Patents

Literature

49results about How to "Guaranteed shear strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

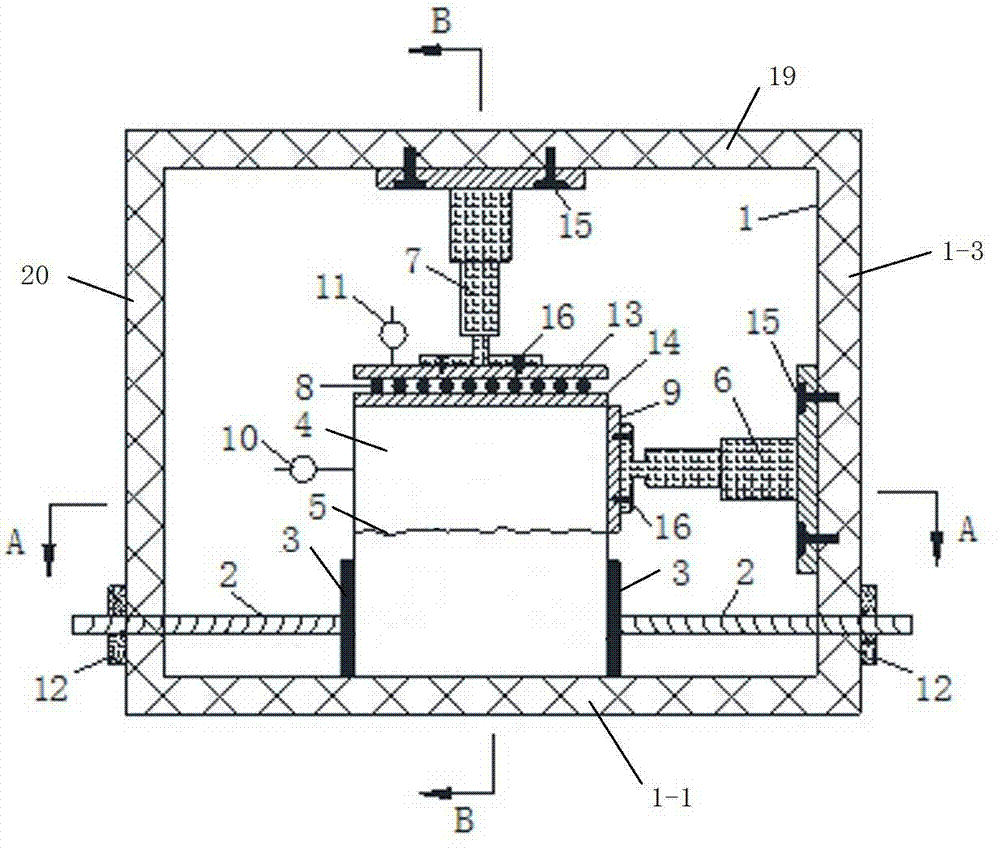

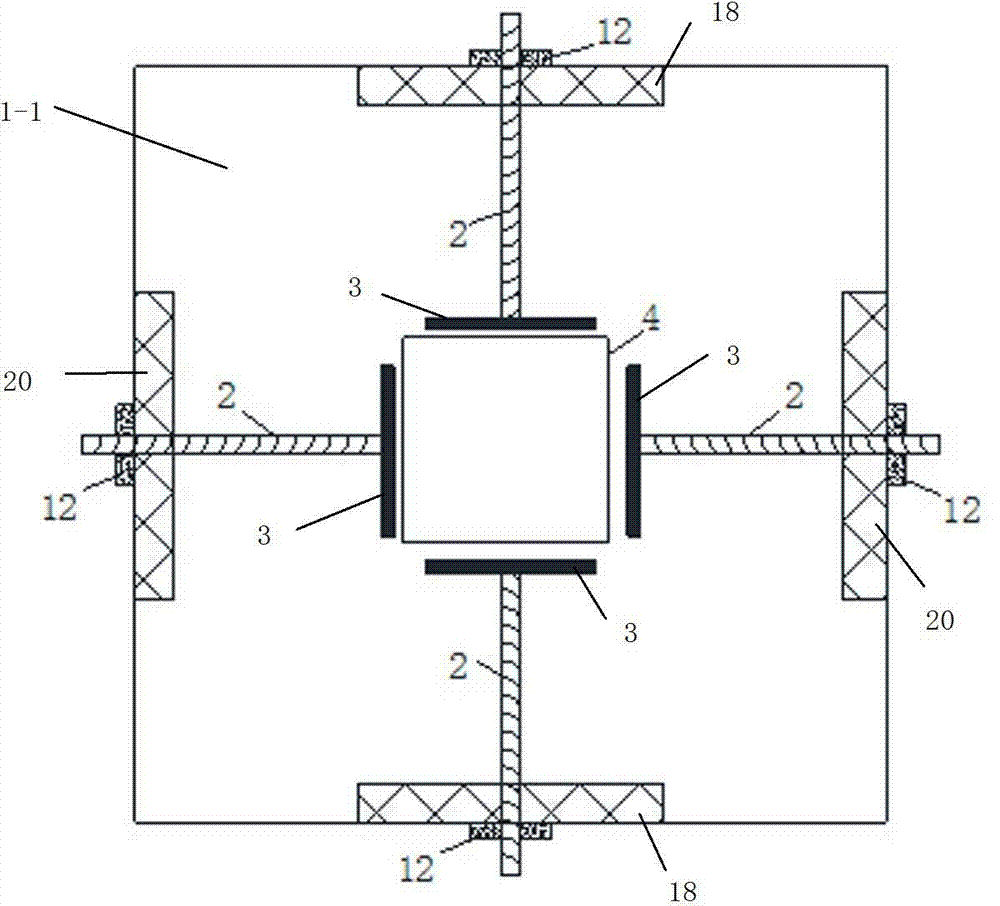

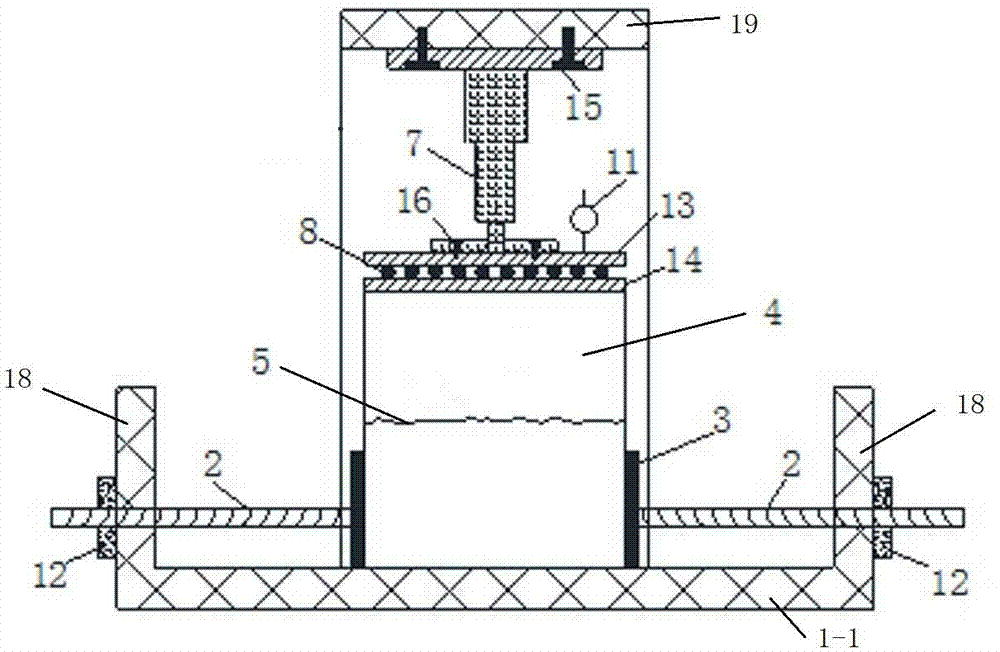

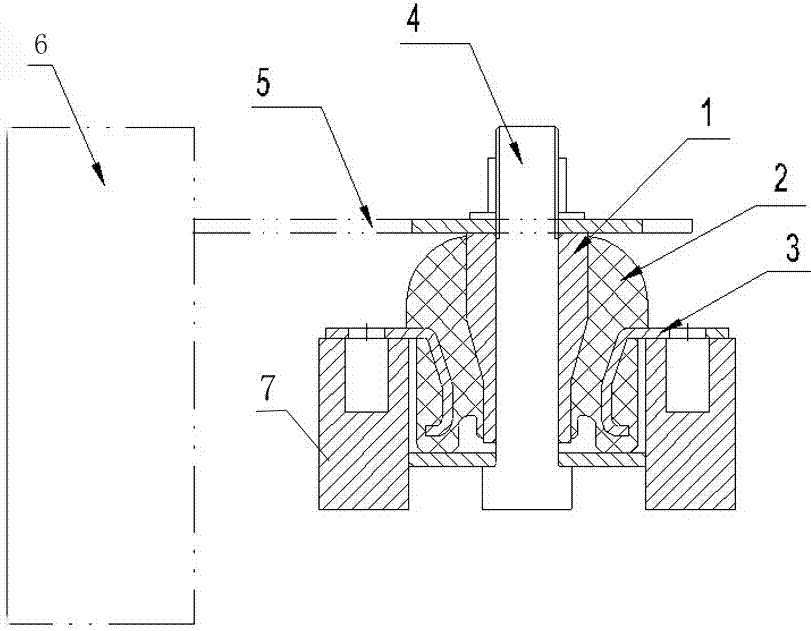

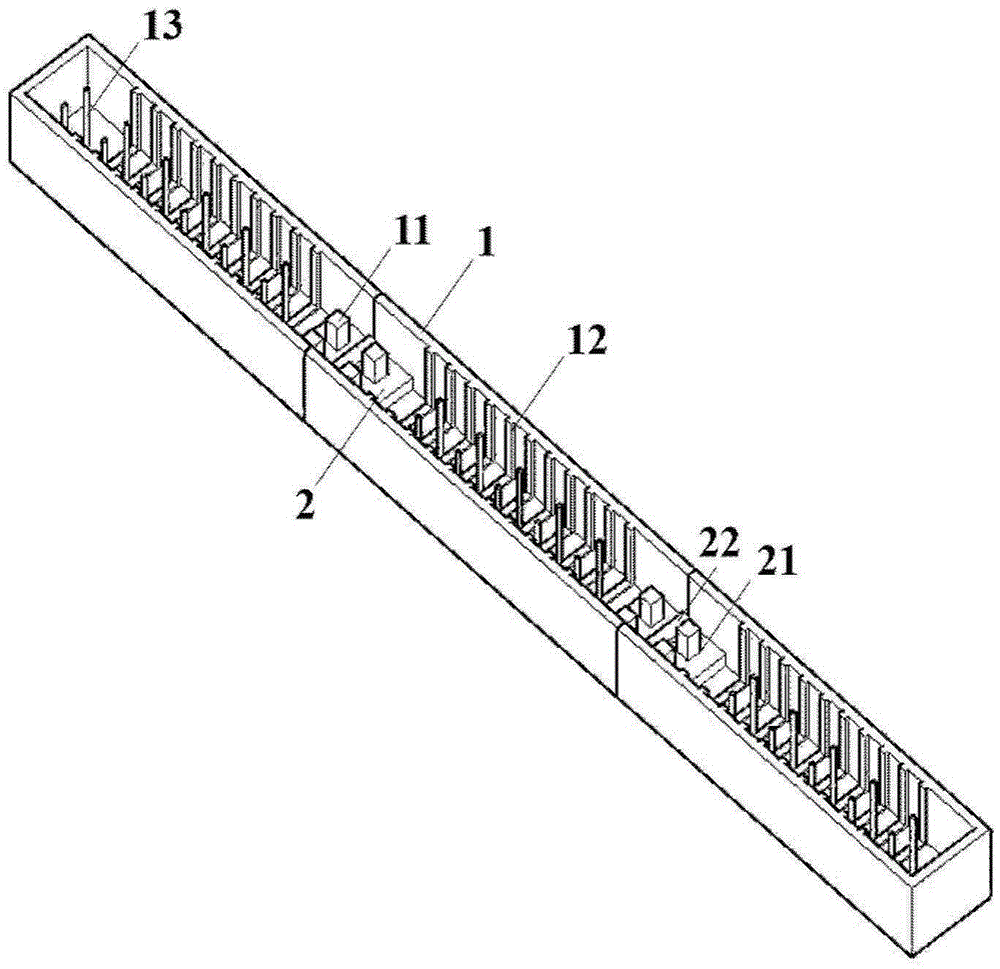

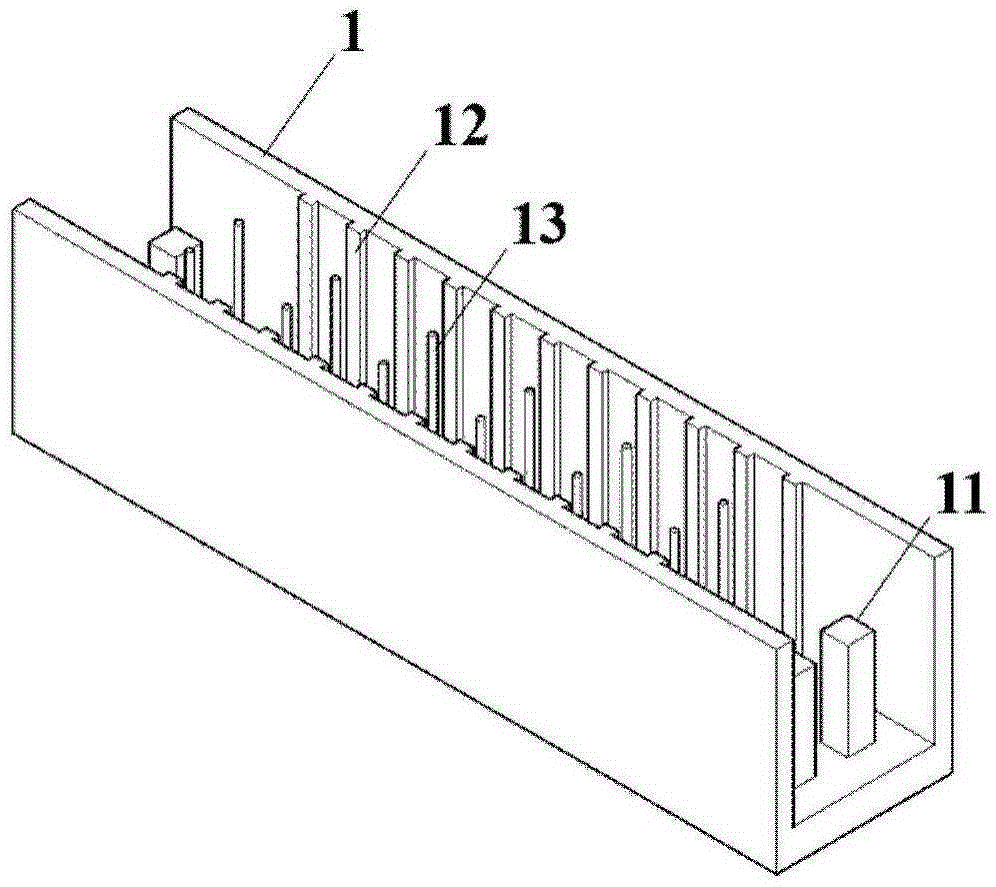

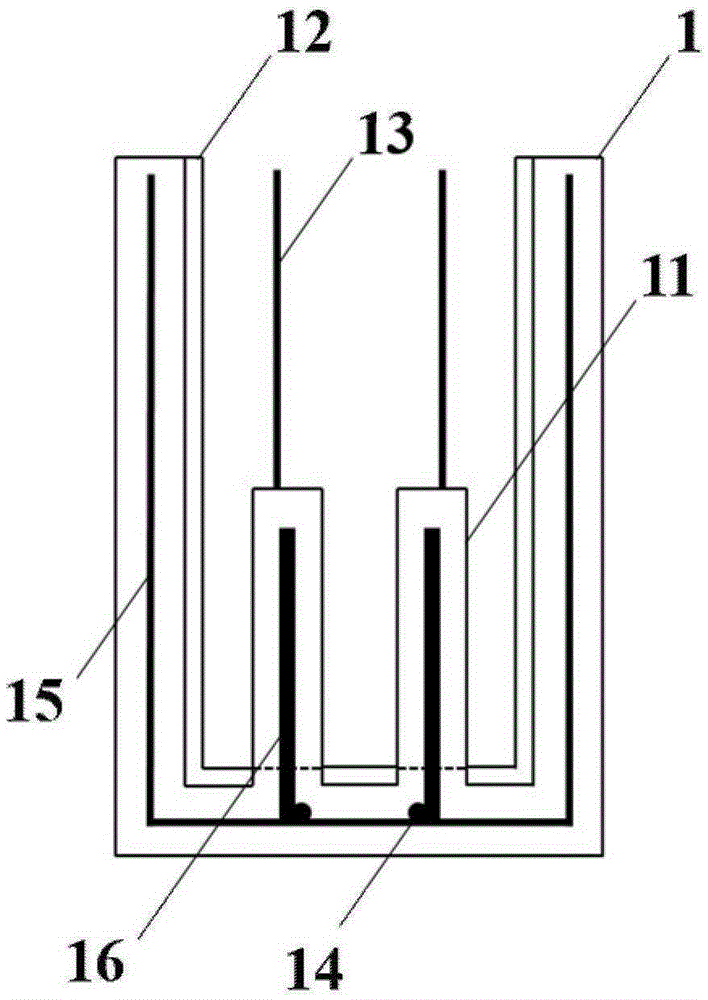

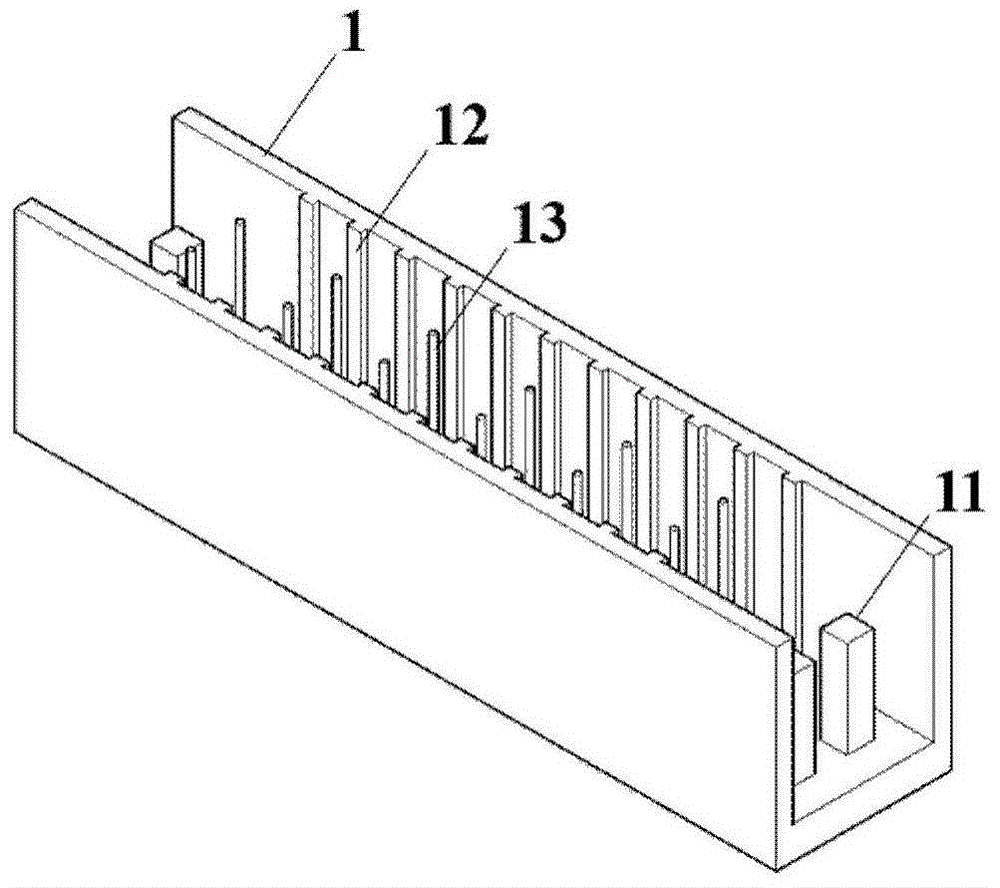

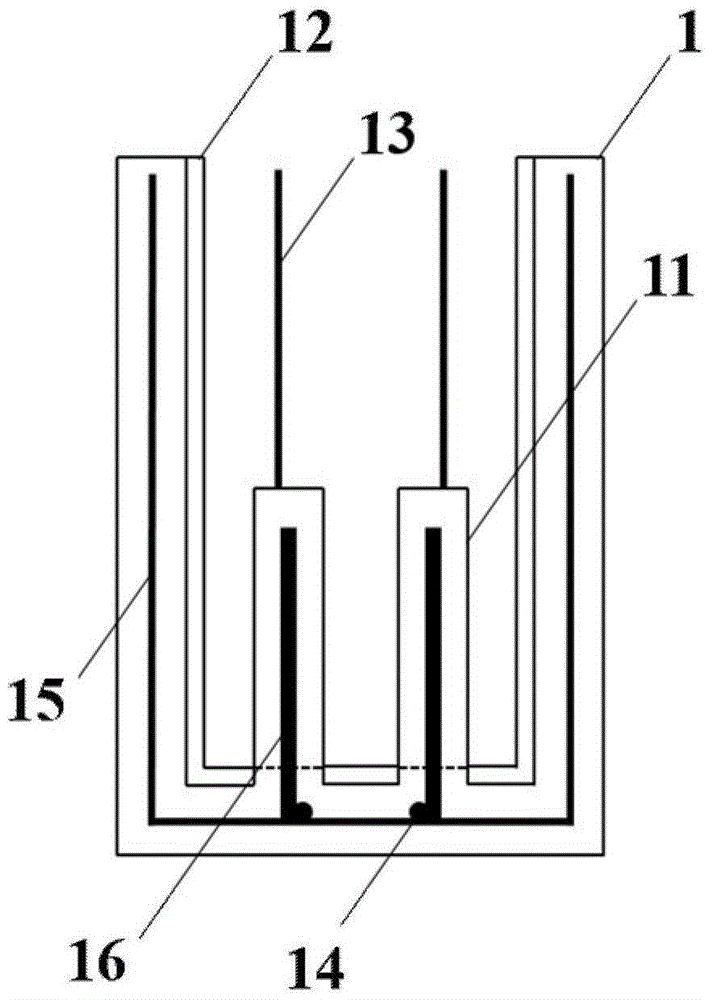

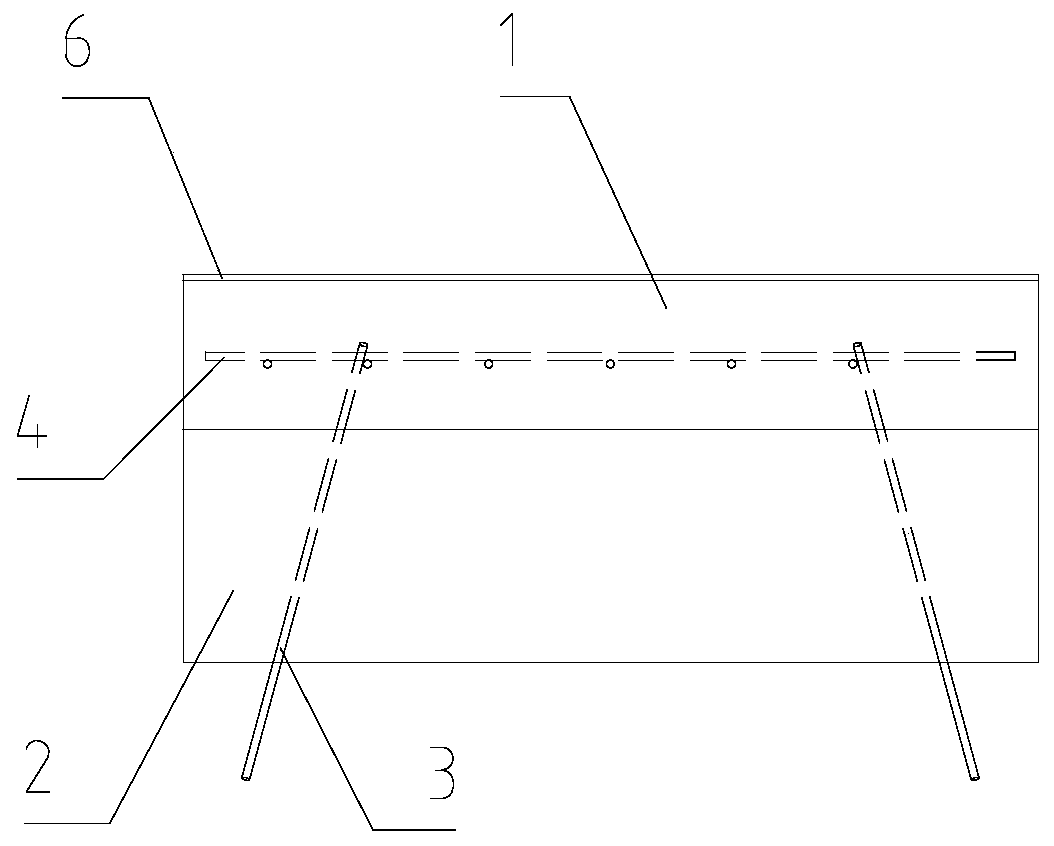

Rock mass structural surface shear test method and device

InactiveCN104749049AGuaranteed shear strengthGuaranteed StrengthMaterial strength using steady shearing forcesHorizontal axisSurface shear

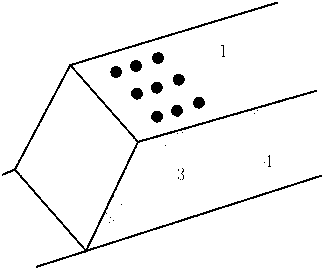

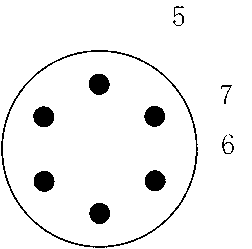

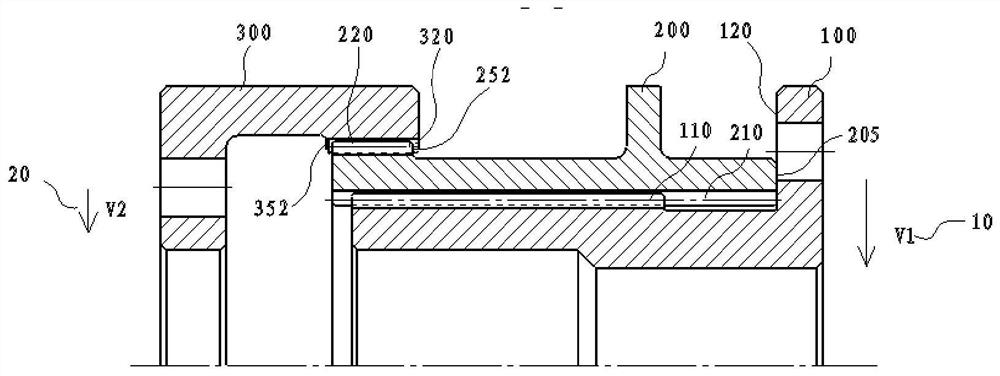

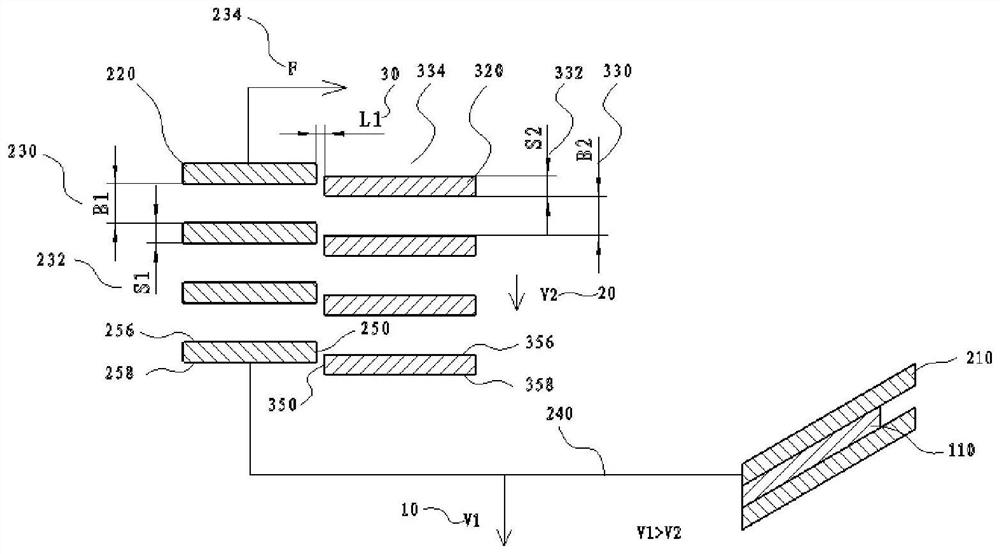

The invention discloses a rock mass structural surface shear test method, which comprises the following steps of firstly, cutting a rock mass test piece into a cuboid and marking a vertical axis line and a horizontal axis line; then adjusting an adjusting rod, fixing the rock mass test piece by a movable steel baffle, enabling the vertical axis line of the rock mass test piece to coincide with the vertical axis line of a normal loading mechanism, enabling the horizontal axis line of the rock mass test piece to coincide with the horizontal axis line of a shear loading mechanism, and enabling the structural surface of the rock mass test piece to be located above the movable steel baffle; carrying out grading force application on the rock mass test piece by the normal loading mechanism from the vertical direction, and carrying out grading force application on the rock mass test piece by the shear loading mechanism from the horizontal direction; receiving the force application data of the normal loading mechanism and the shear loading mechanism and the displacement values of a normal displacement sensor and a horizontal displacement sensor by a computer, and analyzing and calculating the data. The invention also provides a rock mass structural surface shear test device. According to the invention, the stress bearing condition of a rock mass in the reality can be simulated, and test data are accurate and reliable.

