACR enhancer 1.8 parts;

[0069] 0.25 parts of stearic acid 0.35 parts of calcium stearate;

[0070] 0.28 parts of PE wax.

[0071] The manufacturing method of the above-mentioned environmentally friendly lead-free PVC ceiling board is as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com