Organic solderability preservative pre-soaking treating agent and organic solderability preservation film forming method

A technology of pre-preg treatment and flux protection, applied in welding equipment, arc welding equipment, electrical components, etc., can solve problems such as difficult to ensure the appearance of printed circuit boards, limited service life of bath liquid, Giavani effect, etc., and achieve guaranteed shear Cutting strength and reliability of solder joints, service life extension, effect of preventing Giavanni effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below through specific embodiments.

[0041] Using the same organic solder preservative (OSP) main solution, its composition is as follows by weight ratio:

[0042] 2-n-Heptylbenzimidazole 5.0%

[0043] Acetic acid 20%

[0044] Caproic acid 0.2%

[0045] Sodium edetate 0.8%

[0046] The pH value of the above organic solder preservative (OSP) main solution was adjusted to 3.3.

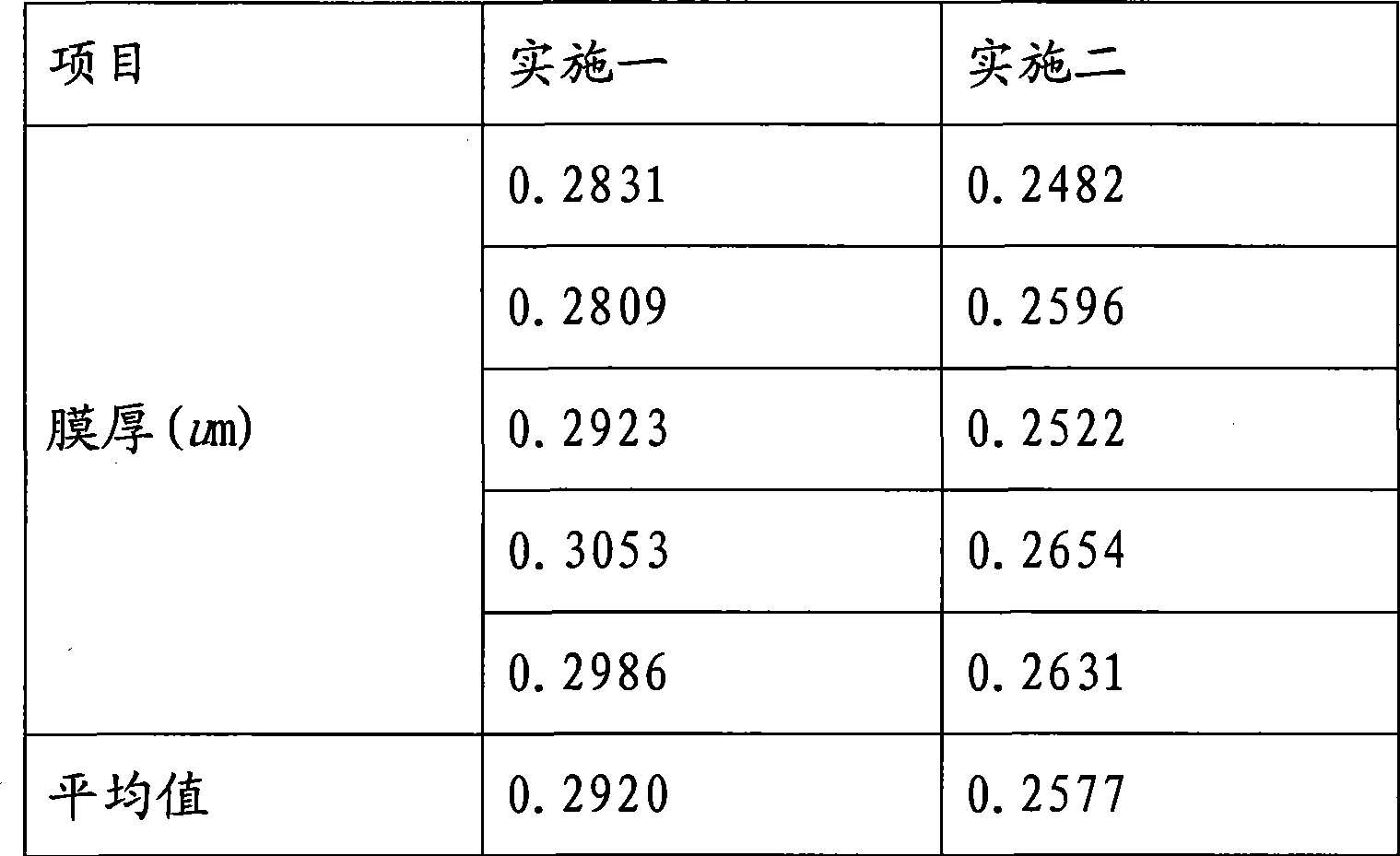

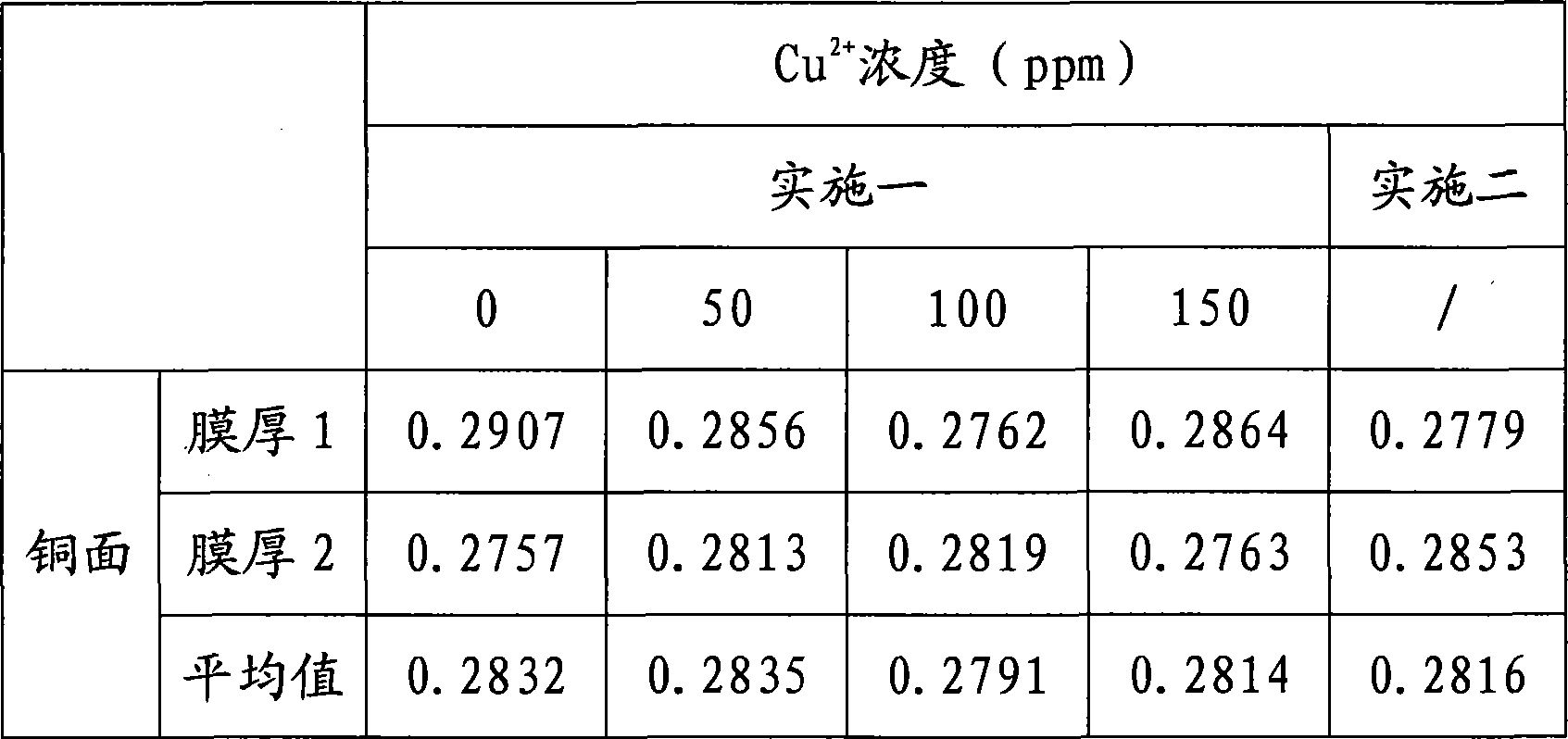

[0047] Implementation 1: Take a printed circuit board test piece with two types of soldering pads on the copper surface and the gold surface, and go through the following process of using the organic solder prepreg treatment agent.

[0048] Process Soaking time (sec) Temperature (℃)

[0049] Detergent 120 40

[0050] Washed 60 25

[0051] Microetching 60 25

[0052] Washed 60 25

[0053] Organic flux pre-dip (Pre-dip) 25 25

[0054] Washed 60 25

[0055] Organic Solder Preservative (OSP) Main Solution 60 38

[0056] Washed 60 25

[0057] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com