Owner:WUHAN UNIV OF TECH

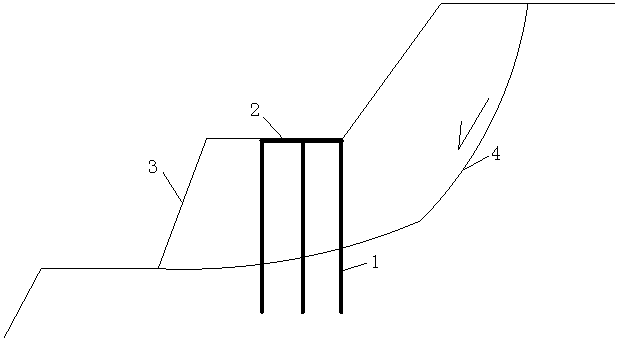

Structural design method for load-bearing section of miniature anti-slip compound pile

InactiveCN103225310AIncreased bending stiffnessReduce in quantityExcavationsBulkheads/pilesThrust bearingGeological survey

The invention discloses a structural design method for a load-bearing section of a miniature anti-slip compound pile. The method comprises the following steps: 1, performing a field geological survey, and determining mechanical properties of a geotechnical slope body through tests; 2, evaluating the stability of a slope, and calculating the residual slide thrust of the slope; 3, considering the adjustment and the distribution of the slide force among piles of the miniature anti-slip compound pile, and determining the distribution ratio of the slide force under each pile; 4, calculating to obtain the residual slide thrust borne by each pile; 5, calculating the bending moment, the shearing force, corners and the displacement of the load-bearing section of each pile; 6, performing reinforcement design on the miniature anti-slip pile according to the calculated bending moment; and 7, rechecking designed reinforcing bars according to the calculated shearing force. According to the design method, the residual slope slide thrust distribution conditions of each pile of the miniature anti-slip compound pile are determined, the reinforcing function of each pile body in the combined pile consisting of multiple piles is determined, the distribution of the anti-slip effect on each pile is obtained, the structure effect and the pile-soil action effect of the miniature anti-slip compound pile are considered, and the internal force calculation result is accurate and scientific, so that the bending resistance, the shearing resistance and the safety of the miniature anti-slip compound pile are guaranteed.

Owner:CENT SOUTH UNIV

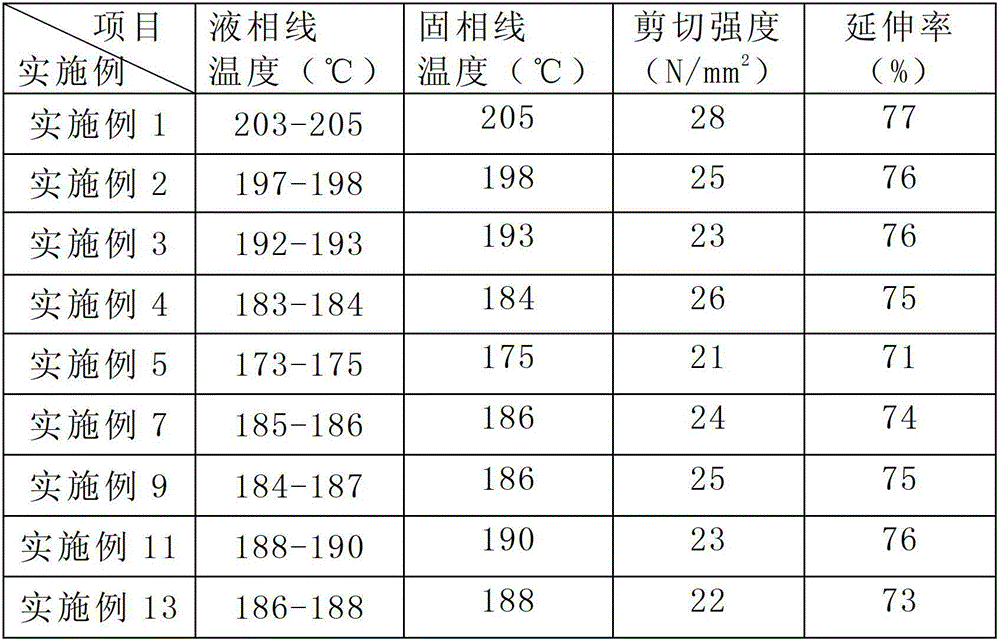

Low-melting-point lead-free solder alloy

ActiveCN102936669ALow melting pointUniform tissueWelding/cutting media/materialsSoldering mediaShock resistanceUltimate tensile strength

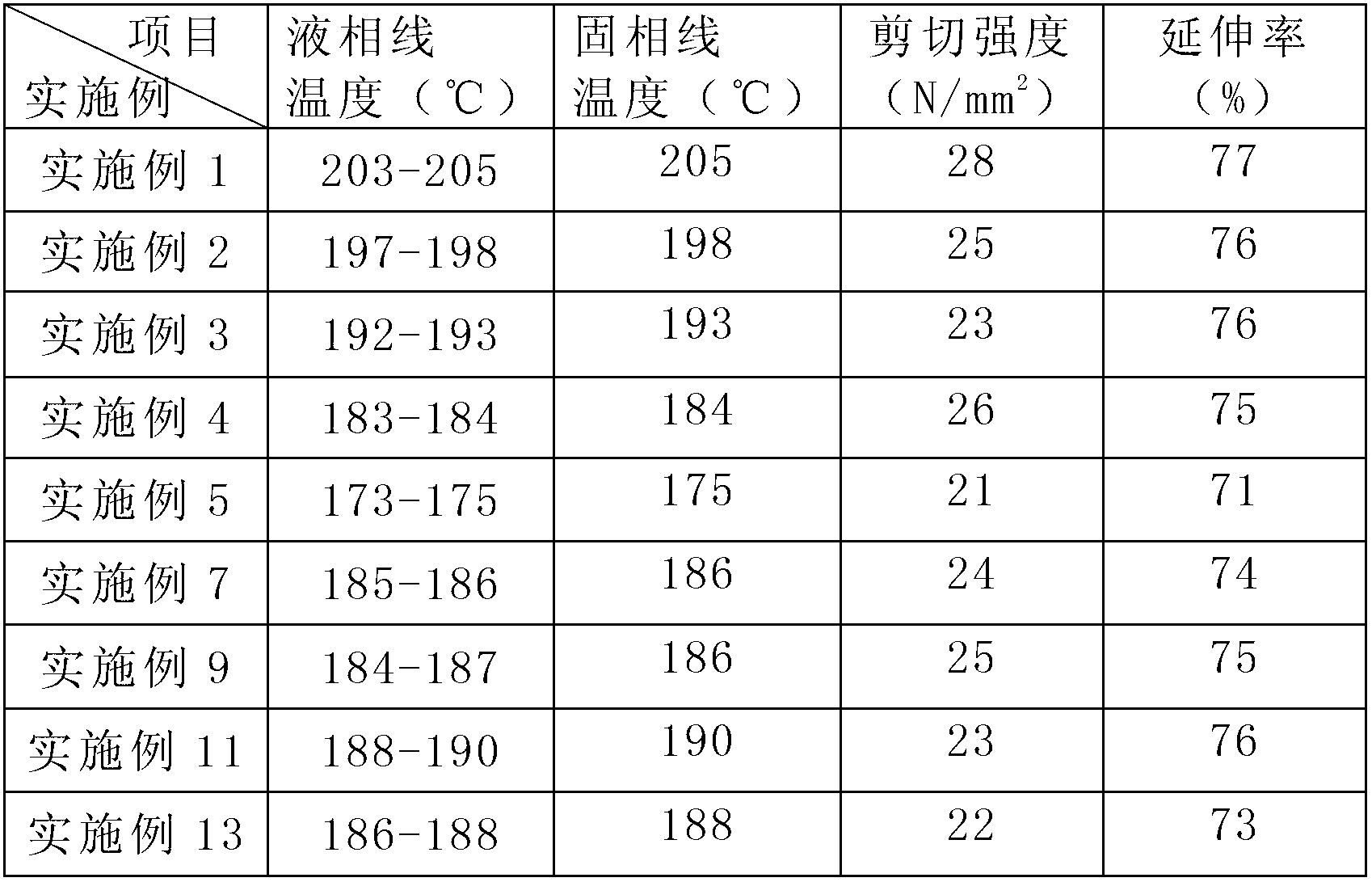

The invention relates to a low-melting-point lead-free solder alloy which belongs to the technical field of welding materials and is used for solving the problem that the conventional solder alloys are high in melting point and low in shearing strength. The low-melting-point lead-free solder alloy comprises the following components in percentage by weight: 10-30% of Bi, 2.2-3.0% of Ag, 0.5-1.0% of In, 0.004-0.008% of P and the balance being tin. The low-melting-point lead-free solder alloy also can comprise 0.002-0.005% of RE and 0.002-0.005% of Co. According to the low-melting-point lead-free solder alloy, the melting point is low, the alloy eutectic temperature is about 170-200 DEG C, the shearing strength is good and between 21-28N / mm<2>, the RE is capable of improving the glossliness of the solder alloy and refining the grains, the Co is capable of improving the soldering performance and the shock resistance, and Zr has the function of homogenizing and refining the alloy tissues.

Owner:上海一远电子科技有限公司

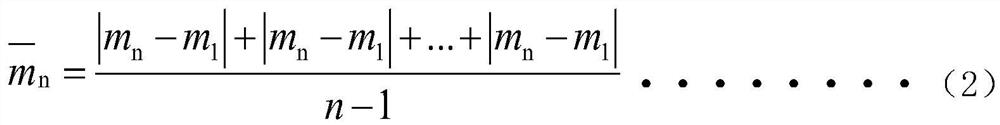

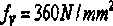

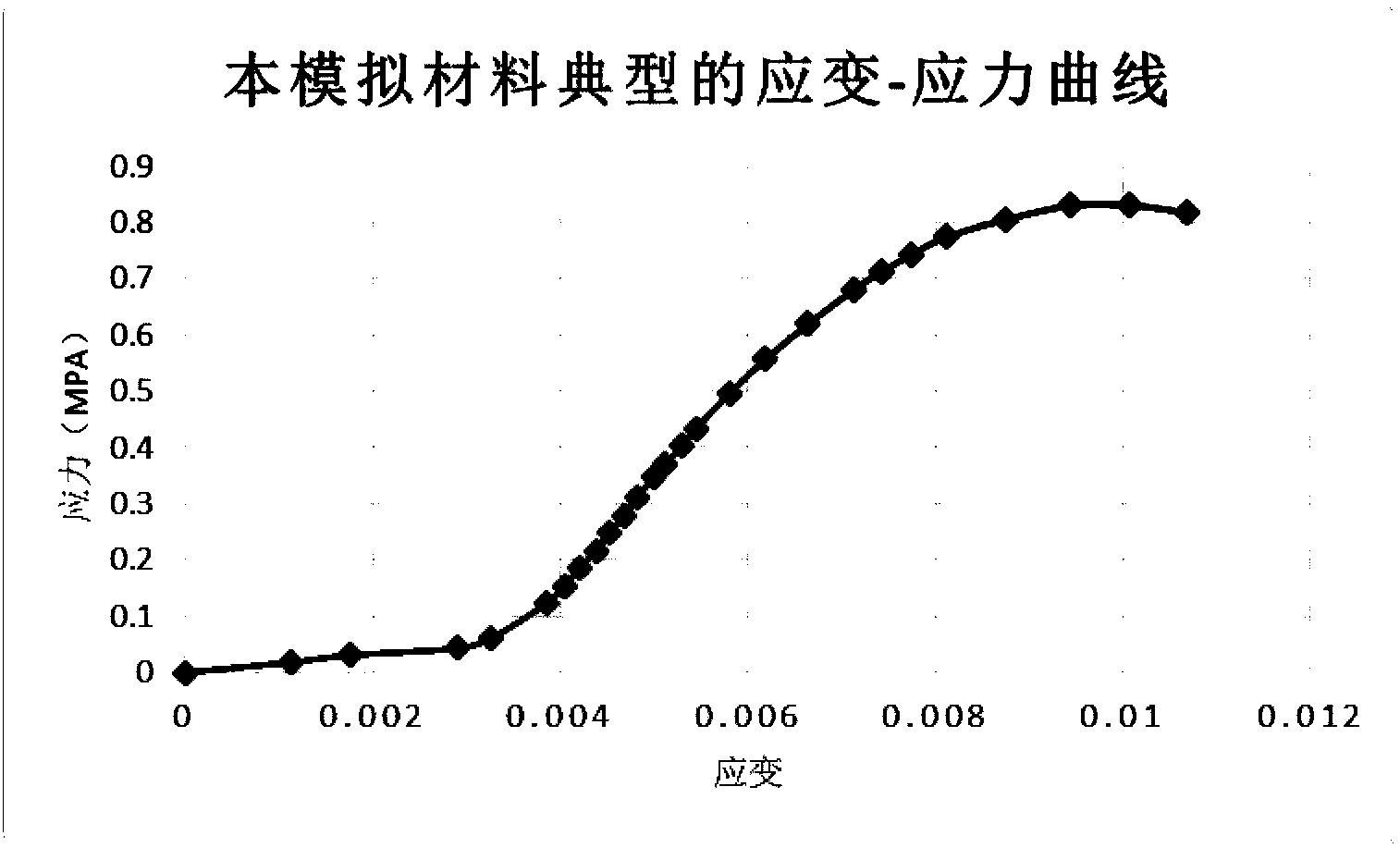

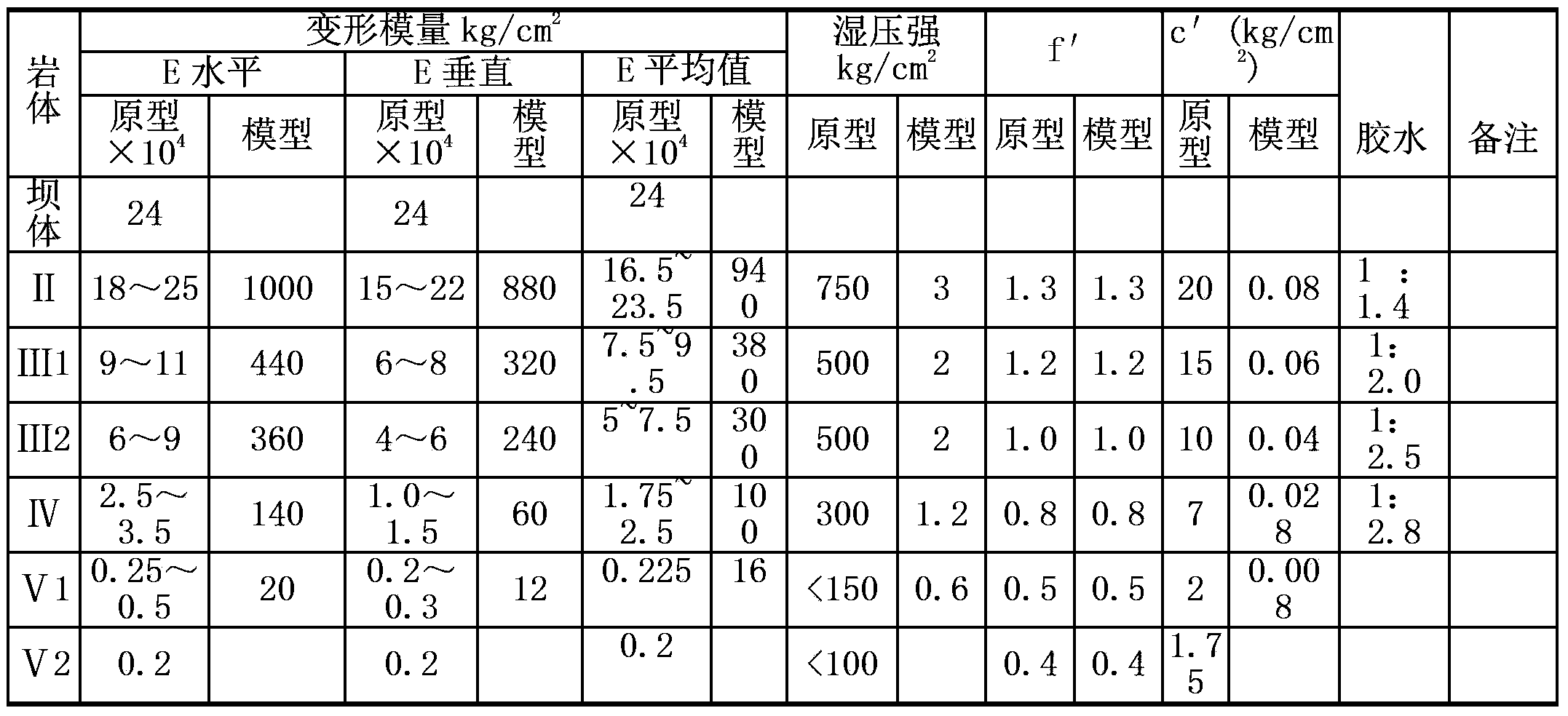

Blanc fixe cementitious rock soil-like material and method for making simulative rock from the blanc fixe cementitious rock soil-like material

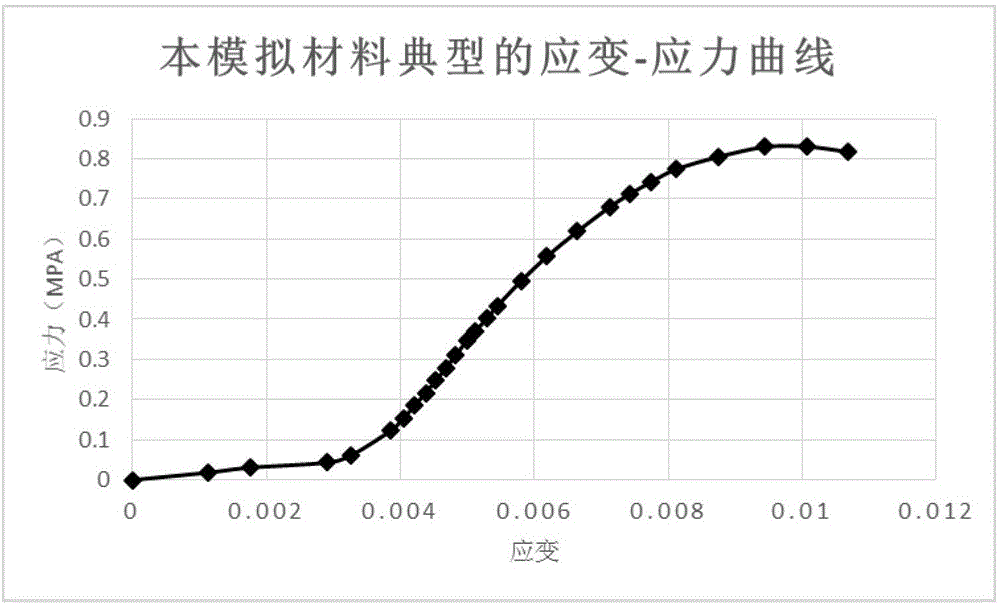

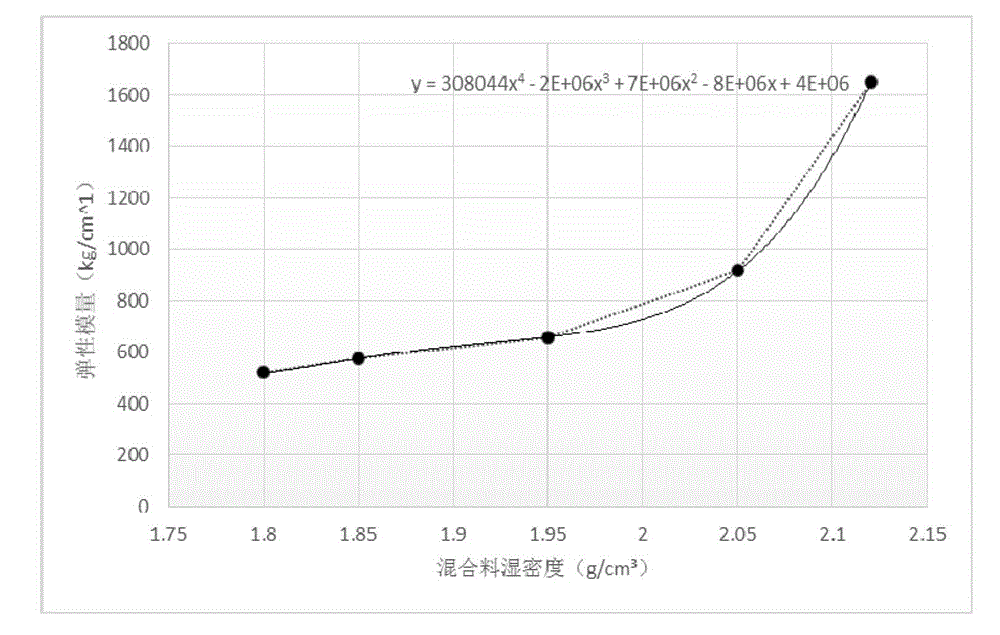

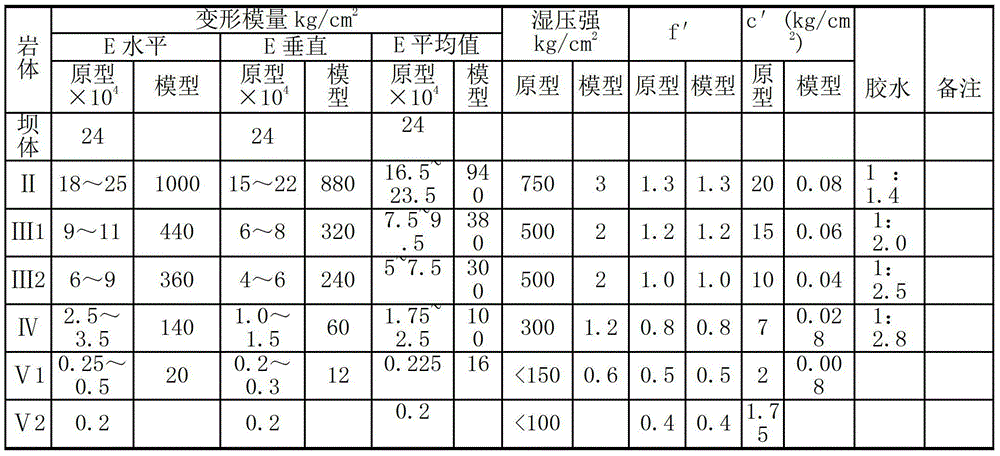

ActiveCN103332885ALow costSpeed upPreparing sample for investigationModel testUltimate tensile strength

The invention relates to a blanc fixe cementitious rock soil-like material and a method for making simulative rock from the blanc fixe cementitious rock soil-like material and belongs to the technical field of rock material simulation in a geomechanical model test. The blanc fixe cementitious rock soil-like material comprises blanc fixe as a aggregate, bentonite as an auxiliary material, and dilute glue composed of 107 glue and water. The method comprises the following steps of drawing a water-binder ratio-shearing strength f curve by the blanc fixe cementitious rock soil-like material, calculating wet density of different batches of the blanc fixe cementitious rock soil-like materials, and making a small test-piece from different batches of the blanc fixe cementitious rock soil-like materials. The blanc fixe cementitious rock soil-like material has a low cost and no toxicity, can be processed into small blocks easily, and can satisfy requirements of a geomechanical model test on the blanc fixe cementitious rock soil-like material. Simulative rock made from the blanc fixe cementitious rock soil-like material does not influence a model building process and can be made fast so that a model test rate is greatly improved. The blanc fixe cementitious rock soil-like material is suitable for the field of a test on a model built by laying small blocks.

