Polyamide hot melt adhesive for adhering nonpolar materials and preparation method thereof

A polyamide hot-melt adhesive and non-polar material technology, applied in the direction of adhesives, etc., can solve the problems of poor low temperature resistance, low elongation, high water absorption, etc., and achieve high bonding reliability, low high temperature melt viscosity, Excellent effect of low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

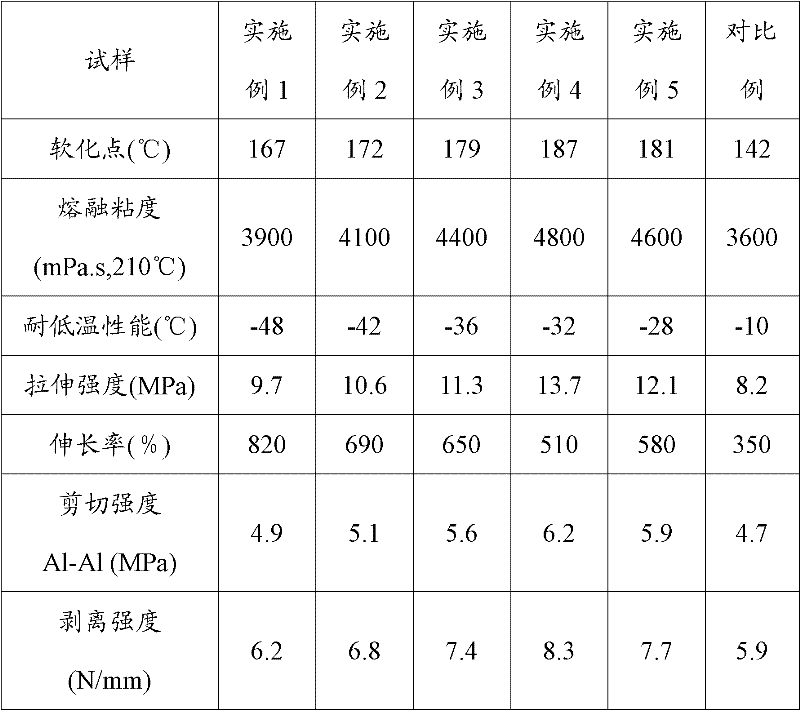

Examples

Embodiment 1

[0030] Add C to a 1000ml reaction flask equipped with a thermometer, mechanical stirrer, condenser and nitrogen 18Dimerized linoleic acid 227.2g, sebacic acid 121.7g, polyether glycol PEG-400 and PEG-2000 total 180g, ethylene glycol 12.4g, piperazine 17.2g, stearic acid 6.0g, hypophosphorous acid 0.5g 12.1g of ethylenediamine was put into a 100ml constant pressure dropping tube, nitrogen gas was introduced to prevent oxidation, and the temperature was raised while stirring. When the temperature in the reaction bottle reached 140°C, ethylenediamine was added dropwise, and the temperature was controlled at 140°C. , after the dropwise addition, start to slowly raise the temperature to about 220°C, water will distill out during the heating process, when the reaction temperature reaches 220°C, use a vacuum pump to vacuumize and depressurize, the vacuum degree is <100Pa, keep the stirring rate at a certain value After 3 hours of reaction, the vacuum was released to end the reaction,...

Embodiment 2

[0032] Add C to a 1000ml reaction flask equipped with a thermometer, mechanical stirrer, condenser and nitrogen 18 Dimerized oleic acid 283.9g, suberic acid 87.0g, polyether glycol PEG-400 and PEG-2000 total 200g, ethylene glycol 12.4g, piperazine 8.6g, stearic acid 6.0g, hypophosphorous acid 0.5g, Put 24.2g of ethylenediamine into a 1000ml constant pressure dropping tube, pass nitrogen gas to prevent oxidation, heat up while stirring, when the temperature in the reaction bottle reaches 140°C, start adding ethylenediamine dropwise, and control the temperature at 140°C. After the dropwise addition, start to raise the temperature slowly to about 220°C. During the heating process, water distills out. When the reaction temperature reaches 220°C, use a vacuum pump to vacuumize and reduce pressure. The vacuum degree is <100Pa, and the stirring rate is kept at a certain value. After 3 hours of reaction, the vacuum was released to end the reaction, and the molten polyamide resin was p...

Embodiment 3

[0034] Add C to a 1000ml reaction flask equipped with a thermometer, mechanical stirrer, condenser and nitrogen 18 340.8g of dimerized oleic acid, 69.6g of suberic acid, 168g of polyether glycol PEG-400 and PEG-2000, 6.2g of ethylene glycol, 14.4g of cyclohexyl p-dimethylamine, 6.0g of stearic acid, Phosphoric acid 0.5g, ethylenediamine 36.4g was put into a 1000ml constant-pressure dropper, nitrogen gas was introduced to prevent oxidation, and the temperature was raised while stirring. At 140°C, after the dropwise addition, start to slowly heat up to about 220°C, water distills out during the heating process, when the reaction temperature reaches 220°C, use a vacuum pump to evacuate and depressurize, the vacuum degree is <100Pa, keep the stirring rate at After a certain value, after 3 hours of reaction, the vacuum was released to end the reaction, and the molten polyamide resin was poured on a perchlorethylene plate to obtain a yellow rubber strip, which was dried at 50°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com