High-temperature pressure sensor and manufacturing method thereof

A pressure sensor, high temperature technology, applied in the direction of measuring fluid pressure, fluid pressure measurement by changing ohmic resistance, instruments, etc., can solve the problems of low shear strength, mismatch of high temperature thermal expansion coefficient, long-term and reliable work, etc. To achieve the effect of buffering thermal stress and compensating zero temperature drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

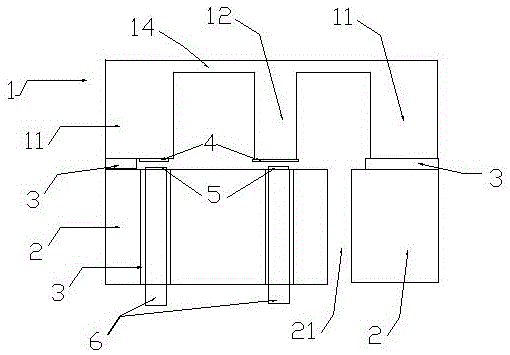

[0025] Such as figure 1 As shown, the sapphire single wafer (or zirconia, silicon carbide, alumina ceramics) is ground and processed into an integrated elastic element 1 having a fixed side 11, an elastic diaphragm 14 and a central column 12, namely an E-shaped cup, a reflective film, 4 and semi-permeable membrane 5 are metal oxides or nitrides formed by sputtering or reactive sputtering process, another sapphire single wafer (or zirconia, silicon carbide, alumina ceramic) as the base 2, two sapphire fibers 6 Pass through the hole and fix it on the base 2 with a high-temperature sintered layer 3 with aluminum oxide nanopowder as the main component. There is also a vent 21 on the base 2. The base 2 and the integrated elastic element 1 The fixed support 3 is composed of a high-temperature sintered layer 3 with aluminum oxide nanopowder as the main component to form a pressure-sensitive core 7 together.

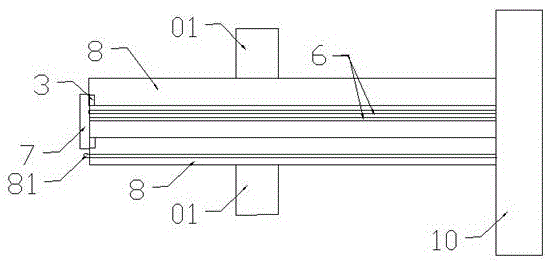

[0026] Such as figure 2 As shown, the pressure-sensitive core 7 uses a high-...

Embodiment 2

[0028] The manufacturing method of a high temperature pressure sensor is as follows:

[0029] First, use a tubular grinding head with a gap at the end and an abrasive with a Mohs hardness greater than 9 on the drill press to grind annular grooves on a double-sided polished sapphire single crystal (or zirconia, alumina ceramic) sheet to make The integrated elastic element 1 of the fixed supporting edge 11, the elastic diaphragm 14 and the central hard core 12;

[0030] Second, use a sputtering process to form a metal oxide or nitride film on the end surface of the central hard core as the reflective film 4;

[0031] Third, use aluminum oxide powder (particle size less than 0.5 microns) as the main raw material, supplemented by solvents, resins, plasticizers, dispersants and other organic additives to make slurry. The slurry is coated on the corresponding area of the base 2 and the fixed side 11 with a screen printer, and the slurry is dried and degummed. The sapphire optical fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com