Owner:TSINGHUA UNIV

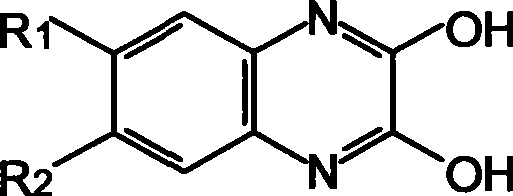

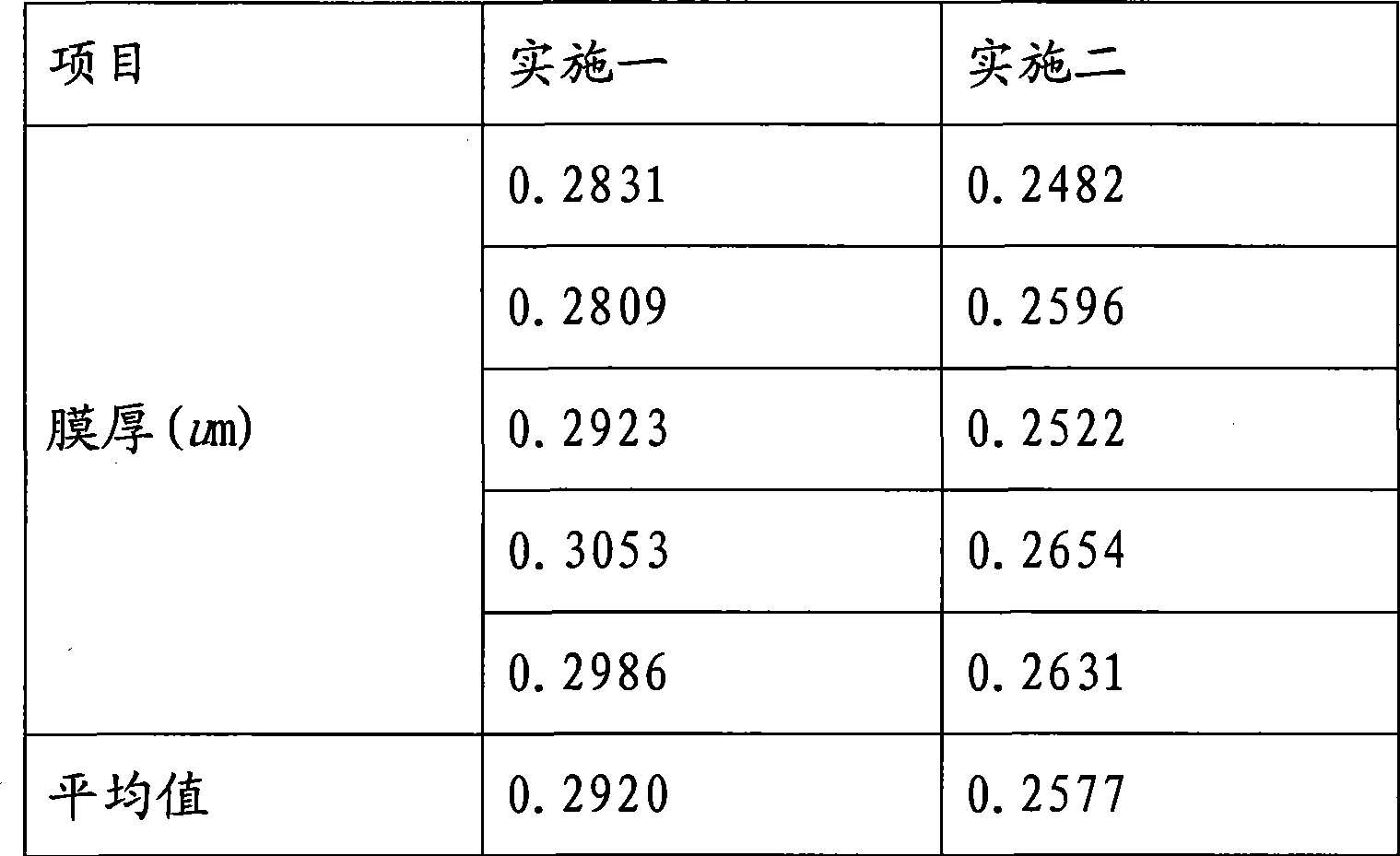

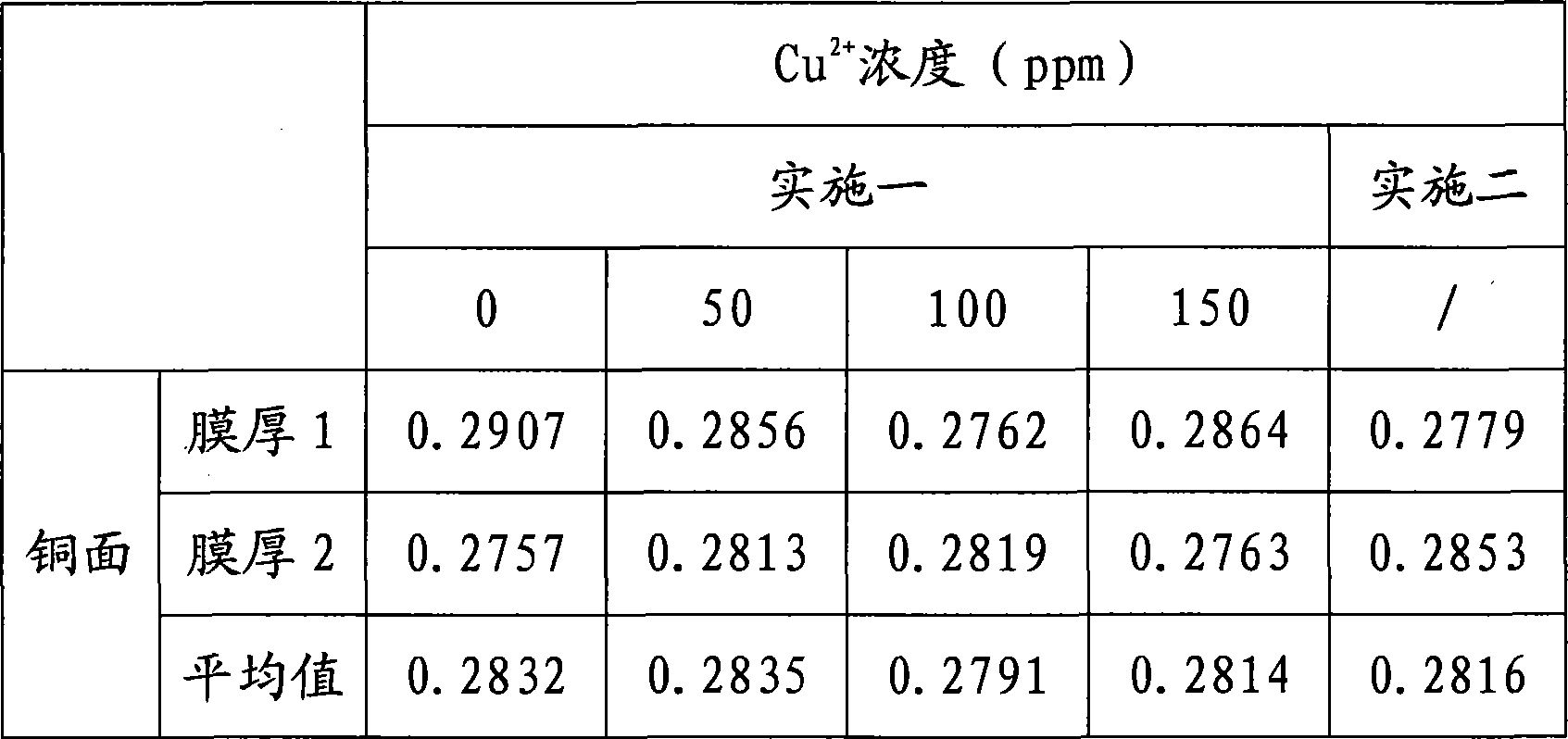

Organic solderability preservative pre-soaking treating agent and organic solderability preservation film forming method

InactiveCN101508051AFast film formationShort duration of actionArc welding apparatusMetallic material coating processesQuinoxalineBuffering agent

The invention relates to the technical field of printed circuit board solderability preservation, in particular to an organic solderability preservative preimpregnation finishing agent and an organic solderability preservative forming method. The adopted organic solderability preservative preimpregnation finishing agent comprises the following components in percentage by weight: 0.05 to 6.0 percent of nanometer accelerating agent, 0.01 to 2.0 percent of quinoxaline compound, 0.05 to 2.0 percent of inorganic base, 0.001 to 15.0 percent of ammonia or amine buffering agent, 0.001 to 0.5 percent of metallic salts, and 0.01 to 5.0 percent of halide. The invention firstly forms a nano material active layer on the copper face, and can increase the thickness of the organic solderability preservative by more than 20 percent in the same reaction time, reduce metal pollution speed of tank liquor, double the service life of the tank liquor, prevent galvanic effect, ensure good appearance of a printed circuit board, reduce the thickness of intermetallic compounds (IMC) after soldering, and guarantee the shear strength of welding joints and reliability of welding spots.

Owner:林原标 +1

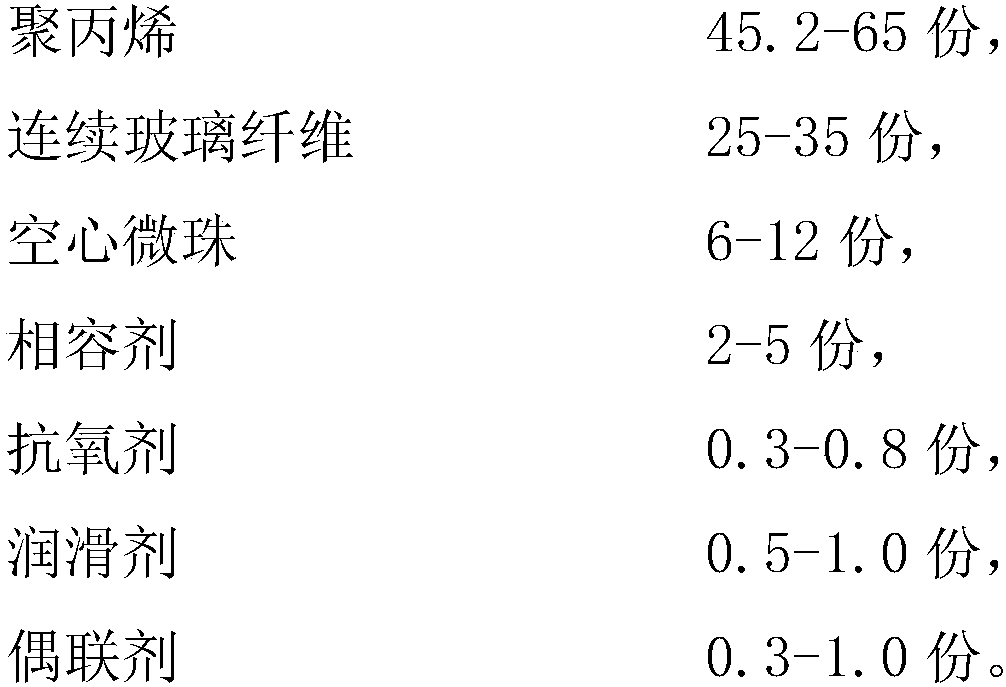

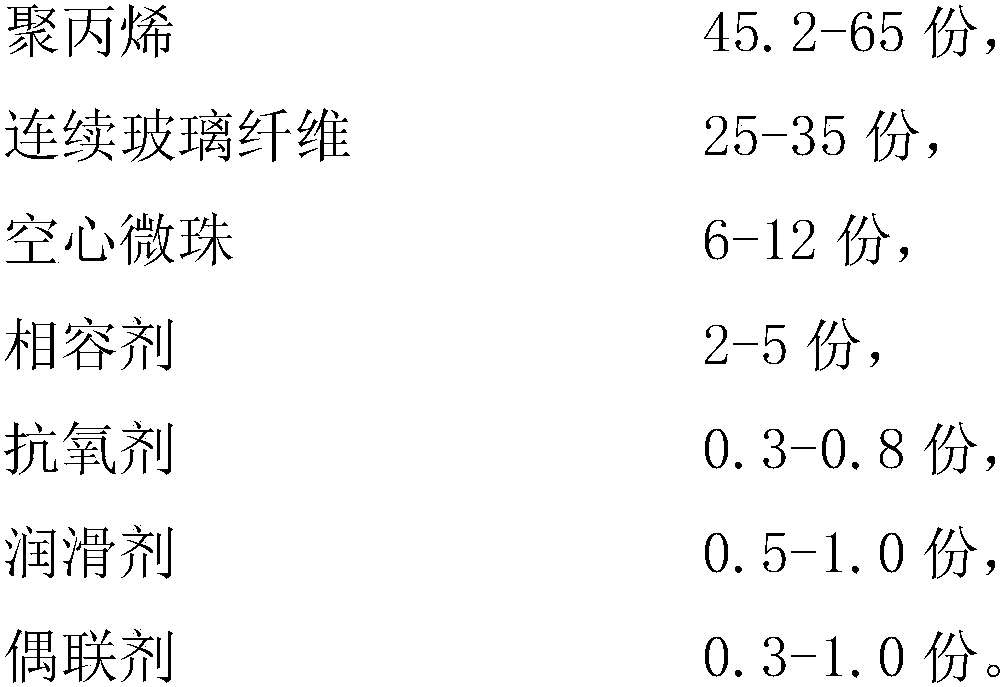

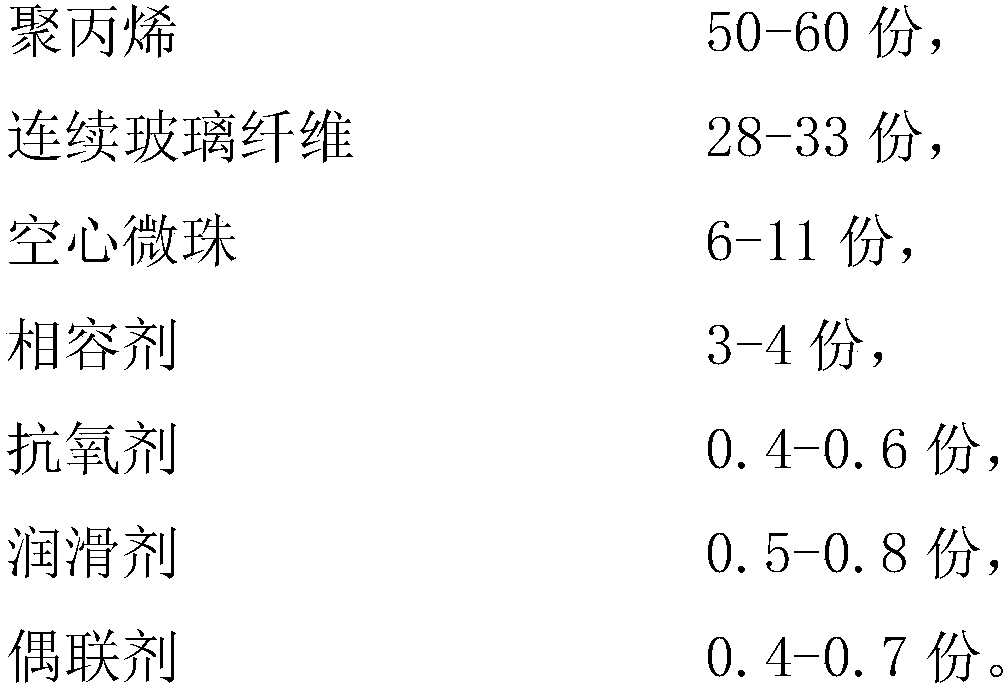

Lightweight warping-resistant continuous glass fiber enhanced polypropylene composite material, and preparation method thereof

InactiveCN107892772ASolve densitySolve problems such as easy warpingGlass fiberPolypropylene composites

The invention discloses a lightweight warping-resistant continuous glass fiber enhanced polypropylene composite material, and a preparation method thereof. 100 parts of the lightweight warping-resistant continuous glass fiber enhanced polypropylene composite material comprises, by mass, 45.2 to 65 parts of polypropylene, 25 to 35 parts of continuous glass fiber, 6 to 12 parts of hollow bead, 2 to5 parts of a compatilizer, 0.3 to 0.8 part of an anti-oxidant, 0.5 to 1.0 part of a lubricant, and 0.3 to 1.0 part of a coupling agent. The lightweight warping-resistant continuous glass fiber enhanced polypropylene composite material is obtained via uniform mixing and extrusion processing. Full utilization of the advantages of hollow beads that intensity is low and isotropy is achieved is realized, problems of glass fiber enhanced polypropylene composite materials such as high density and easily caused warping are solved without influencing the physical mechanical properties of glass fiber enhanced polypropylene; the commercial available hollow bead products and continuous glass fiber relatively low in cost are selected to realize strict control on raw material cost. The preparation method is capable of ensuring the shearing strength of continuous glass fiber, and avoiding broken of hollow beads at the same time; and the performance of the prepared materials are better.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

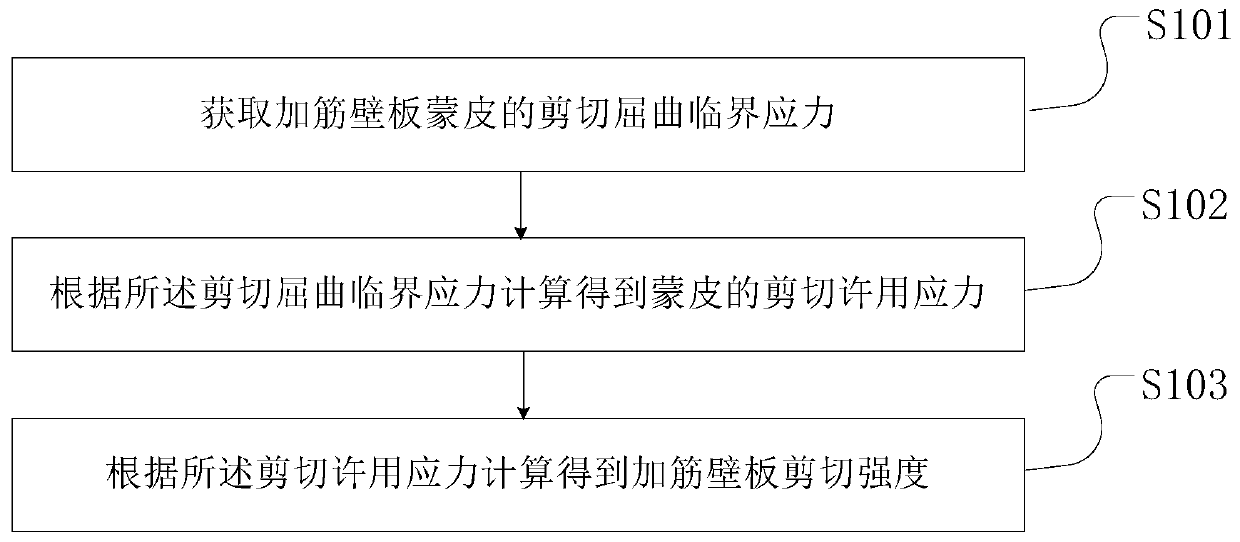

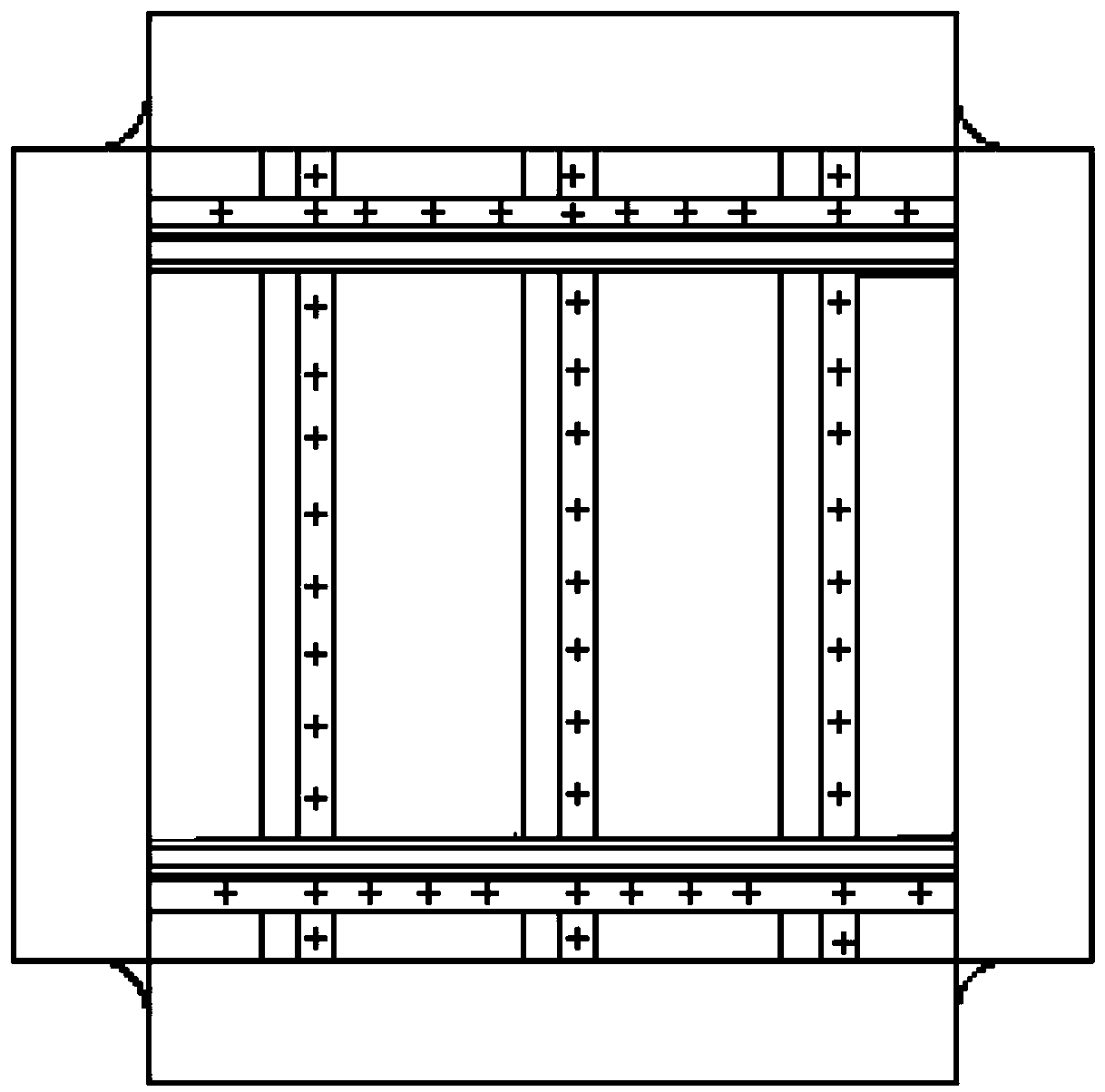

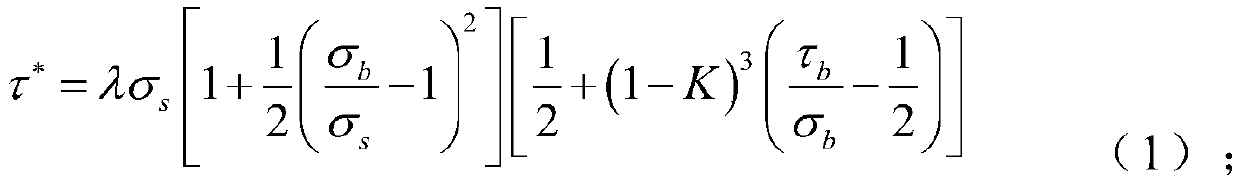

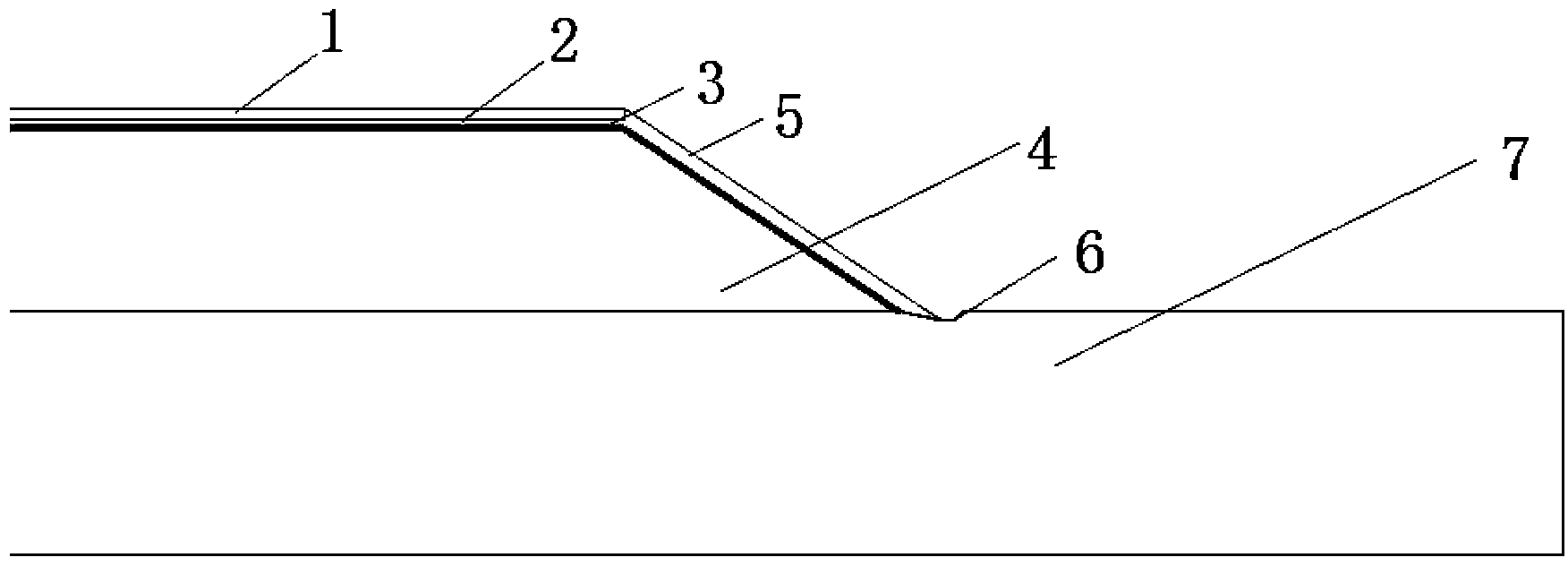

Method for estimating shear strength of reinforced wallboard

ActiveCN110362882AGuaranteed shear strengthCalculation steps are clearSustainable transportationDesign optimisation/simulationAviationUltimate tensile strength

The invention belongs to the technical field of aviation structure strength analysis, and particularly relates to a method for estimating the shear strength of an reinforced wallboard, which comprisesthe following steps: acquiring shear buckling critical stress of a reinforced wallboard skin; calculating according to the shear buckling critical stress to obtain shear allowable stress of the skin;and carrying out calculating according to the shearing allowable stress to obtain the shearing strength of the reinforced wallboard. The method for estimating the shear strength of the reinforced wallboard is clear in calculation step, simple and convenient in calculation process and accurate in calculation result; the method overcomes the defects of an existing method, is suitable for reinforcedwall plates made of different materials and of different structures, can calculate the shear strength of structures such as riveting, screw joint, welding and integral reinforced wall plates, is goodin universality and high in flexibility, and reduces the structural weight on the premise that the shear strength of the reinforced wall plates is guaranteed.

