Novel automobile engine rear suspension cushion assembly

A technology of automobile engine and rear suspension, which is applied in the direction of power plant, vehicle parts, jet propulsion device, etc., can solve the problems of life reduction and aging, and achieve the goal of improving product fatigue life, ensuring shear strength and reducing shear strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

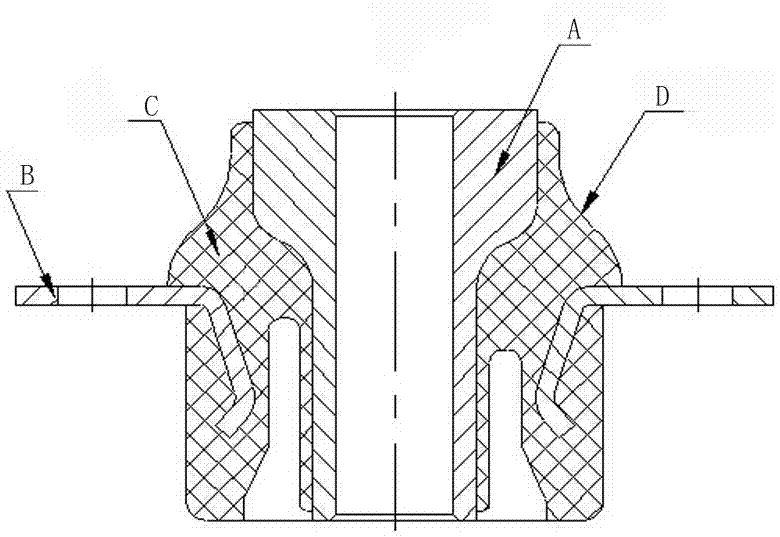

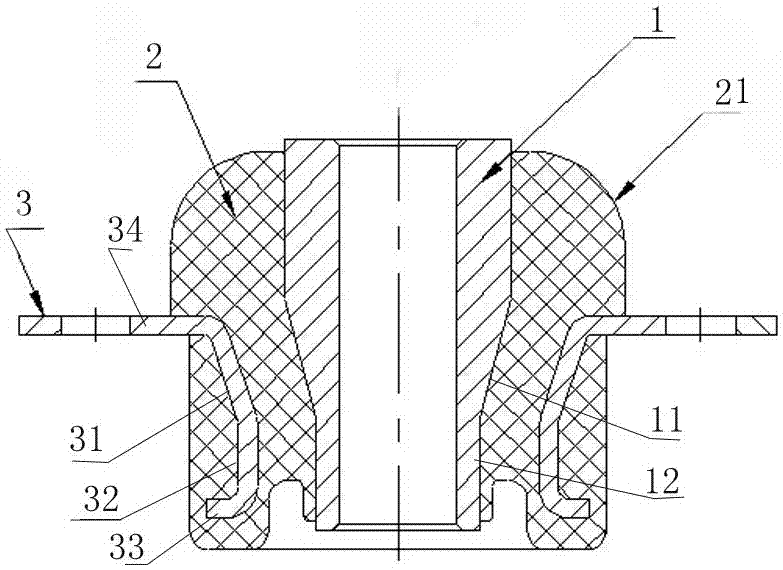

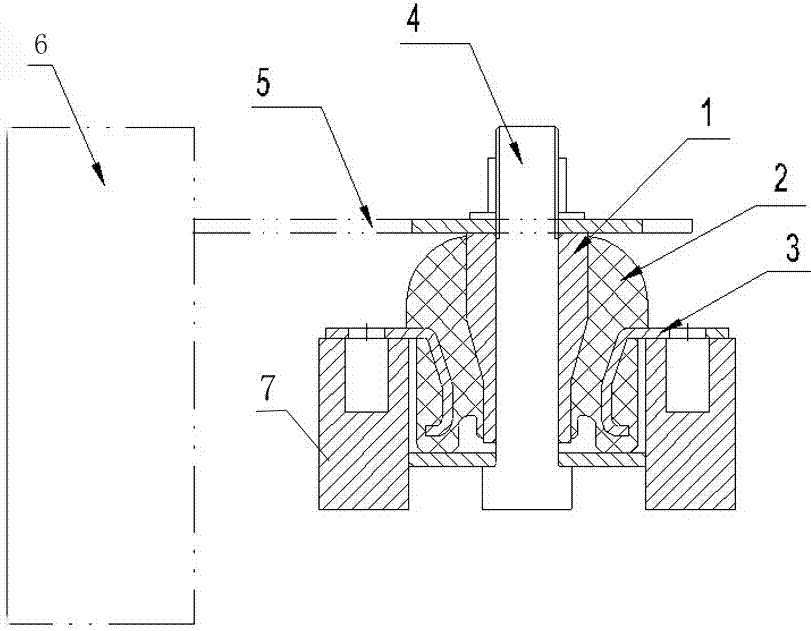

[0020] The present invention as figure 2 , 3 shown.

[0021] The new automobile engine rear suspension cushion assembly includes an inner frame 1 and an outer frame 3. There is a vulcanized rubber body 2 between the inner and outer frames 1 and 3. At the same time, the outer frame 3 is wrapped in the vulcanized rubber body 2. The inner frame 1 The outer diameter passes through the taper transition section 11 to the straight section 12; the corresponding outer frame 3 also includes a straight section 34, the straight section 34 is provided with an inclination angle 31 inwardly, and the inclination angle 31 is provided with a vertical section 32 downward, and the vertical section 32 A crotch 33 is provided at the rear; wherein the inclination angle 31 of the outer skeleton 3 corresponds to the taper transition section 11 of the outer diameter of the inner skeleton 1 , and the vertical section 32 of the outer skeleton 3 corresponds to the straight section 12 of the outer diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com