Owner:CHINA AIRPLANT STRENGTH RES INST

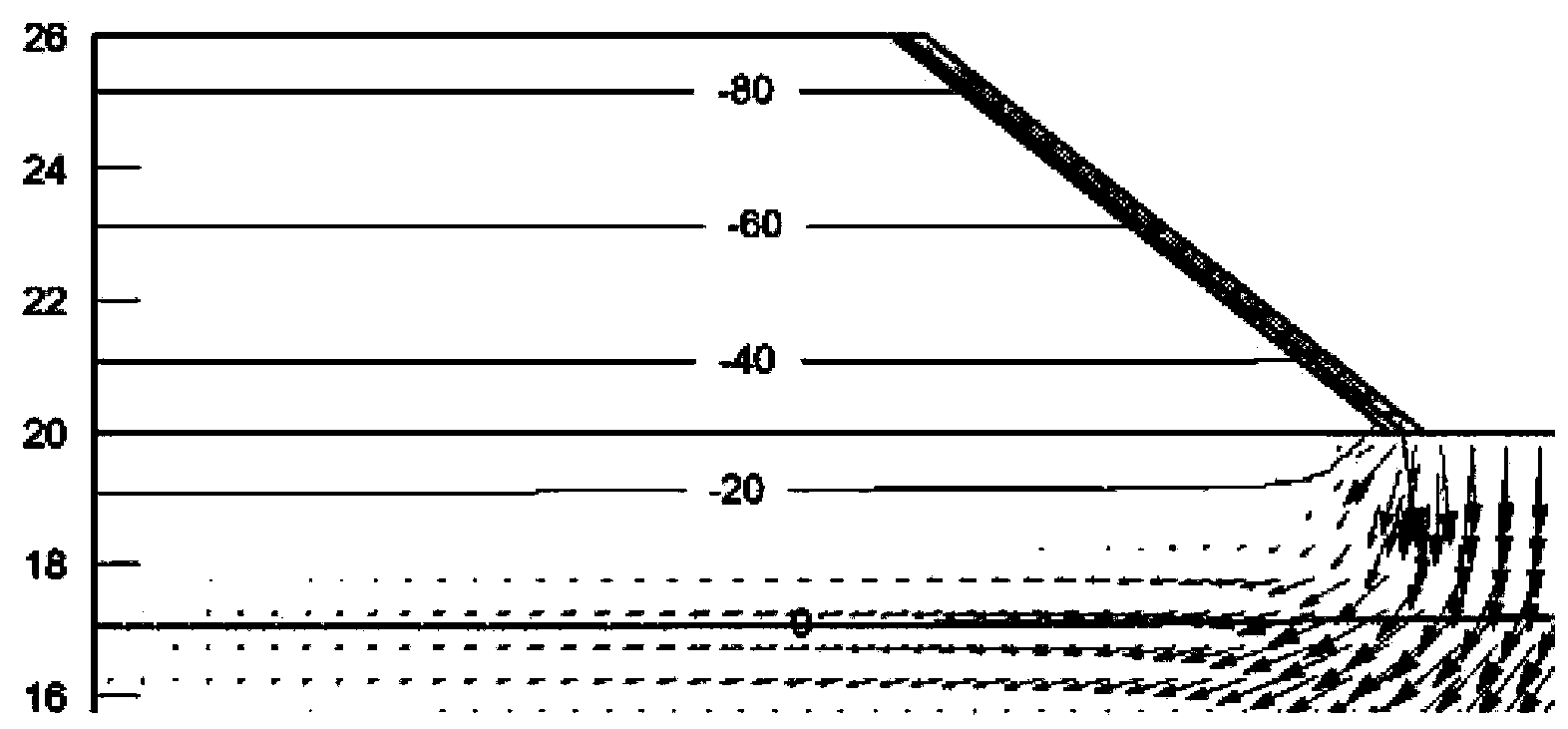

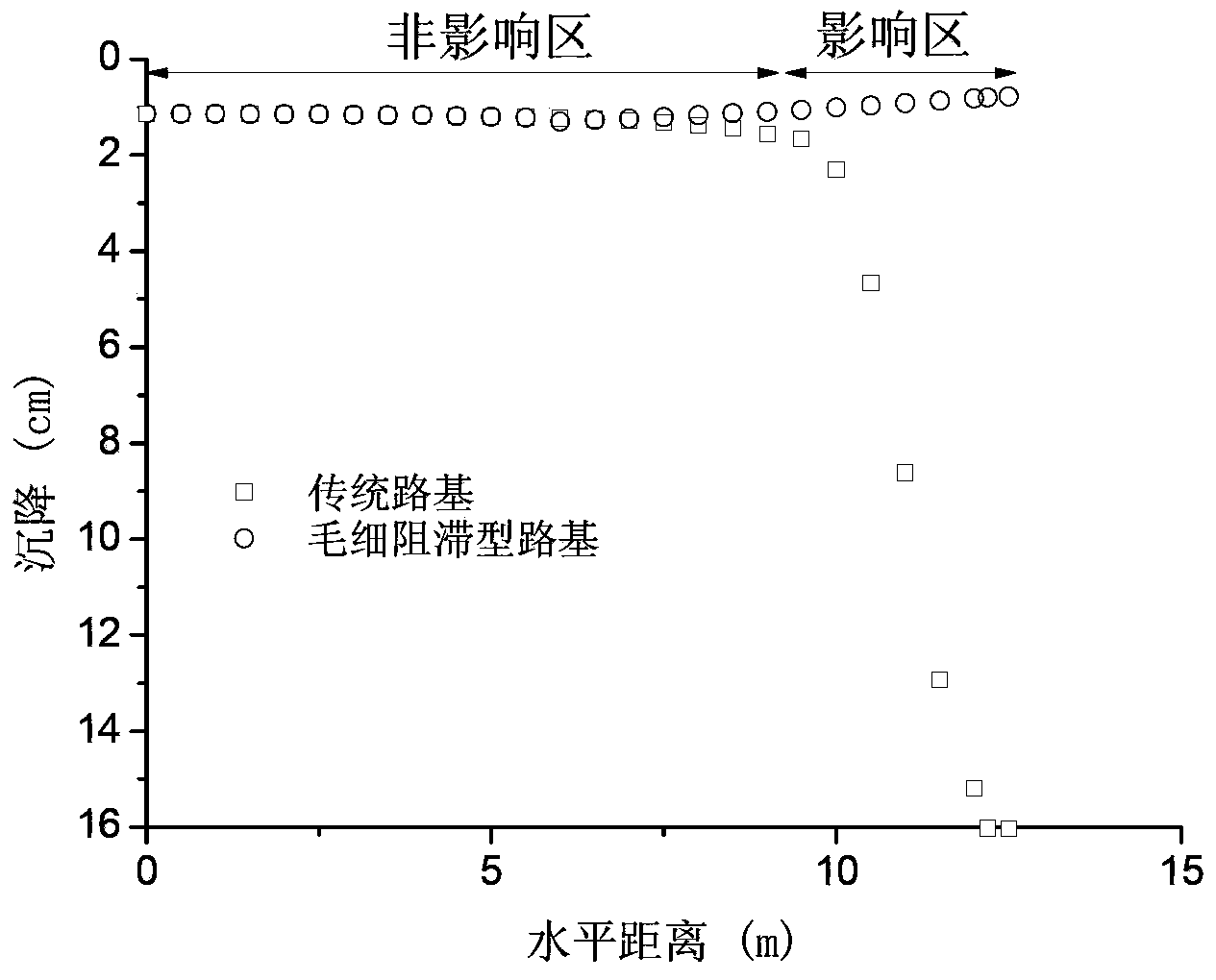

Capillary barrier roadbed structure capable of effectively preventing and treating roadbed humidification diseases and construction method

The invention provides a capillary barrier roadbed structure capable of effectively preventing and treating roadbed humidification diseases. The capillary barrier roadbed structure comprises a drainage ditch, a roadbed and a side slope. The roadbed and the side slope are connected with each other and arranged on foundations. The roadbed comprises a road surface, a superficial roadbed soil layer, a geotechnical cloth or coarse grained soil layer and a deep roadbed soil layer which are sequentially arranged from top to bottom. The side slope comprises a fill side slope layer, the geotechnical cloth or coarse grained soil layer and the deep roadbed soil layer which are sequentially arranged from top to bottom. The superficial roadbed soil layer and the geotechnical cloth or coarse grained soil layer form a first capillary barrier layer. The fill side slope layer and the geotechnical cloth or coarse grained soil layer form a second capillary barrier layer. The first capillary barrier layer and the second capillary barrier layer are connected in sequence. The drainage ditch is arranged at the bottom of the fill side slope layer and connected with the second capillary barrier layer. The roadbed structure is low in construction cost, the humidification diseases caused by cracks on the road surface and dried cracks at a fill side slope and a deep layer thereof can be effectively controlled, uneven settlement of the roadbed due to humidification is reduced, and shearing strength of roadbed soil is maintained.

Owner:HOHAI UNIV

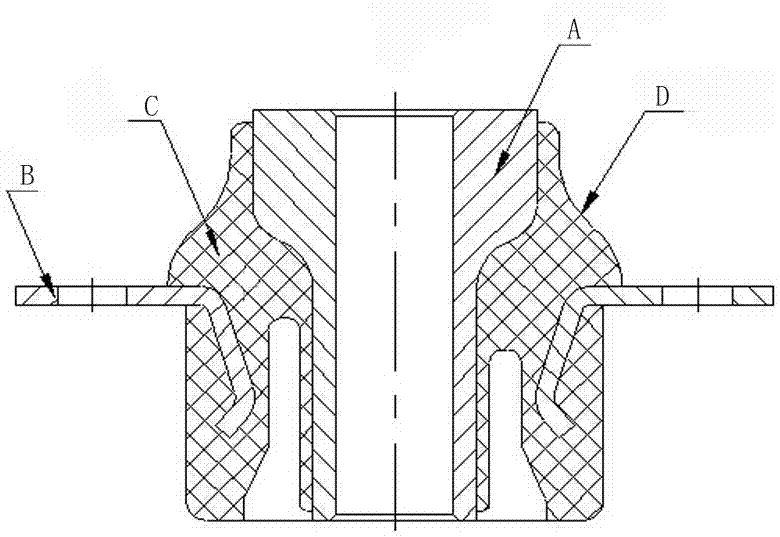

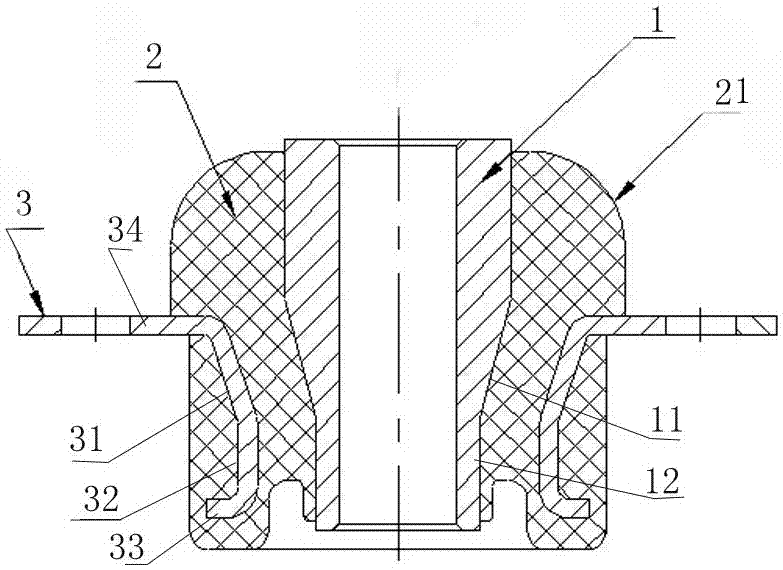

Novel automobile engine rear suspension cushion assembly

InactiveCN107117004ALow shear strengthImprove fatigue lifeJet propulsion mountingInternal combustion mountingUltimate tensile strengthAutomotive engine

The present invention is a new automobile engine rear suspension cushion assembly, including an inner frame and an outer frame. There is a vulcanized rubber body between the inner and outer frames. At the same time, the outer frame is wrapped in the vulcanized rubber body. The outer diameter of the inner frame passes through a taper transition section to a straight line section; the corresponding outer skeleton also includes a straight section, the straight section is provided with an inclination angle, the inclination angle is downwardly provided with a vertical section, and a hook is provided behind the vertical section; the inclination angle of the outer skeleton corresponds to the outer diameter of the inner skeleton The taper transition section, the vertical section of the outer skeleton corresponds to the straight section of the outer diameter of the inner skeleton; the shock-absorbing arc of the shoulder of the rubber body is an outer arc. The present invention vulcanizes the inner and outer skeletons and the vulcanized rubber body as one, and adjusts the original inner skeleton structure at the same time. The upper part is changed from an arc excessive design to an inclination angle design, that is, a taper transition section design, which is consistent with the inclination angle of the outer skeleton. It can reduce the shear strength of rubber and improve the fatigue life of products.

Owner:十堰风神汽车橡塑制品有限公司

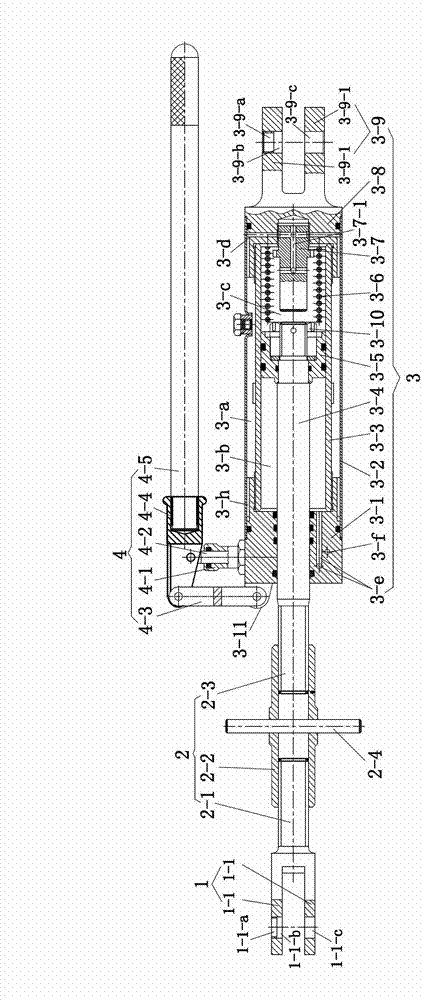

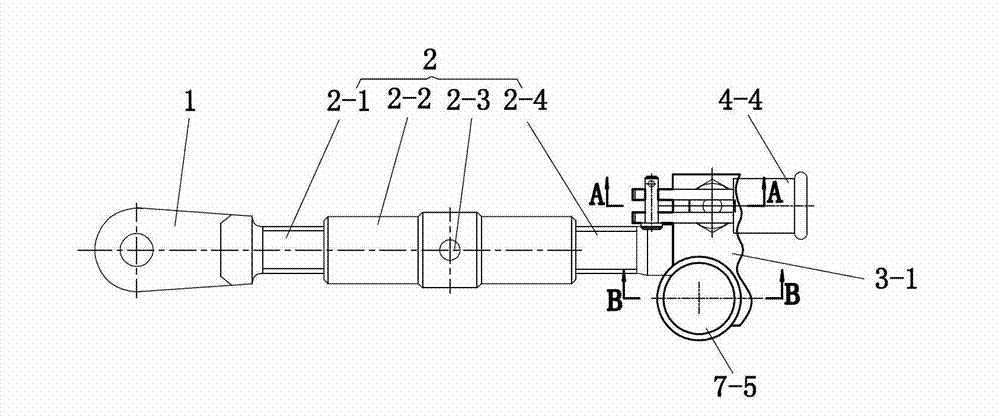

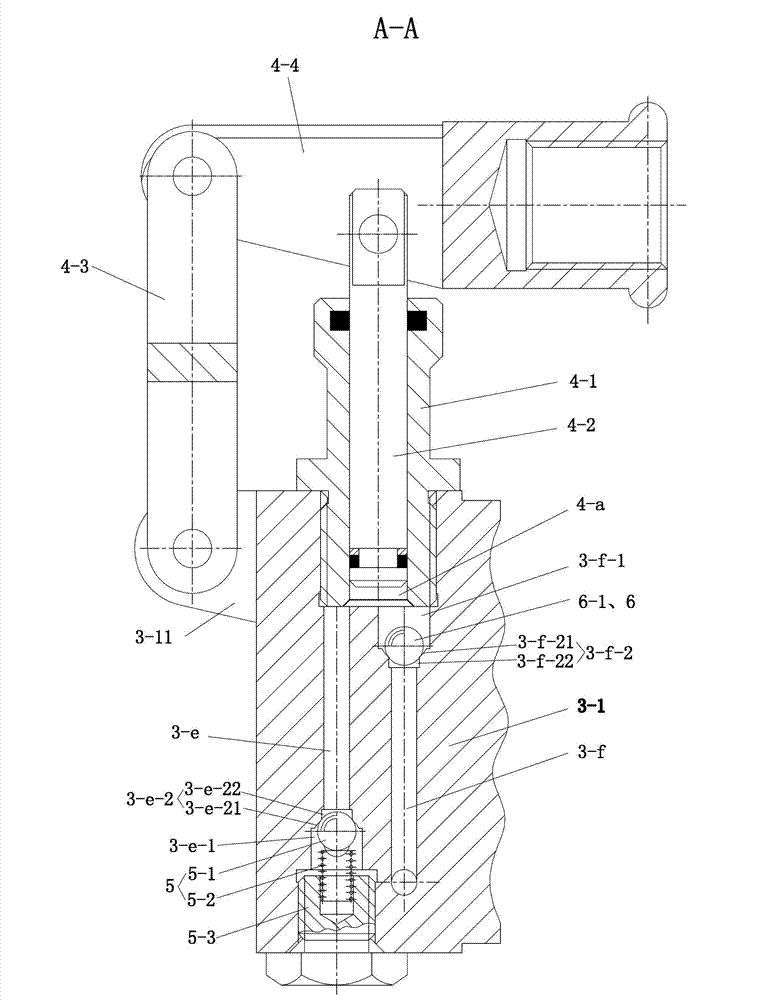

Tightening device of insulator replacement device

ActiveCN102904193ASimple structureCompact structureApparatus for overhead lines/cablesClassical mechanicsCylinder block

The invention provides tightening device of an insulator replacement device. The tightening device comprises a forked joint, a screw rod and a hydraulic device, wherein the screw rod consists of a screw rod I, a screw rod II and a double-ended screw sleeve connected between the screw rod I and the screw rod II, wherein the middle of the double-ended screw sleeve is connected with a spanner; the forked joint is connected to the terminal of the screw rod I; the piston rod of the hydraulic device stretches out from the front end of a cylinder body and is fixedly connected with the screw rod II; the rear side of the cylinder body of the hydraulic device is a forked part; and the hydraulic device is connected with a stirrup pump. The tightening device adopts a screw rod and hydraulic device combined structure; the spanner is utilized to rotate the double-ended screw sleeve to adjust the length of the screw rods, so as to pre-absorb redundant stroke; then the hydraulic device provides effective working stroke, not only can the portability of the screw rods during an unstressed state and a slightly stressed state be utilized, but also the hydraulic device is utilized to complete the tightening operation under a rated working load by virtue of a smaller operating force, and the operation is labor-saving and convenient. The hydraulic device adopts a one-way throttle valve to automatically control the return oil flow, and the stroke fine adjustment of the hydraulic device is realized.

Owner:CHANGZHOU POWER SUPPLY OF JIANGSU ELECTRIC POWER +2

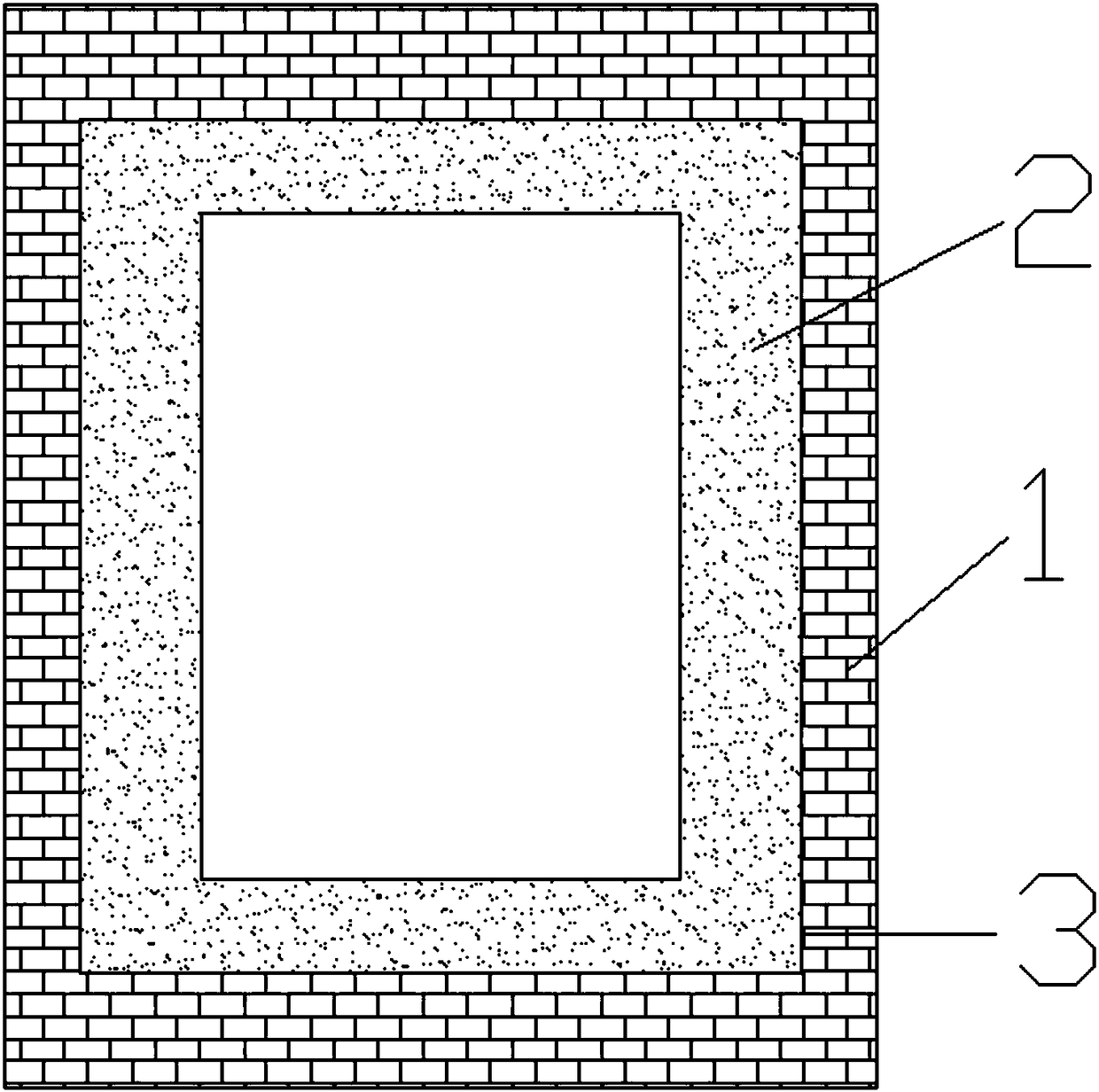

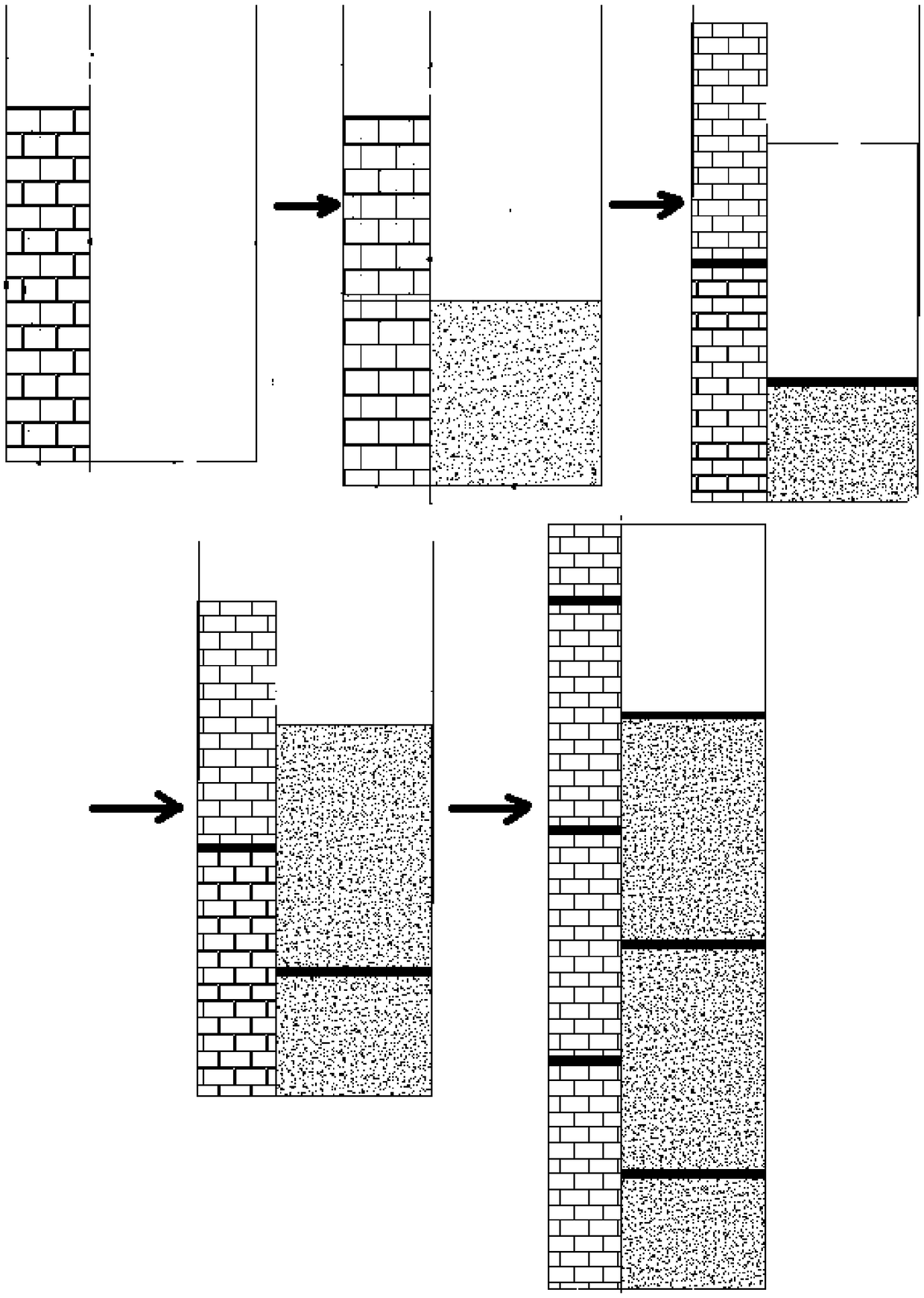

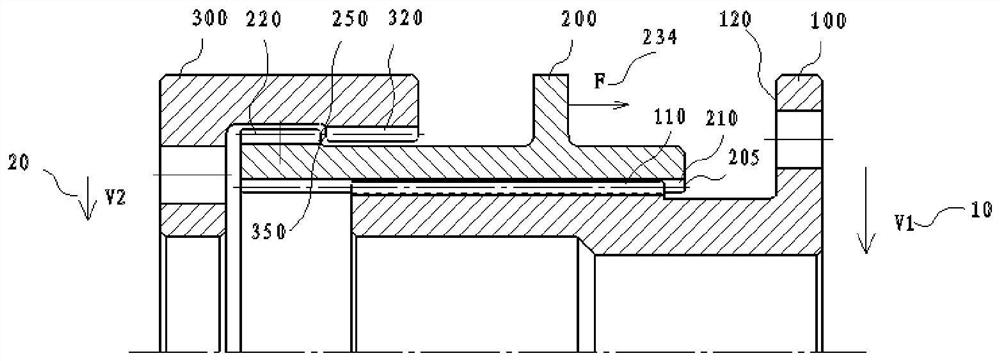

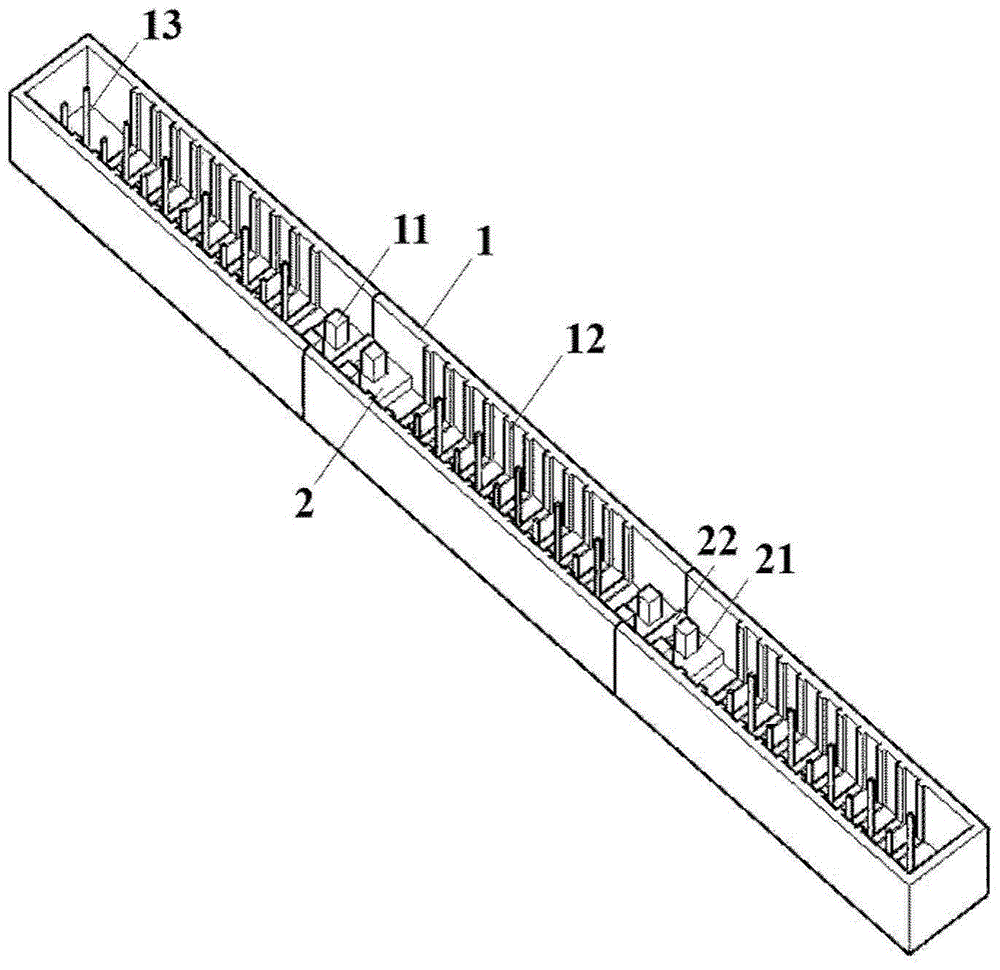

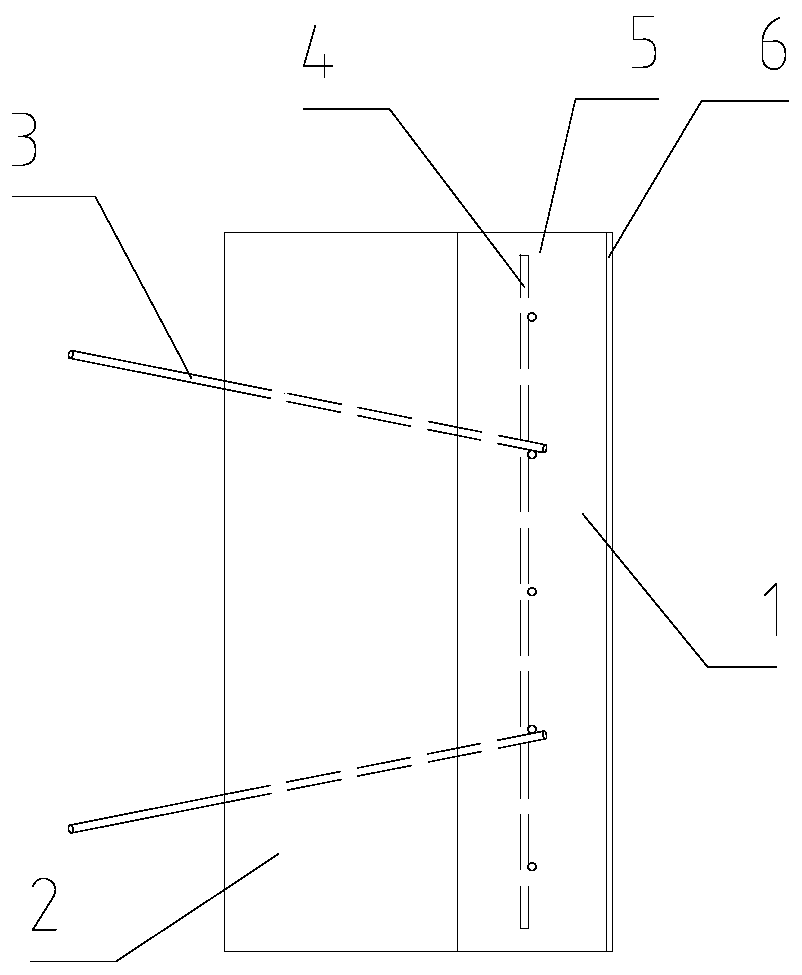

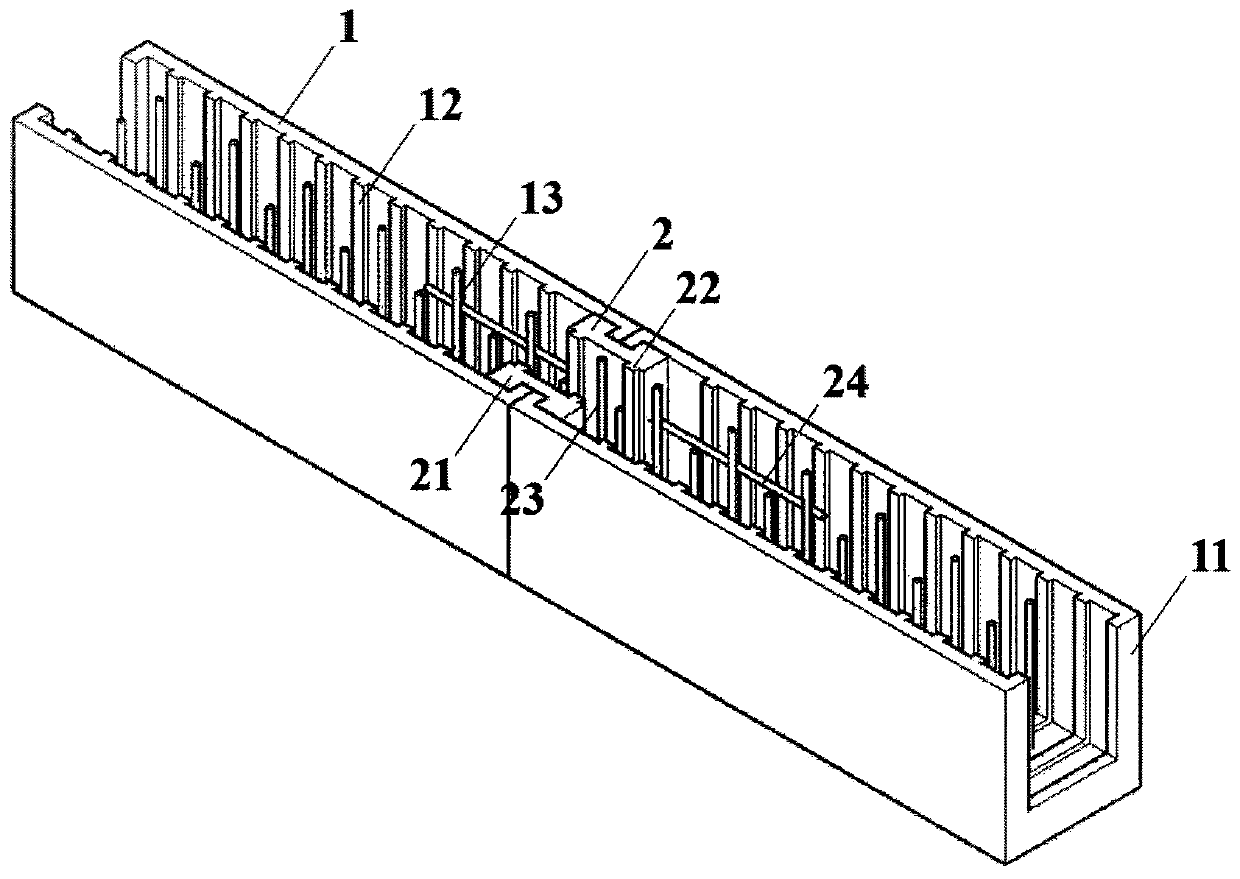

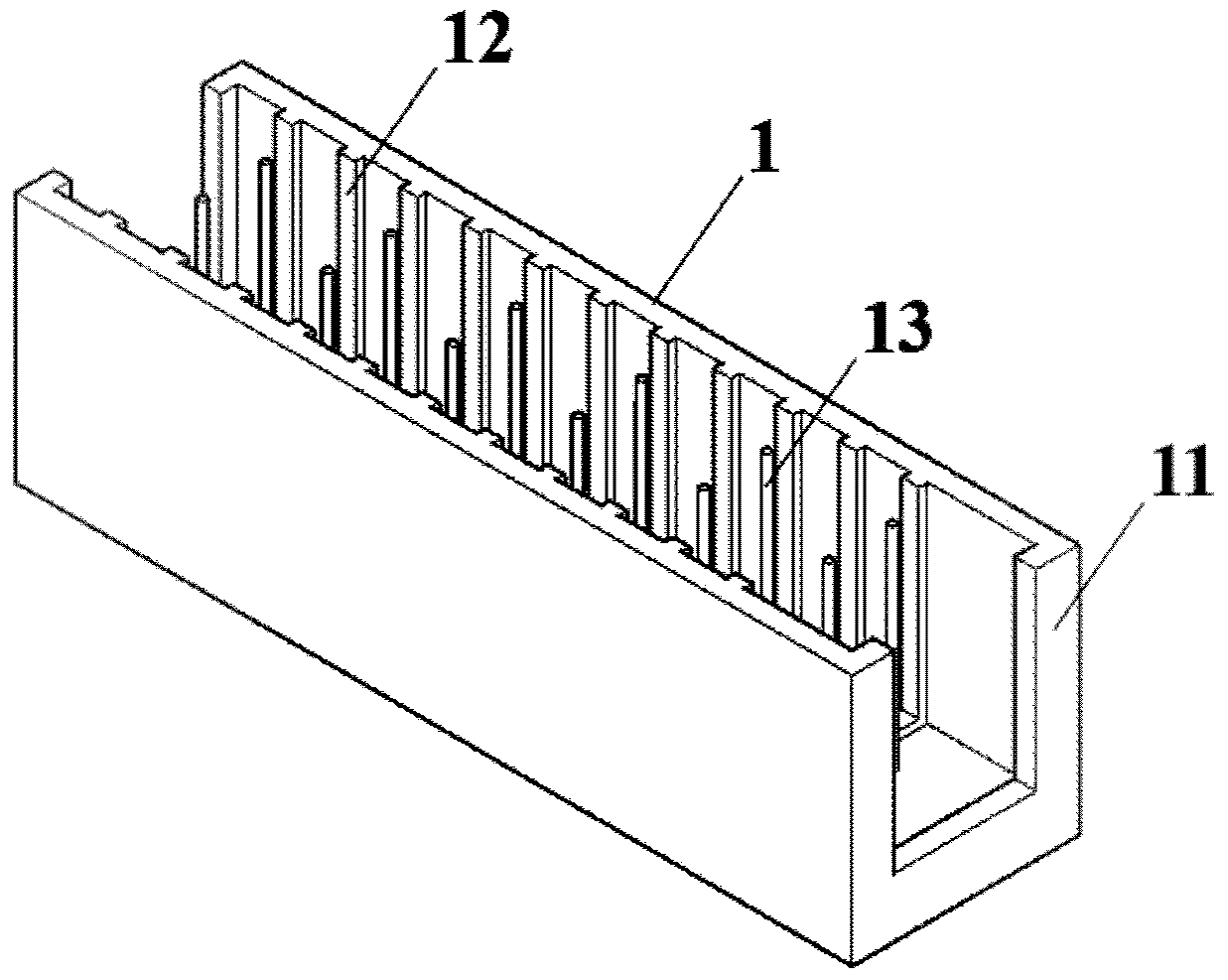

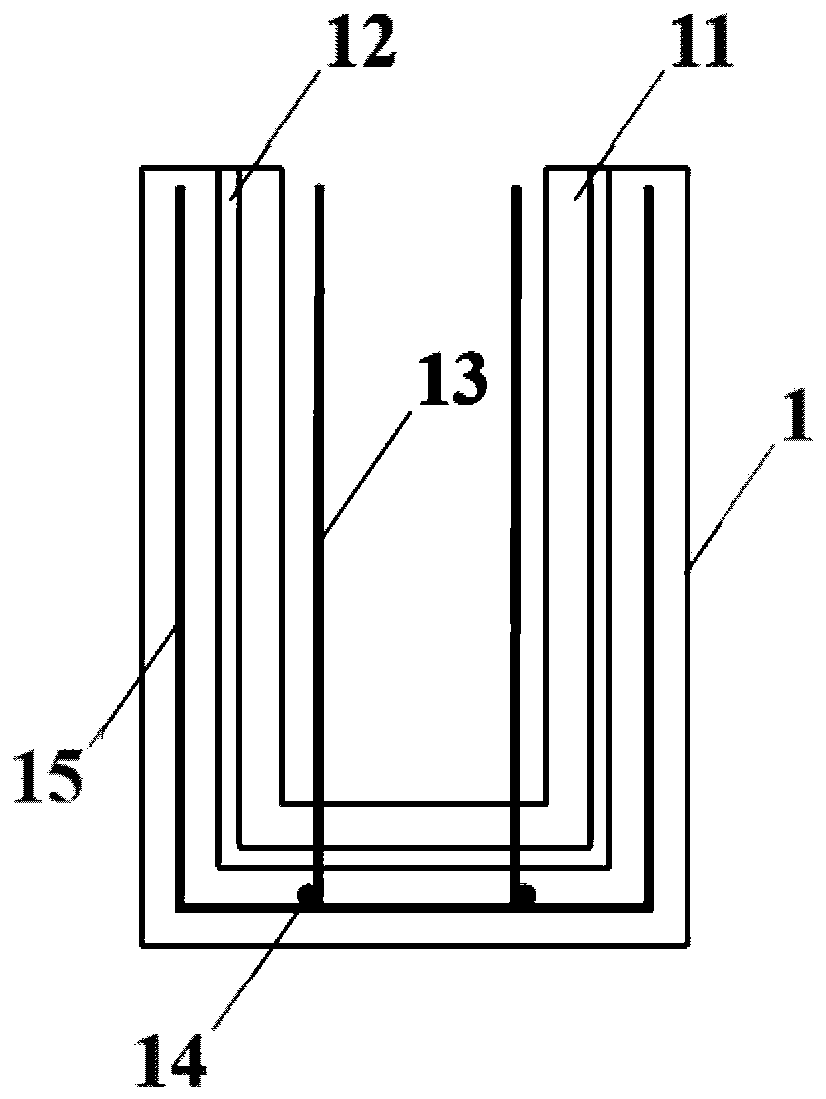

Construction method of prefabricated underground diaphragm wall

PendingCN113136858AGuaranteed shear strengthHigh precisionBulkheads/pilesSlurry wallArchitectural engineering

The invention discloses a construction method of a prefabricated underground diaphragm wall. The construction method comprises the steps that underground diaphragm wall body units are prefabricated; an underground diaphragm wall groove is excavated; rubber capsule bodies are pasted in a second groove and a third groove of each wall body unit; second steel parts and first steel parts are installed in gaps and fourth grooves in the wall units; a first wall body unit is put into the groove; a second wall body unit is inserted along the first groove of each wall body unit, so that a tenon of the second wall body unit is embedded into the first groove of the first wall body unit, and the second steel parts and the first steel parts are mutually tied; the subsequent wall body units are continuously inserted in the groove direction of the underground diaphragm wall, and liquid grouting bodies are injected into the bag bodies at the joints of the first wall body unit and the second wall body unit; cement-based grout is injected into a steel floral tube of the second steel part; after the multiple wall units are constructed, cement slurry is poured into gaps between the wall units and the grooves, and slurry in the gaps is replaced; and the steps are carried out until construction of the underground diaphragm wall is completed. According to the construction method, the construction speed is high, and the waterproof effect is good.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

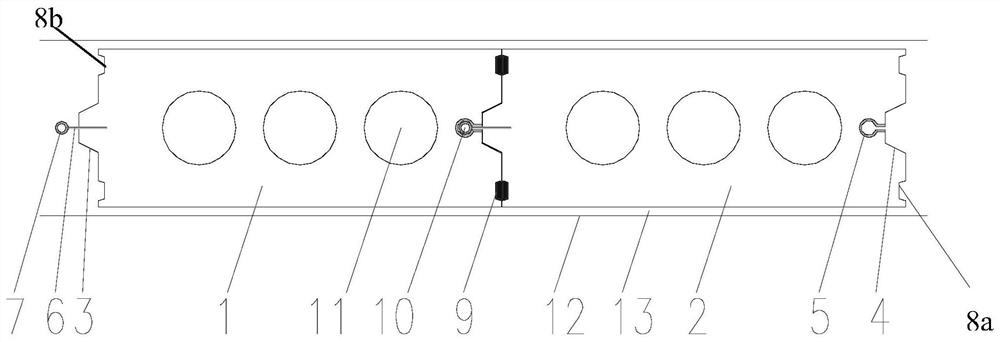

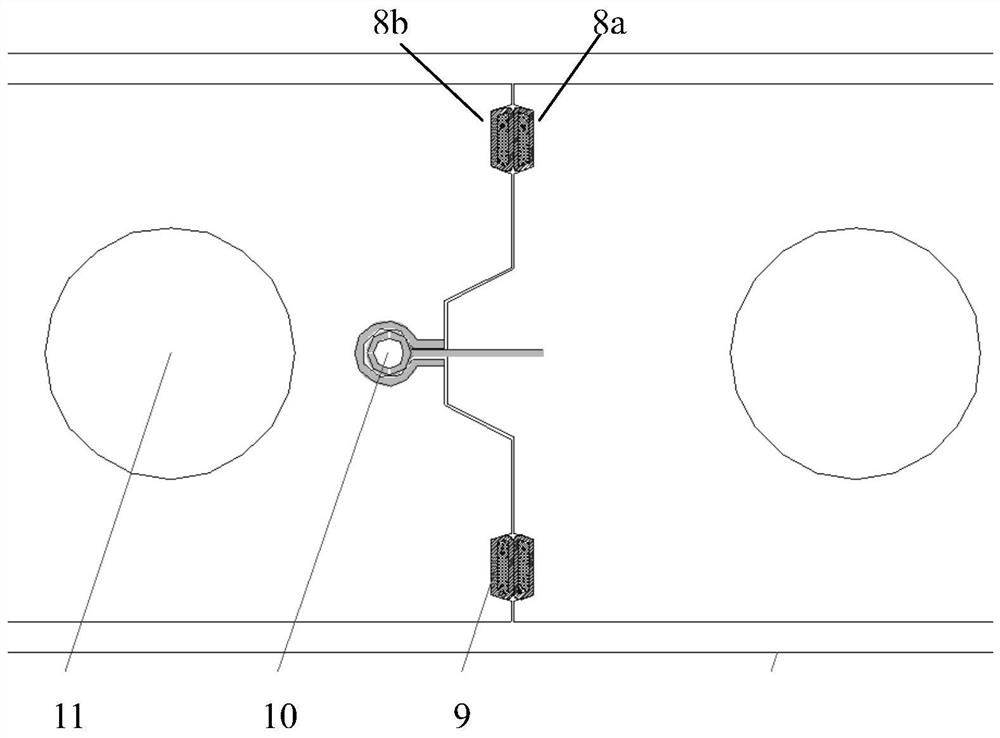

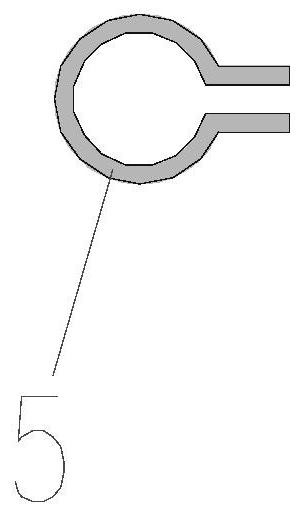

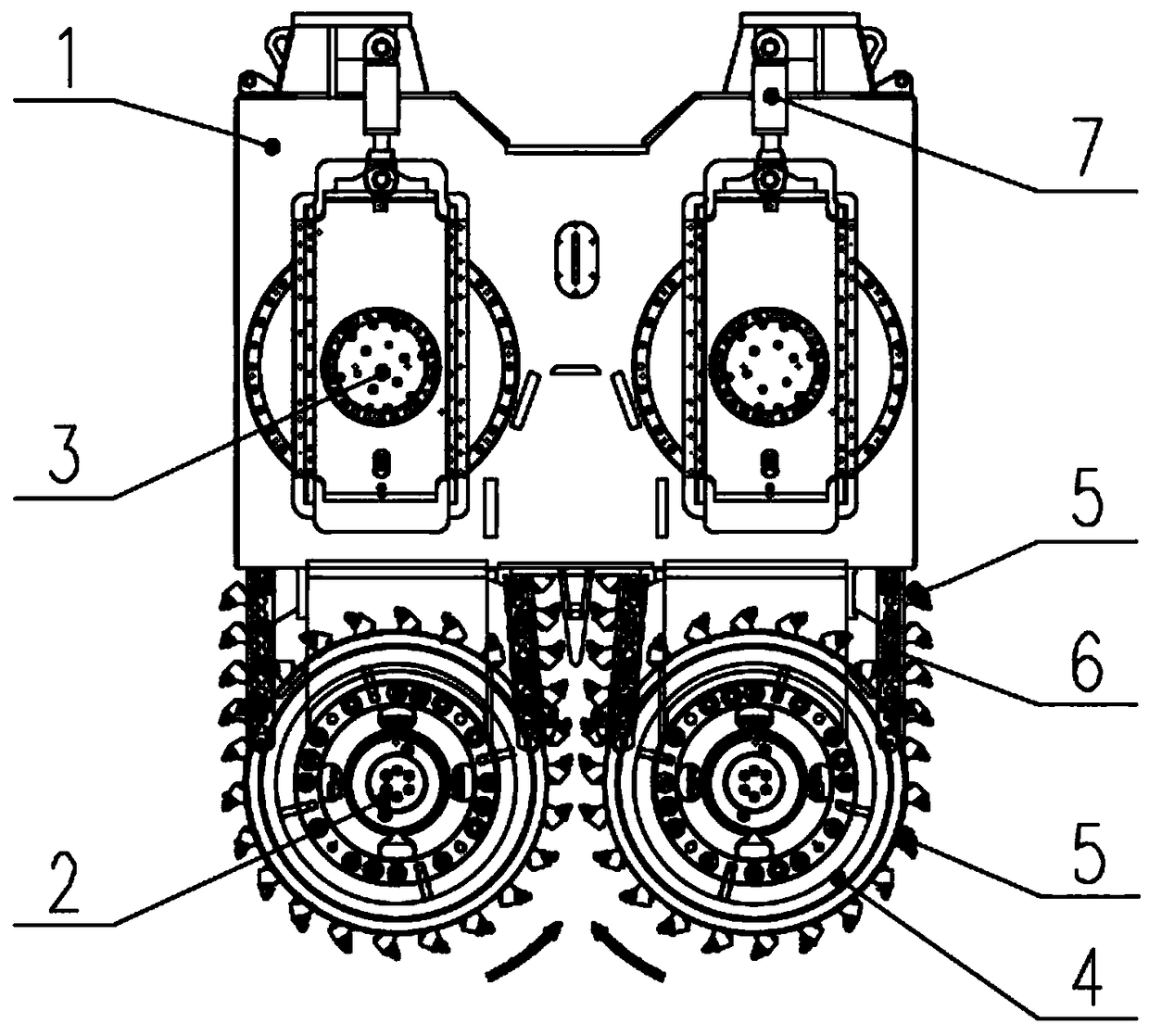

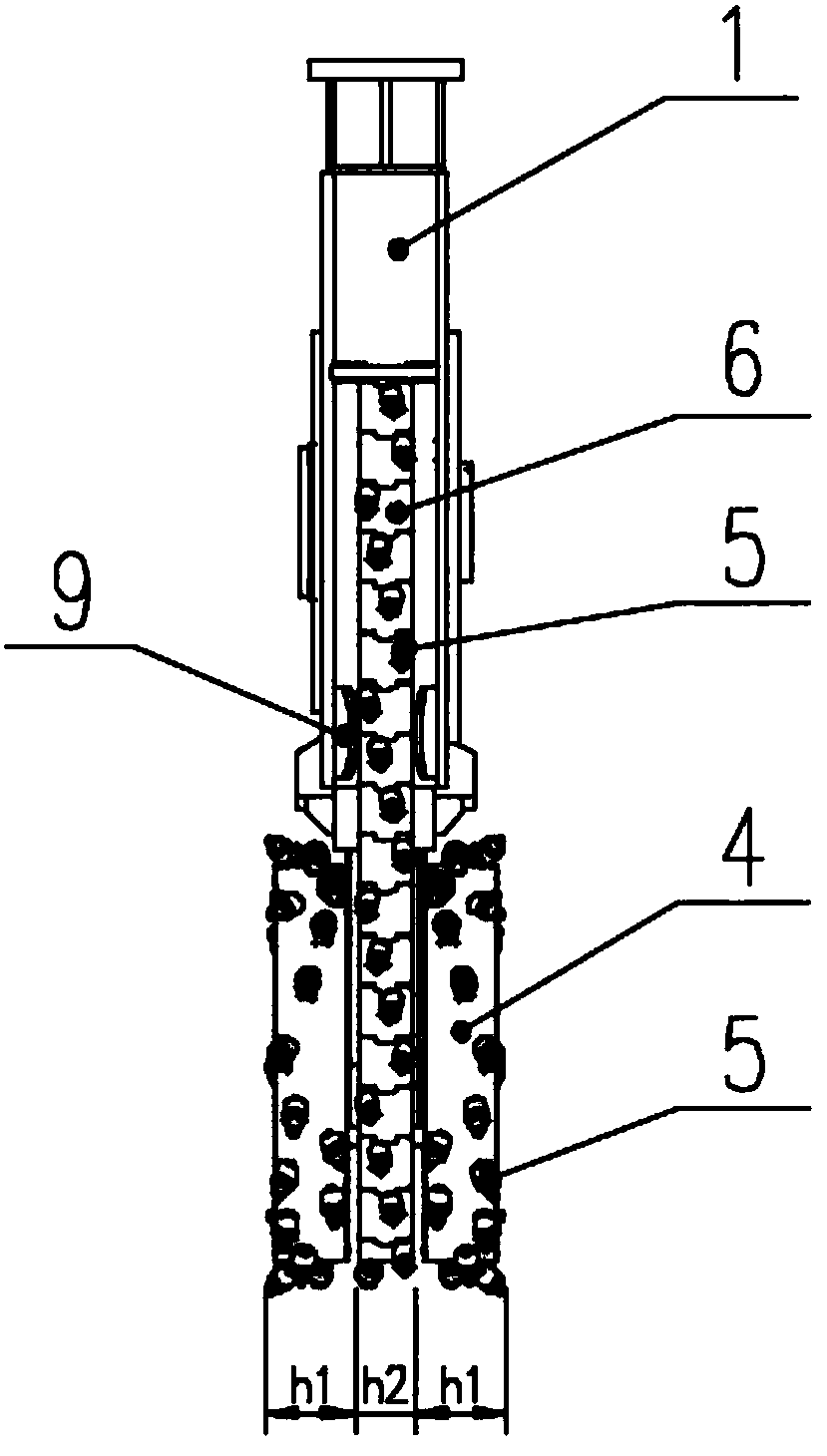

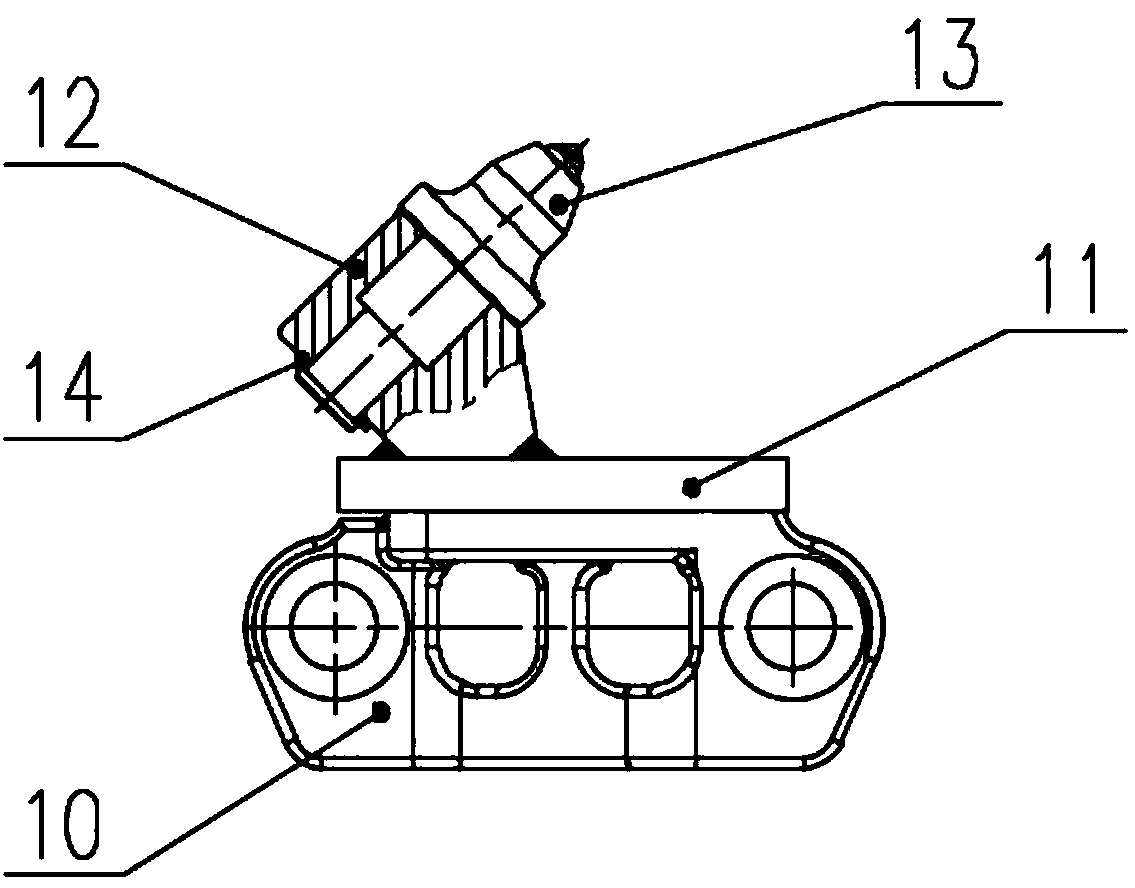

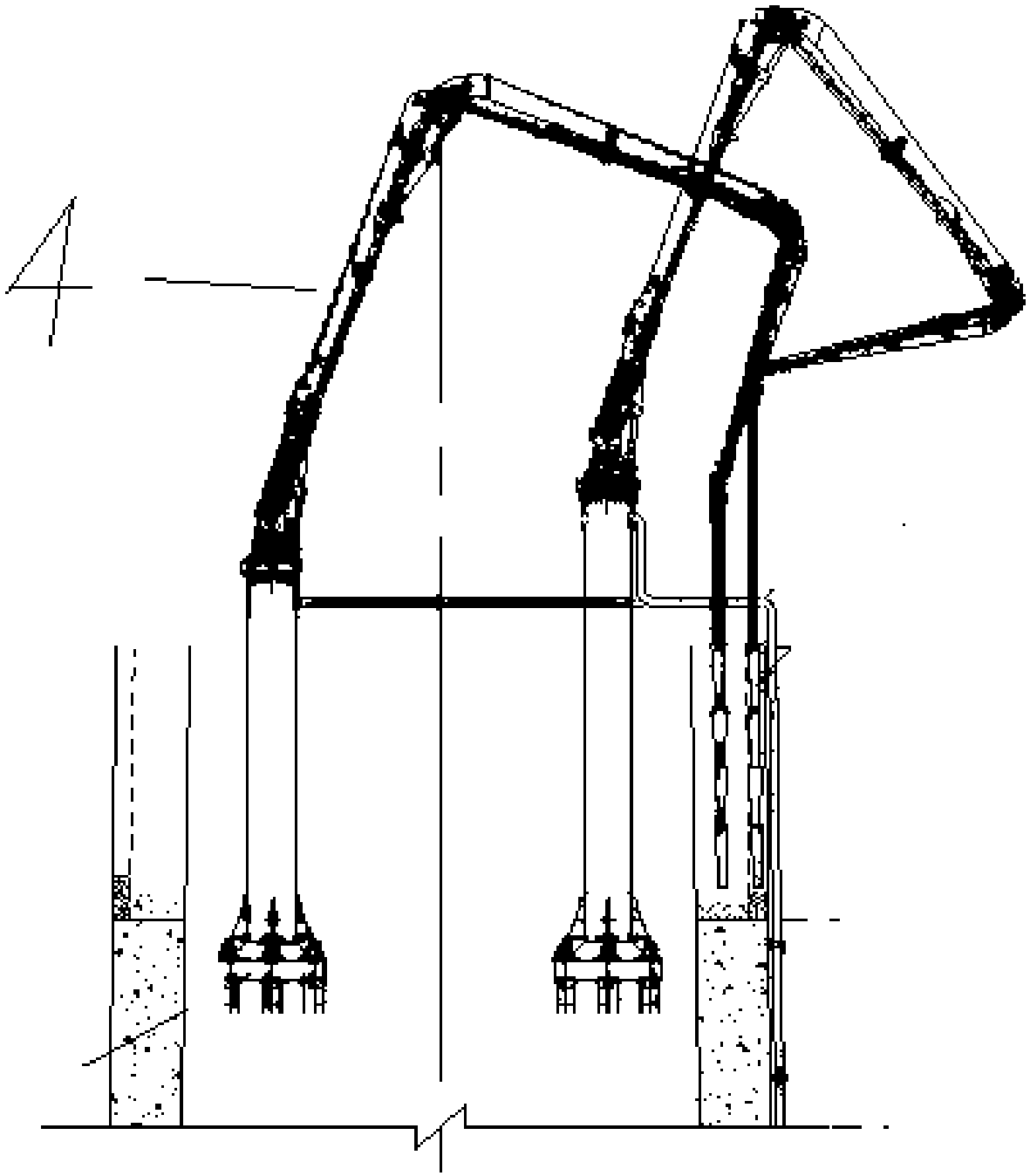

Double-wheel slot milling machine based on sprocket transmission and milling, and slot forming method

PendingCN108086381AIncreased shear strengthImprove anti-seepage performanceMechanical machines/dredgersBulkheads/pilesDrive wheelBraced frame

The invention discloses a double-wheel slot milling machine based on sprocket transmission and milling, and a slot forming method. The double-wheel slot milling machine at least comprises a support frame, a rotary milling wheel, a driving wheel, milling wheel hubs, a milling cutter gear, a sprocket, a sprocket tensioning device and a sprocket wheel. The sprocket tensioning device pulls the drivingwheel to move up and down. The sprocket is connected with the driving wheel and the rotary milling wheel in a surrounding mode to achieve driving. A plurality of milling teeth are welded on the peripheral edge of the sprocket. The milling wheel hubs are arranged on two sides of the rotary milling wheel. A plurality of milling teeth are arranged on the circumferences of the milling wheel hubs at intervals. The sprocket wheel is located on the inner side of the sprocket to eject the sprocket outwardly during mounting. The double-wheel slot milling machine has the advantages that technical problems in the prior art are solved, rock stratums below the support frame can be milled completely, smoothness of the side wall of a milling groove is guaranteed, and slurry and rock debris are discharged quickly; triangular grooves can be formed in two sides of the milling groove respectively, and shearing strength and seepage-proofing effect at casted continuous wall joints after slotting are improved greatly.

Owner:CHINA RAILWAY ENG MASCH RES & DESIGN INST CO LTD

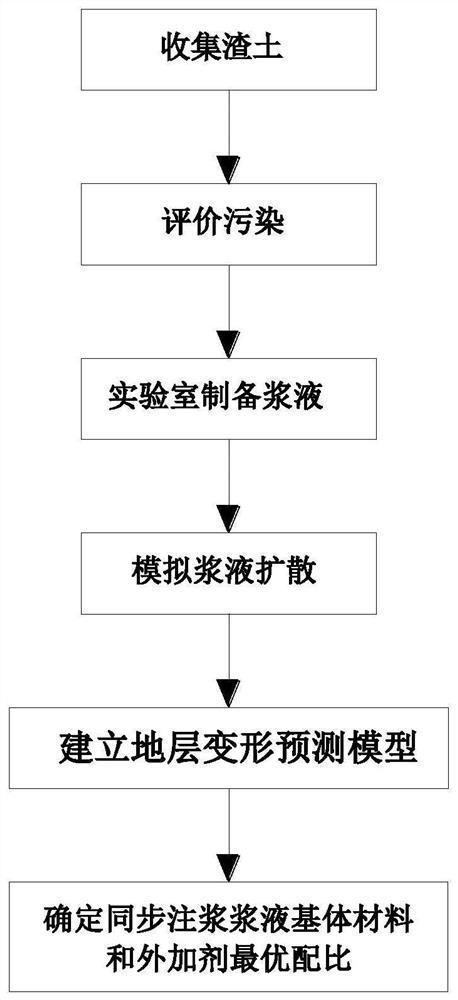

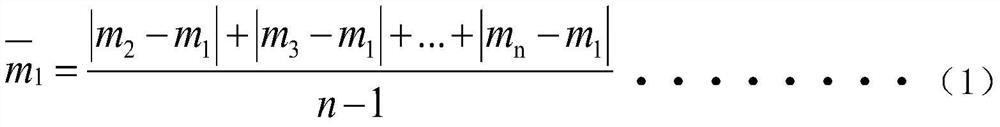

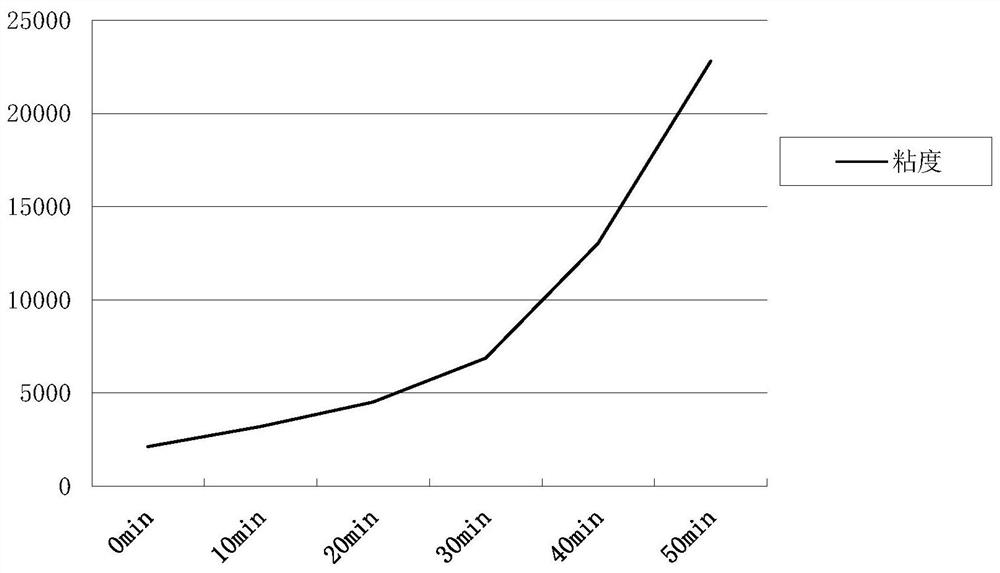

Environment-friendly treatment method for silty clay in shield synchronous grouting

ActiveCN112851225AMeet pollution control requirementsRaise the ratioEarth material testingInorganic saltsMuck

The invention relates to a muck resource utilization treatment method, in particular to an environment-friendly treatment method for silty clay in shield synchronous grouting, and belongs to the technical field of geotechnical engineering and tunnel engineering. The method comprises the steps: S1, collecting muck, wherein the muck is silty clay muck; S2, evaluating the pollution; S3, preparing slurry in a laboratory, taking silty clay muck as a basic material of the slurry, adding the silty clay muck into the synchronous grouting slurry to replace a bentonite component in synchronous grouting, and carrying out a uniform experiment; S4, simulating slurry diffusion; S5, establishing a stratum deformation prediction model after slurry solidification by using a neural network; S6, performing regression analysis on the performance and pollution degree of the slurry and the stone body obtained in the S3 and the ground surface settlement obtained in the S5, and determining the optimal proportion of the synchronous grouting slurry base material and the additive. By means of slurry solidification, pollution of heavy metal, inorganic salt and the like caused by the additive added for muck improvement and slurry improvement can be treated, and the treated slurry can meet the pollution control requirement.

Owner:HOHAI UNIV

Gradient functional concrete tower column structure and construction method thereof

InactiveCN108086154AGuarantee the construction qualityIncreased durabilityBridge structural detailsBridge erection/assemblyStructure of the EarthHoneycomb

The invention discloses a gradient functional concrete tower column structure and a construction method thereof. The gradient functional concrete tower column structure comprises a functional layer and a structural layer whose cross sections are arranged in sequence from outside to inside; a functional structure transitional area is arranged between the functional layer and the structural layer; the functional layer and the structural layer are respectively formed by pouring; a concrete tower column structure, which has no macroscopic interface, whose components are in gradient transition andwhich simulates skin, is formed among the functional layer, the structural layer and the functional structure transitional area; the mixed concrete of the functional layer and the structural layer istransported to the field to be poured; during pouring, the top surface of the concrete of the functional layer is always kept to be about 30 cm higher than the concrete of the structural layer; vibrating is carried out during pouring; and when the concrete is poured to a height of 4.5 m, the pouring is stopped. The gradient functional concrete tower column structure has the advantages that the concrete construction quality is effectively guaranteed, problems of honeycombs and dot surfaces are avoided, the durability and ornamental value of the concrete tower column are enhanced; the later maintenance cost of the ultrahigh tower concrete structure is reduced to adapt the composite demands of the concrete tower column on mechanical property, durability and beauty.

Owner:ANHUI TRANSPORTATION HLDG GRP CO LTD

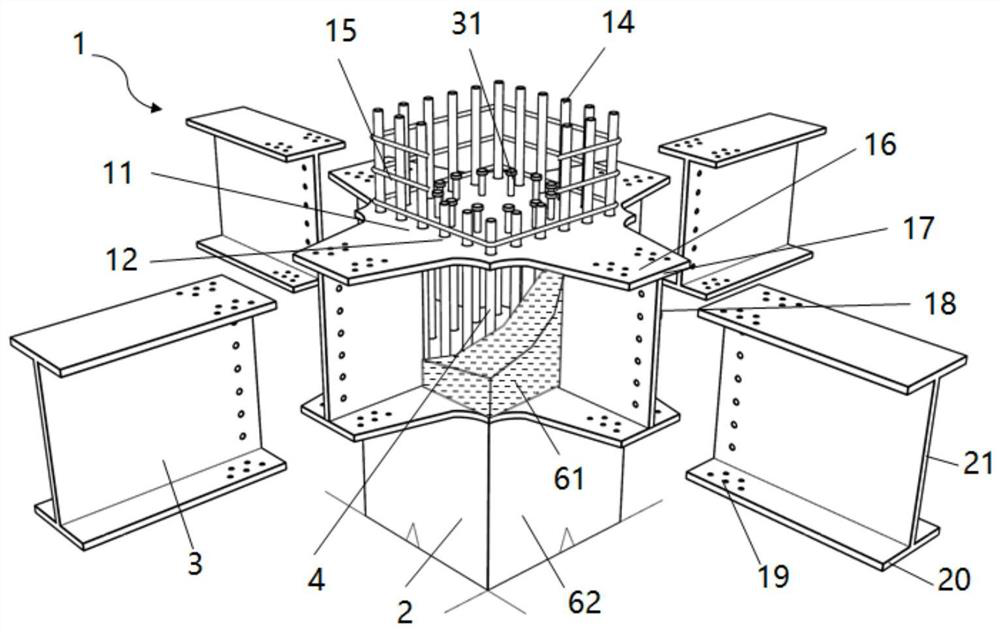

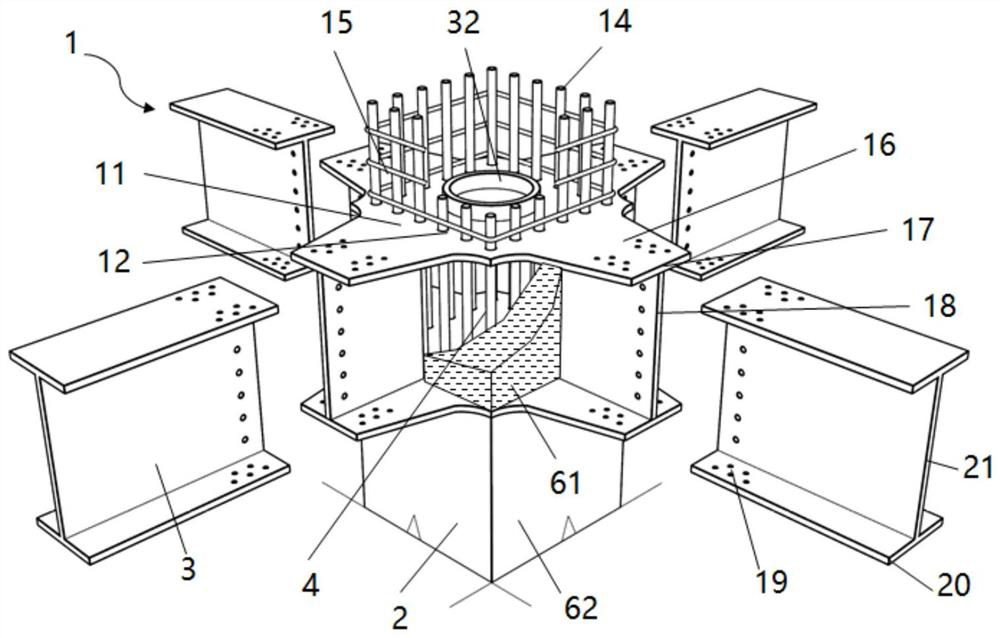

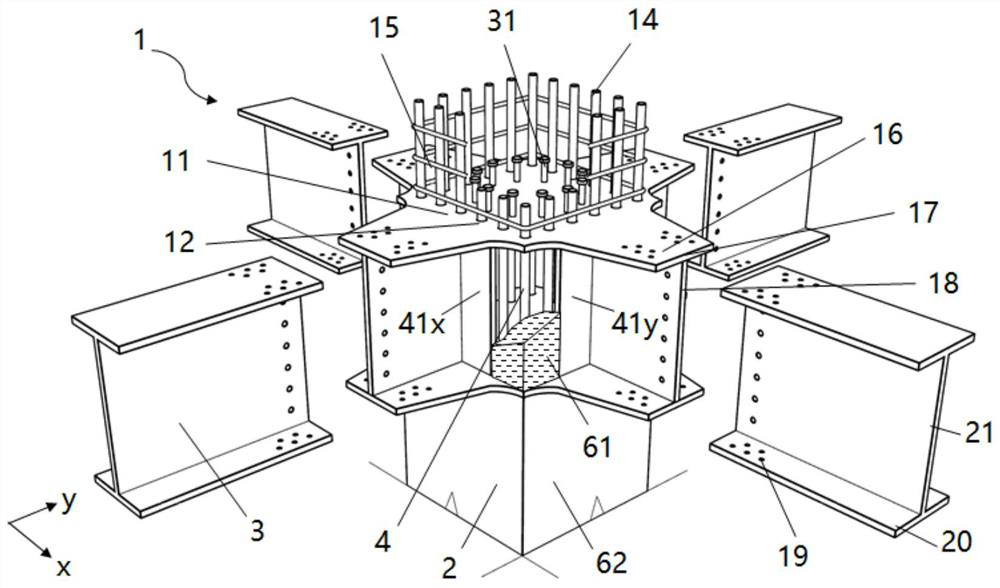

Column full-section partition plate type stirrup-free fiber reinforced concrete mixed frame joint

PendingCN112049254ASimplify the construction processImprove applicabilityStrutsGirdersReinforced concrete columnEngineering

The invention relates to the field of concrete structures and combined structure buildings, and provides a reinforced concrete column-steel beam mixed frame joint adopting a column full-section partition plate type and fiber reinforced concrete. An upper horizontal joint plate and a lower horizontal joint plate which are in the column full-section partition plate type are adopted; round holes areformed in the peripheries of the joint plates, and column longitudinal steel bars penetrate through the round holes; horizontal shear keys are arranged on the surfaces of the joint plates; no stirrupis arranged between the upper joint plate and the lower joint plate, and the fiber reinforced concrete is poured; the joint plates extend outwards to form short beams, the flanges of the short beams are variable sections, and webs are welded between the flanges and are in bolted connection or welded connection with a midspan steel beam; and the inner ends of the webs of the short beams can be provided with surface bearing plates perpendicular to the webs, and the surface bearing plates are welded to the webs, the upper joint plate and the lower joint plate so as to increase the shear capacityof the joint. According to the reinforced concrete column-steel beam mixed frame joint, the column end can be prevented from being damaged due to pressure bearing, and the stress performance of the joint is improved; and meanwhile, the joint stirrup is omitted, the manufacturing process of the joint is simplified, and prefabricated construction is facilitated.

Owner:ZHEJIANG UNIV

Low-melting-point lead-free solder alloy

ActiveCN102936669BLow melting pointUniform tissueWelding/cutting media/materialsSoldering mediaShock resistanceUltimate tensile strength

The invention relates to a low-melting-point lead-free solder alloy which belongs to the technical field of welding materials and is used for solving the problem that the conventional solder alloys are high in melting point and low in shearing strength. The low-melting-point lead-free solder alloy comprises the following components in percentage by weight: 10-30% of Bi, 2.2-3.0% of Ag, 0.5-1.0% of In, 0.004-0.008% of P and the balance being tin. The low-melting-point lead-free solder alloy also can comprise 0.002-0.005% of RE and 0.002-0.005% of Co. According to the low-melting-point lead-free solder alloy, the melting point is low, the alloy eutectic temperature is about 170-200 DEG C, the shearing strength is good and between 21-28N / mm<2>, the RE is capable of improving the glossliness of the solder alloy and refining the grains, the Co is capable of improving the soldering performance and the shock resistance, and Zr has the function of homogenizing and refining the alloy tissues.

Owner:上海一远电子科技有限公司

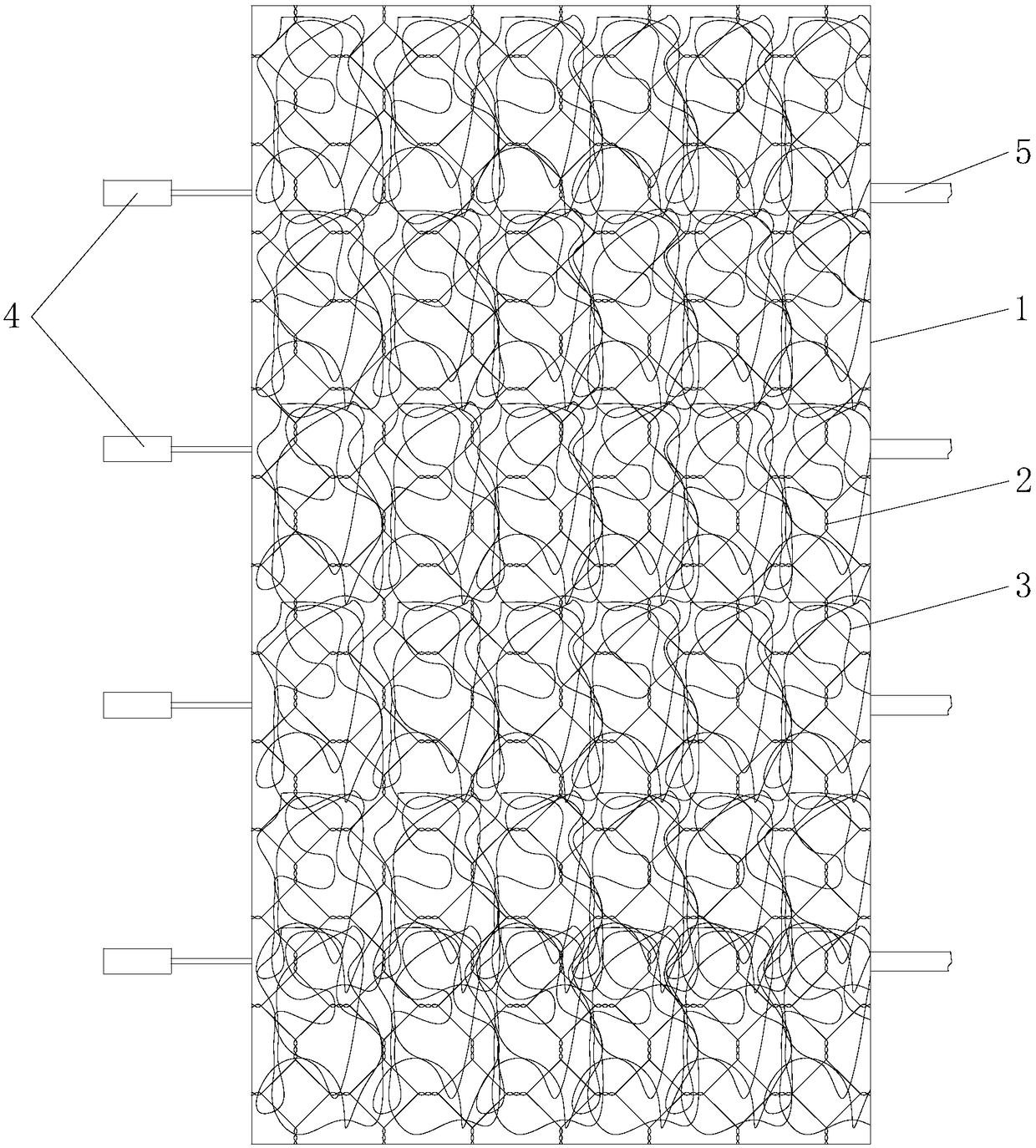

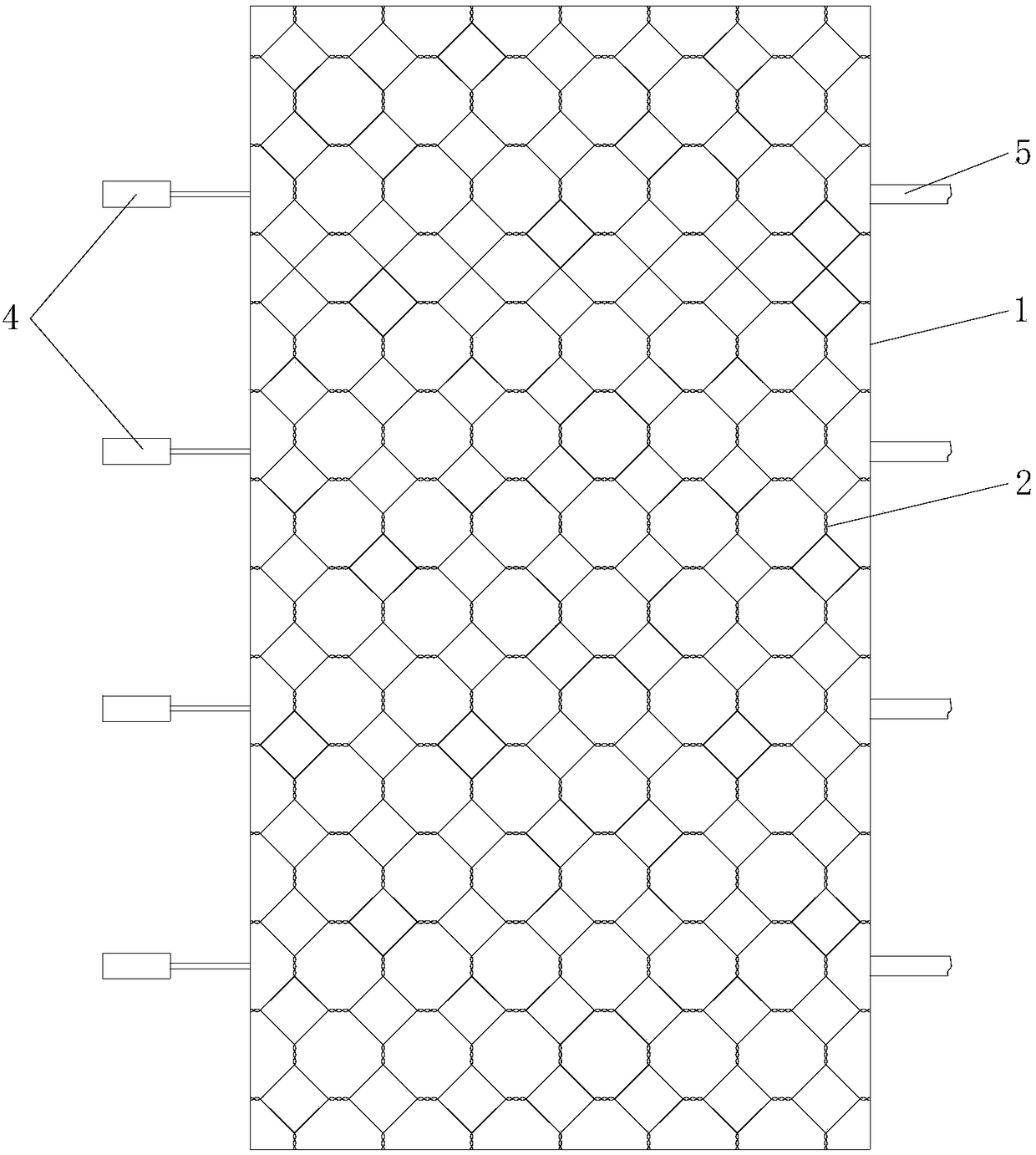

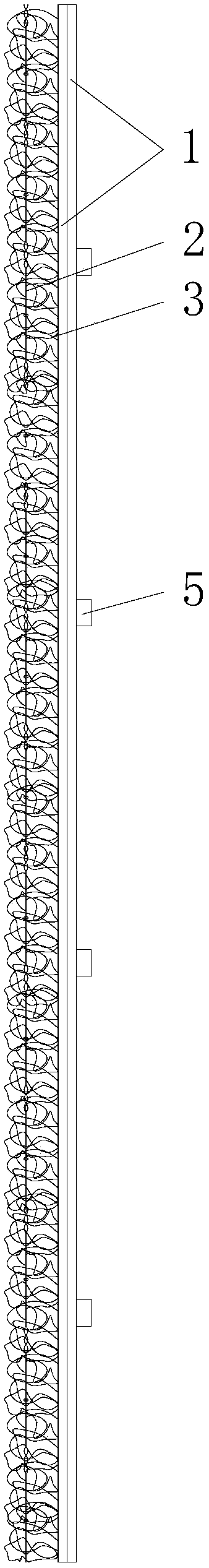

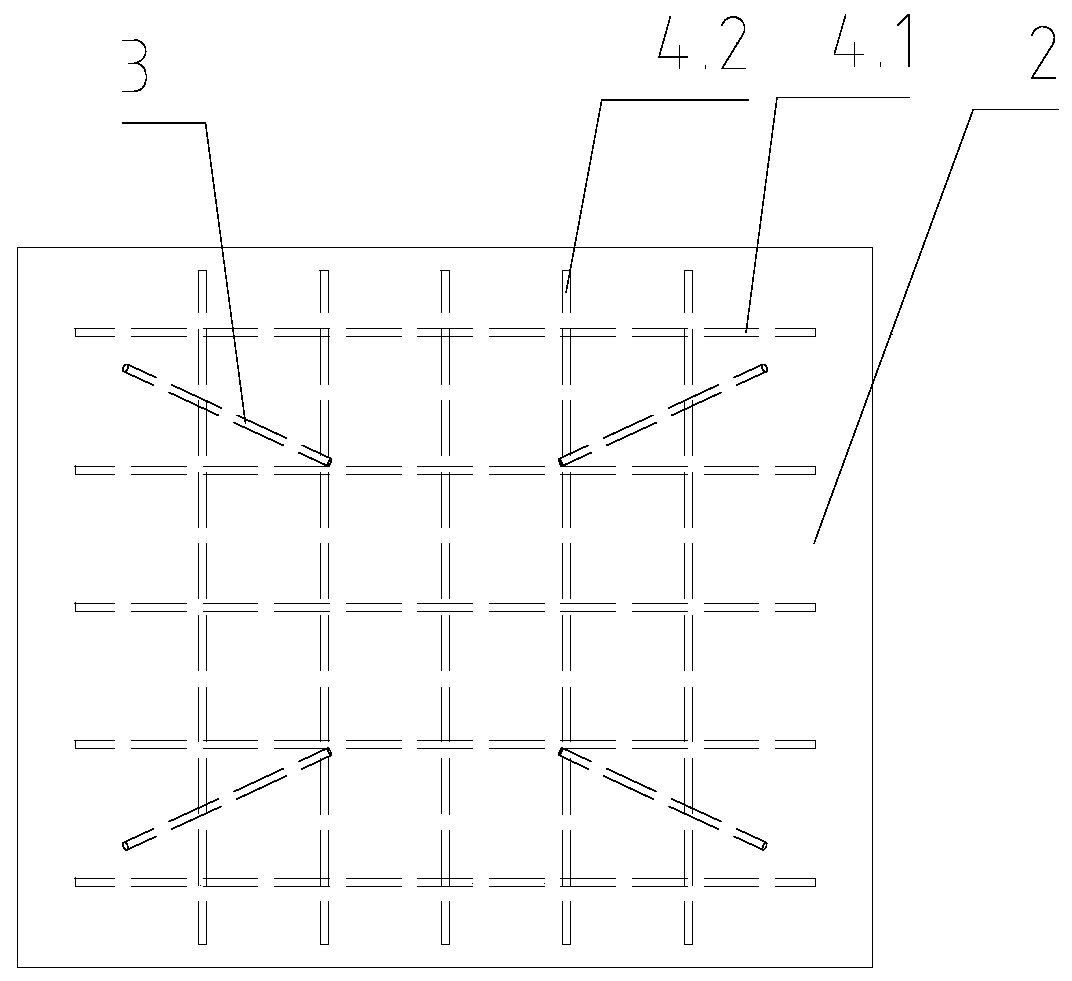

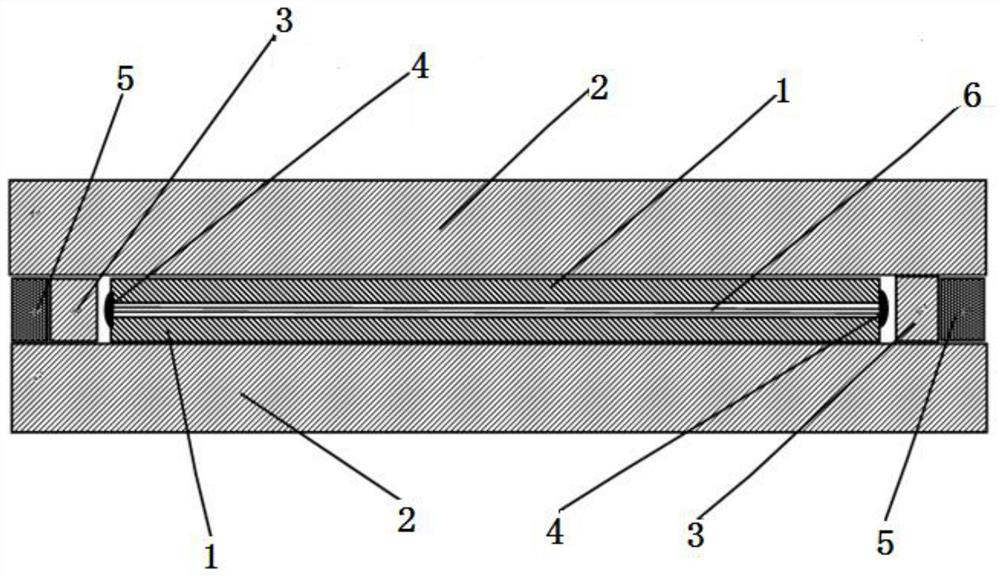

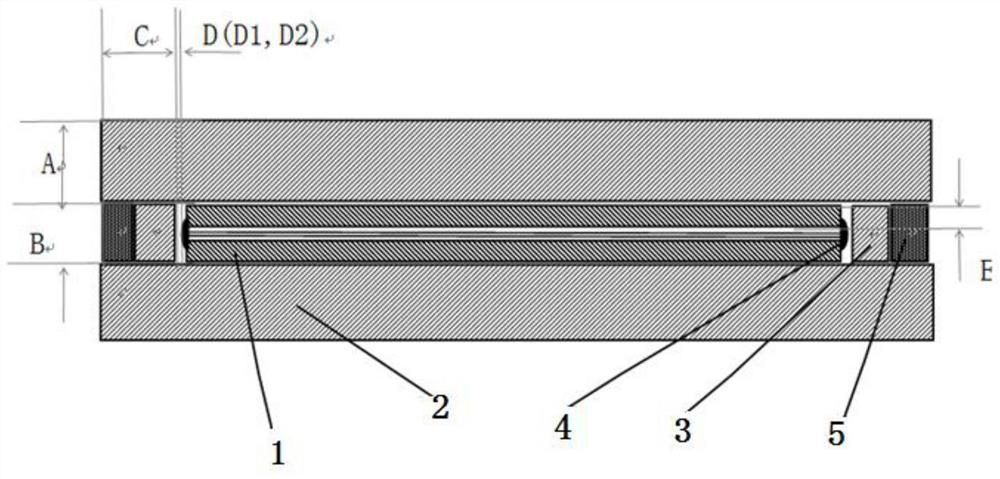

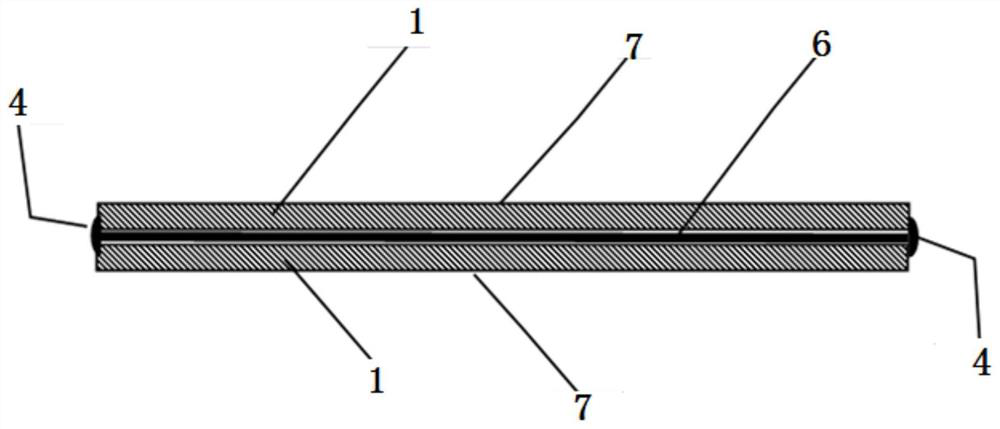

Reinforcement pin joint permanency beam formwork, concrete structural member and manufacturing method

ActiveCN105350717AGuaranteed shear strengthTroubleshoot stirrup placement issuesBridge structural detailsGirdersUltimate tensile strengthStructural element

Owner:ZHEJIANG UNIV

Gear clutch with high meshing success probability

InactiveCN112696439AGuaranteed bending strengthGuaranteed shear strengthPortable liftingInterengaging clutchesGear wheelTorque transmission

The invention provides a gear clutch with the high meshing success probability. A section of inclined face is manufactured on the side, close to a non-torque-transmission gear face, of the gear tooth end face of a movable sleeve gear and the gear tooth end face of a static sleeve gear, a straight face is reserved on the side close to a torque-transmission gear face, and the width of the inclined face accounts for about 95% of the gear thickness. The inclination direction of the movable sleeve tooth end face slope is opposite to the moving direction of the movable sleeve teeth, the inclination direction of the static sleeve tooth end face slopes is the same as the moving direction of the movable sleeve teeth, and the inclination angles of the tooth end face slopes of the movable sleeve teeth and the static sleeve teeth are equal. During meshing, the movable sleeve teeth move downwards to the static sleeve teeth under the action of an external force, the inclined faces of the tooth end faces of the movable sleeve teeth and the inclined faces of the tooth end faces of the static sleeve teeth make contact with each other, and along with rotation of the movable sleeve teeth, due to the action of the inclined faces, the movable sleeve teeth generate an axial movement distance L relative to the static sleeve teeth; when the gear teeth of the movable sleeve gear rotate over the current static sleeve gear tooth in contact with the gear teeth and are in contact with the working tooth surface of the next static sleeve gear tooth, the distance L can avoid the tooth collision phenomenon, the probability of one-time meshing success of the sleeve gear is improved, and the torque transmission strength of the sleeve gear is kept not to be reduced.

Owner:中国船舶重工集团公司第七0三研究所

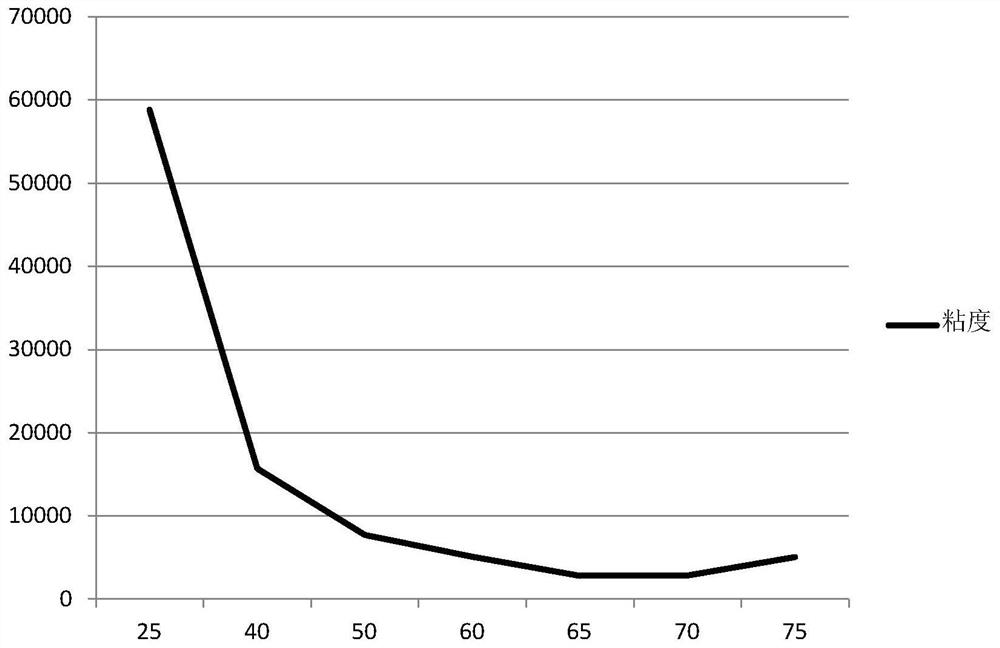

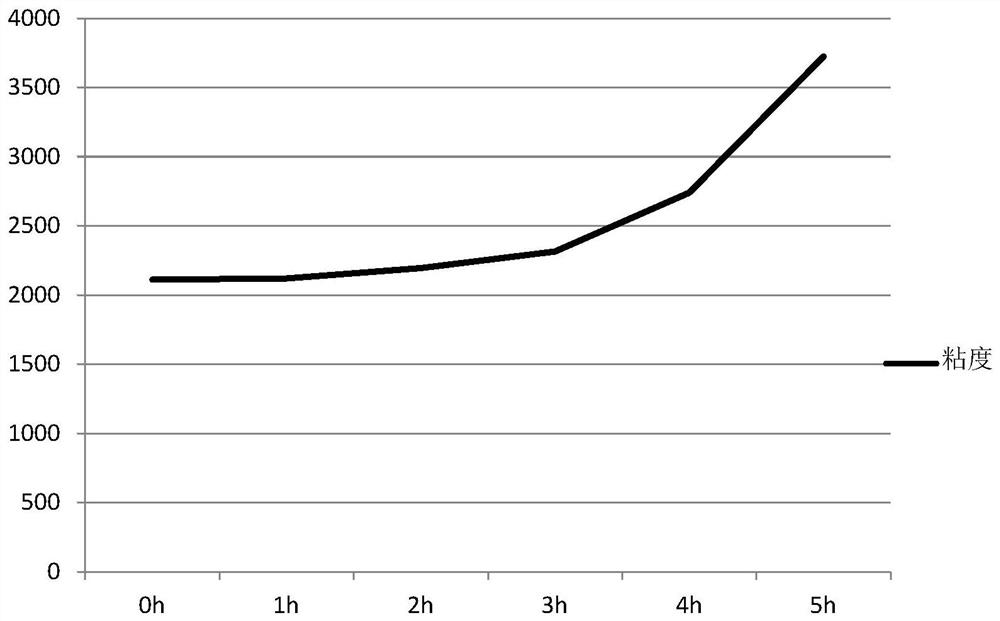

Technology for gluing stator punching sheet by adopting KH-225 glue, gluing technology and tool for gluing technology

PendingCN113489254AImprove liquidityReduce adverse effectsManufacturing stator/rotor bodiesPunchingEngineering

The invention discloses a technology for gluing a stator punching sheet by adopting KH-225 glue. The technology comprises the following steps of S1, cleaning: cleaning the punching sheet to remove oil stains on the surface of the punching sheet, S2, gluing: gluing each punching sheet by adopting a heating gluing process, wherein the gluing temperature is kept at 65+ / -5 DEG C, S3, clamping: gluing the punching sheets, stacking the punching sheets on a tool, and ensuring that the thickness of a glue layer between the punching sheets is greater than or equal to 5 microns after mounting, S4, curing: preserving heat at 80+ / -5 DEG C for 6+ / -0.1 h or preserving heat at 120+ / -5 DEG C for 3+ / -0.1 h, and S5, cooling: cooling along with the furnace for 12+ / -2 hours, and then dismounting the tool and taking out a pressed finished product; on the basis of the gluing technology, gluing parameters and a clamping tool have originality, by adopting the technology, the gluing temperature is strictly controlled to enable the punching sheet to have better fluidity, gluing on the surface of the punching sheet is facilitated, the thickness of a glue layer is limited between 5 mum and 15 mum through the tool, what can be ensured is that the shearing strength is larger than or equal to 15 MPa, and cohesive stress and black lines caused by the too thick glue layer can be avoided.

Owner:SHAANXI AEROSPACE TIMES NAVIGATION EQUIP CO LTD

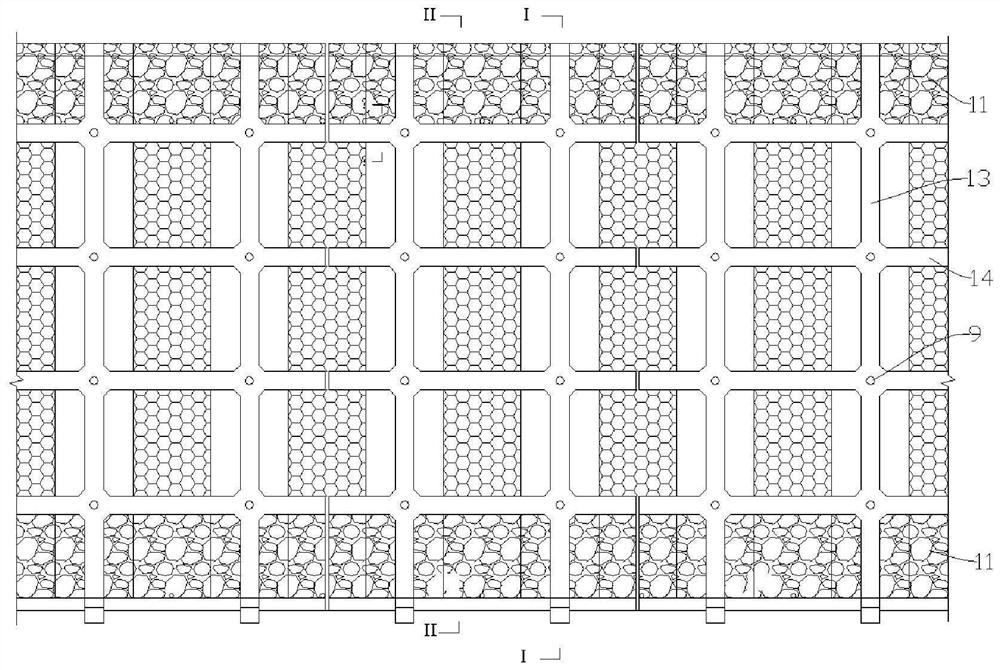

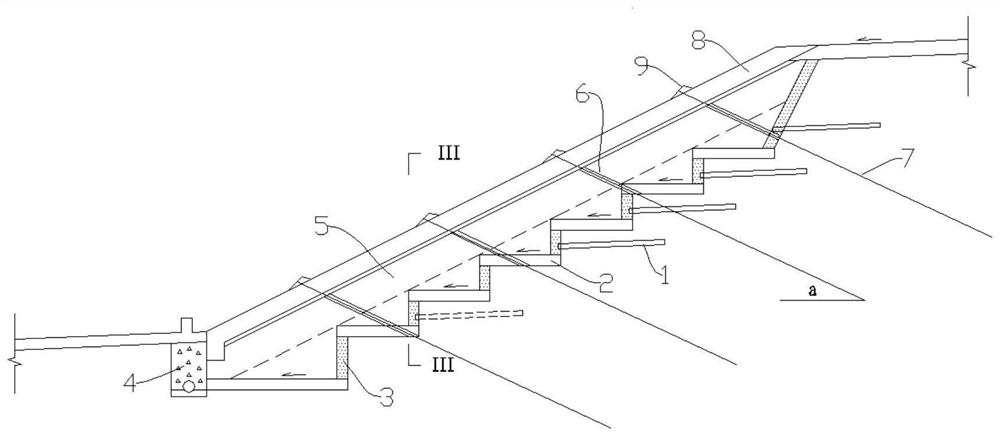

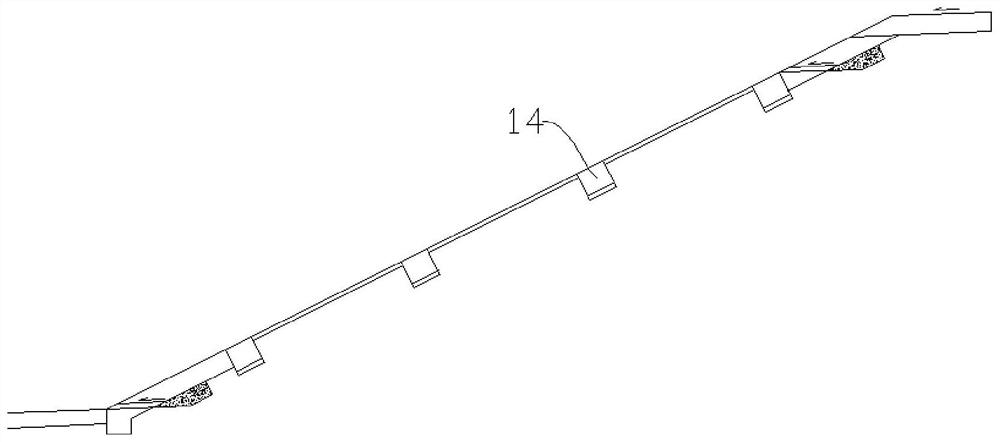

Composite side slope reinforcing structure

PendingCN113186955ASolve winter drainage needsSolving Deep Drainage ProblemsExcavationsBulkheads/pilesSoil scienceLandslide

The invention provides a composite side slope reinforcing structure. The reinforcing structure comprises supporting seepage ditches which are obliquely and longitudinally arranged along a side slope at intervals, and the supporting seepage ditches are defined by the following structures: an upper ditch surface which is obliquely and longitudinally arranged along the side slope, concrete flowing water surfaces which are arranged in a step shape below the upper ditch surface, a rear inverted filter layer which is connected between two adjacent concrete flowing water surfaces, and side inverted filter layers which are arranged on two sides of the concrete flowing water surfaces and are connected with the upper ditch surface; the hollow structure of each supporting seepage ditch is filled with dry masonry rubbles, a plurality of anchor cable hole steel pipes are embedded inwards in the supporting seepage ditches from the upper ditch surface, anchor cables are installed in the anchor cable hole steel pipes, and the ends of the anchor cables are fixed through anchor piers arranged on the upper ditch surface; and blind ditches communicating with the supporting seepage ditches are formed in the bottoms of the supporting seepage ditches, and the blind ditches are perpendicular to the supporting seepage ditches and are transversely arranged. The problem of water-rich soft soil landslide treatment under special terrain and geological conditions is effectively solved, the construction risk is low, and the structure has application and popularization value.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

High-strength reinforced ecological mat and manufacturing method thereof

ActiveCN108476922AImprove tensile propertiesImprove tear resistanceGrowth substratesCulture mediaFiberPlanting seed

The invention provides a high-strength reinforced ecological mat and a manufacturing method thereof. The high-strength reinforced ecological mat provided by the invention comprises a mat body, a stranded metal mesh, a fiber layer, a locking member and a locking belt, wherein the stranded metal mesh is arranged in the interior of the fiber layer and arranged on the lower surface of the mat body through the fiber layer; one long edge of the mat body is provided with the locking member used for connection; the other long edge of the mat body is provided with the locking belt corresponding to thelocking member; and plant seeds are attached on the upper surface of the mat body. The high-strength reinforced ecological mat provided by the invention has the following advantages: the speed and efficiency of installation are improved; the output of labor force is reduced; meanwhile, the structural strength of the mat body is improved; the service life of the mat body is prolonged; the ability of fixing soil is reinforced; and ecological balance is promoted.

Owner:农安隆兴土工材料有限公司

Reinforced pin-jointed permanent beam formwork, concrete structural member and manufacturing method

ActiveCN105350717BGuaranteed shear strengthTroubleshoot stirrup placement issuesBridge structural detailsGirdersEngineeringUltimate tensile strength

Owner:ZHEJIANG UNIV

Insulation board provided with two layers of mesh fabric

PendingCN110777954AHigh strengthAvoid edge collapseHeat proofingStructural engineeringInsulation layer

The invention provides an insulation board provided with two layers of mesh fabric. The insulation board is provided with an insulation layer. A concrete layer is arranged on one side of the insulation layer. A steel mesh supporting framework is arranged in the concrete layer. The insulation board is characterized in that the two layers of mesh fabric are arranged in the concrete layer in parallel, web wires are arranged on the steel mesh supporting framework, one end of each web wire is connected with the steel mesh supporting framework in an overlap mode, and the other end of the web wire penetrates through the insulation layer to be exposed out of the insulation layer. By the adoption of the insulation board, the technical problem that an existing insulation board is poor in shear capacity, low in strength and prone to edge collapses is solved. The insulation board can be widely applied to buildings.

Owner:山东隆济时节能科技股份有限公司

The method of making up the raw material of titanium steel clad plate

ActiveCN113020295BGuaranteed shear strengthNo gas accumulationAuxillary arrangementsMetal rolling arrangementsManganeseTitanium

The invention relates to the technical field of composite plate manufacturing, in particular to a titanium-steel composite plate; the technical problem to be solved by the invention is to provide a method for assembling a raw material blank of a titanium-steel composite plate. A method for forming a raw material blank of a titanium-steel clad plate includes the following steps: A. limiting the value range of the compression ratio; B. limiting the carbon and manganese content of the base steel sheet and the plugging steel sheet; C. removing the base material and the cladding material Oxide film and cleaning treatment; D. Align the base material and the cladding material, apply a release agent between the cladding materials, and weld the cladding materials into a whole; E. Pump the gap between the cladding materials Vacuum treatment and hold pressure; F. Place the cladding material after assembly welding between the lower base materials, and the geometric center of the cladding material and the base material is on a straight line; G. Use the sealing steel plate to weld the base material to make The cladding material is sealed between the sealing steel plate and the base material; H. Vacuum treatment and pressure retention are performed on the gap between the base material.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

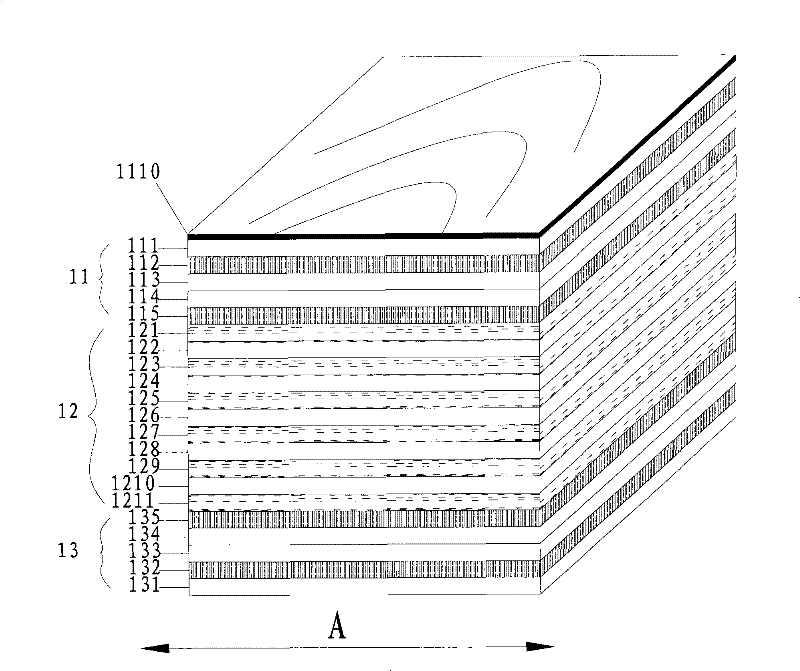

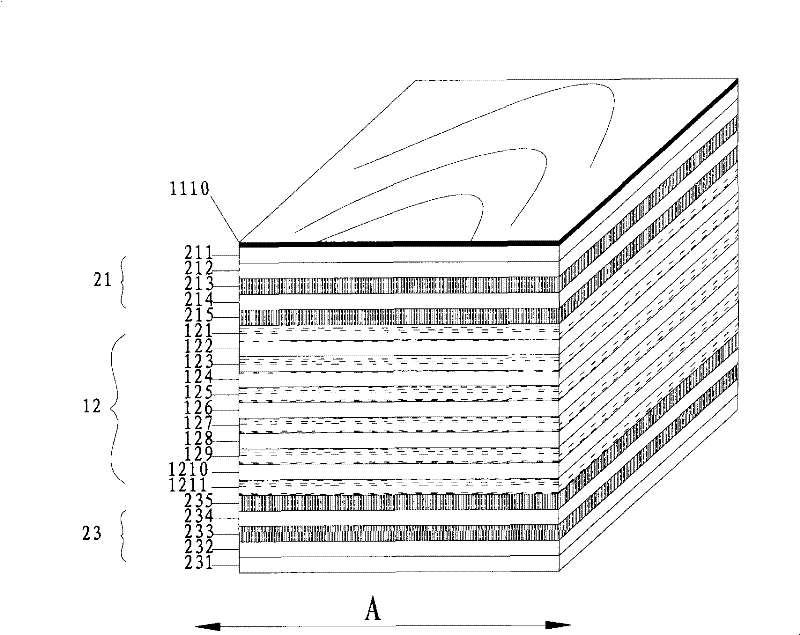

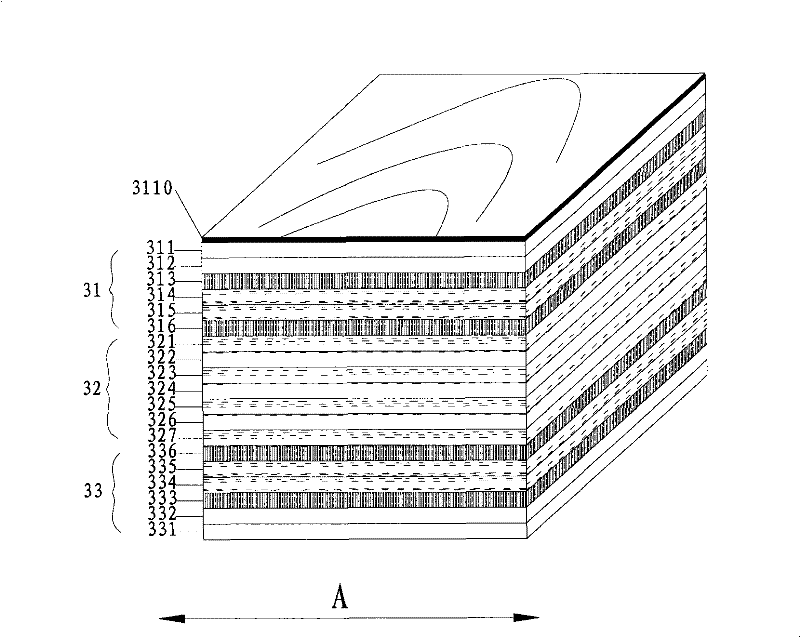

Plywood used for bottom plate of container

ActiveCN101767354BReduce material costsIncrease profitWood veneer joiningWood layered productsSurface layerSingle plate

The invention discloses a plywood used for a bottom plate of a container, which is formed by a plurality of layers of single plates by gluing pressing and comprises an upper surface layer, a lower surface layer and a middle layer between the upper surface layer and the lower surface layer; both the upper surface layer and the lower surface layer comprise single plates with longitudinal striationsand single plates with transverse striations, and the upper surface layer sequentially comprises one to two layers of single plates with longitudinal striations, one layer of single plate with transverse striations, two layers of single plates with longitudinal striations and one layer of single plate with transverse striations. The plywood used for the bottom plate of the container changes the structural characteristics of the bottom plate of the traditional container by adopting the method of continuously laminating a plurality of layers of single plates with longitudinal striations, thus guaranteeing the shearing strength of the middle layer of the bottom plate, reinforcing the bending strength of the whole bottom plate, and well meeting the harsh requirement of the bottom plate of thecontainer on strength.

Owner:寰宇东方国际集装箱(启东)有限公司

A permanent beam formwork, a concrete structural member and a manufacturing method for a reinforced embedded buckle connection

ActiveCN105369981BHigh strengthFirmly connectedBridge structural detailsHydraulic engineering apparatusUltimate tensile strengthStructural element

The invention discloses a reinforcement-type embedded buckle connection permanent beam template, a concrete structural member and a manufacturing method, and belongs to the technical field of building templates and manufacturing methods thereof. By adopting the technical solution of the present invention, a permanent beam formwork with good strength, rigidity and connection performance, which does not need to be additionally configured with longitudinal reinforcement and stirrup when pouring structural members, can be obtained. Further, by adopting the manufacturing method of the present invention, the permanent formwork and its forming components can be manufactured quantitatively, which solves the problem of stirrup manufacture and configuration of the permanent beam formwork; more efficient utilization of materials can be realized, thereby reducing its cost . On this basis, the technical scheme of the invention simplifies the pouring construction using the permanent beam formwork, and has broad application prospects.

Owner:ZHEJIANG UNIV

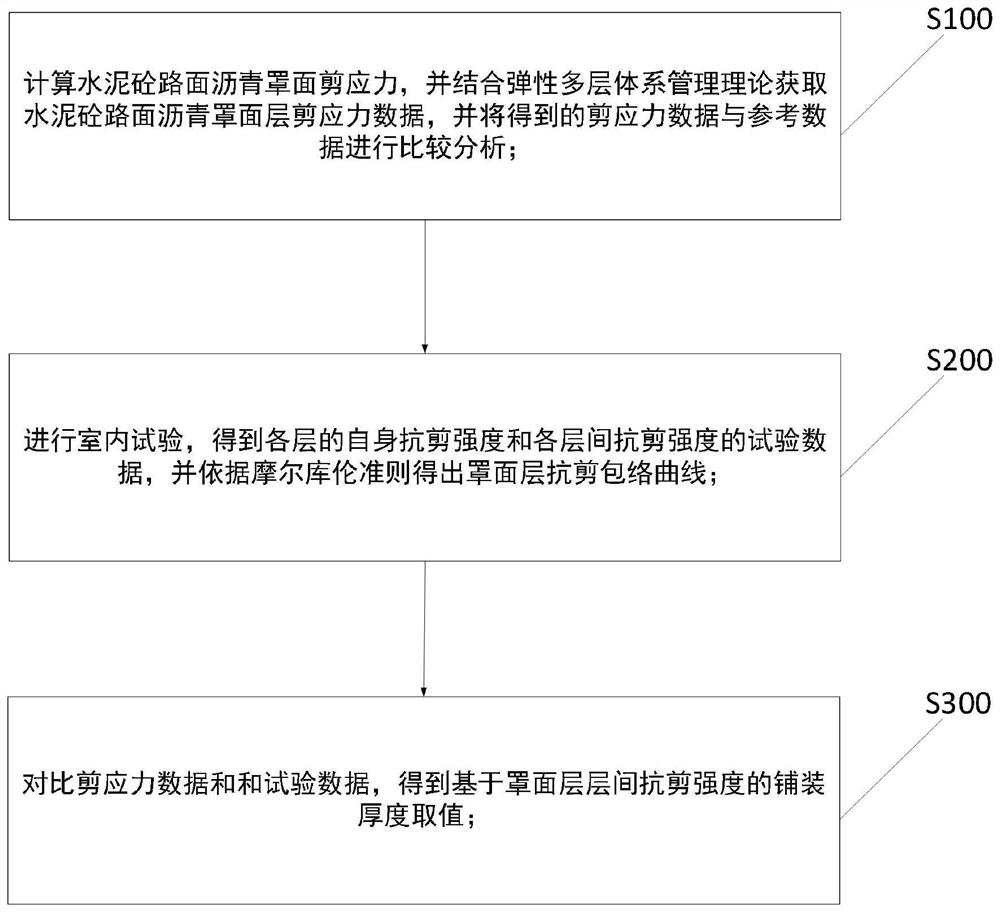

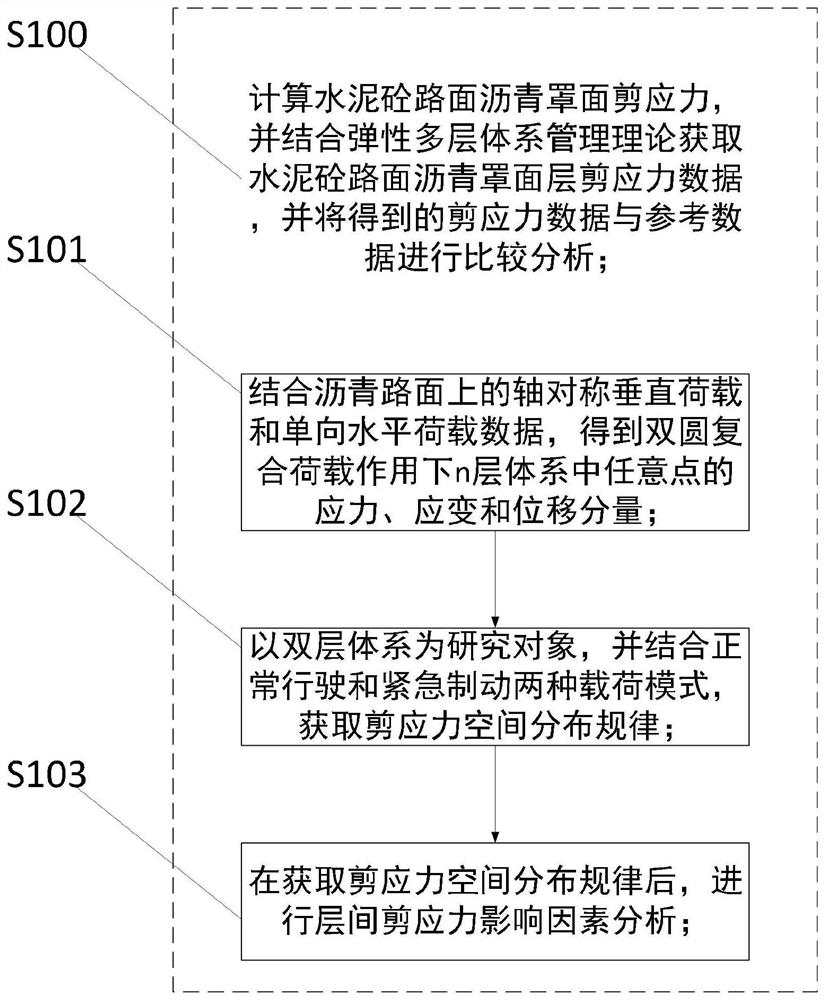

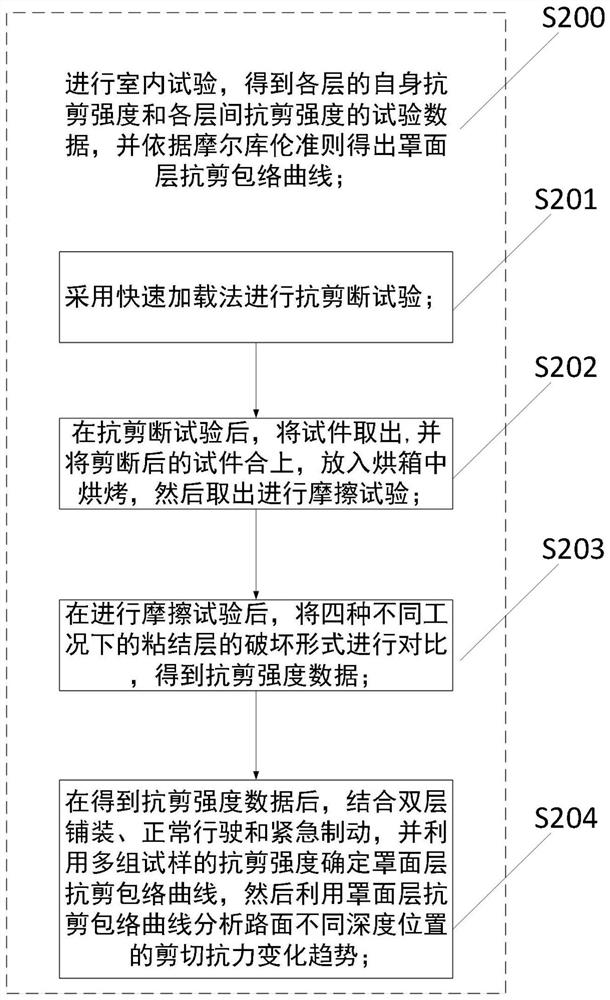

A Method for Determining the Pavement Thickness of Asphalt Overlay on Cement Concrete Pavement

ActiveCN110629627BGuaranteed shear strengthPavement Thickness GuaranteeGeometric CADIn situ pavingsShear stressInterlaminar shear

The invention discloses a method for determining the pavement thickness of the asphalt overlay on cement concrete pavement, calculating the shear stress of the asphalt overlay on the cement concrete pavement, and obtaining the shear stress data of the asphalt overlay on the cement concrete pavement in combination with the elastic multi-layer system management theory, And compare and analyze the shear stress data obtained with the reference data; carry out indoor tests to obtain the test data of the self-shear strength of each layer and the shear strength of each layer, and obtain the shear envelope of the overlay layer according to the Mohr-Coulomb criterion. curve; compare the shear stress data with the test data, and obtain the value of the pavement thickness based on the interlayer shear strength of the overlay. To achieve the research on the shear resistance between asphalt overlays on cement concrete pavement, from the perspective of design rationality, a comprehensive analysis and research is made on the various problems of the current overlay layer due to insufficient shear resistance, and it is determined that the cement concrete pavement The pavement thickness of the asphalt overlay is to ensure the shear thickness of the overlay.

Owner:CHONGQING JIAOTONG UNIVERSITY

High-melt-strength foamable modified PP material and preparation method thereof

InactiveCN110540700AGood compatibilityExcellent dispersibility and fluidityColloidal particlePelletizing

The invention discloses a high-melt-strength foamable modified PP material and a preparation method thereof. The preparation method comprises the following steps: step 1, mixing of main raw materials;step 2, selection of a double-screw extruder with proper screw lead according to the original viscosity of PP resin; step 3, feeding the main raw materials; step 4, mixing of additives; step 5, addition of the additives from a side feeding port; step 6, pelletizing through underwater pelletizing equipment; step 7, drying of a pelletized product obtained in the step 6; and step 8, packaging. According to the invention, the blending technology of double-screw segmented feeding is adopted; PP resin, EPDM colloidal particles, talcum powder, a PP compatilizer, a powdery degradation agent, a release agent and an antioxidant are mixed in proportion, and a secondary side feeding powdery degradation agent is added according to physical flowing requirements, so the mixed modified high-viscosity PPmaterial has sufficiently large viscosity, and foam holes are not broken in the process of injection molding; and the size uniformity of the foam holes can be guaranteed due to reasonable control overthe flowability of the material.

Owner:ZHEJIANG UFO AUTOMOBILE MFG CO LTD +1

Structural design method for load-bearing section of miniature anti-slip compound pile

InactiveCN103225310BIncreased bending stiffnessReduce in quantityExcavationsBulkheads/pilesThrust bearingGeological survey

Owner:CENT SOUTH UNIV

Blanc fixe cementitious rock soil-like material and method for making simulative rock from the blanc fixe cementitious rock soil-like material

ActiveCN103332885BHigh bulk densityGuaranteed shear strengthPreparing sample for investigationModel testUltimate tensile strength

The invention relates to a blanc fixe cementitious rock soil-like material and a method for making simulative rock from the blanc fixe cementitious rock soil-like material and belongs to the technical field of rock material simulation in a geomechanical model test. The blanc fixe cementitious rock soil-like material comprises blanc fixe as a aggregate, bentonite as an auxiliary material, and dilute glue composed of 107 glue and water. The method comprises the following steps of drawing a water-binder ratio-shearing strength f curve by the blanc fixe cementitious rock soil-like material, calculating wet density of different batches of the blanc fixe cementitious rock soil-like materials, and making a small test-piece from different batches of the blanc fixe cementitious rock soil-like materials. The blanc fixe cementitious rock soil-like material has a low cost and no toxicity, can be processed into small blocks easily, and can satisfy requirements of a geomechanical model test on the blanc fixe cementitious rock soil-like material. Simulative rock made from the blanc fixe cementitious rock soil-like material does not influence a model building process and can be made fast so that a model test rate is greatly improved. The blanc fixe cementitious rock soil-like material is suitable for the field of a test on a model built by laying small blocks.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com